Patents

Literature

32results about How to "Realize fully mechanized operation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

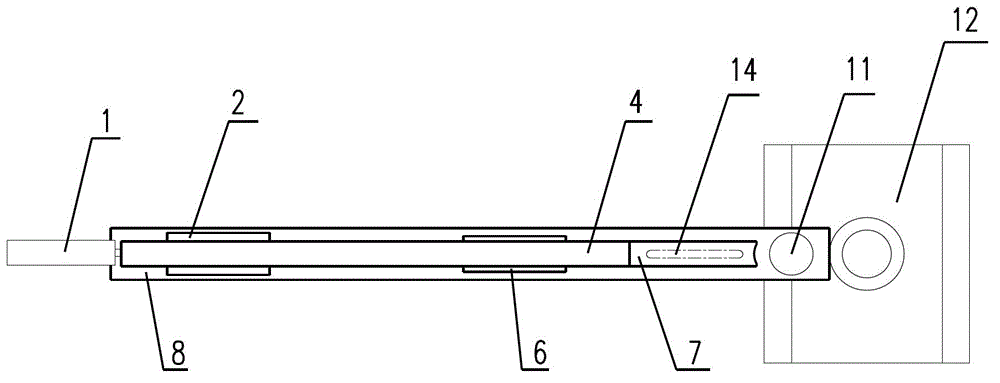

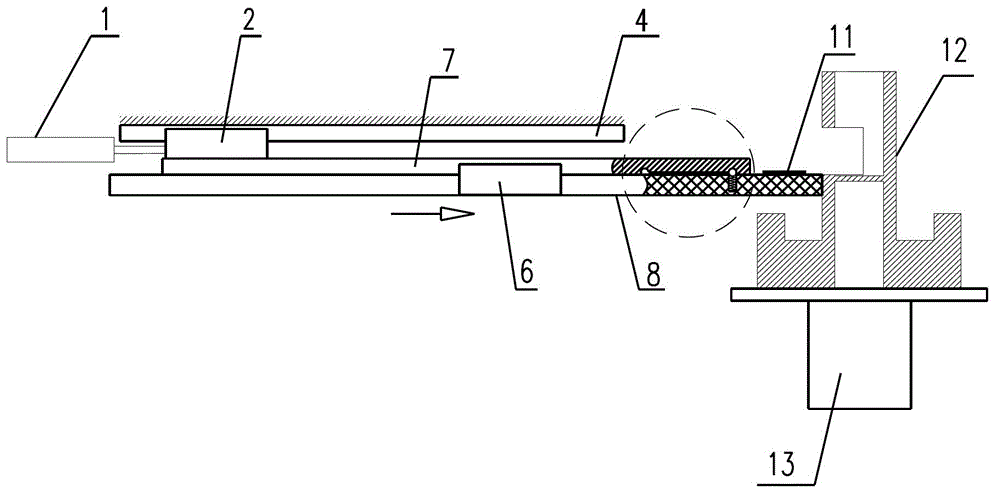

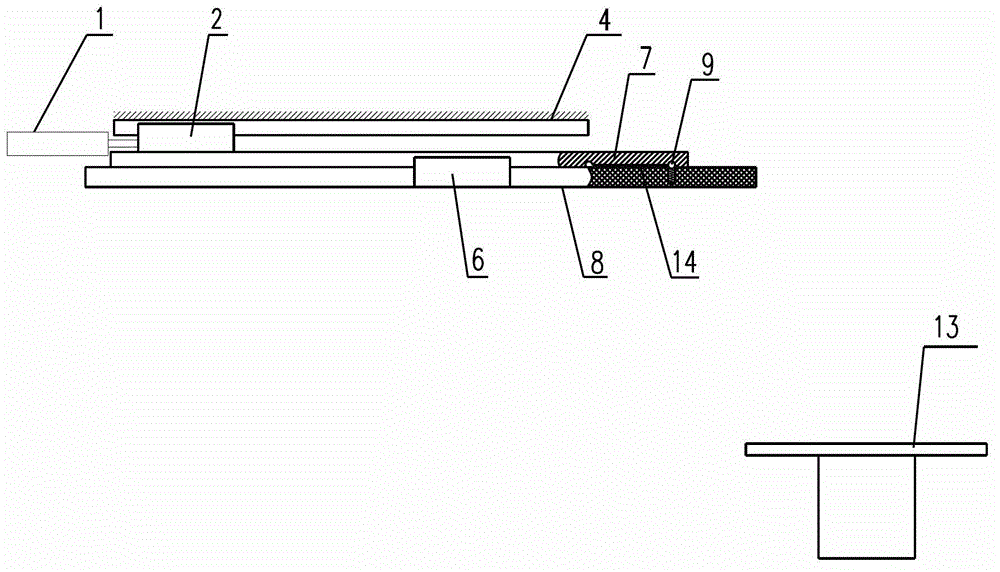

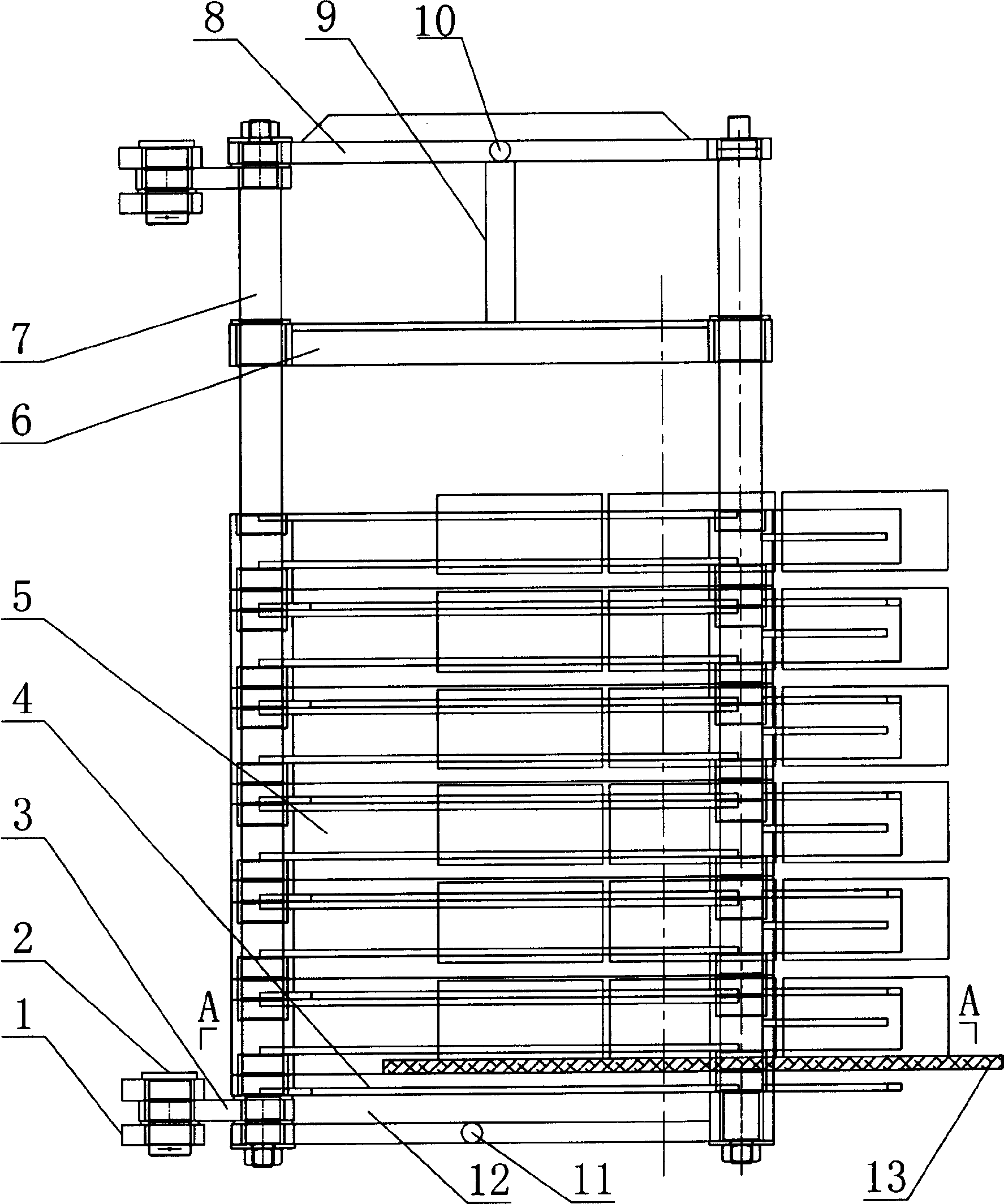

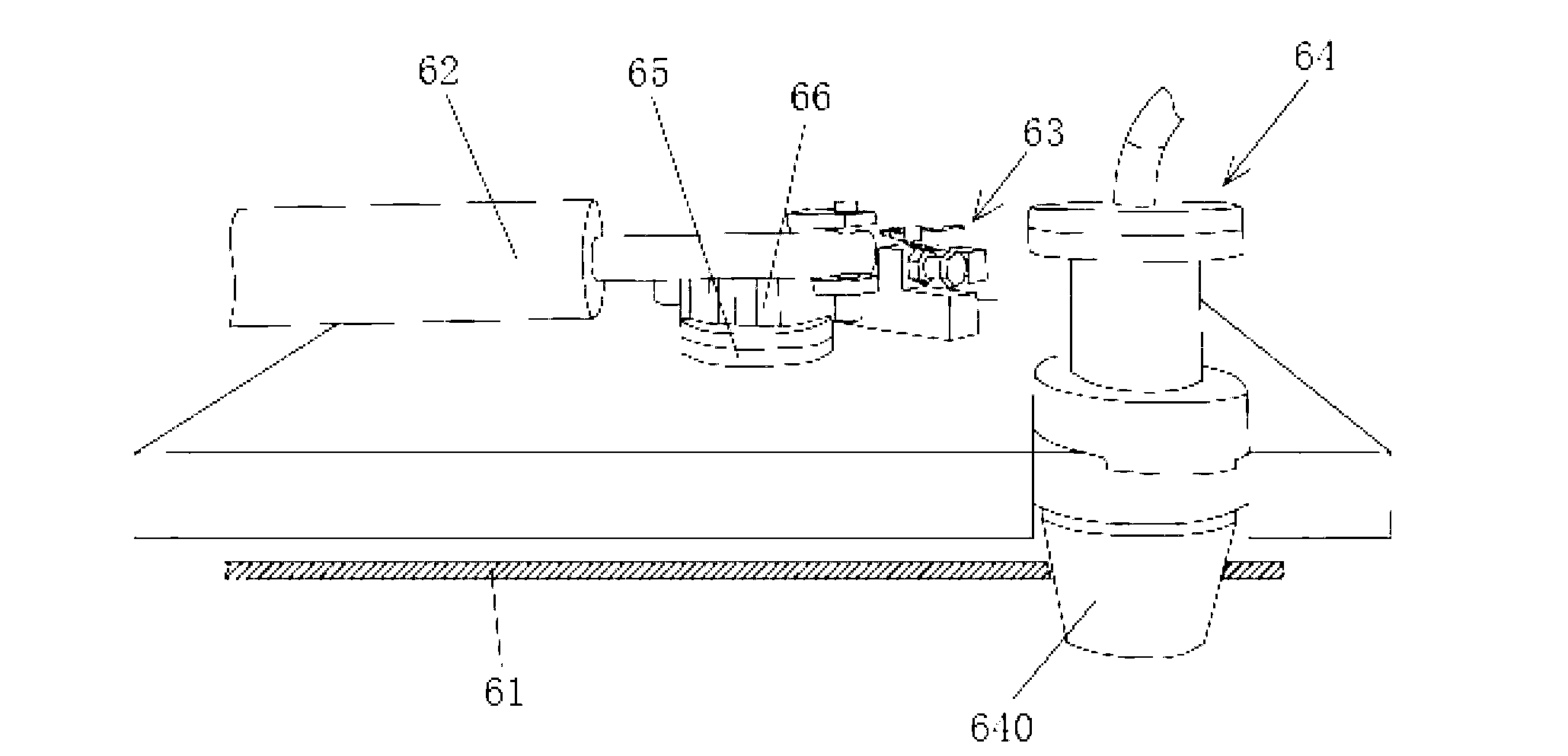

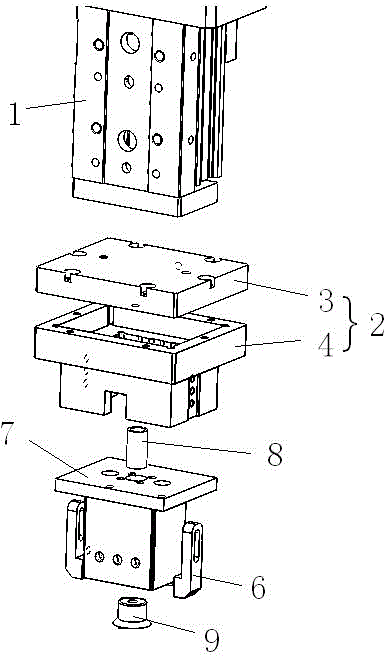

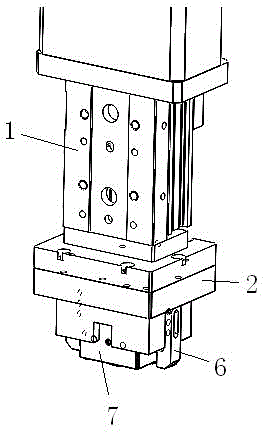

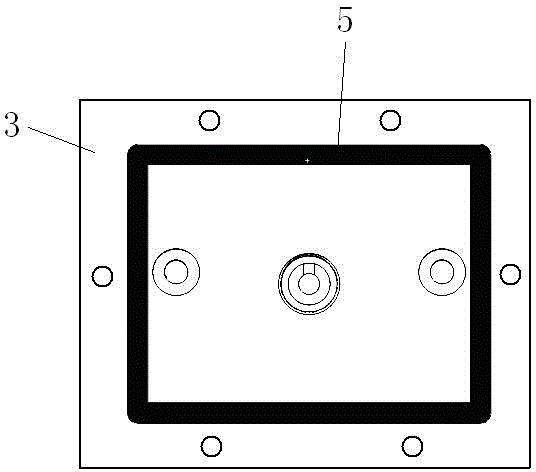

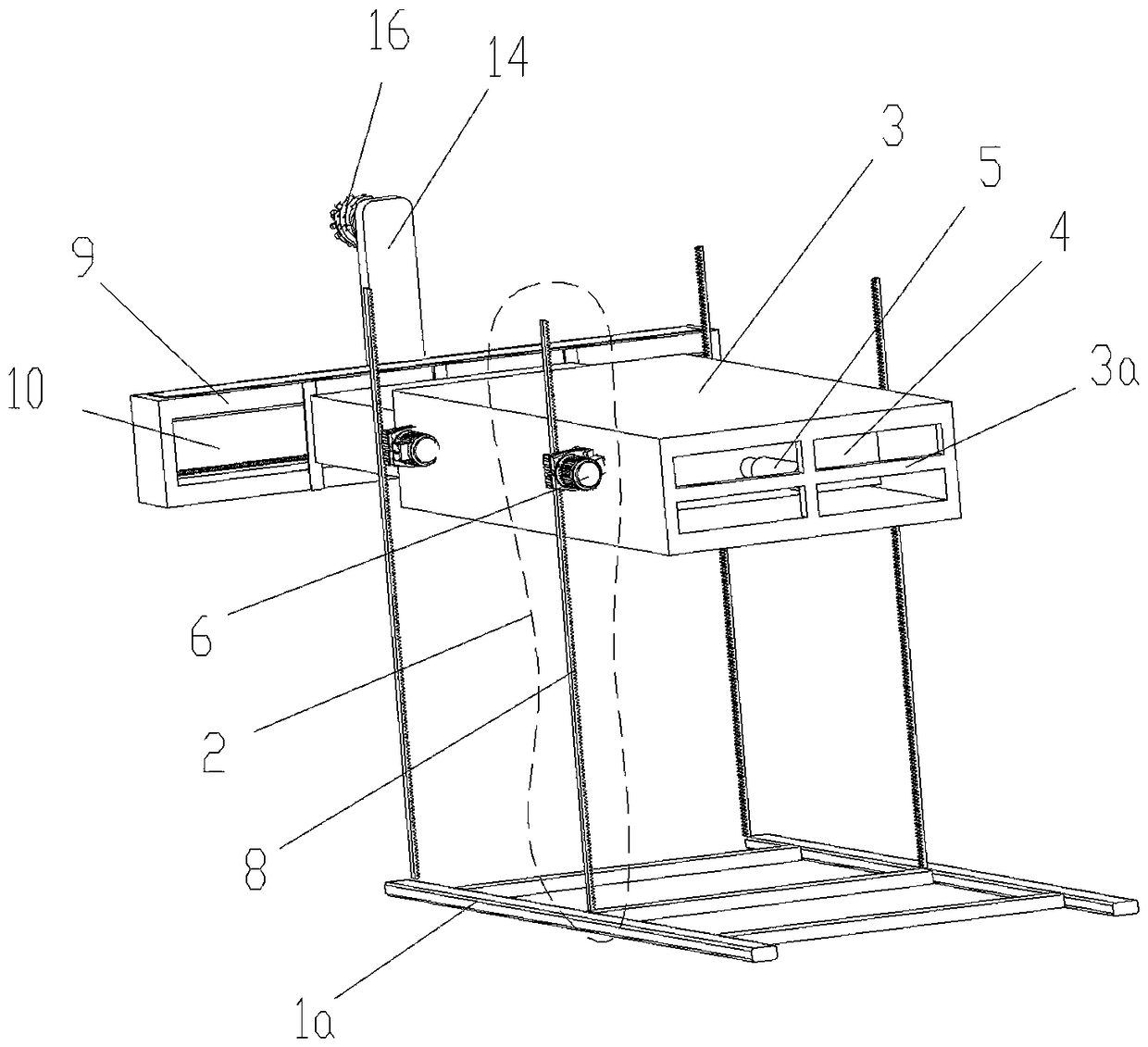

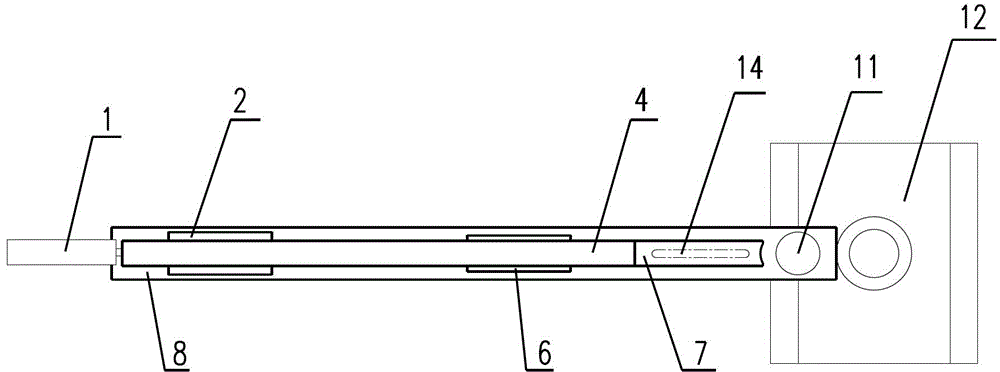

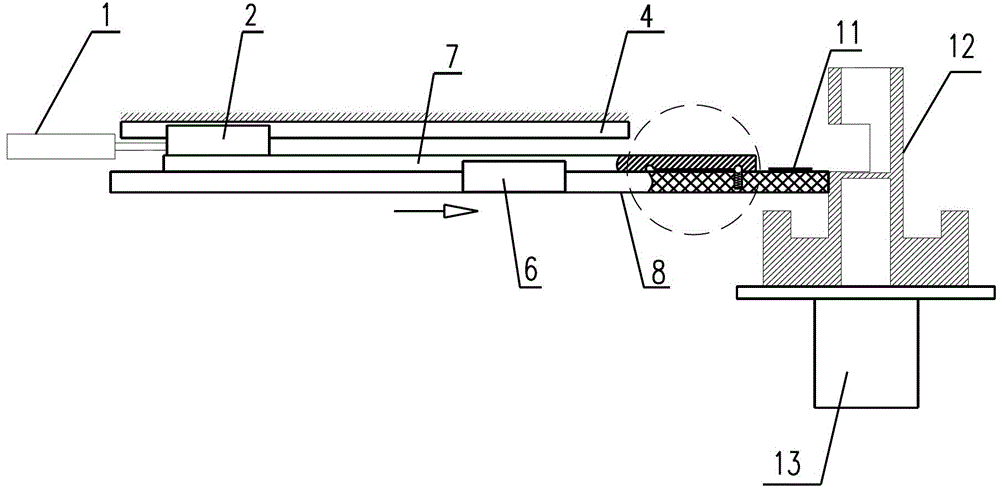

Gasket assembling mechanism

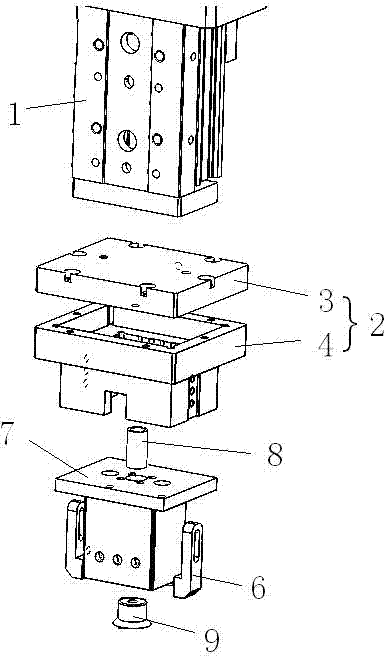

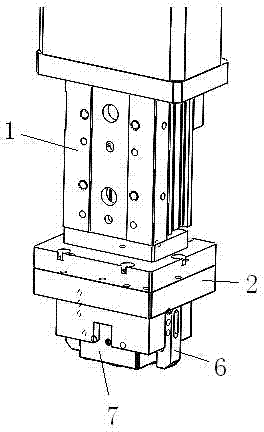

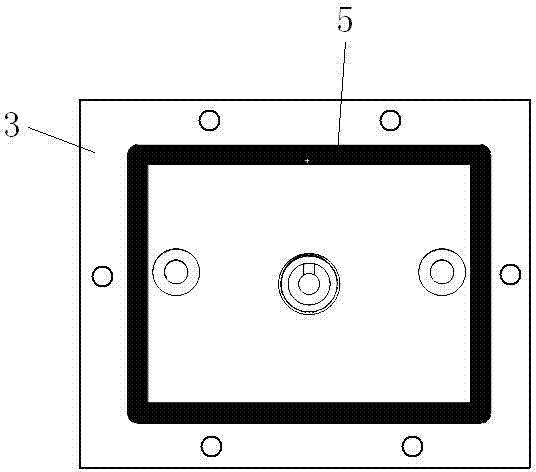

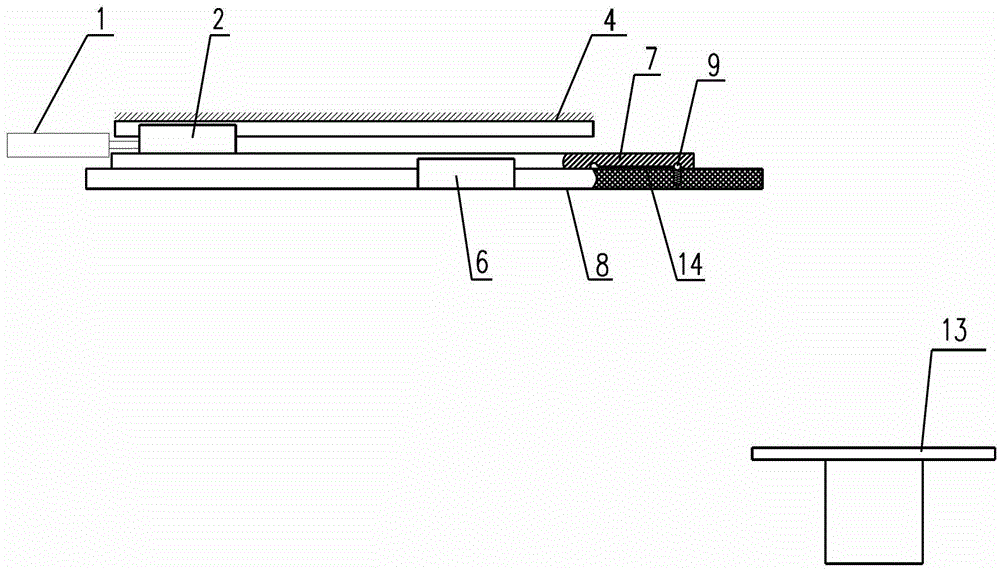

The invention provides a gasket assembling mechanism. The mechanism comprises upper and lower slide rails, which are horizontally and transversely arranged, wherein a first slide rail is fixed on a base; a second slide rail is mounted on the first slide rail by a slide block; a horizontal long bottom plate is placed close to the lower surface of the second slide rail; the bottom plate is mounted on the second slide rail by a slide block; a locating groove and a locating hole matched with each other are respectively formed in the second slide rail and the bottom plate; a spring and a locating block are pressed into the locating hole in sequence; the locating block is impelled upward by the spring; a compression cylinder is placed on one side of the second slide rail; a rack for bearing parts is arranged on the right side of the bottom plate; the rack can lift up and down; and by a double-slide-rail moving mechanism, a gasket is pushed to enter a narrow part recess of a mounting space; full mechanical operation of the whole assembling process can be achieved, manual assembling is not needed and high assembling efficiency is achieved; moreover, the gasket assembling mechanism provided by the invention has the advantages of simple structure, good reliability, accurate assembling position and comparatively low production and machining cost.

Owner:SHANGHAI UNIV OF ENG SCI

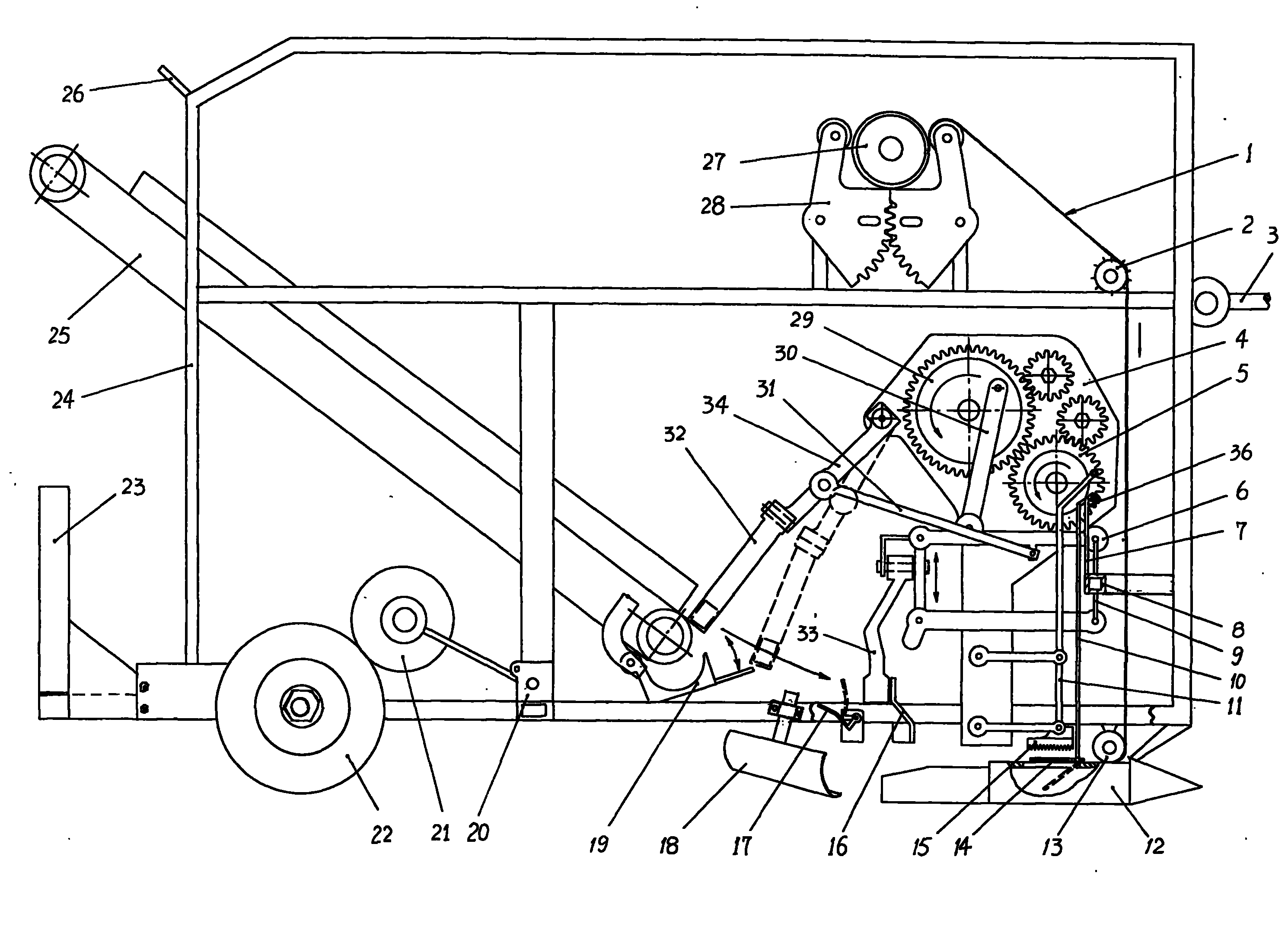

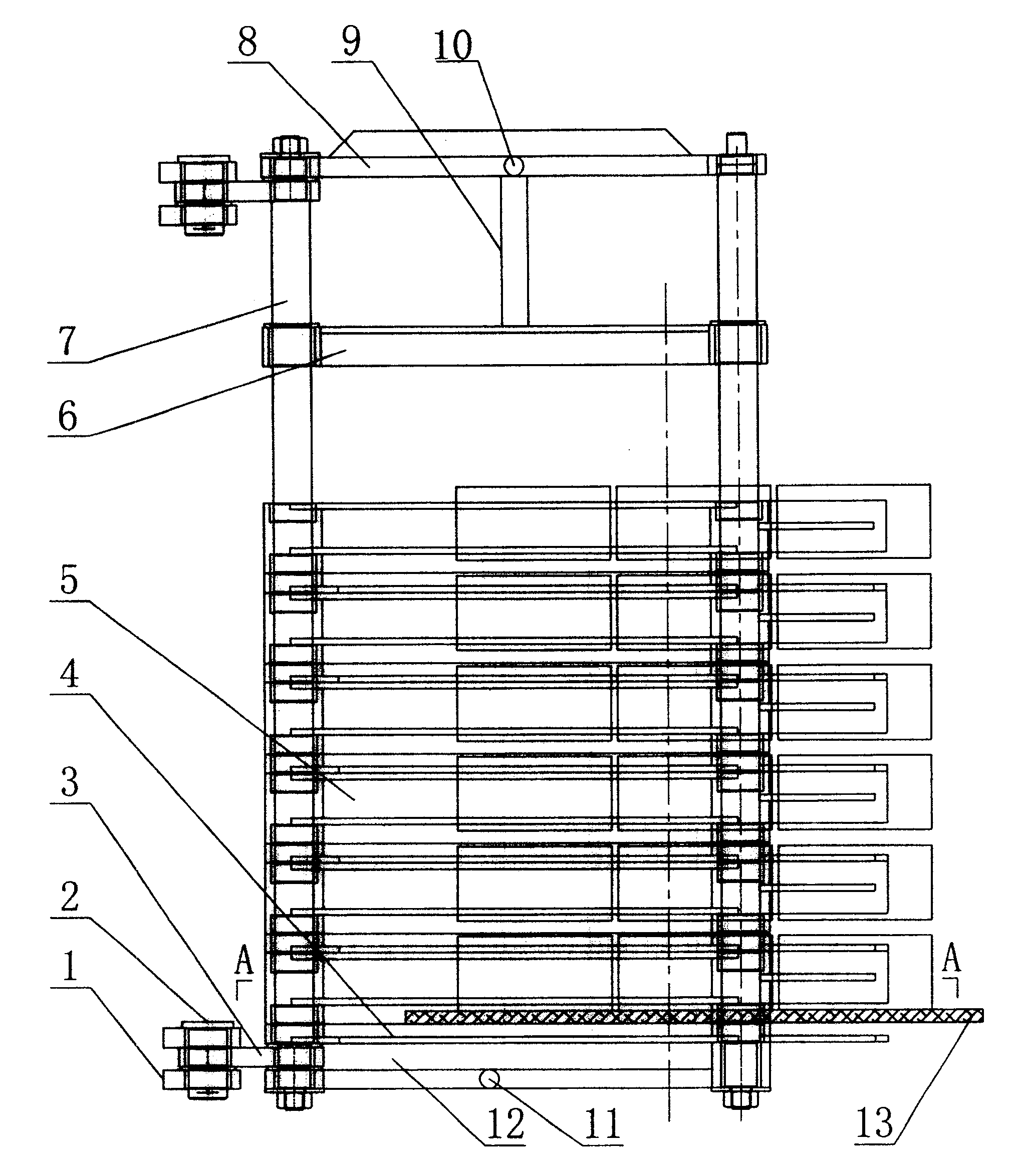

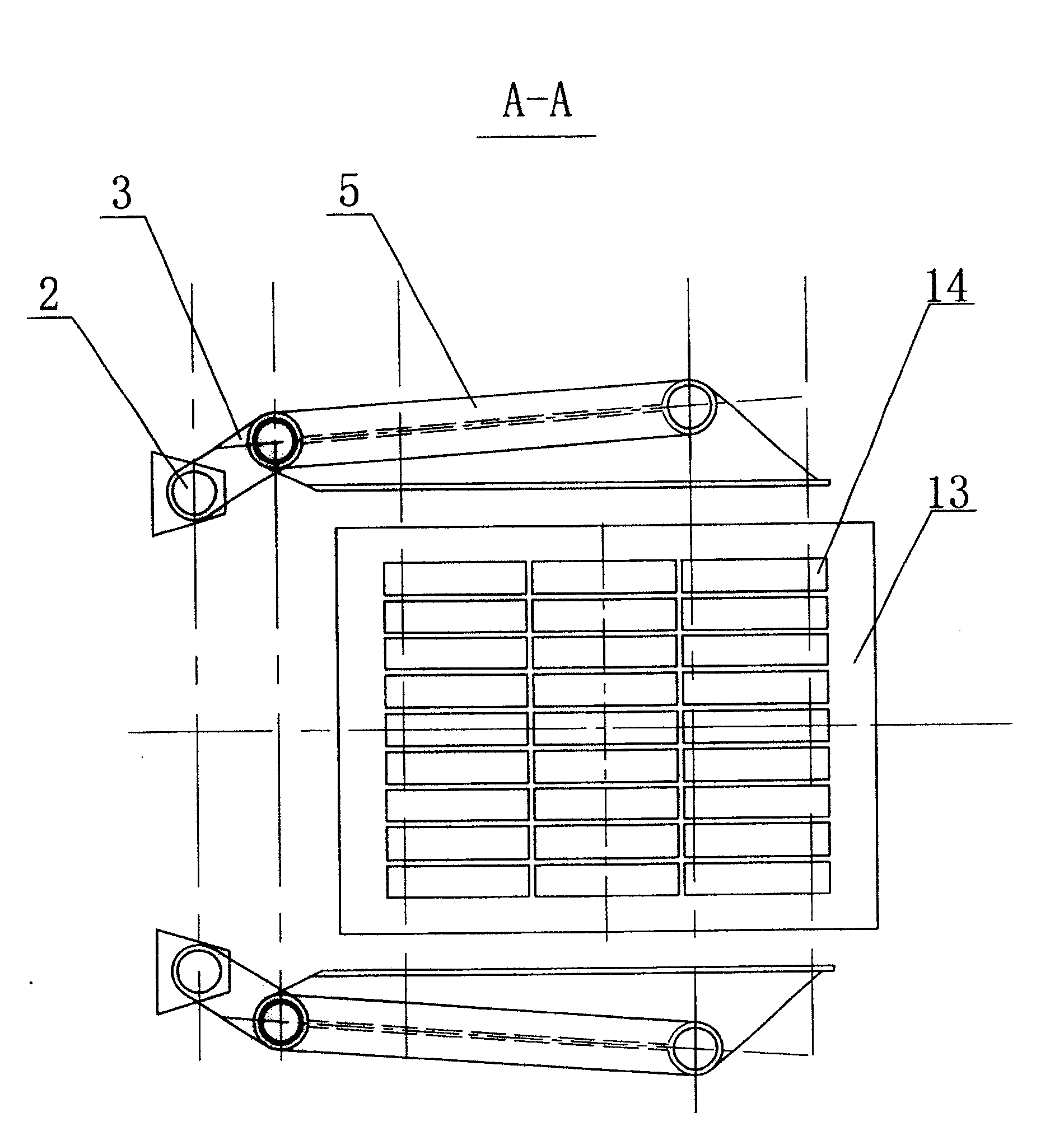

Machine for piling up and fetching bricks

InactiveCN1915630ARealize fully mechanized operationDischarging arrangementStacking articlesBrickControl theory

A trick stacking-taking machine is composed of a hydraulic fork lifter, and a brick stacking-tacking mechanism consisting of two groups of two vertical posts the upper and lower connecting rods connected with two vertical posts in one group, a movable frame under upper connecting rod and linked with vertical posts in slide mode, 2-8 groups of pallet and supporter between said movable frame and lower connecting rod, the their connecting rod, lug plate, pins, brick supporter, etc.

Owner:鞍钢集团房产建设第五建筑工程公司

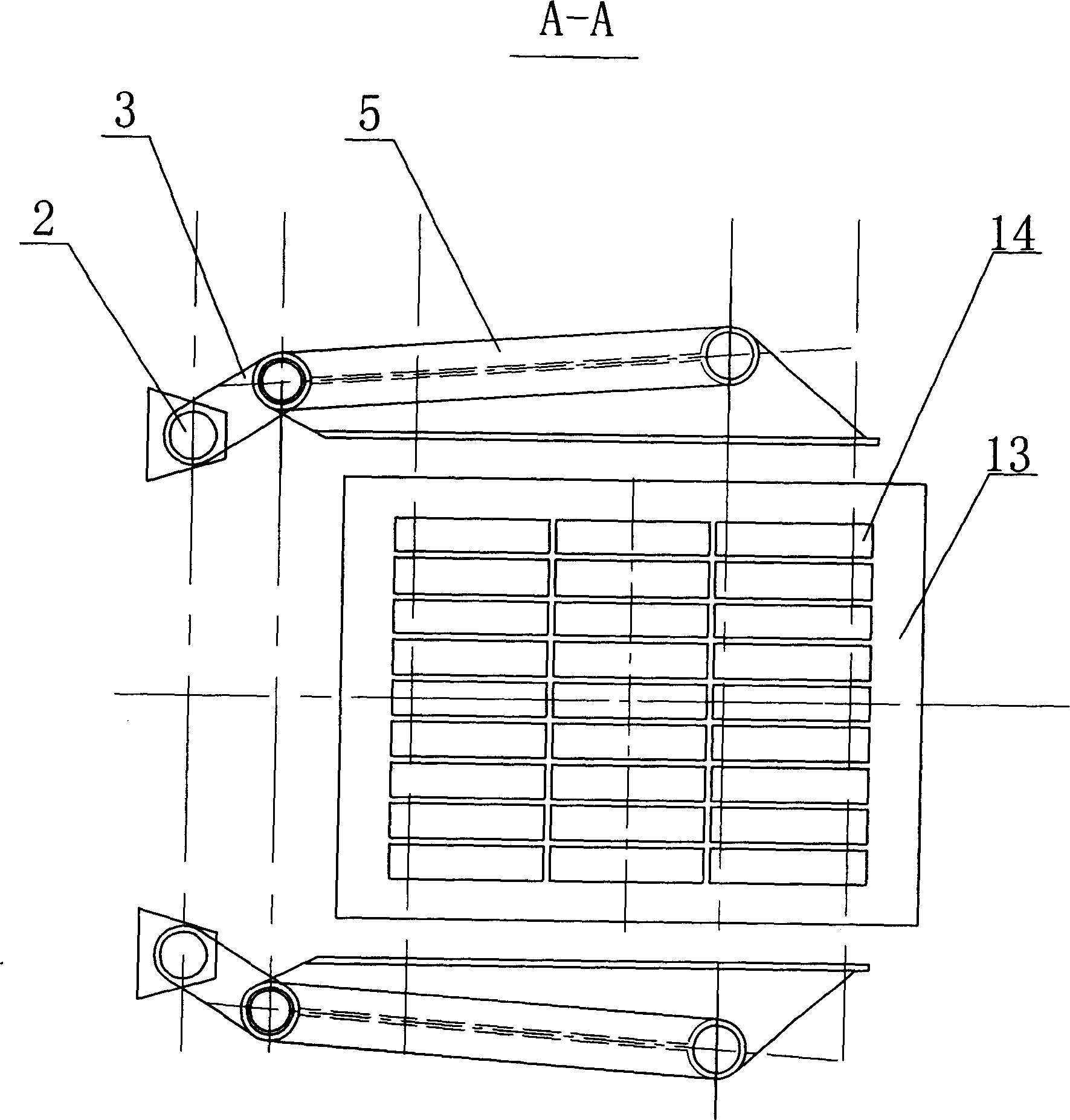

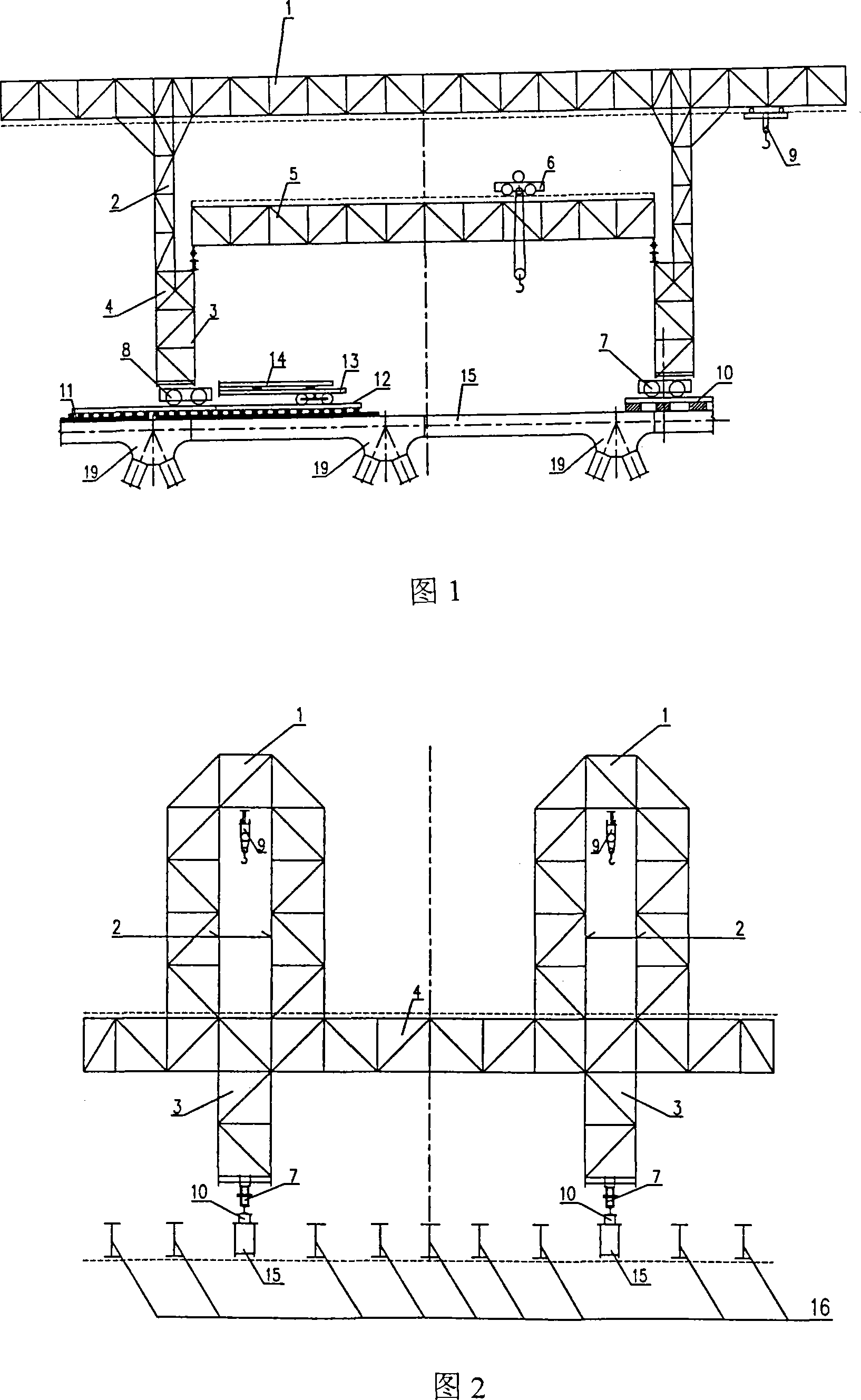

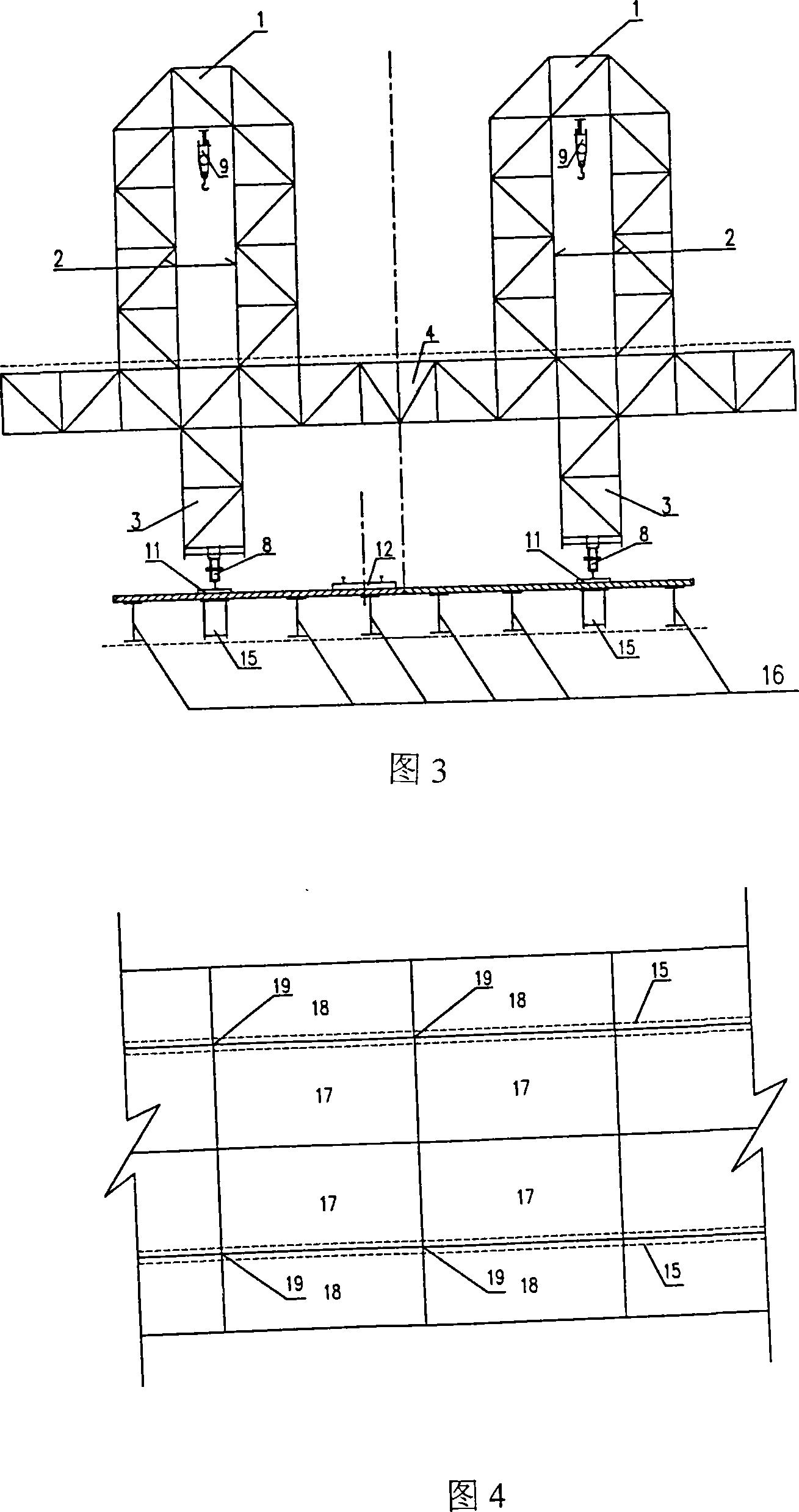

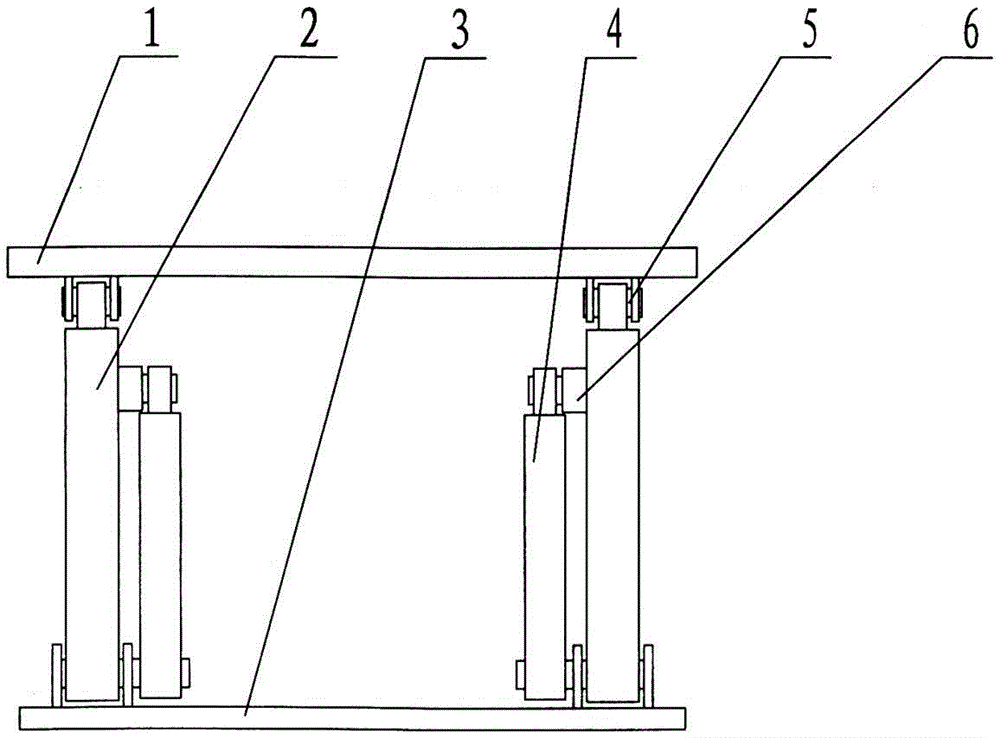

High-altitude framework type simple plate supporting machine

ActiveCN101117794AImprove wind load resistanceAssembly time is shortBridge erection/assemblyLoad resistanceBridge deck

The present invention relates to a high altitude frame simple machine for an erecting plate, the structure is stated below: a gantry binding beam is connected with an upper column of the gantry, which is connected with a walkway beam of a hoisting truss, which is connected with a lower column of the gantry. The hoisting trolley is arranged on the hoisting truss. The front end and the rear end of the hoisting truss are positioned on the hoisting truss. A front walking wheel box group and a rear walking wheel box group are arranged under the lower column of the gantry; the front walking wheel box group and the rear walking wheel box group are arranged at a walkway of a transportation board of a trolley and a front walking wheel rail and a rear walking wheel are arranged at the lower position of the walkway of the transportation road; a plurality of upper stringer joints of the steel truss are arranged on an upper stringer rod of the steel truss, a longitudinal beam of the steel truss beam is connected with the upper string rod of the steel truss beam, and an electric hoist is positioned at the bottom of the gantry binding beam. The present invention has the advantages of free transverse and longitudinal travel, four concrete bridge decks between joints are erected one time; normal universal rod structures are used to make a frame structure. the present invention has the advantages of sound stability, high air-load resistance, short manufacturing time and low production cost, easy and convenient use.

Owner:THE FOURTH ENG CO LTD OF CHINA ZHONGTIEMAJOR BRIDGE ENG GRP

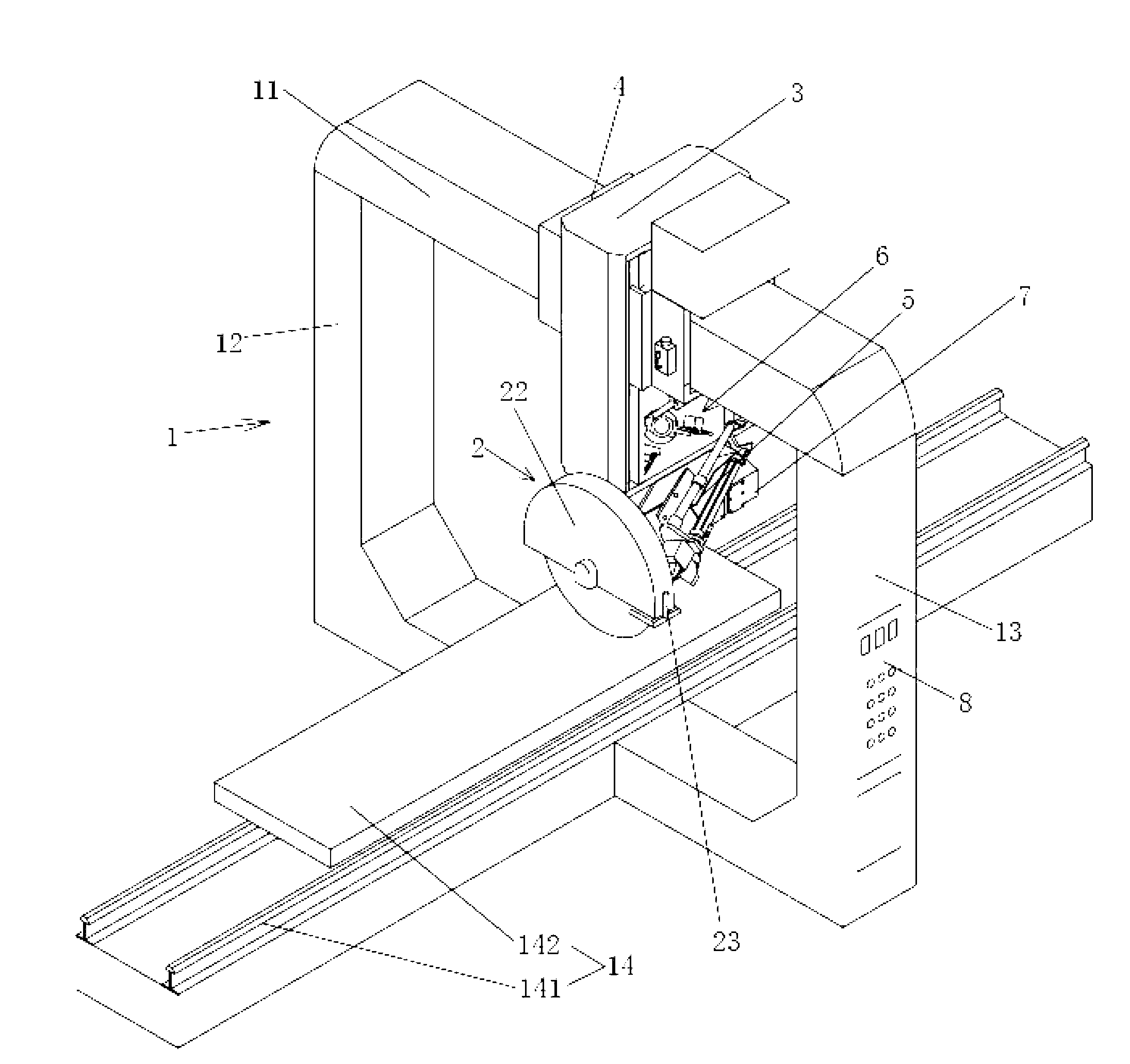

Stone middle cutting machine

InactiveCN103009487APrecise positioningInsert smoothlyStone-like material working toolsEngineeringWorkbench

The invention provides a stone middle cutting machine which solves the problem that the existing stone middle cutting machine only can be fixed in one direction for cutting and is low in processing efficiency. The stone middle cutting machine comprises a machine frame, a main cutter head, a lifting feeding mechanism and a transverse motion mechanism, wherein the machine frame comprises a cross beam; the transverse motion mechanism is installed on the cross beam; a transverse movement rack is arranged on the cross beam; the transverse motion mechanism is provided with a transverse movement gear meshed with the transverse movement rack; and a lifting oil cylinder for driving the lifting feeding mechanism to lift is vertically installed on the transverse motion mechanism. The stone middle cutting machine further comprises an indexing mechanism; the main cutter head is installed on the lifting feeding mechanism through the indexing mechanism; the machine frame further comprises a workbench positioned below the cross beam; and the workbench comprises a walking track and a workbench plate capable of moving on the walking track.

Owner:吴文章

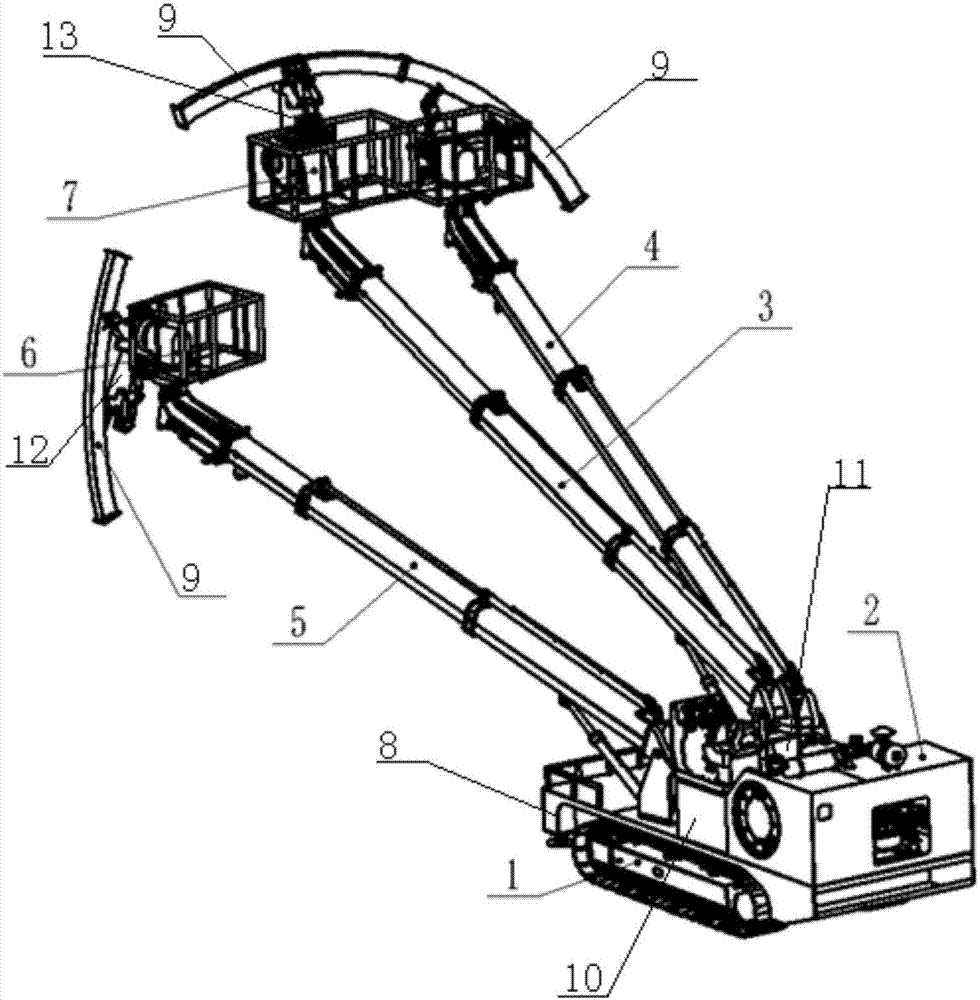

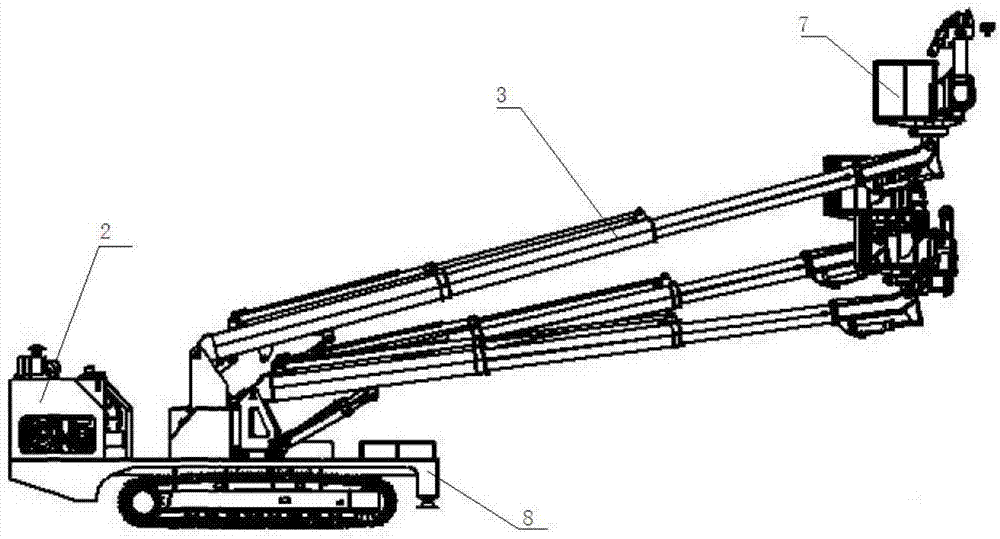

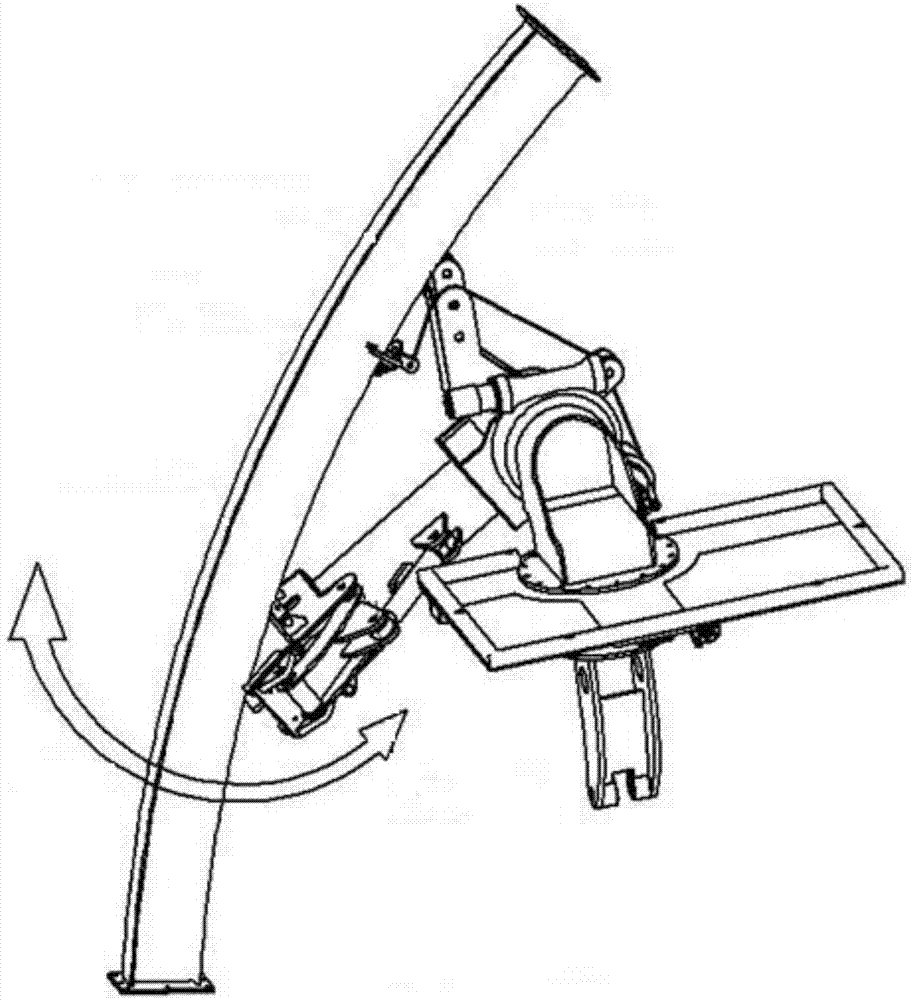

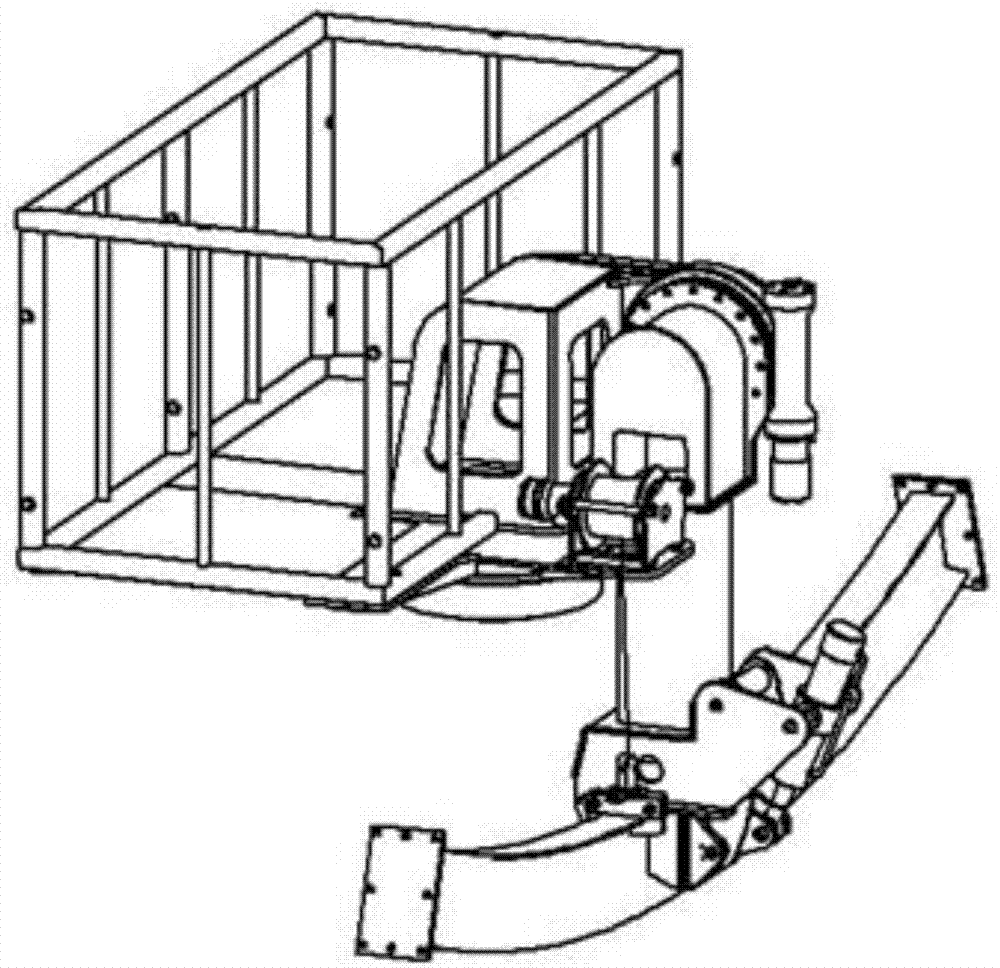

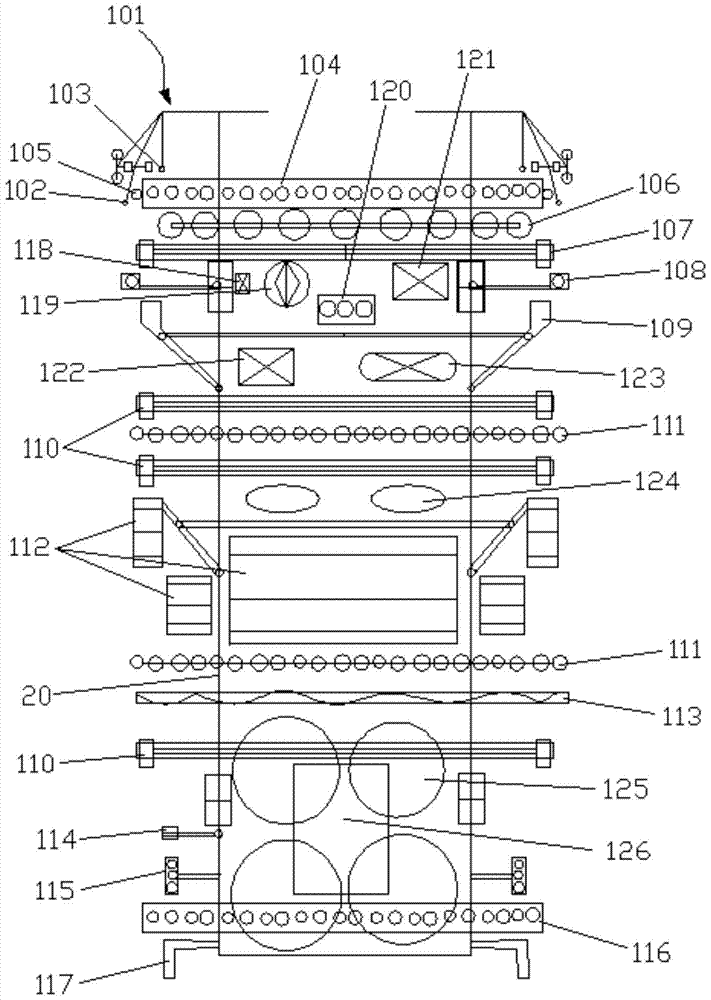

Novel multi-functional operation trolley used for tunnel construction

PendingCN107514264AImprove securityRealize fully mechanized operationUnderground chambersTunnel liningLight railTunnel construction

The invention discloses a novel multi-functional operation trolley used for tunnel construction. The operation trolley includes a chassis, a caterpillar band and a power device; the lower portion of the chassis is provided with the caterpillar band, the upper portion of the front part of the chassis is provided with the power device, the rear portion of the chassis is provided with retractable support legs, the middle of the upper portion of the chassis is provided with a middle working arm, the left side and right side of the chassis are symmetrically provided with a left-side working arm and a right-side working arm respectively, the top of the middle working arm is provided with a main hanging basket, and the top of the left-side working arm and the top of the right-side working arm are provided with side hanging baskets arranged in a symmetrical mode respectively. The multi-functional operation trolley is mainly used for primary support, explosive material filling and other kinds of high-altitude operation and construction of tunnel excavation of high-speed railways, light rails, subways and the like, and mainly devoted to solving the problems occurring in all primary support, explosive material filling and other kinds of high-altitude operation in the tunnel construction, the operation includes back break and dangerous rock processing of a tunnel face, installation of a steel arch and erecting of a reinforcing mesh, and at the same time, other kinds of high-altitude operation and hoisting operation in the tunnel can also be completed.

Owner:CHINA RAILWAY NO 5 ENG GRP +1

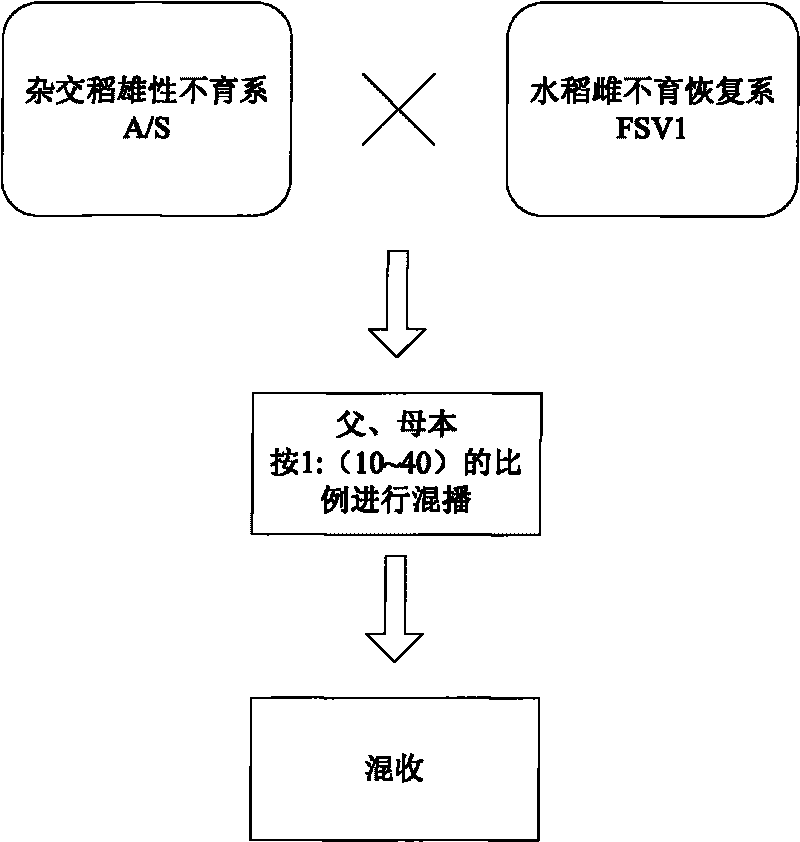

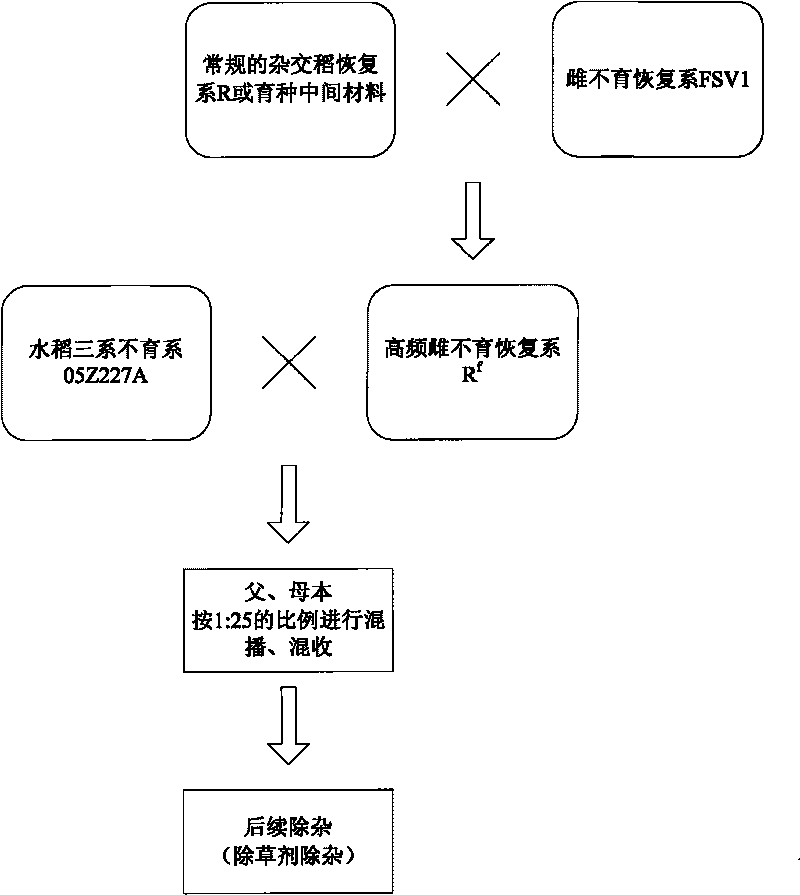

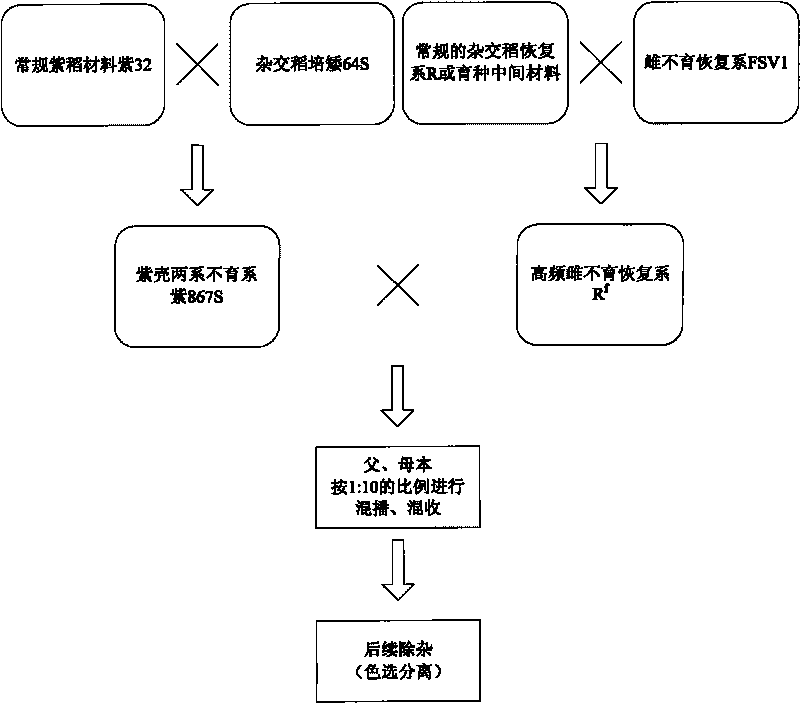

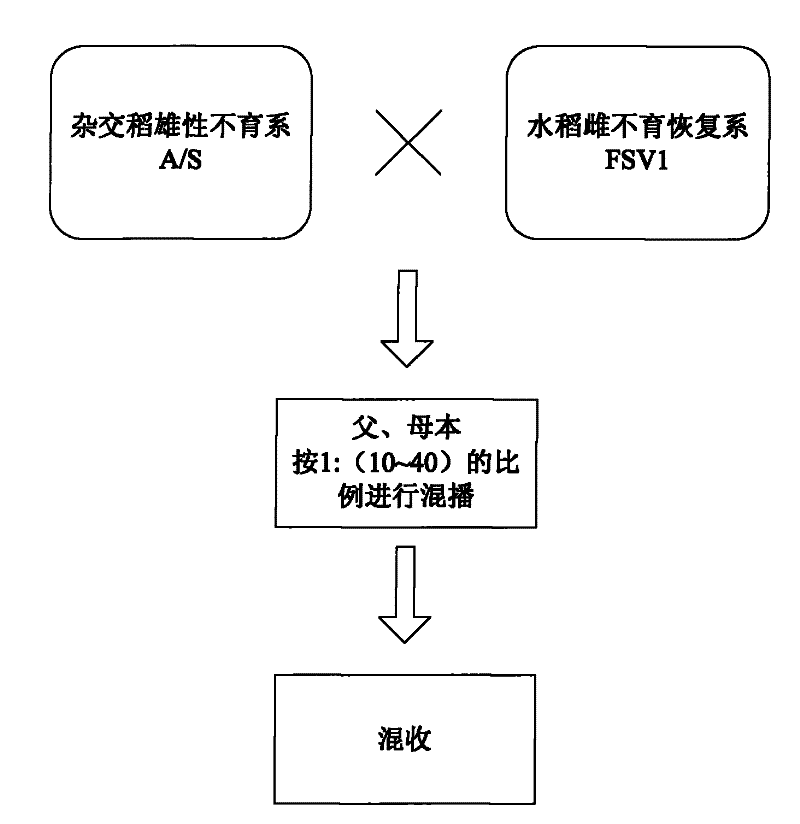

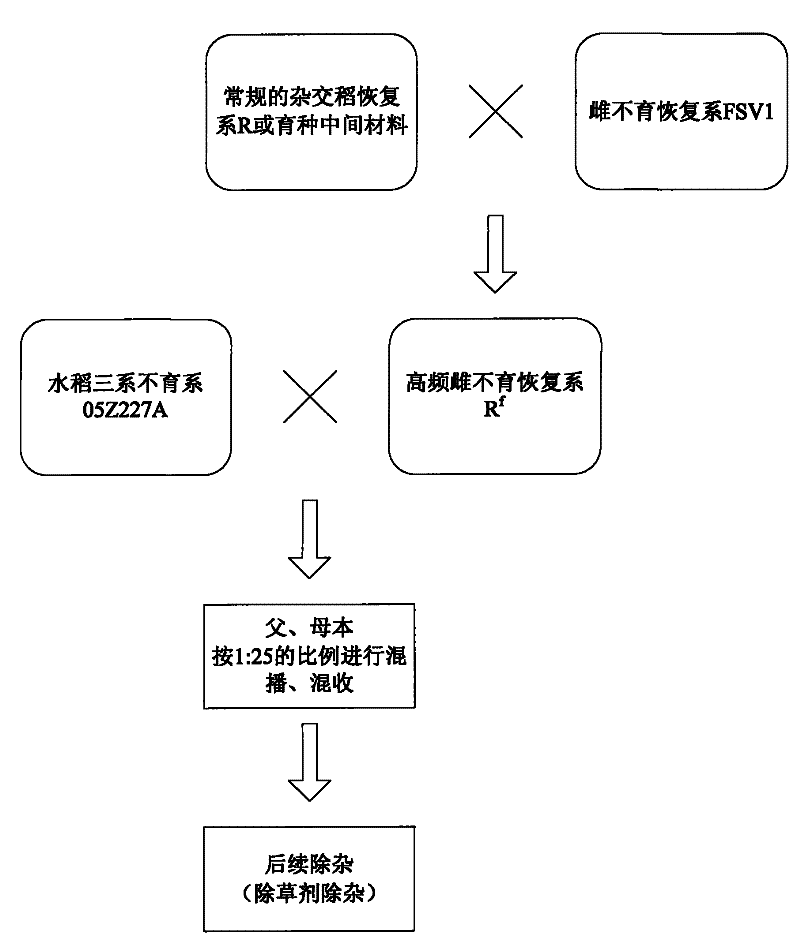

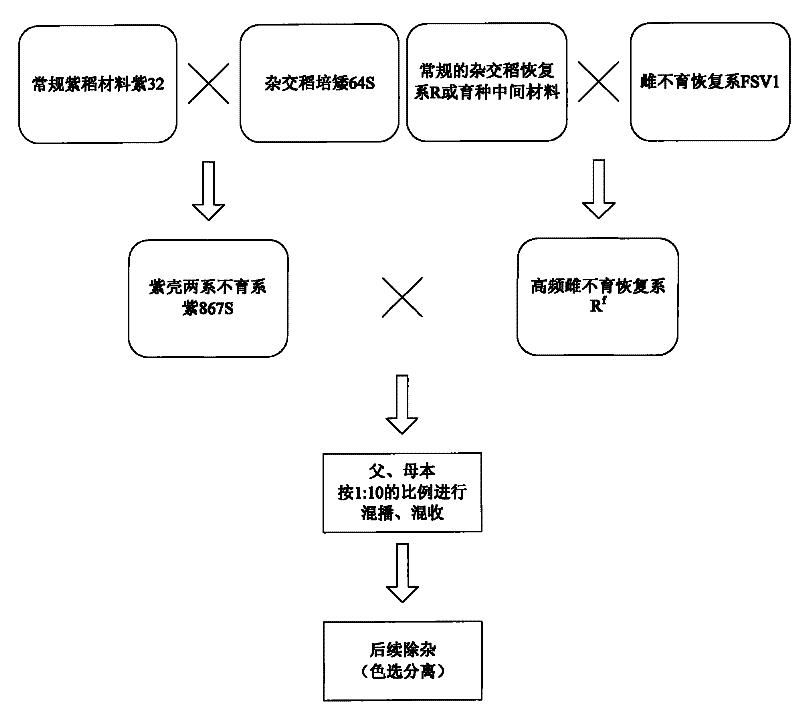

Application and cultivation method of high-frequency recessive female sterile rice restorer lines

ActiveCN101697706AImprove efficiencyRealize fully mechanized operationPlant genotype modificationAgricultural scienceSeparation method

The invention discloses application of high-frequency recessive female sterile rice restorer lines in mixed-sowing or mixed-harvesting type rice seed production. A specific method of the application comprises the steps of taking a high-frequency recessive female sterile rice restorer line as a male parent, taking a hybrid rice male sterile line as a female parent, performing mixed sowing on male / female-parent seeds and performing mixed harvesting on the male / female-parent seeds subjected to hybridization and completing the process of seed production, or the steps of taking the hybrid rice male sterile line with screenable genetic specific characters as the female parent, performing mixed sowing and mixed harvesting and then adopting different separation methods to perform further impurity removal on the seeds subjected to mixed harvesting. The invention also provides a cultivation method which hybridizes a female sterile restorer line FSV1 with a conventional hybrid rice restorer line R, chooses and gets the high-frequency recessive female sterile rice restorer line with stable genetic characters and excellent comprehensive agronomic characters from F1 progenies. The method has the advantages of realizing the full-mechanized operation of producing and processing hybrid rice seeds and greatly improving the efficiency of hybrid rice seed production.

Owner:HUNAN HYBRID RICE RES CENT

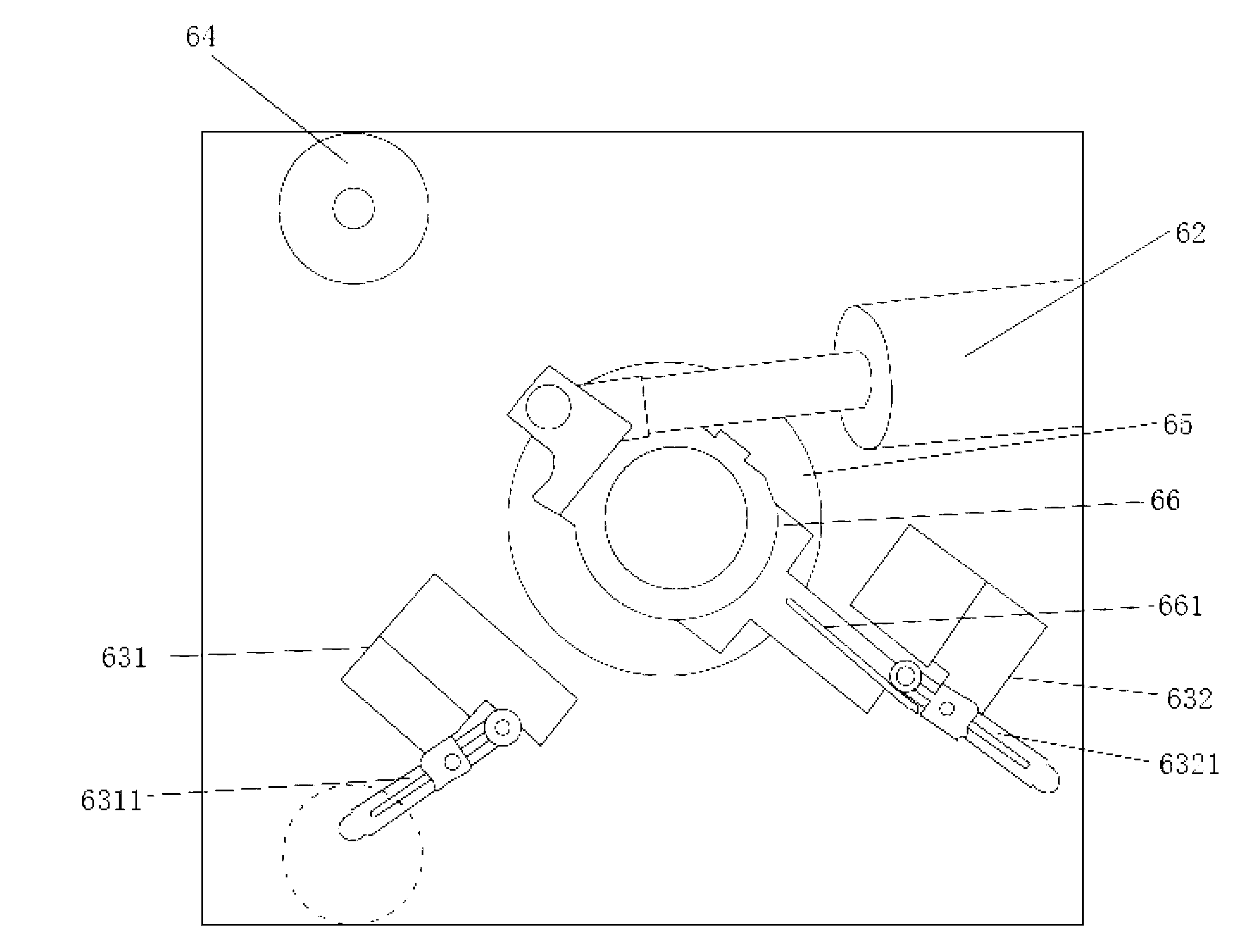

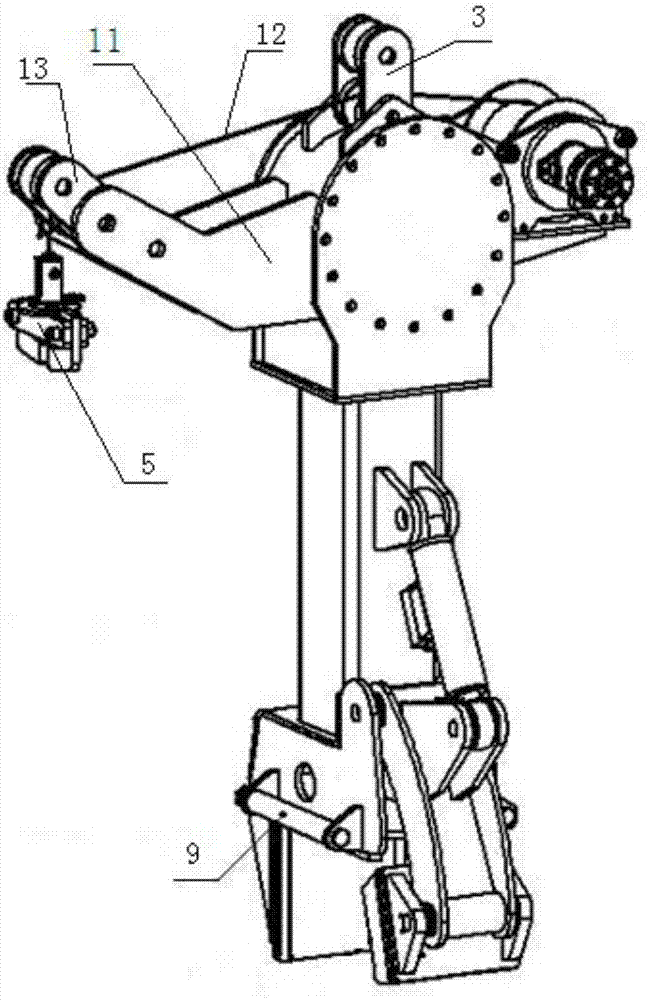

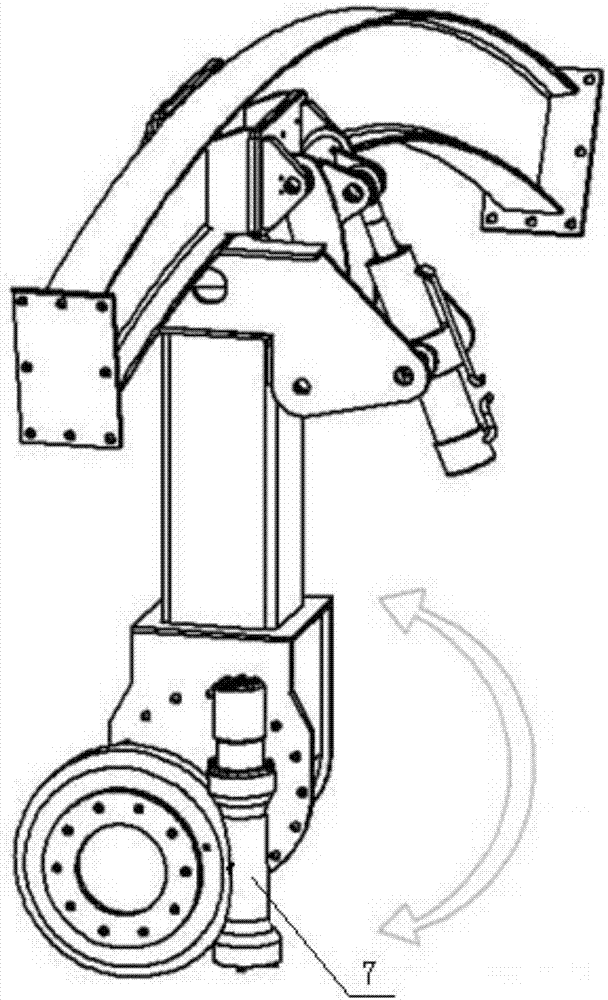

Deflection clamping device used for installation of arch frame in tunnel construction

PendingCN107503773AImprove securityRealize fully mechanized operationUnderground chambersTunnel liningArchitectural engineeringSteel frame

The invention discloses a deflection clamping device used for installation of an arch frame in tunnel construction. The deflection clamping device contains a vertical revolving support device, a hydraulic winch, a limiting pulley, a deflection arm and a lifting support cantilever. The side edge at one end of the deflection arm is fixedly connected to the vertical revolving support device through bolts. The other end of the deflection arm is provided with a cantilever end. One end of the lifting support cantilever is fixedly connected to a fixing end of the deflection arm. The vertical revolving support device is fixedly connected to a base of a construction platform. Rapidly and flexible butt-joint and firm connection of an installation flange of the arc frame in tunnel construction are realized. The same kind of equipment does not need to perform accurate operation repetitively so that a time-consuming and labor-consuming problem of hard butt-joint is resolved. Meanwhile, the device can work with a main clamping device (a middle arm clamping device) to form a three-point fixing type after installation and formation of the overall arch frame so that the front-and-back distance of the overall arch frame is adjusted. It is no longer difficult to adjust the overall arch steel frame by other similar equipment. The device obtains good effect.

Owner:CHINA RAILWAY NO 5 ENG GRP +1

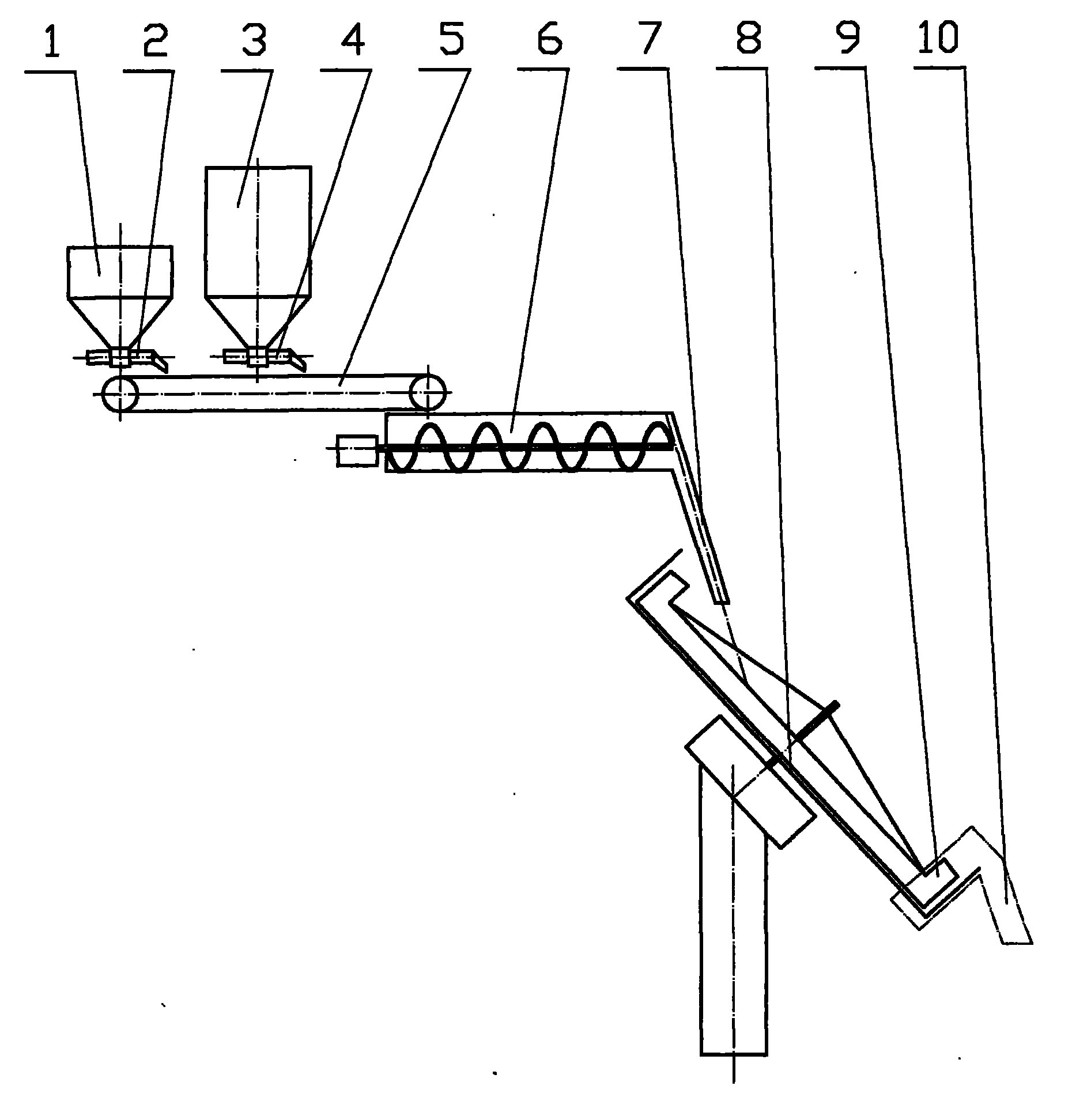

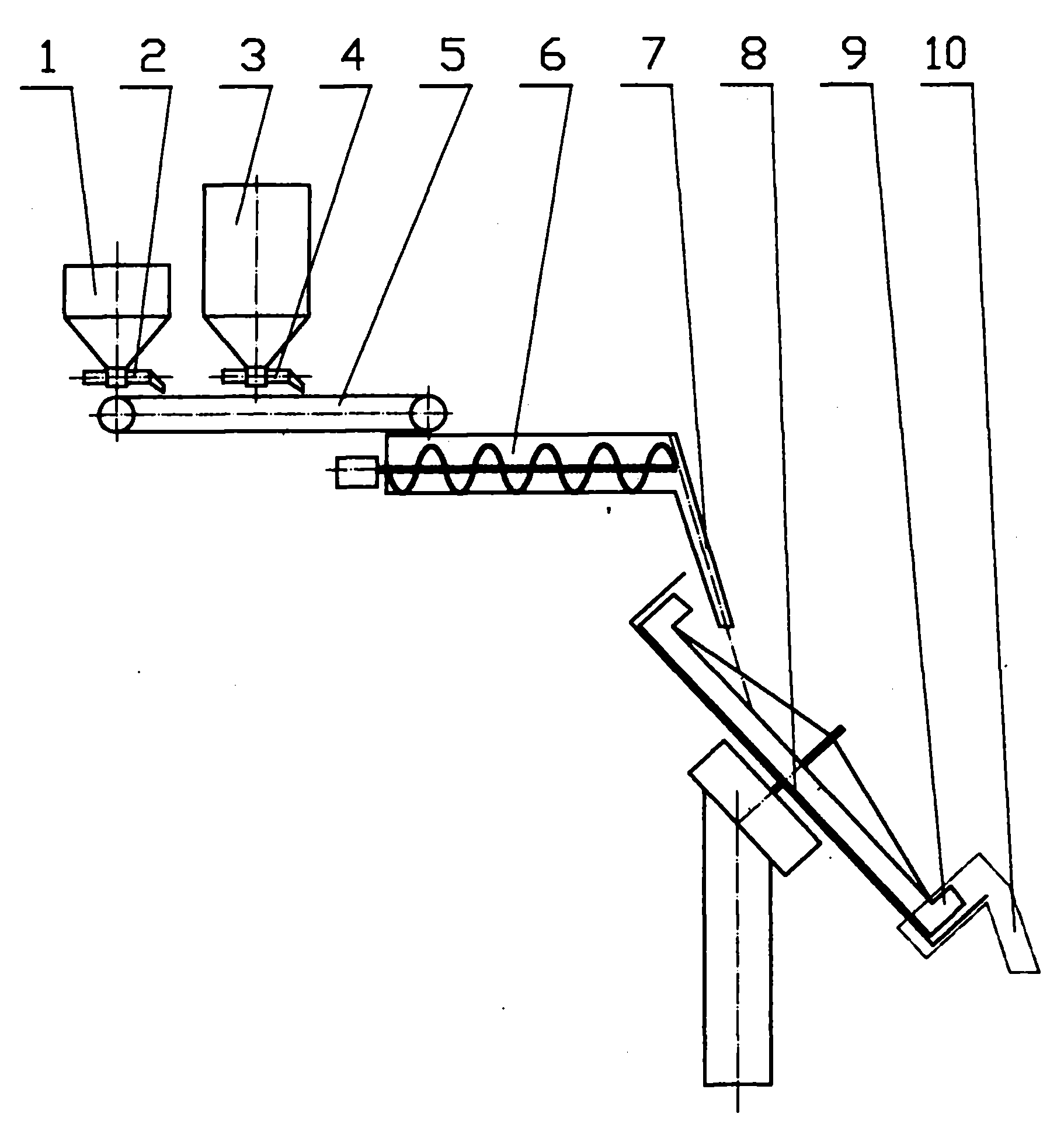

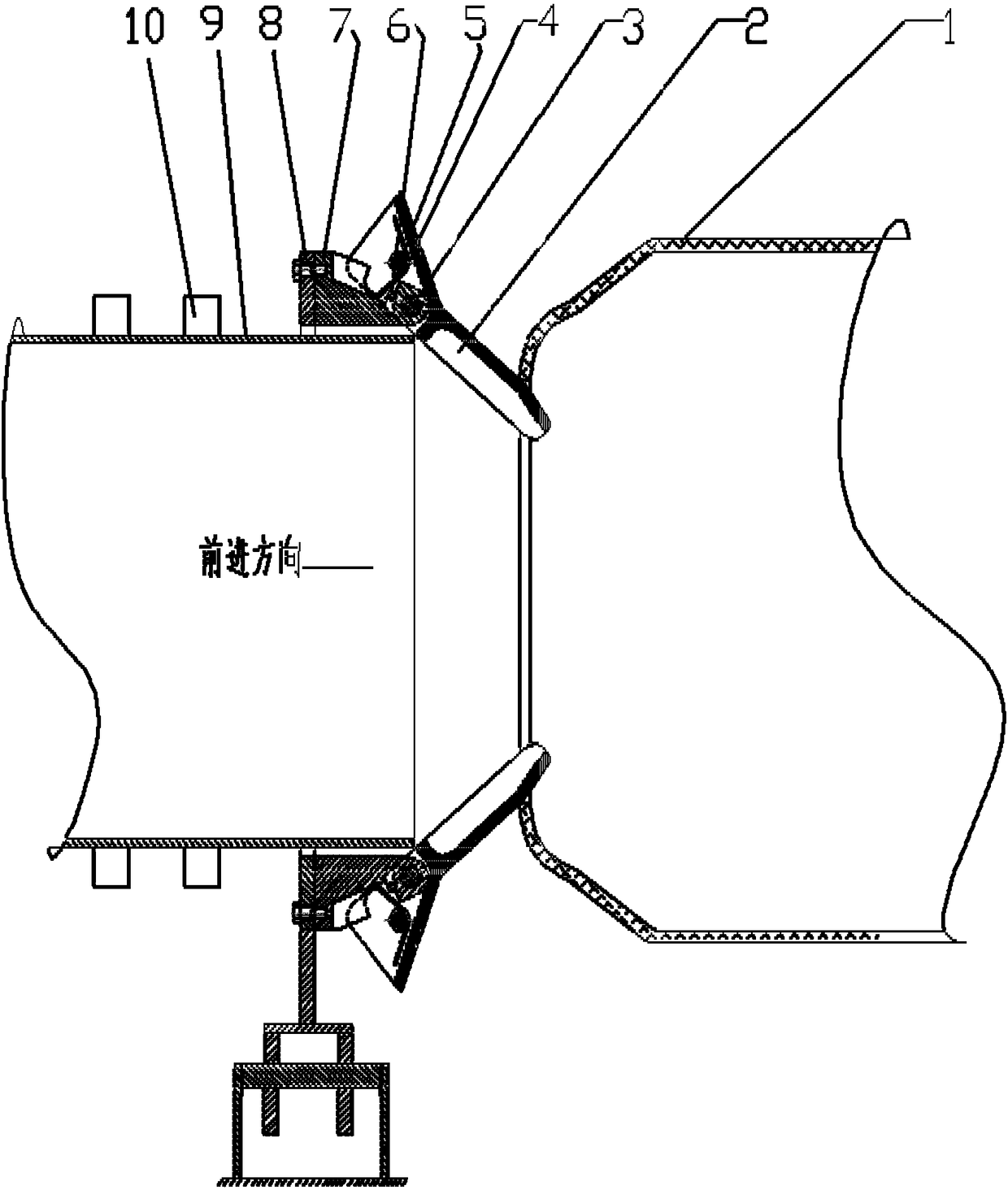

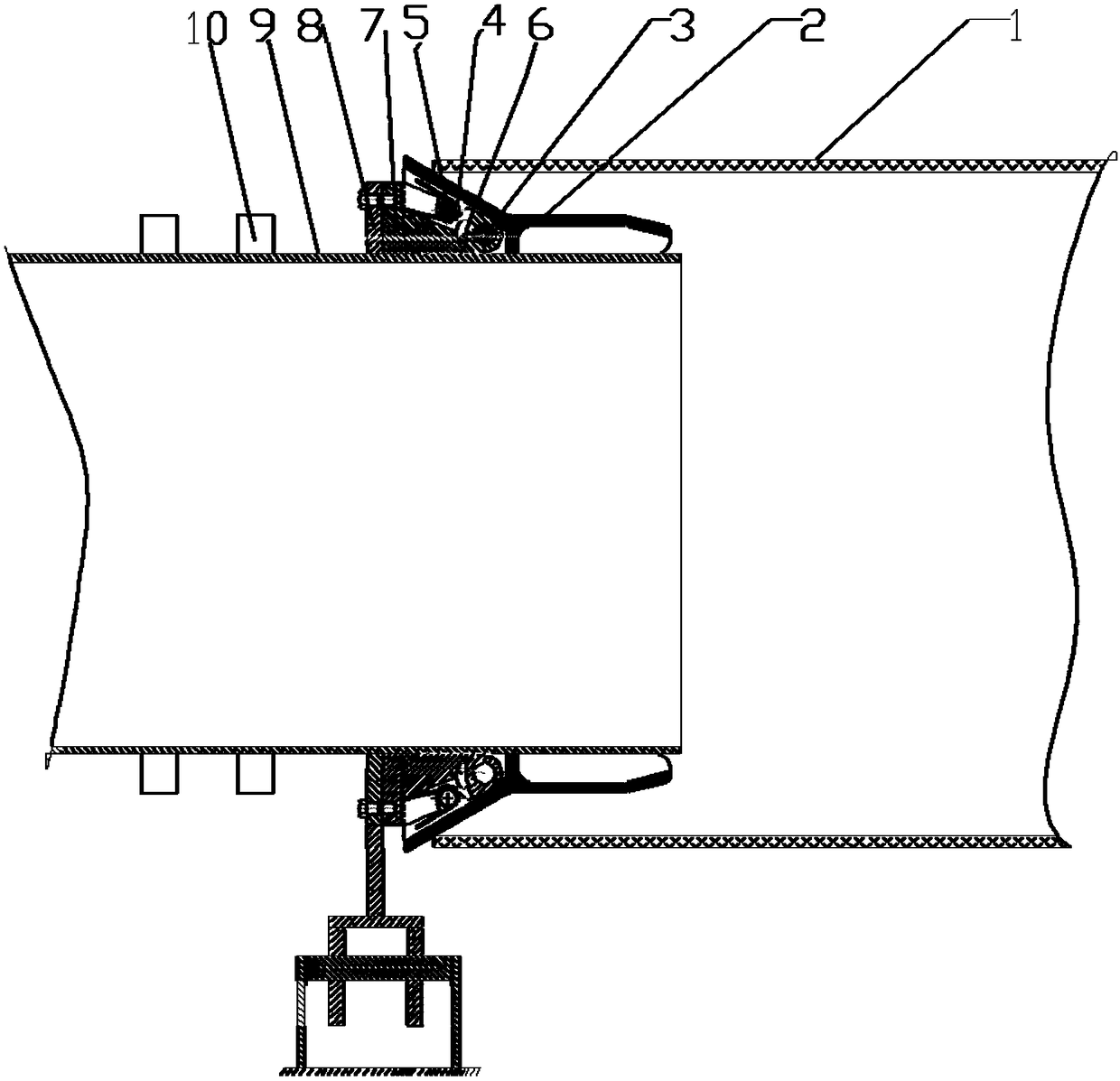

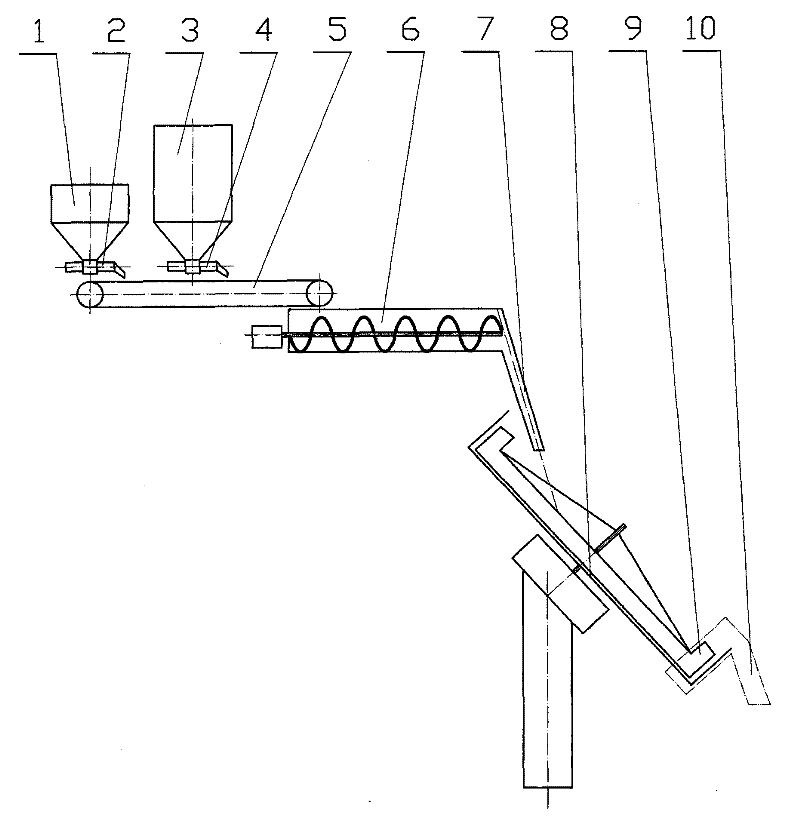

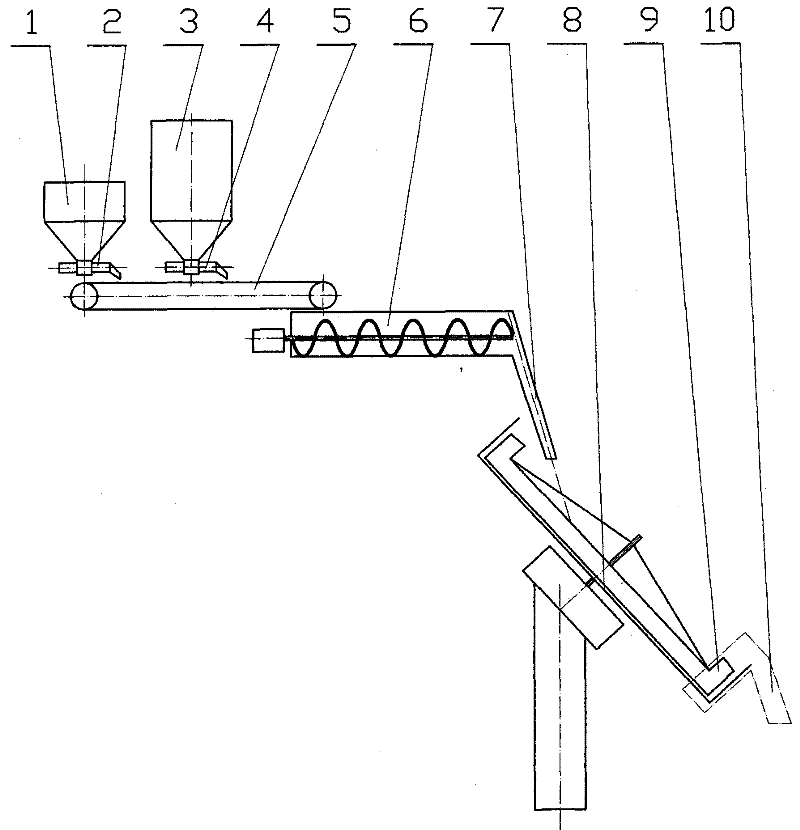

Feeding and pelletizing system for smelting antimony

InactiveCN101956065ADecrease stockUniform sizeGranulation in rotating dishes/pansEngineeringAntimony

The invention discloses a feeding and pelletizing system for smelting antimony, which relates to the technical field of smelting. The system consists of an antimony concentrate hopper 1, an antimony concentrate screw feeder 2, a fine lime warehouse 3, a fine lime screw feeder 4, a burdening belt conveyer 5, a screw stirring conveyer 6, a blanking hopper 7, a disc type pelletizer 8 and a particle output hopper 10. The system has the characteristics of realizing fully mechanical operation, reducing the operation intensity of personnel, reducing raw material stock, lowering production cost and the like, is suitable for pelletizing antimony concentrate in the process of smelting antimony and can be used for pelletizing powder raw materials in other industries.

Owner:湖南东港锑品有限公司

Cover opening and closing device

ActiveCN103600875AAvoid stickingRealize fully mechanized operationPackagingAir cylinder PressIntegrated circuit

The invention relates to the technical field of integrated circuit chip processing and discloses a cover opening and closing device used for closing and opening a cover of a chip box. The chip box comprises a base, a chip accommodating cavity formed in the base and buckles arranged at upper ends of two sides of the base, a buckle head is arranged on the inner side of each buckle, and an arc concave surface is arranged on the outer side of each buckle. The cover comprises clamping grooves which are formed on two sides and used for matching with the buckle heads. The cover opening and closing device further comprises an air cylinder and a press block groove fixedly formed at the lower end of the air cylinder, two J-shaped claws are arranged on two sides of the press block groove respectively, the two claws are matched with the arc concave surfaces of the two buckles on the chip box respectively to achieve opening and closing of the buckles, a press block is arranged in the press block groove, a sucker which is controlled by a vacuum air channel is arranged at the lower end of the press block, and when the air cylinder presses downwards till the sucker is on the upper surface of the cover, the claws are located at opening positions of the buckles. By the cover opening and closing device, fully-mechanized operation is realized through the mechanical claws and the air cylinder.

Owner:JIAXING JINGYAN INTELLIGENT EQUIP TECH

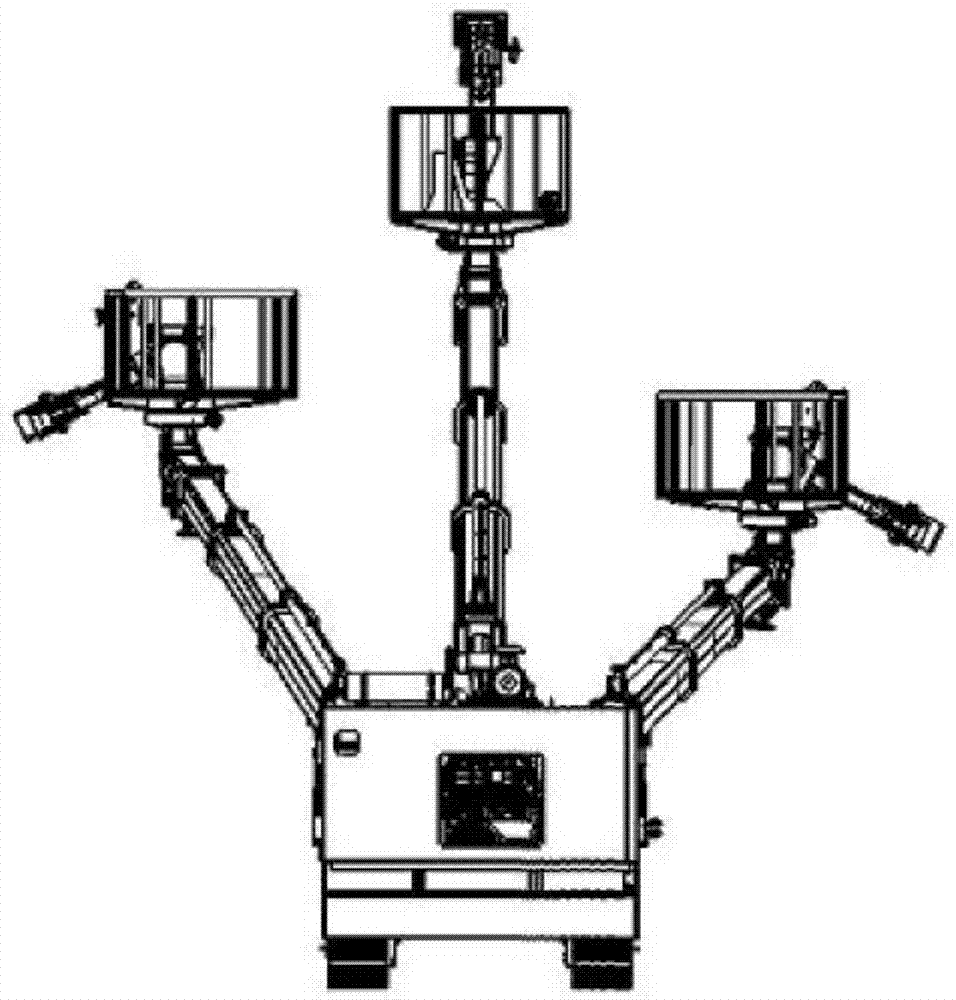

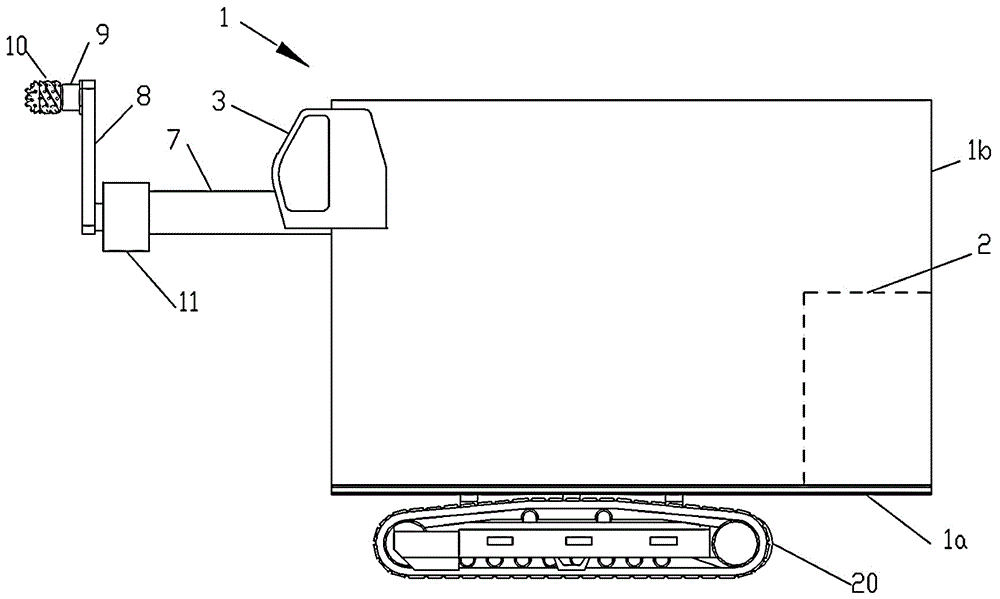

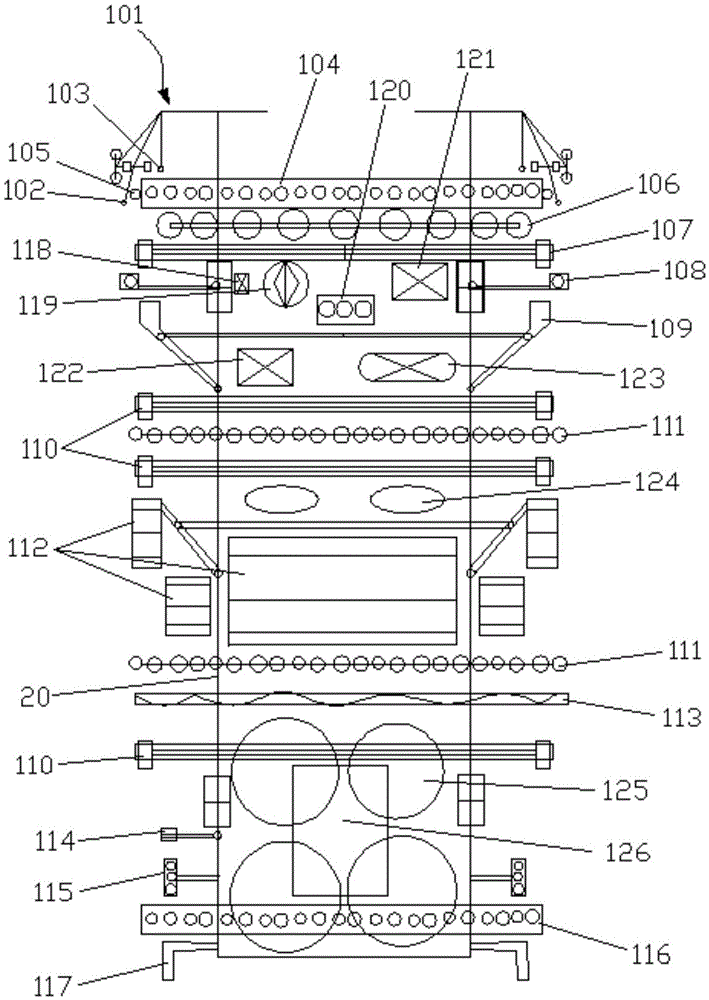

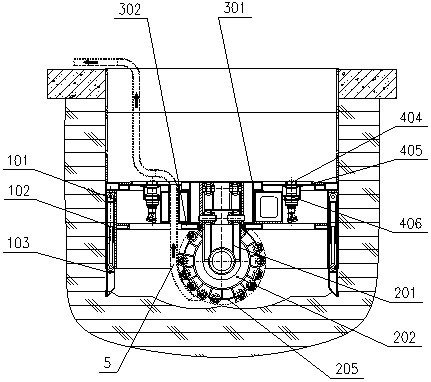

Tunnel underground excavation machine

The invention relates to a tunnel underground excavation machine, which comprises a vehicle frame (1), wherein an electric control device (2) and a cab (3) are arranged above the vehicle frame; a crawler traveling device (20) is arranged under the vehicle frame (1). The tunnel underground excavation machine is characterized in that a main sleeve (6) ascending and descending in a vertical direction is also arranged on the vehicle frame; an axial line of the main sleeve (6) is arranged along the length direction of the vehicle frame (1); a sub sleeve (7) sliding along the axial direction of the main sleeve (6) is arranged in the main sleeve (6); one end of the sub sleeve (7) is connected with a cutter head frame (11); at least one cutter head driving device (9) is arranged on the cutter head frame (11); a power output shaft of each cutter head driving device is connected with a milling-planing cutter head (10). The tunnel underground excavation machine has the beneficial effects that the structure is simple; the safety is high; the excavation can be performed in the full cross section range of a tunnel; the layered excavation can be performed according to the practical condition of the tunnel; the fully mechanical operation of the tunnel underground excavation construction is realized; the characteristic of wide application range is realized.

Owner:ANHUI XINGYU TRACK EQUIP

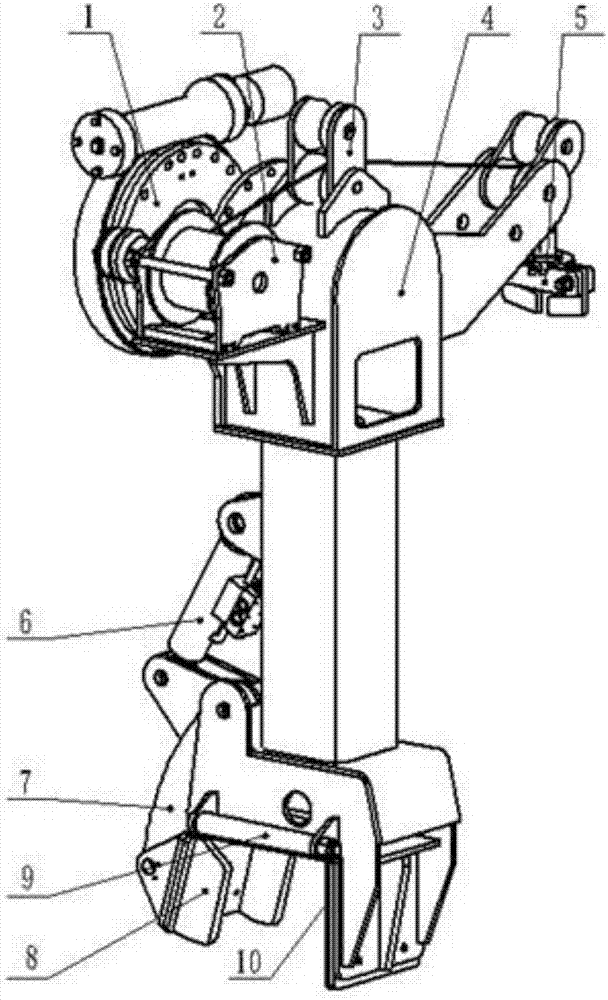

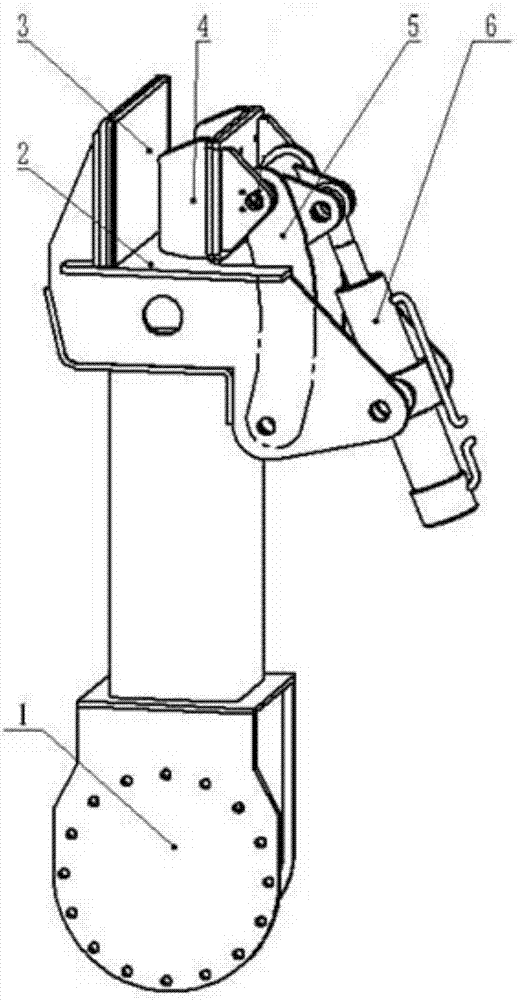

Main clamping device for installation of tunnel construction arch support

PendingCN107514270AImprove securityRealize fully mechanized operationUnderground chambersTunnel liningButt jointArchitectural engineering

The invention discloses a main clamping device for installation of a tunnel construction arch support. The main clamping device comprises a rotating base, a clamping head base, a rubber supporting back plate, a steel arch support clamping plate, a clamping connecting rod and a longitudinal rotary support device, wherein the rotating base is fixedly connected with the longitudinal rotary support device through bolts, the rotating base is fixedly connected with the clamping head base through a square tube, the rubber supporting back plate is arranged on one side of the clamping head base, the clamping connecting rod is hinged to the other side of the clamping head base, the steel arch support clamping plate is hinged to the movable end of the clamping connecting rod, and the longitudinal rotary support device is fixedly connected to the pedestal of a construction platform. The main clamping device for installation of the steel arch support can rotate by 180 degrees, the first section (middle section) of the steel arch support can be automatically picked up under any working condition and can also be safely clamped in a balanced mode, the process can be completed with little assistance from only one worker in construction, and the problem is solved that some devices of the same type need complex and precise rigid butt joint which consumes time and labor.

Owner:CHINA RAILWAY NO 5 ENG GRP +1

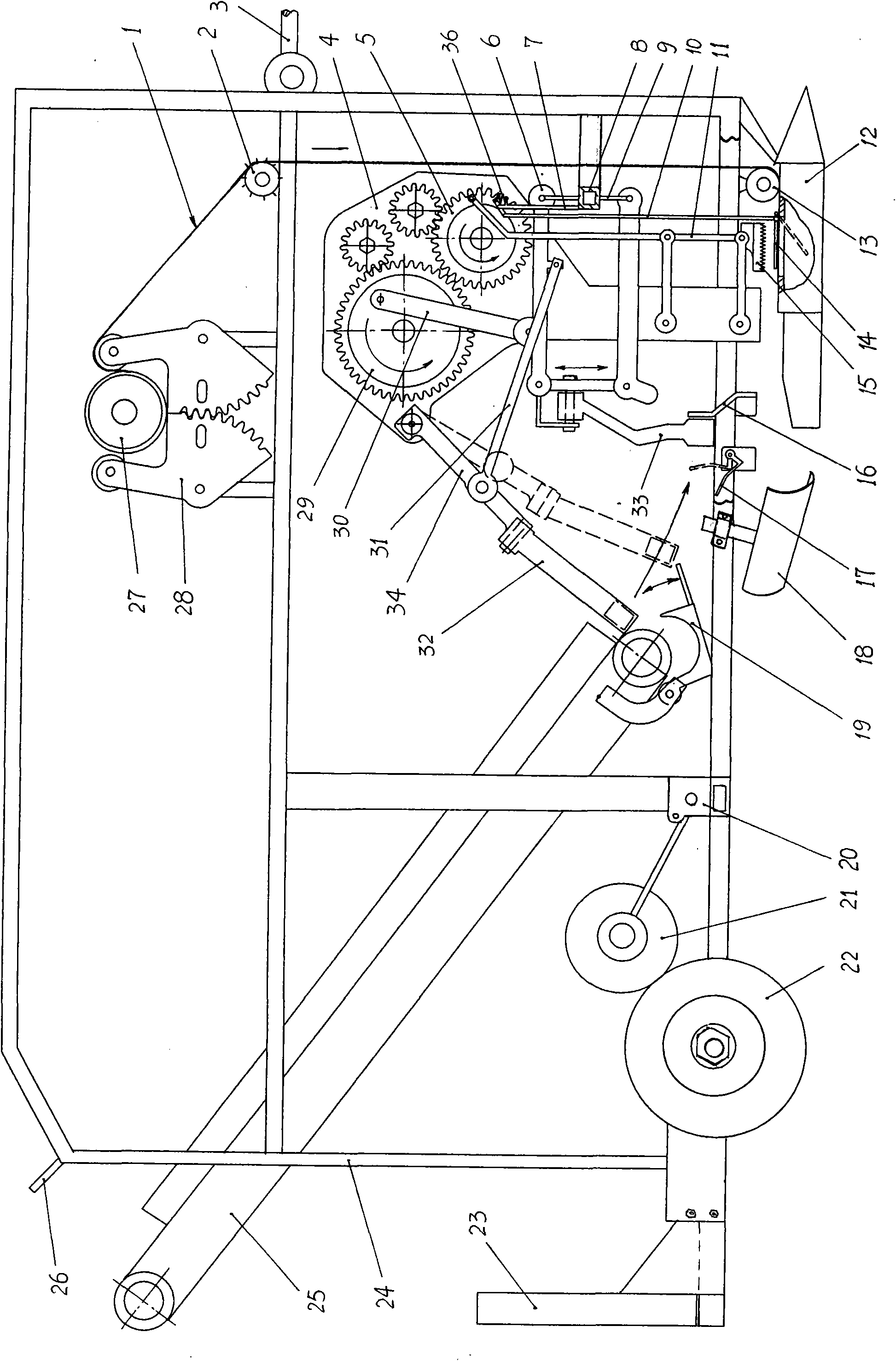

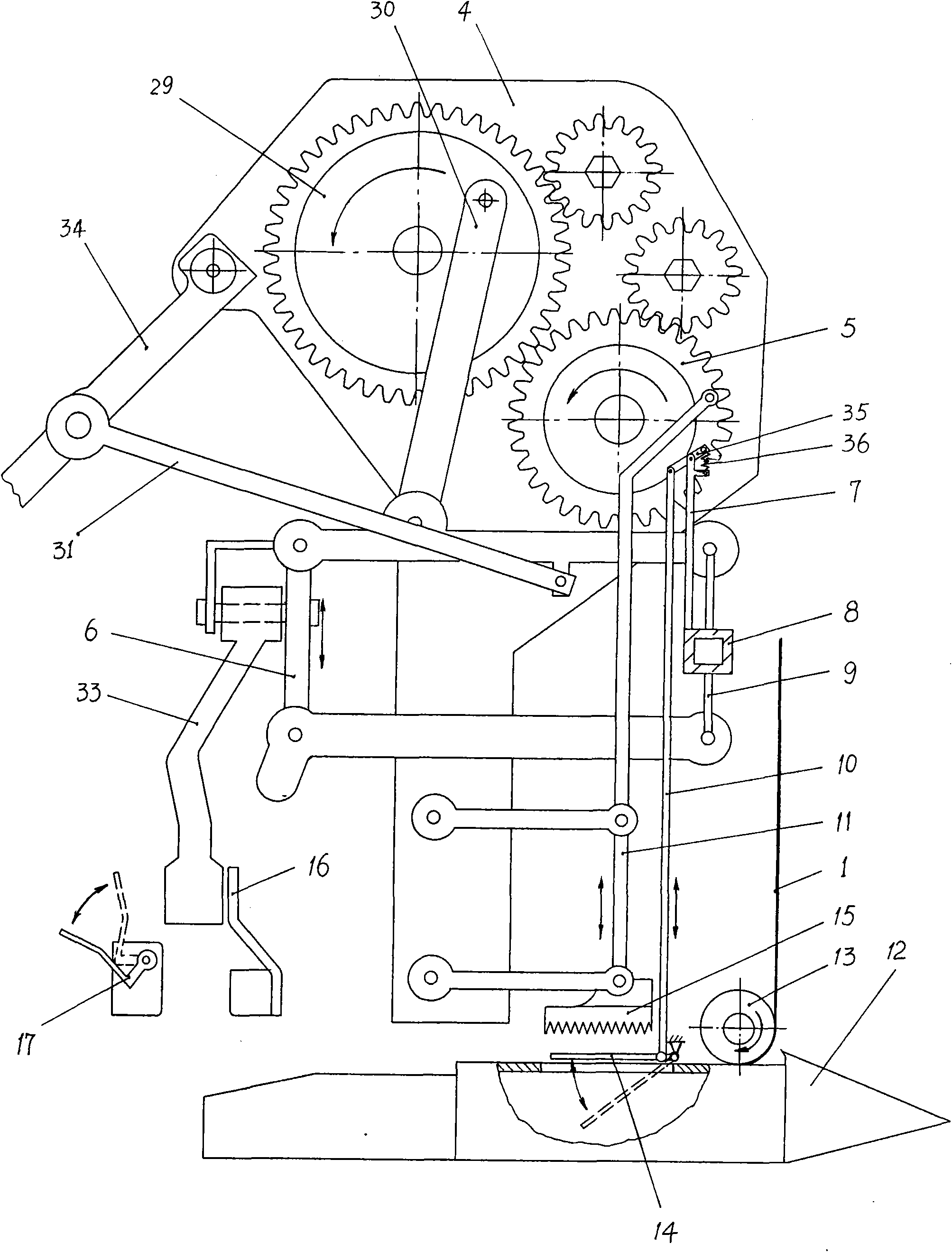

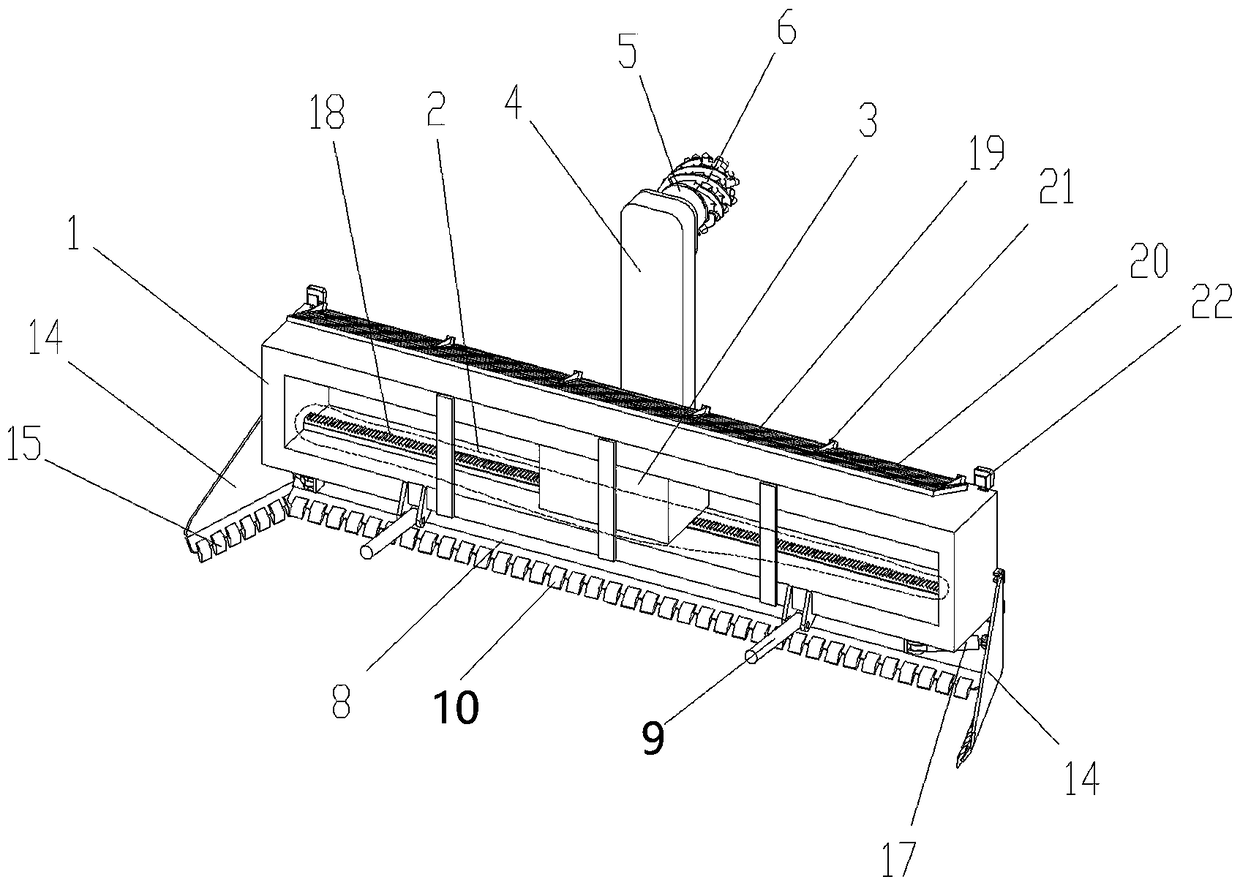

Seedling transplanter

The invention relates to a seedling transplanter, the structure of the seedling transplanter is characterized in that the lower part of a machine frame is provided with a traveling wheel, the lower part of the front end of the machine frame is provided with an opener; the back of the machine frame is provided with a seedling pot conveying mechanism and a pedal frame; the middle part of the machine frame is provided with a cabinet plate which is connected with a transmission mechanism, a mechanical linkage mechanism and a pneumatic clamping transmission mechanism; the pneumatic clamping transmission mechanism is connected with the transmission mechanism by the mechanical linkage mechanism; the mechanical linkage mechanism is connected with a pneumatic clamping and inserting mechanism; and a controller which controls the parts to cooperatively operate is arranged on the machine frame. The seedling transplanter can continuously finish the grabbing, transmission and inserting in a crossing, consistent and cooperative way; an operating mechanism has short action stroke, takes little time and embodies the shortcut characteristics of the mechanical seedling transplantation. The seedling transplanter is suitable for transplanting the seedlings of various crops with more than 20 cm of row spacing.

Owner:CANGZHOU LINGANG FUCAI AGRI MACHINERY

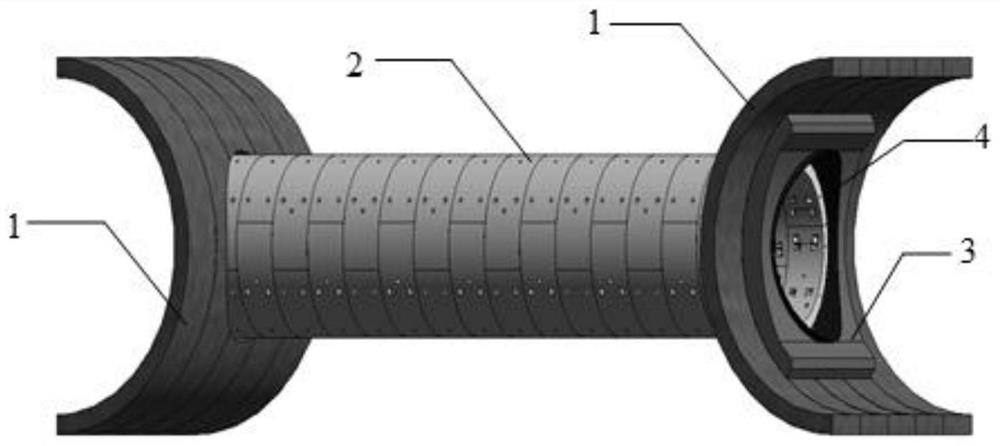

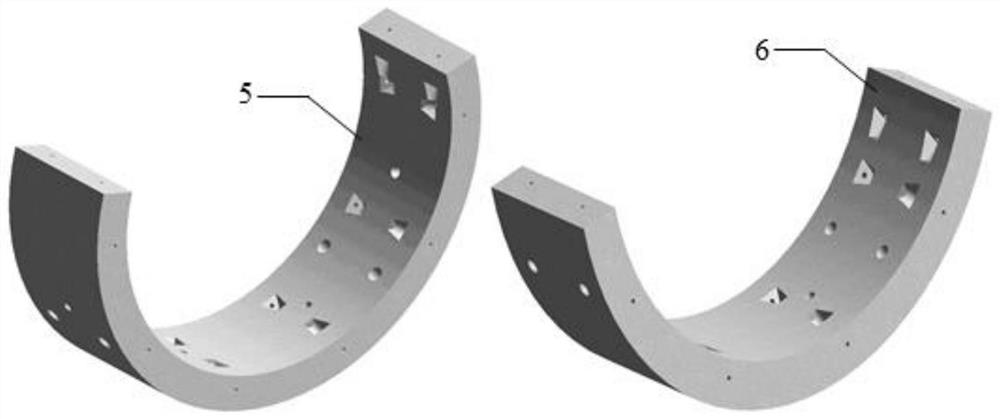

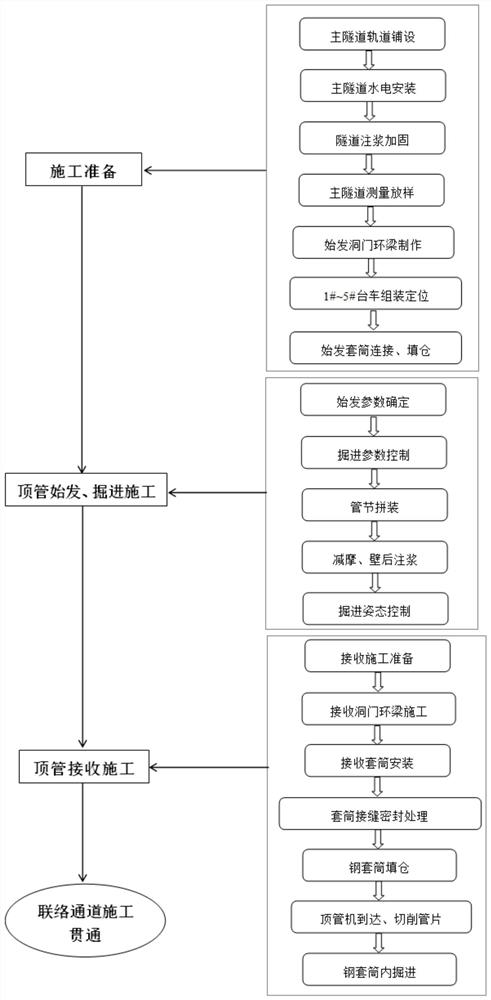

Mechanical method connecting channel construction method using pipe jacking technology

PendingCN113756825AHigh degree of construction mechanizationQuality improvementUnderground chambersTunnel liningSupporting systemArchitectural engineering

The invention relates to a mechanical method connecting channel construction method using a pipe jacking technology. The method comprises the steps: S1, conducting construction preparation; S2, starting pipe jacking and carrying out tunneling construction; and S3, conducting pipe jacking receiving construction. The method have the beneficial effects that the spliced connecting channel structure and the pipe jacking method construction method have the advantages of high construction mechanization degree, reliable quality, high speed, no soil body pre-reinforcement, low manufacturing cost and small environmental disturbance and the like. A small-diameter earth pressure balance pipe jacking machine and post-corollary equipment are integrally designed with a supporting system in a tunnel, tunneling, pipe piece splicing, deslagging, feeding and grouting in the tunnel construction process are achieved, and full-mechanical operation is achieved. An inner supporting system is provided with an automatic oil pressure adjusting device, the jacking force of a supporting oil cylinder is automatically adjusted along with tunnel stress changes, and automatic service is comprehensively achieved.

Owner:浙江杭海城际铁路有限公司 +2

Intelligent multipurpose efficient road marking vehicle

InactiveCN105463976ARealize fully mechanized operationImprove construction efficiencyRoads maintainenceEngineeringSprayer

The invention discloses an intelligent multipurpose efficient road marking vehicle which comprises a frame and a marking mechanism installed on the frame, wherein the marking mechanism comprises sideline localizers, location identifier distributors and coating sprayers which are relatively arranged at two sides of the frame from front to back as well as at least a location identifier recoverer; the sideline localizers are positioned at the front end of the frame and used for carrying out sideline location for the marking vehicle; location systems are arranged on the sideline localizers; the location identifier distributors make identifiers through specific location points positioned on a pavement; the coating sprayers catch the location identifiers on the pavement timely or control the spraying of the coating through a computer instruction; and the location identifier recoverer is positioned at the rear end of the frame and is used for catching and recovering the location identifiers on the pavement after each working procedure of a project is completed. The intelligent multipurpose efficient road marking vehicle realizes fully-mechanized operation, improves the construction efficiency, saves the labor cost and also greatly improves the safety guarantee as well as has favorable market prospects and economic benefits.

Owner:王乾仲

Rubber pipe port expanding device for heat insulation pipe

PendingCN108099172ASolve the difficulties of manual operationExpand the scope of processingThick wallMechanical engineering

The invention provides a rubber pipe port expanding device for a heat insulation pipe. The device comprises supporting mechanisms and a supporting arm mounting rack, wherein a plurality of supportingmechanisms encircle a circular structure and are uniformly distributed on the supporting arm mounting rack; each supporting mechanism comprises a supporting arm and a supporting arm base; the supporting arms are arranged on the supporting arm bases through rotating hinging shafts; a supporting spring is clamped between each supporting arm and the corresponding supporting arm base and is used for expanding each supporting arm and the corresponding supporting arm base, and thus the plurality of supporting arms can be kept in one angle in order to encircle a cone structure; the minimum diameter of a cone angle of the cone structure is less than the rubber pipe port deformation range. According to the device, the operation is completely mechanically carried out, so that the problem of manual threading of an existing heat insulation pipe in processing can be solved; the whole processing of the heat insulation pipe is completely automatically performed, so that the processing speed and the processing safety are greatly improved; and moreover, the heat insulation pipe processing range is greatly expanded; rubber pipes with thicker walls can be processed; and heat insulation pipe which higher diameter can be processed.

Owner:天津市九赢百信科技有限公司

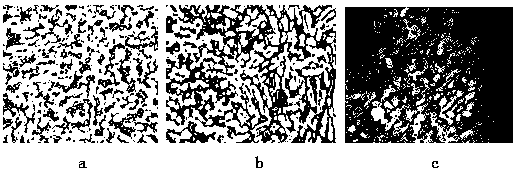

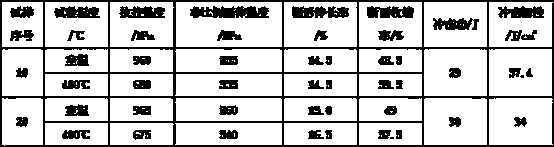

Method for machining TC4-DT titanium alloy large-specification slab forged piece

ActiveCN102581188BSingle weight increaseIncrease the amount of deformationMetal-working apparatusDiameter ratioTitanium alloy

A method for machining TC4-DT titanium alloy large-specification slab forged piece comprises the following steps: billet forging, intermediate forging, high-low circulating forging, inverting upsetting forging and shaping forging. The method is characterized in that: the large-specification forging stock is adopted for integral forging according to the method; compared with a prior-art small-specification forging blank repeated upsetting forging technique, at a state that the upsetting deformation blank height-to-diameter ratio is restricted, single weight of the forged piece is greatly improved and reaches up to above one ton; according to the deformation role in metal pressure machining, appropriate forging starting temperature and forging finishing temperature are selected, and the technical parameters are reasonably matched; the metal sufficiently deforms in a transverse direction in the forging process; forming penetration efficiency is improved; actual deformation amount and deformation uniformity of the large-specification forged piece are increased; and capability of the product for satisfying the requirement is ensured. The method further has the following advantages: capability of realizing full mechanical operation in the forged piece production process, reduced manual operation arbitrainess, large forging pressure, reduced times of heating, high batch quality consistency, high ultrasonic flow detection grade, and greatly reduced production period.

Owner:湖南湘投金天钛业科技股份有限公司

Underwater concrete pouring process

The invention discloses an underwater concrete pouring process. The underwater concrete pouring process comprises following steps that firstly, a steel reinforcement cage is made on water, wherein according to the actual needs, framework reinforcing steel bars and mesh reinforcing steel bars are machined, the framework reinforcing steel bars are spliced, according to the standard, welding is form,according to the framework reinforcing steel bars, the mesh reinforcing steel bars are assembled, finally, reinforcing meshes are laid on the inner side, that is the periphery, and the bottom of thesteel reinforcement cage, after the meshes are in lap joint, the meshes and the mesh reinforcing steel bars are bound firmly through fibers, and a whole is formed through the meshes and the mesh reinforcing steel bars; secondly, geotechnical cloth is laid in the steel reinforcement cage, wherein on the geotechnical cloth, at intervals of 10 cm, the geotechnical cloth and the reinforcing meshes areconnected through the fibers, and the geotechnical cloth can be tightly attached to the reinforcing meshes on the inner side of the steel reinforcement cage; thirdly, underwater foundation pit excavation is carried out, and the basic plane is leveled; fourthly, the steel reinforcement cage is lifted and immersed into the foundation pit; and fifthly, concrete pouring is carried out. The underwaterconcrete pouring process is higher in work efficiency, safe and reliable in construction and free of formwork erecting.

Owner:浙江省钱塘江管理局勘测设计院

Application and cultivation method of high-frequency recessive female sterile rice restorer lines

ActiveCN101697706BImprove efficiencyRealize fully mechanized operationPlant genotype modificationBiotechnologySowing

The invention discloses application of high-frequency recessive female sterile rice restorer lines in mixed-sowing or mixed-harvesting type rice seed production. A specific method of the application comprises the steps of taking a high-frequency recessive female sterile rice restorer line as a male parent, taking a hybrid rice male sterile line as a female parent, performing mixed sowing on male / female-parent seeds and performing mixed harvesting on the male / female-parent seeds subjected to hybridization and completing the process of seed production, or the steps of taking the hybrid rice male sterile line with screenable genetic specific characters as the female parent, performing mixed sowing and mixed harvesting and then adopting different separation methods to perform further impurityremoval on the seeds subjected to mixed harvesting. The invention also provides a cultivation method which hybridizes a female sterile restorer line FSV1 with a conventional hybrid rice restorer lineR, chooses and gets the high-frequency recessive female sterile rice restorer line with stable genetic characters and excellent comprehensive agronomic characters from F1 progenies. The method has the advantages of realizing the full-mechanized operation of producing and processing hybrid rice seeds and greatly improving the efficiency of hybrid rice seed production.

Owner:HUNAN HYBRID RICE RES CENT

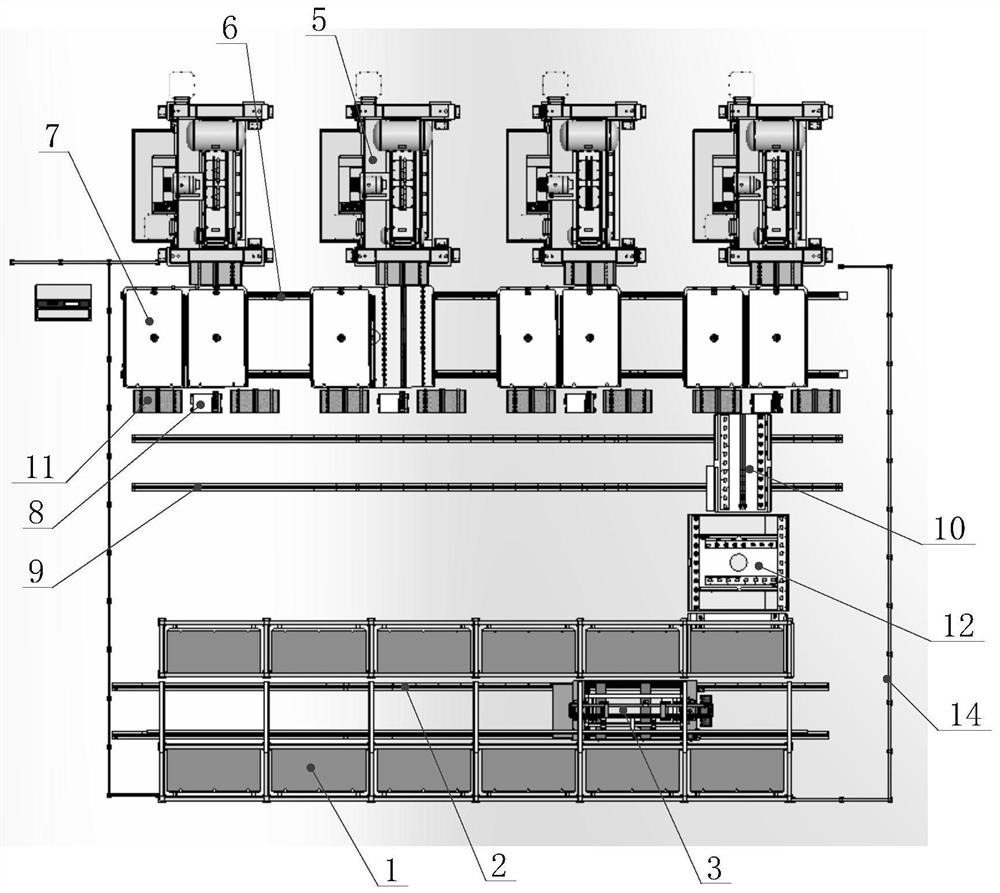

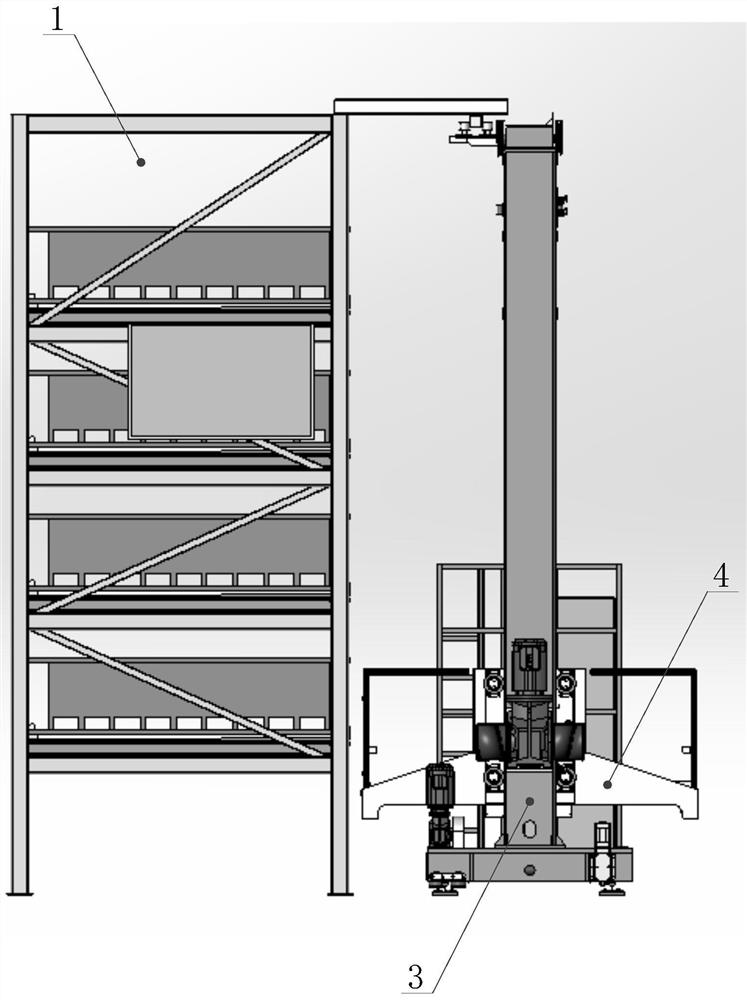

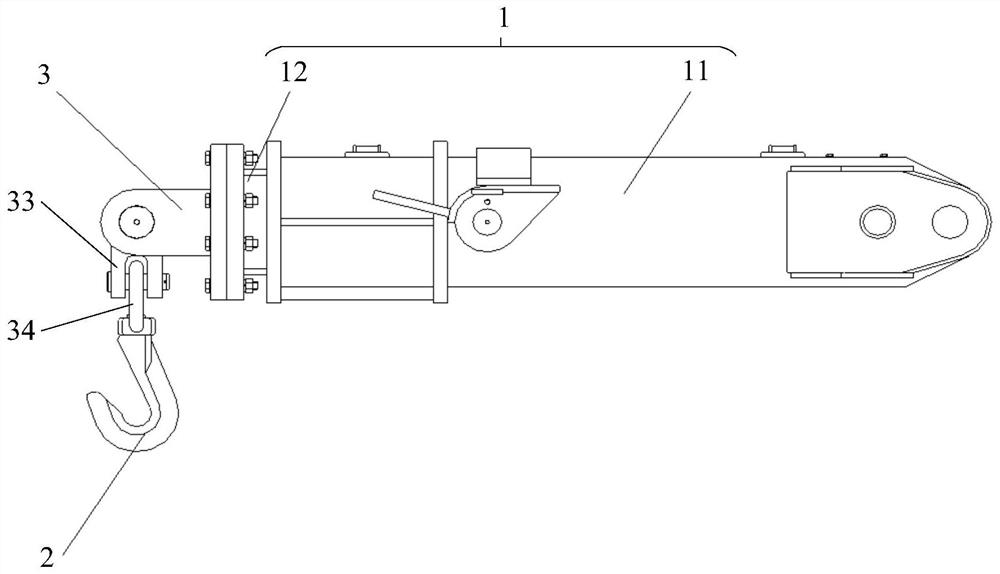

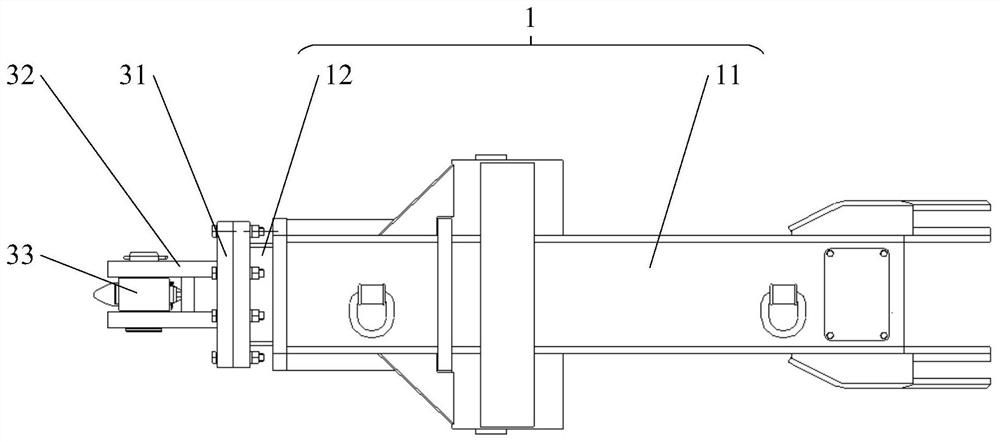

Die changing system for door shell automatic line

PendingCN112893653ARealize automatic storageRealize automatic onlineShaping toolsPush and pullIndustrial engineering

The invention discloses a die changing system for a door shell automatic line. The die changing system for the door shell automatic line comprises a die library, a stacking mechanism, a pressing machine, a die changing mechanism and push-pull devices, wherein the die library is used for storing door shell dies, the stacking mechanism is used for storing or taking out the door shell dies from a storage space, the pressing machine is used for pressing and forming the door shell dies, the die changing mechanism is used for changing the door shell dies on the pressing machine, and the second push-pull device is used for pushing and pulling the door shell dies on a die changing trolley and a pressing machine workbench. By means of the structural design, the die changing system for the door shell automatic line can achieve automatic storage, automatic line feeding, automatic pressing forming, automatic outputting and die changing of the door shell dies, the system is reasonable in design, full-mechanical operation of door shell die pressing forming can be achieved, a product is improved, and the working efficiency is also improved to a great extent.

Owner:青岛北洋天青数联智能有限公司

Consignment vehicle for coal mine

PendingCN113503181AFirmly connectedImprove structural strengthProgramme-controlled manipulatorMine roof supportsWinchCoal

The invention discloses a consignment vehicle for a coal mine. The consignment vehicle for the coal mine comprises a consignment vehicle body and a mechanical arm movably arranged on the consignment vehicle body, the mechanical arm is stretchable, the free end of the mechanical arm is provided with a rotatable rotating connecting piece, and the rotating connecting piece is used for being connected with a base of a hydraulic support. The consignment vehicle for the coal mine, which is provided with the mechanical arm, is adopted to replace a prop pulling winch and a single hydraulic prop, the hydraulic support is removed, and integrated continuous operation of pulling out and dragging of the hydraulic support is achieved; compared with a steel cable hard dragging hydraulic support adopting the prop pulling winch in the prior art, the mechanical arm is large in structural strength and high in safety, and therefore construction safety is improved; and a steel cable does not need to be manually pulled to the removed support or the single hydraulic prop is manually carried and arranged, so that the labor intensity of workers is reduced, and the construction efficiency is improved.

Owner:YANKUANG DONGHUA HEAVY IND CO LTD

Lifting and closing device

ActiveCN103600875BRealize fully mechanized operationAvoid stickingPackagingAir cylinder PressIntegrated circuit

The invention relates to the technical field of integrated circuit chip processing and discloses a cover opening and closing device used for closing and opening a cover of a chip box. The chip box comprises a base, a chip accommodating cavity formed in the base and buckles arranged at upper ends of two sides of the base, a buckle head is arranged on the inner side of each buckle, and an arc concave surface is arranged on the outer side of each buckle. The cover comprises clamping grooves which are formed on two sides and used for matching with the buckle heads. The cover opening and closing device further comprises an air cylinder and a press block groove fixedly formed at the lower end of the air cylinder, two J-shaped claws are arranged on two sides of the press block groove respectively, the two claws are matched with the arc concave surfaces of the two buckles on the chip box respectively to achieve opening and closing of the buckles, a press block is arranged in the press block groove, a sucker which is controlled by a vacuum air channel is arranged at the lower end of the press block, and when the air cylinder presses downwards till the sucker is on the upper surface of the cover, the claws are located at opening positions of the buckles. By the cover opening and closing device, fully-mechanized operation is realized through the mechanical claws and the air cylinder.

Owner:JIAXING JINGYAN INTELLIGENT EQUIP TECH

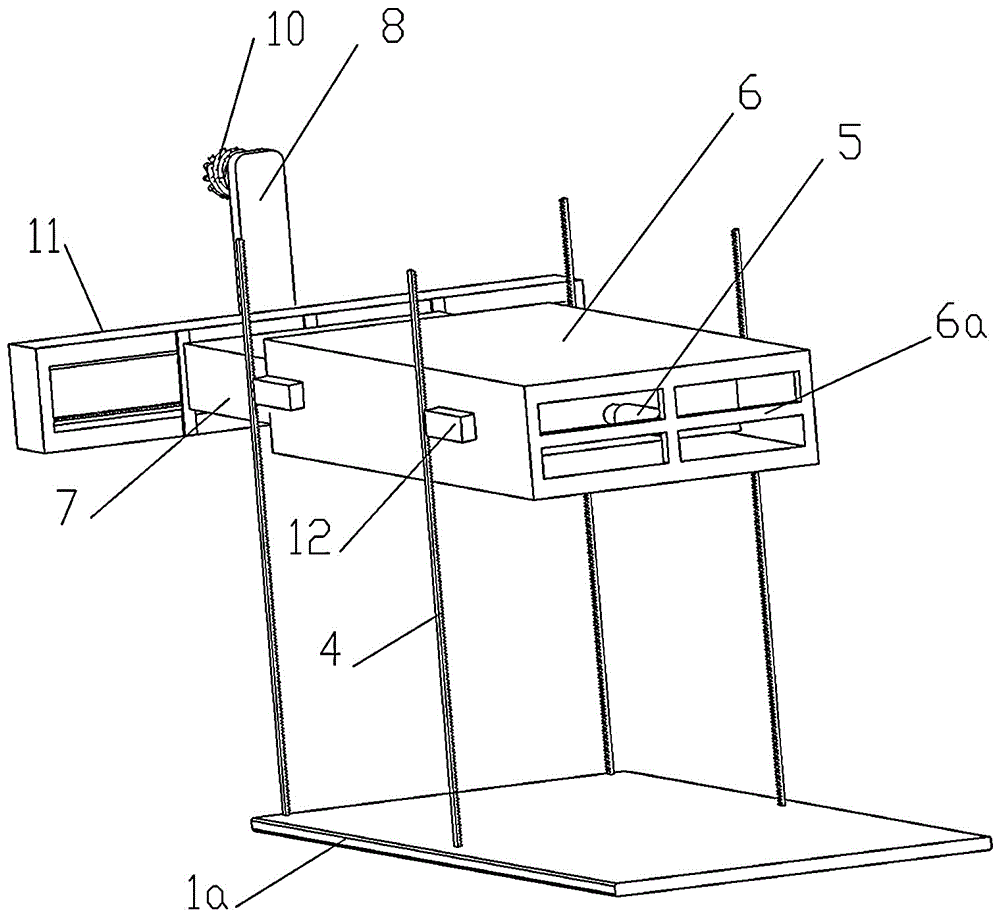

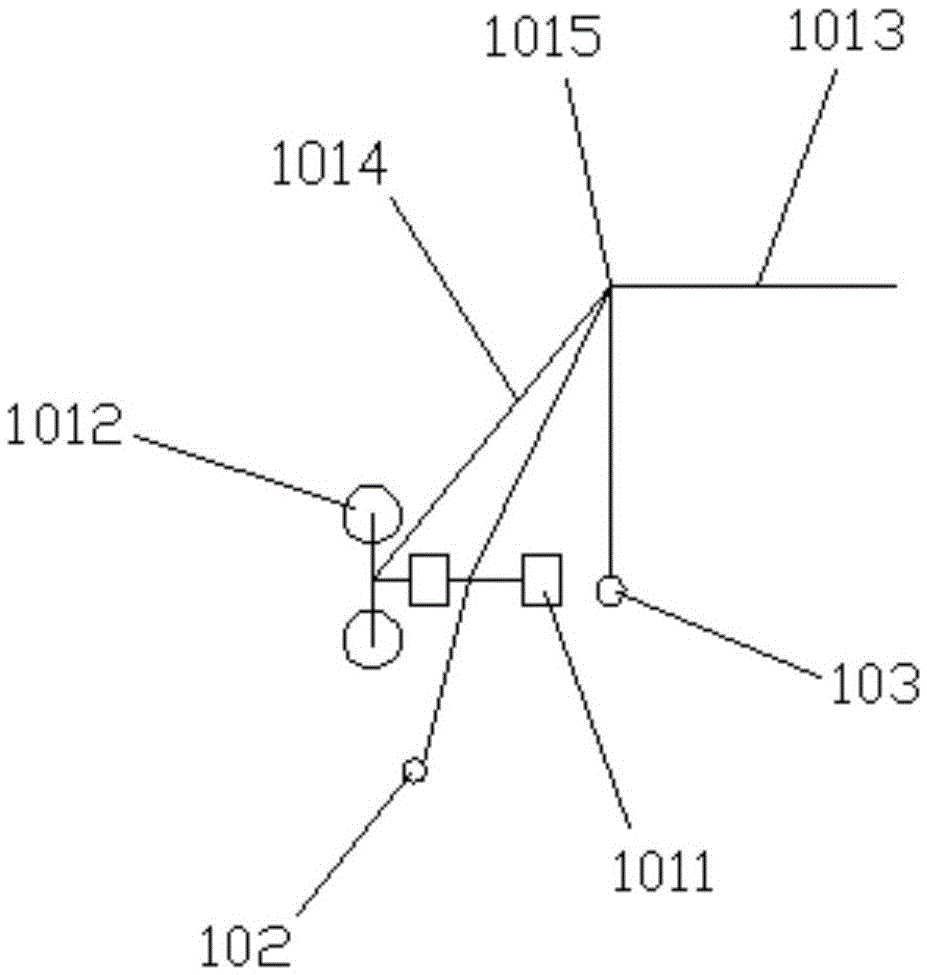

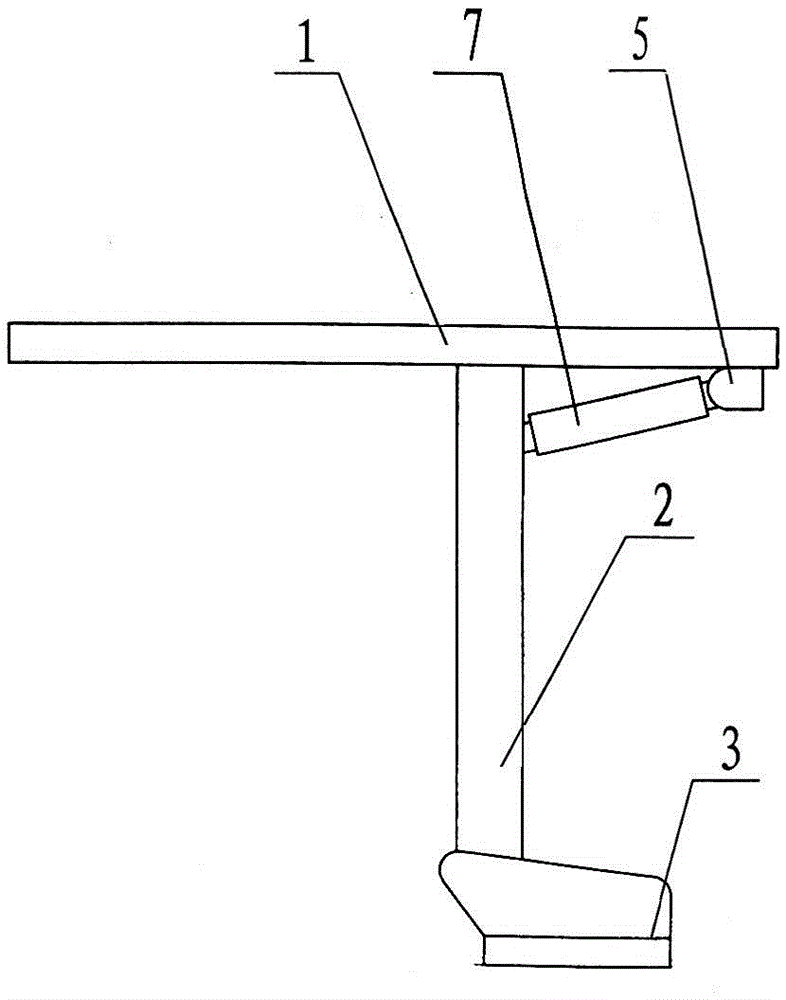

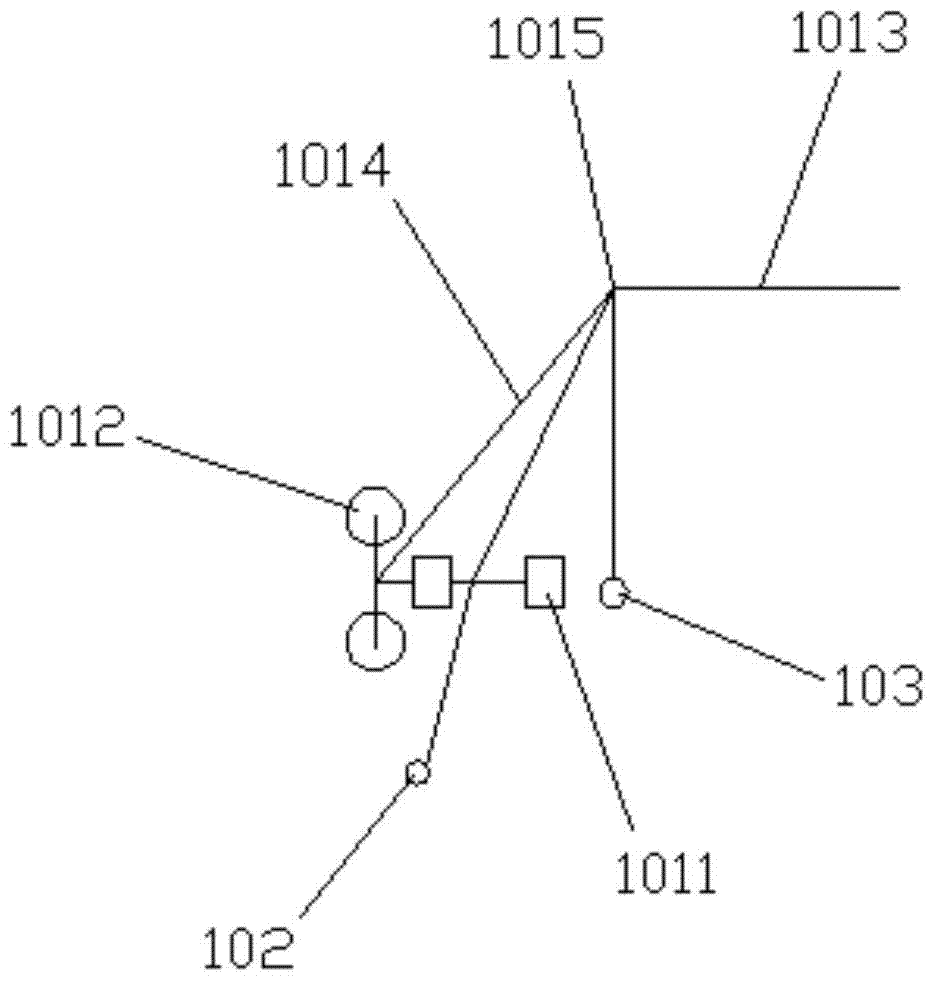

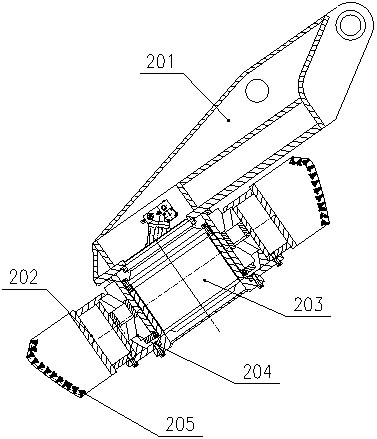

A cutter head frame for tunnel excavator

ActiveCN105840206BEasy to digRealize fully mechanized operationTunnelsHydraulic cylinderVertical plane

The invention relates to a cutter head frame for a tunnel digging machine. The cutter head frame (1) is connected with an adjusting device (3), wherein both the cutter head frame (1) and the adjusting device (3) are rotatably connected with a rotating arm (4), and a cutter head driving device (5) is connected onto the rotating arm (4) and is in driving connection with a mill-planing head (6); a main scraper (8) is fixedly hinged to the cutter head frame (1) through first hinge seats (7), first hydraulic cylinders (10) are hinged to the lower side of the cutter head frame (1), piston rods of the first hydraulic cylinders (10) are fixedly hinged to the main scraper (8), and the first hydraulic cylinders (10) drive the main scraper (8) to rotate in a vertical plane around the first hinge seats (7). The cutter head frame has the advantages that the cutter head frame is large in digging area and high in efficiency, so that the digging of station platforms is facilitated; dug soil can be subjected to centralized treatment, so that the removal is convenient, rapid, timesaving and laborsaving; fully-mechanized operation for tunnel digging construction is achieved, the operation speed is high, and the applicable range is wide, so that the cutter head frame is applicable to popularization and application.

Owner:ANHUI XINGYU TRACK EQUIP

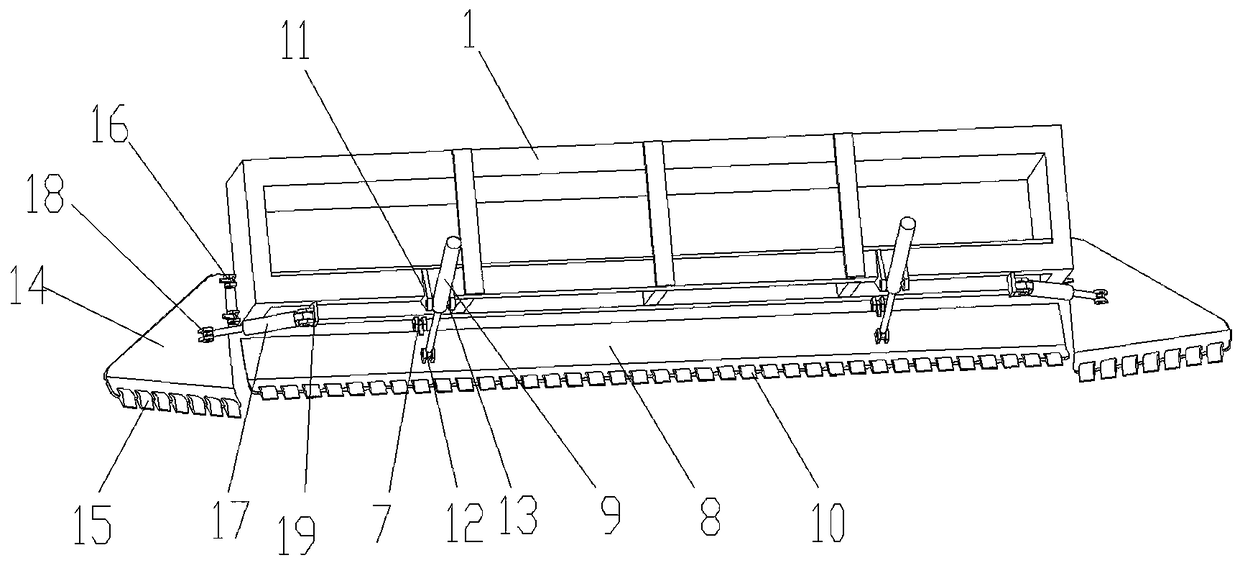

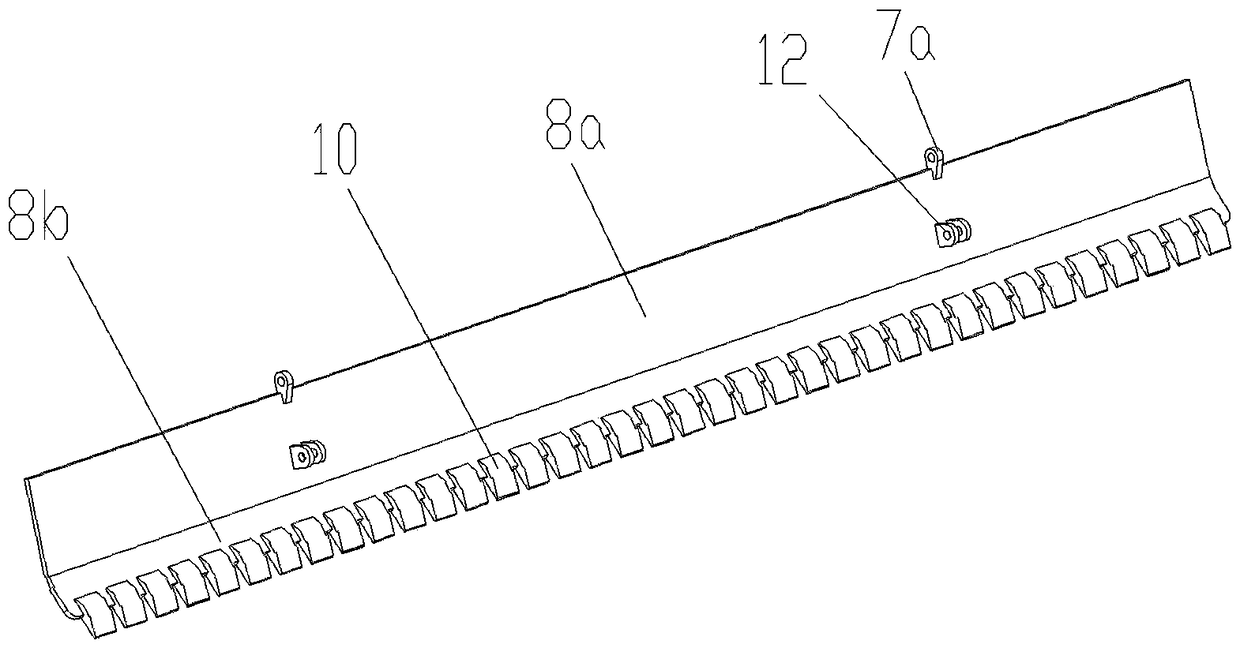

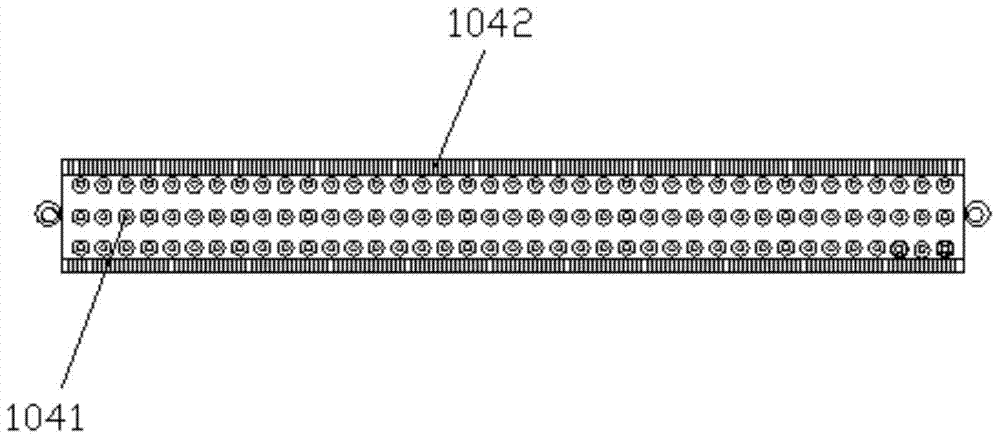

Tunneling machine support net device

InactiveCN104074528BRealize fully mechanized operationReduce labor intensityUnderground chambersTunnel liningPulp and paper industrySupport plane

The invention relates to a heading machine mesh supporting device which comprises a supporting plate, a support rack, a bottom plate, an overturning oil cylinder, an adjusting axis pin, an overturning axis pin and an adjusting oil cylinder. The front end of the bottom plate is connected with the lower end of the support rack, the rear end of the bottom plate is connected with one end of the overturning oil cylinder, the other end of the overturning oil cylinder is connected with the middle end of the support rack, the upper end of the support rack is connected with the front end of the supporting plate, the rear end of the supporting plate is connected with one end of the adjusting oil cylinder, and the other end of the supporting plate is connected with the support rack. The heading machine mesh supporting device is simple in structure, and reasonable in design, achieves the organic combination and combined operation of a cutting part of a heading machine and the supporting mesh device, is coordinated in motion, is interference-free, greatly reduces labor intensity of workers, improves working efficiency, quickens construction progress, lays a foundation for quick driving, completely prevents the unsafe hazards when underground workers support meshes manually, and achieves whole mechanized operation of downhole mesh supporting.

Owner:久益环球(佳木斯)采矿设备有限公司

Feeding and pelletizing system for smelting antimony

InactiveCN101956065BDecrease stockUniform sizeGranulation in rotating dishes/pansEngineeringAntimony

The invention discloses a feeding and pelletizing system for smelting antimony, which relates to the technical field of smelting. The system consists of an antimony concentrate hopper 1, an antimony concentrate screw feeder 2, a fine lime warehouse 3, a fine lime screw feeder 4, a burdening belt conveyer 5, a screw stirring conveyer 6, a blanking hopper 7, a disc type pelletizer 8 and a particle output hopper 10. The system has the characteristics of realizing fully mechanical operation, reducing the operation intensity of personnel, reducing raw material stock, lowering production cost and the like, is suitable for pelletizing antimony concentrate in the process of smelting antimony and can be used for pelletizing powder raw materials in other industries.

Owner:湖南东港锑品有限公司

Machine for piling up and fetching bricks

InactiveCN100544921CRealize fully mechanized operationDischarging arrangementStacking articlesHydraulic cylinderBrick

The invention belongs to the technical field of brick making machinery, in particular to a brick stacking and brick removing machine, including a hydraulic hairpin cart, which is characterized in that a brick removing and stacking mechanism is connected with the hydraulic cylinder of the hydraulic hairpin cart, and the The mechanism for stacking bricks and taking bricks includes two sets of four vertical shafts, each set of two vertical shafts, an upper link and a lower link connected with each set of vertical shafts, and a sliding connection with the vertical shaft under the upper link The movable frame, the 2-8 groups of pallet-supporting racks that are slidably connected with the vertical shaft, the third connecting rod hinged with the vertical shaft on one side, and the third connecting rod are arranged between the movable frame and the lower link. The lug plate at the other end of the connecting rod and its connecting pin and the brick support falling on the pallet frame. The hydraulic cylinder is respectively connected with the upper link rod and the lower link rod, and another hydraulic cylinder is connected between the upper link rod and the movable frame. By adopting the brick stacking and brick removing machine of the present invention, full mechanization of the brick stacking and brick removal operations can be realized, labor intensity is reduced, and labor productivity is improved.

Owner:鞍钢集团房产建设第五建筑工程公司

Intelligent multi-purpose high-efficiency road marking vehicle

InactiveCN105463976BRealize fully mechanized operationImprove construction efficiencyRoads maintainenceIntelligent lightingVehicle frame

The invention discloses an intelligent multipurpose efficient road marking vehicle which comprises a frame and a marking mechanism installed on the frame, wherein the marking mechanism comprises sideline localizers, location identifier distributors and coating sprayers which are relatively arranged at two sides of the frame from front to back as well as at least a location identifier recoverer; the sideline localizers are positioned at the front end of the frame and used for carrying out sideline location for the marking vehicle; location systems are arranged on the sideline localizers; the location identifier distributors make identifiers through specific location points positioned on a pavement; the coating sprayers catch the location identifiers on the pavement timely or control the spraying of the coating through a computer instruction; and the location identifier recoverer is positioned at the rear end of the frame and is used for catching and recovering the location identifiers on the pavement after each working procedure of a project is completed. The intelligent multipurpose efficient road marking vehicle realizes fully-mechanized operation, improves the construction efficiency, saves the labor cost and also greatly improves the safety guarantee as well as has favorable market prospects and economic benefits.

Owner:王乾仲

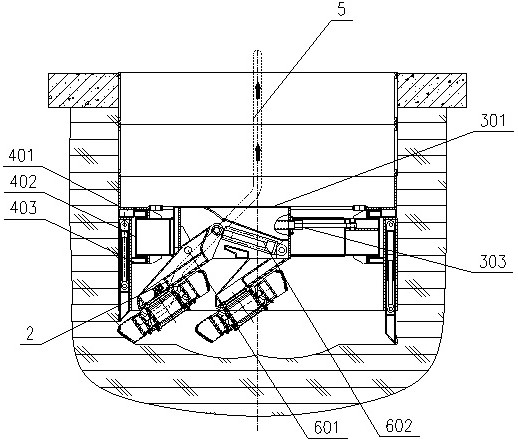

A variable section vertical shaft excavation device

ActiveCN111396059BAchieve mechanical propertiesAutomate operationsShaft sinkingStructural engineeringMechanical engineering

The present invention proposes a shaft excavation device with variable section, which includes a shield body and a muck conveying system, a cutter head device is arranged under the shield body, the cutter head device is connected with a swing device, and the swing device is connected with a cutter head translation device , the cutter head translation device is slidably arranged on the circular rotation device, and the circular rotation device is arranged on the inner side of the shield body. The present invention swings the cutter head up and down under the action of the oscillating device, uses the cutter head translation device to drive the cutter head to move, and cooperates with the circular gyration device to drive the cutter head device to realize a large revolution, thereby realizing the high-efficiency excavation of different sections of the cutter head, realizing It improves the full mechanization and automation of shaft construction, improves the excavation efficiency, facilitates the disassembly and assembly of equipment, reduces the number of operators, and reduces the labor intensity of personnel; It is a prefabricated structure, and the combination of equipment in the shield can be changed according to different sections, which can be applied to shaft projects with different sections.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

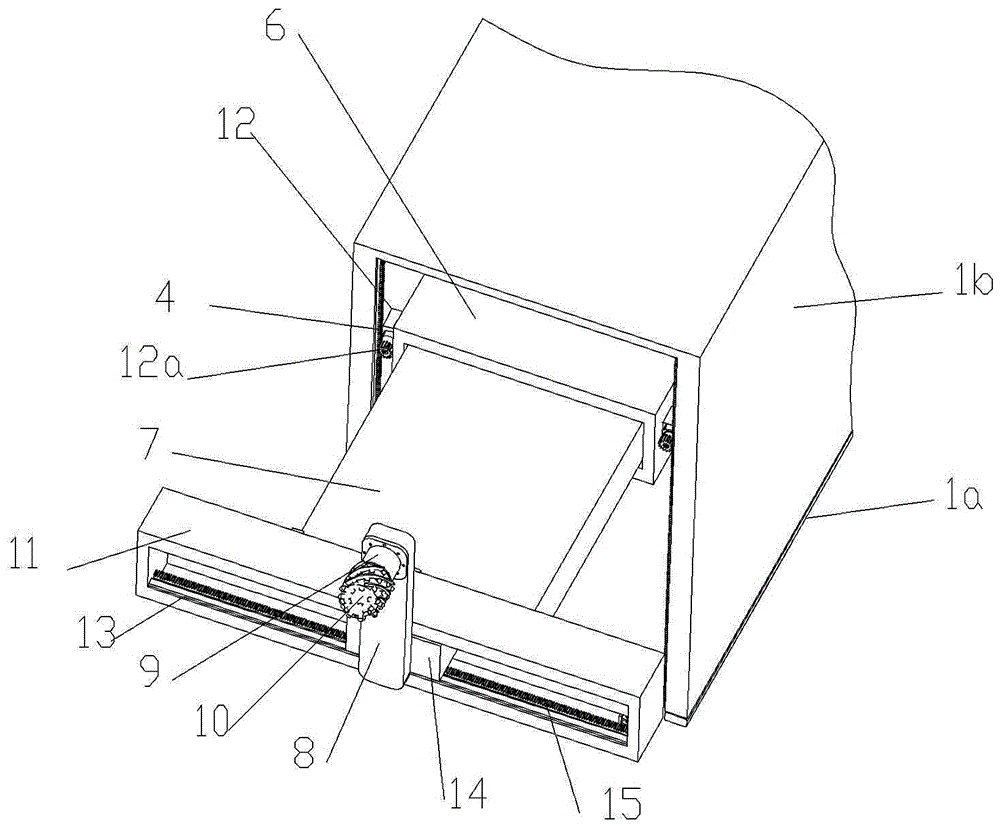

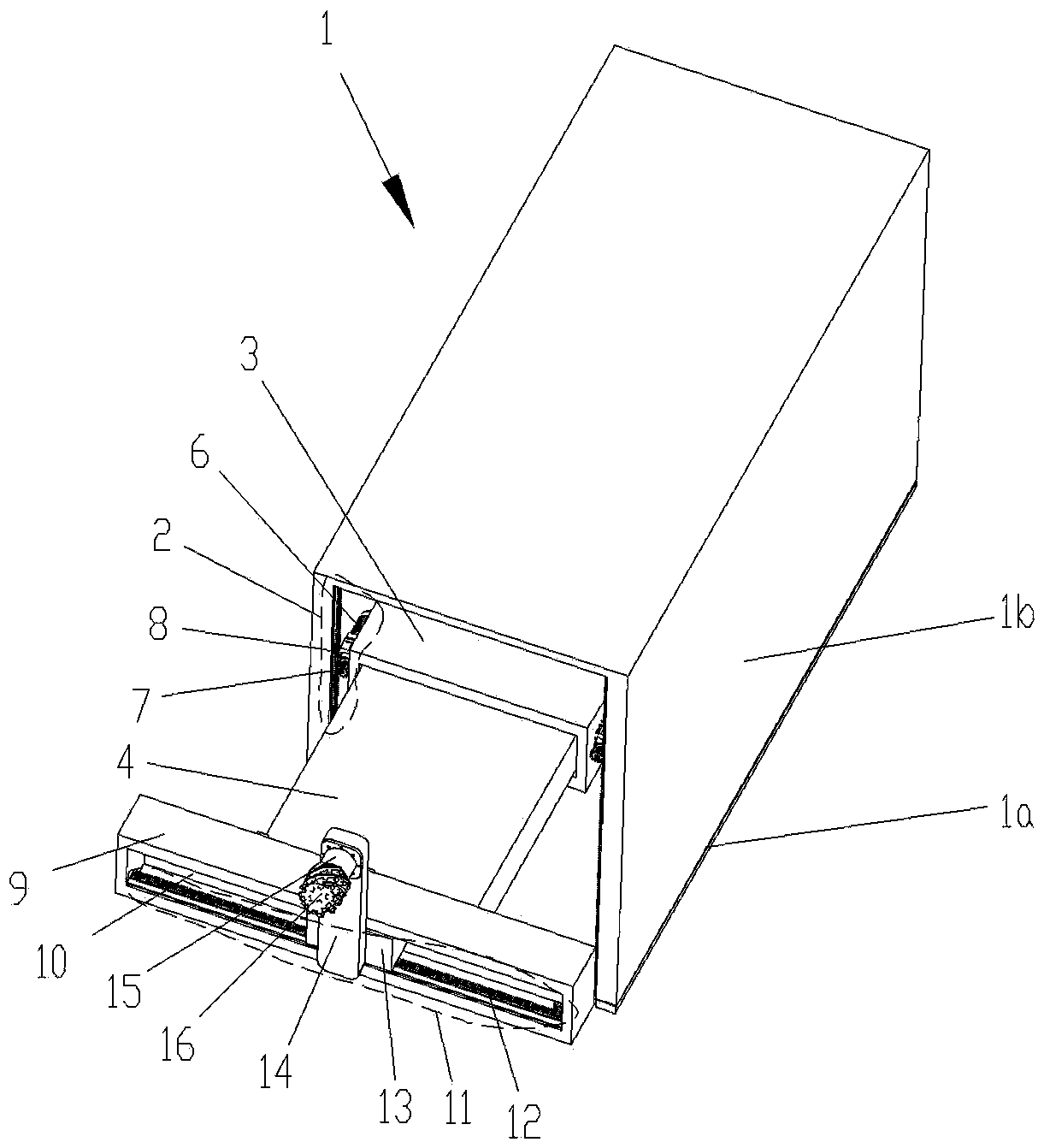

A digging device for tunnel underground excavator

The invention relates to a soil planing device for a tunnel underground excavation machine. The soil planing device comprises a frame (1) formed by a base (1a) and a shell (1b). A longitudinal support (3) is connected in the shell (1b) through a set of lifting devices (2). The front side of the longitudinal support (3) is connected with a transverse support (9). At least one adjusting device (13) is connected in the transverse support (9), each adjusting device (13) is rotationally connected with a rotary arm (14), each rotary arm (14) is at least connected with a tool bit driving device (15), and each tool bit driving device (15) is in driving connection with a mill-planing head (16). The soil planing device has the advantages that the structure is simple, high safety is achieved, upper-layer excavation and lower-layer excavation can be carried out, soil digging within a full-section range of a tunnel is achieved, full-mechanical work of underground excavation tunnel construction is achieved, the work speed is high, the application range is wide, and the device is suitable for being applied and popularized.

Owner:ANHUI XINGYU TRACK EQUIP

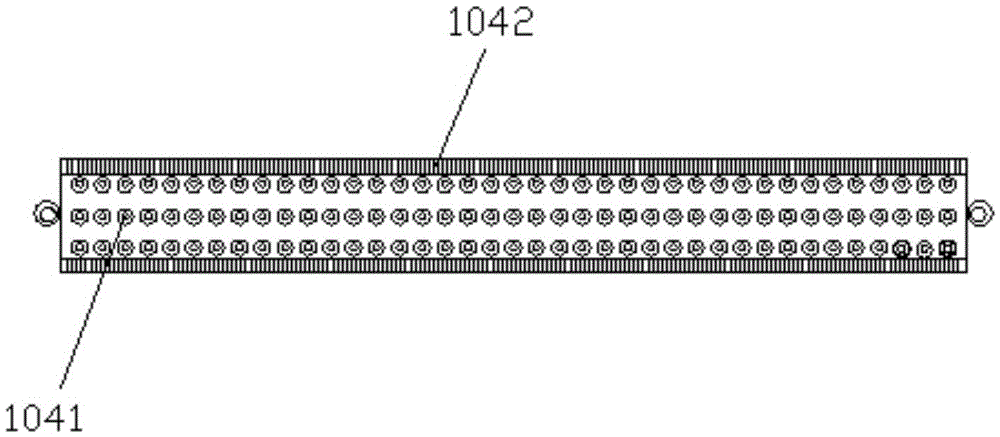

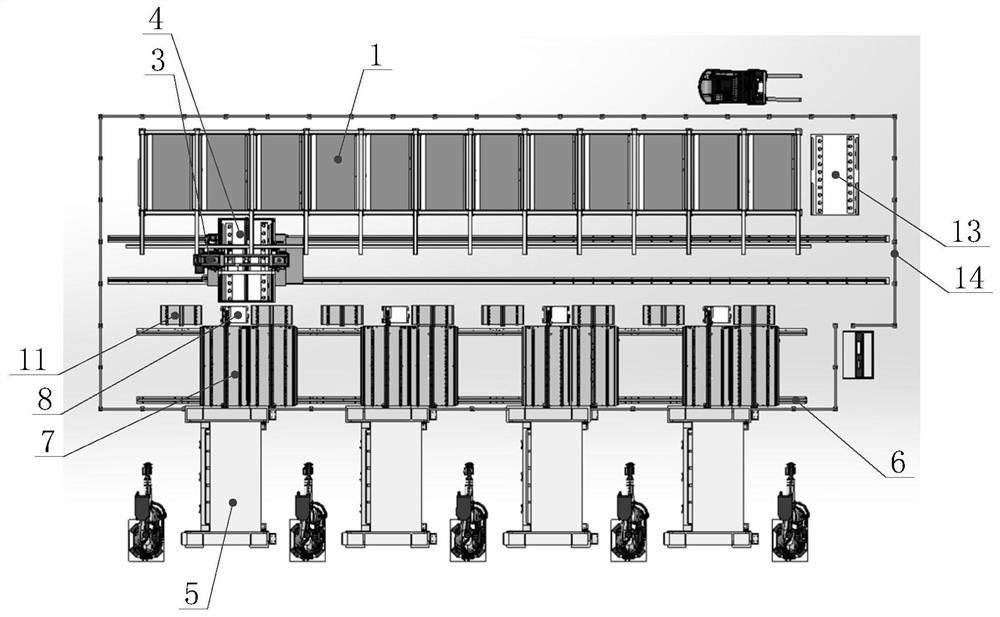

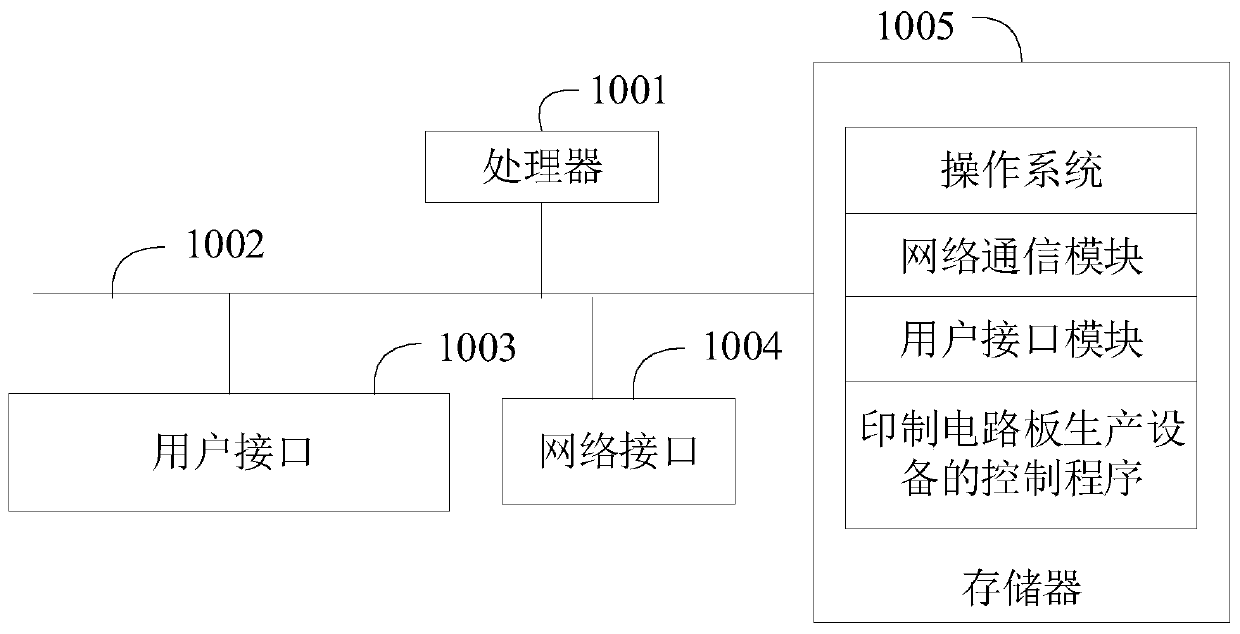

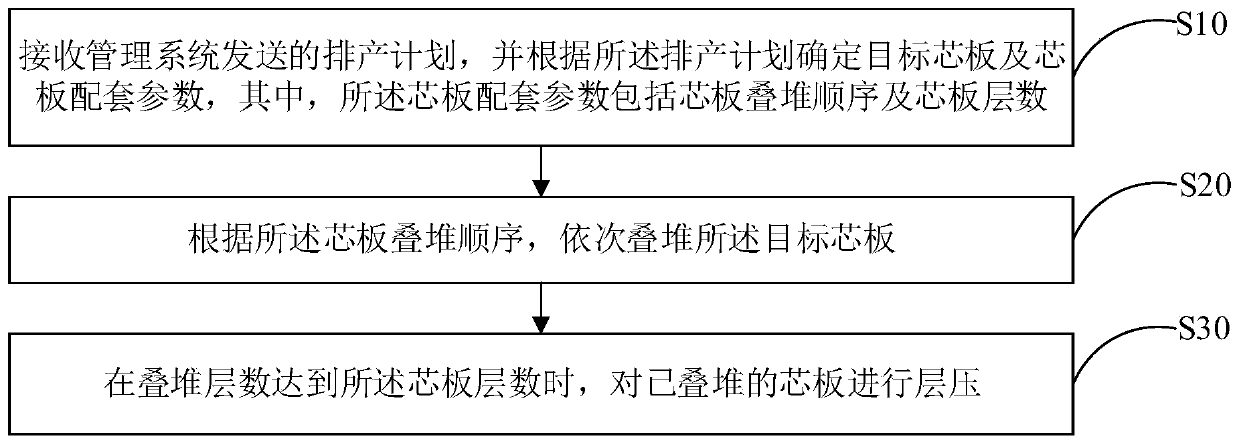

Control method of printed circuit board production equipment and printed circuit board production equipment

ActiveCN110881252AImprove supporting efficiencyIncrease productivityMultilayer circuit manufactureProcess engineeringPrinted circuit board

The invention discloses a control method of printed circuit board production equipment, which comprises the following steps: receiving a production scheduling plan sent by a management system, and determining a target core board and core board matching parameters according to the production scheduling plan, the core board matching parameters comprising a core board stacking sequence and a core board layer number; stacking the target core boards in sequence according to the core board stacking sequence; and laminating the stacked core plates when the number of the stacked layers reaches the number of the layers of the core plates. The invention further discloses the printed circuit board production equipment and a computer readable storage medium, and the core board matching efficiency in the printed circuit board production process is improved.

Owner:南通深南电路有限公司

Gasket assembling mechanism

The invention provides a gasket assembling mechanism. The mechanism comprises upper and lower slide rails, which are horizontally and transversely arranged, wherein a first slide rail is fixed on a base; a second slide rail is mounted on the first slide rail by a slide block; a horizontal long bottom plate is placed close to the lower surface of the second slide rail; the bottom plate is mounted on the second slide rail by a slide block; a locating groove and a locating hole matched with each other are respectively formed in the second slide rail and the bottom plate; a spring and a locating block are pressed into the locating hole in sequence; the locating block is impelled upward by the spring; a compression cylinder is placed on one side of the second slide rail; a rack for bearing parts is arranged on the right side of the bottom plate; the rack can lift up and down; and by a double-slide-rail moving mechanism, a gasket is pushed to enter a narrow part recess of a mounting space; full mechanical operation of the whole assembling process can be achieved, manual assembling is not needed and high assembling efficiency is achieved; moreover, the gasket assembling mechanism provided by the invention has the advantages of simple structure, good reliability, accurate assembling position and comparatively low production and machining cost.

Owner:SHANGHAI UNIV OF ENG SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com