Automatic rolling equipment for lead sheathes

A technology of rolling equipment and lead sleeve, applied in the field of automatic lead sleeve rolling equipment, can solve the problems of acid leakage or seepage, poor sealing effect, low production efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

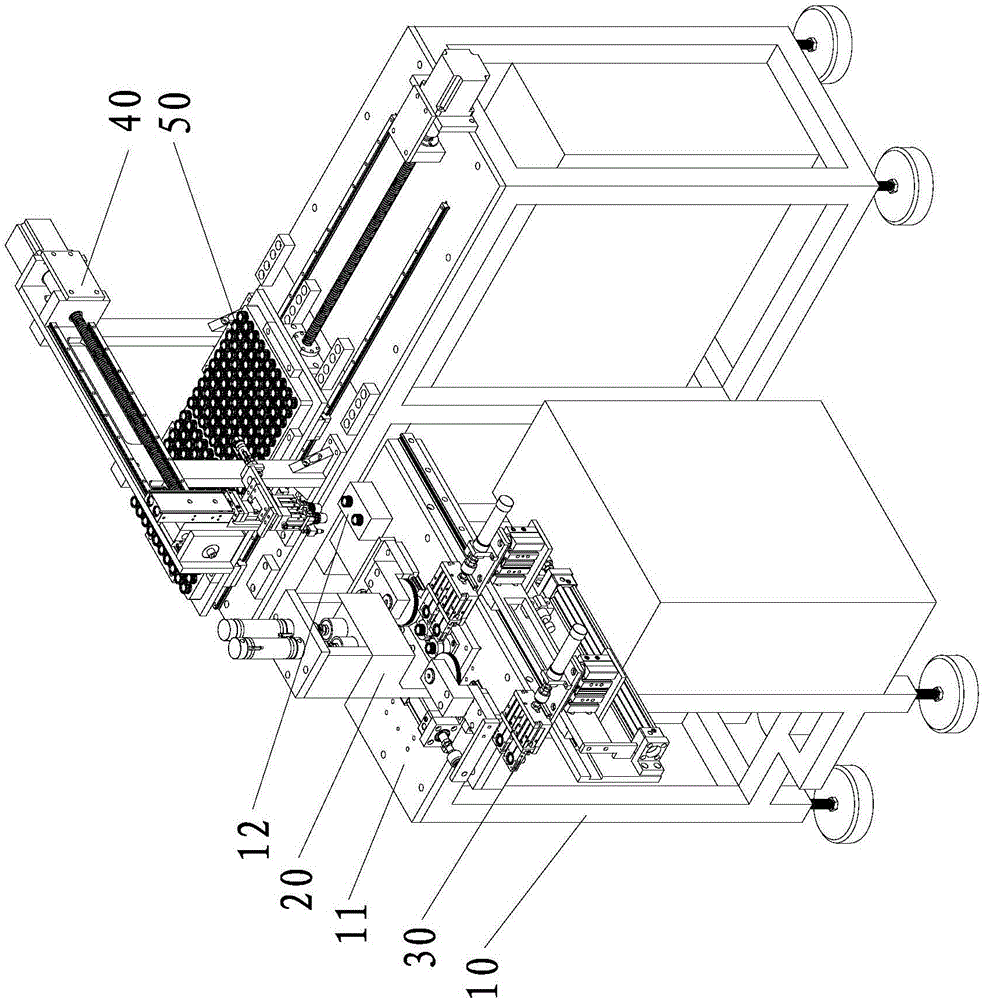

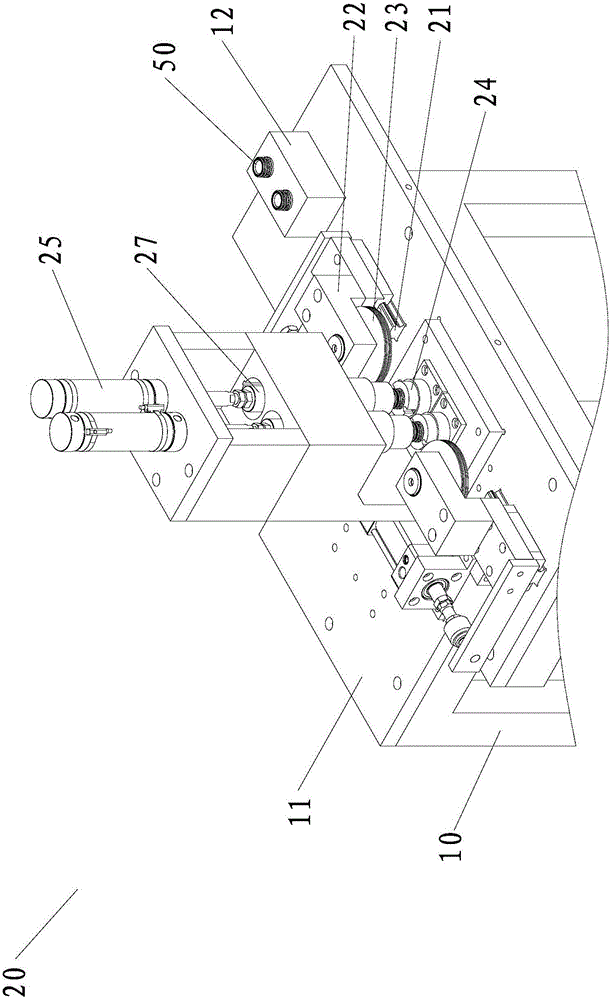

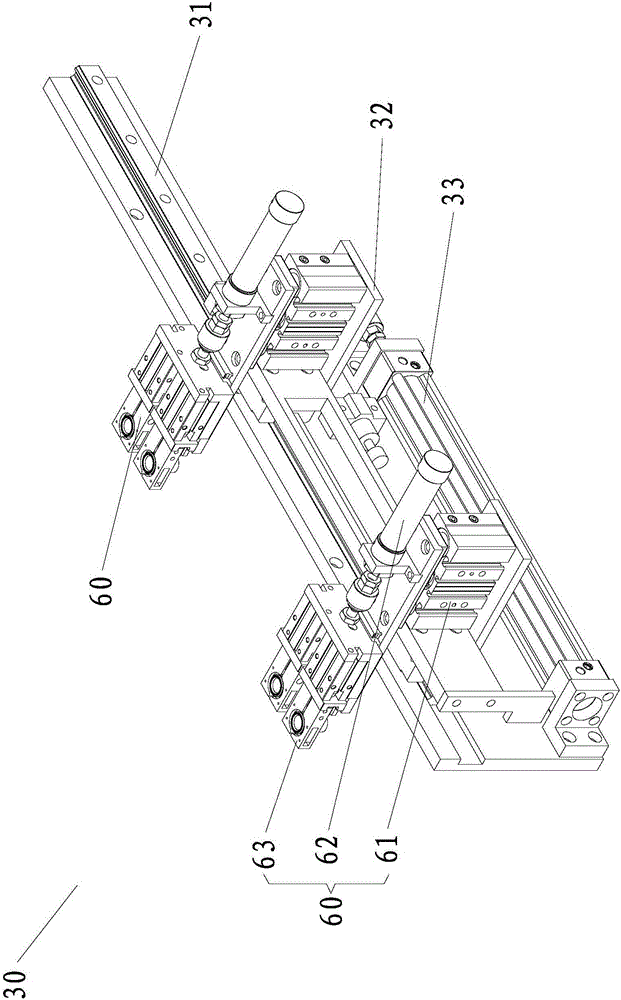

[0041] like figure 1 As shown, the lead sleeve automatic rolling equipment provided in this embodiment includes a frame 10, the frame 10 is provided with a first workbench 11, the first workbench 11 is provided with a rolling device 20, and the first workbench 11 One side is provided with a reclaimer 30 that cooperates with the rolling device 20, and the other side of the first workbench 11 is provided with a rewinder 40. It should be noted that the reclaimer 30 and the rewinder 40 do not necessarily require Located on the corresponding two sides of the first workbench 11, its specific location can be determined according to actual needs. In addition, the first workbench 11 is also provided with a storage tray 12 for placing the rolled lead sleeve 50 at a position facing the receiving device 50 .

[0042] The rolling device 20 is the core dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com