Novel multi-functional operation trolley used for tunnel construction

A tunnel construction, multi-functional technology, applied in tunnels, tunnel linings, shaft linings, etc., can solve the problems of high safety risk, high labor intensity, low efficiency, etc., and achieve the effect of improving safety factor, improving operation efficiency and construction quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

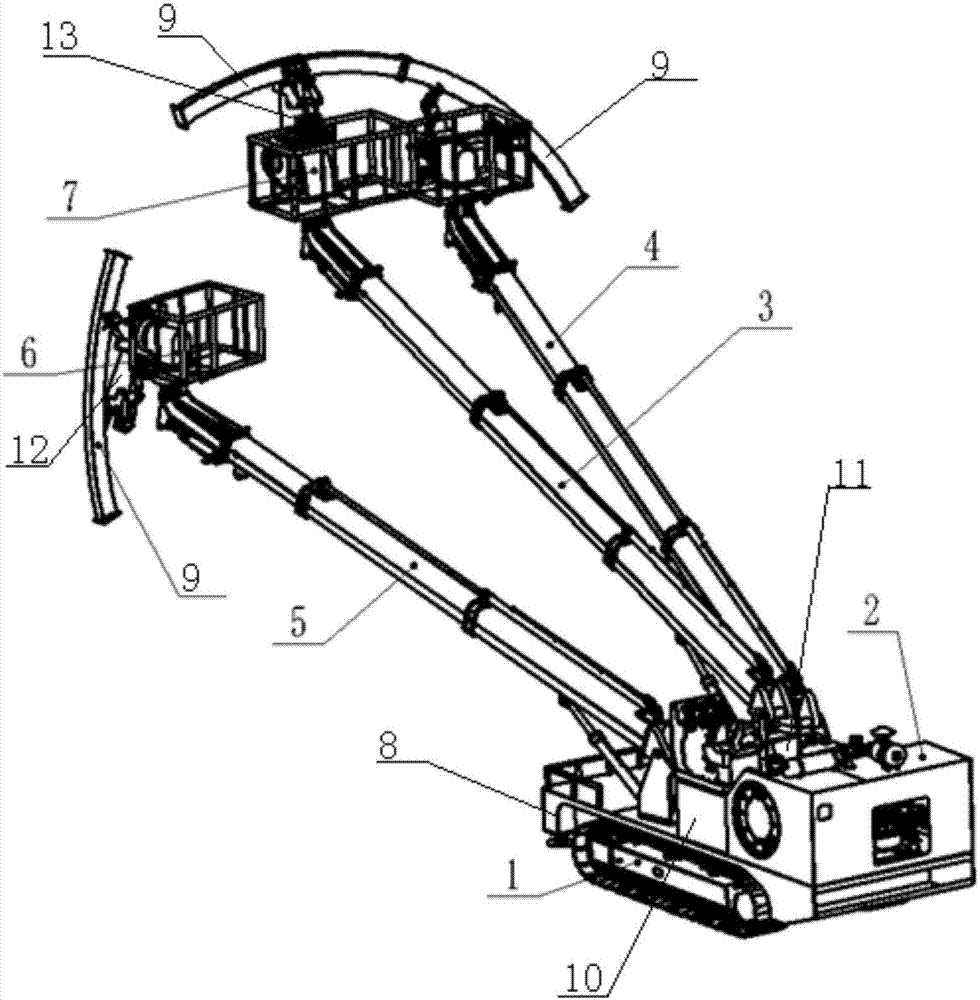

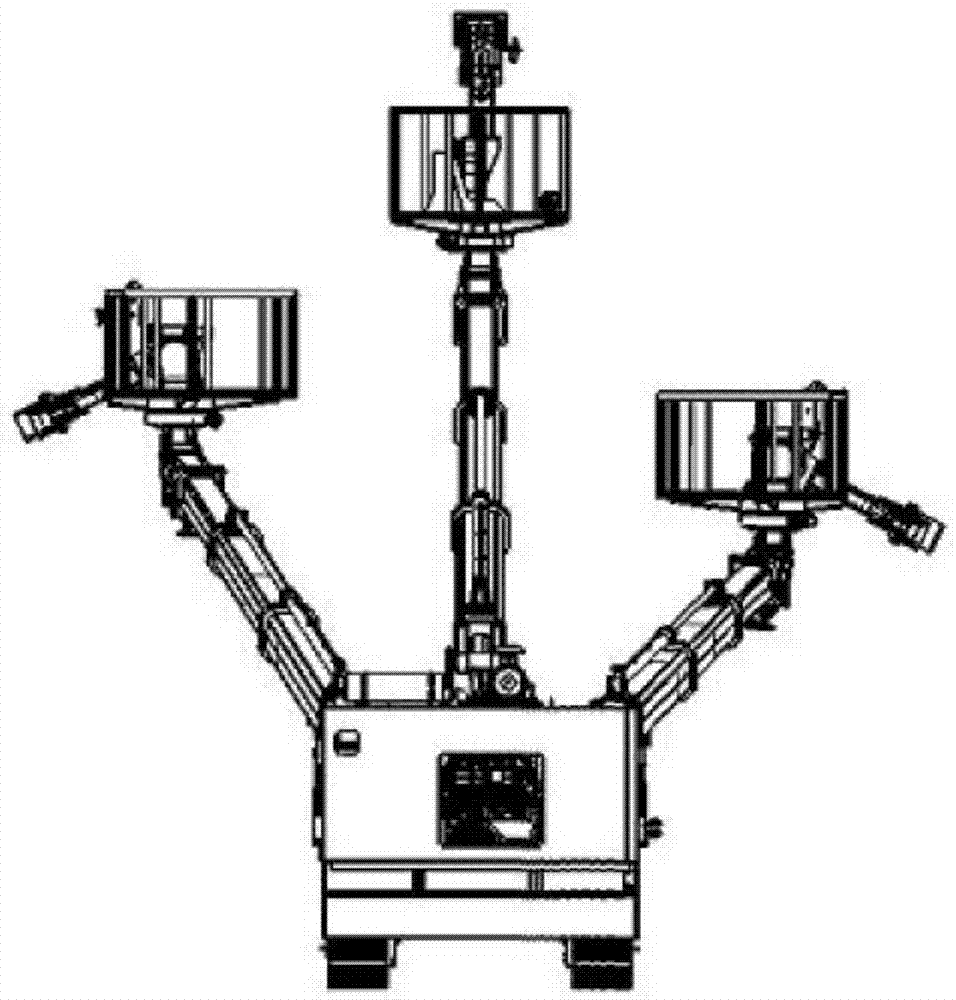

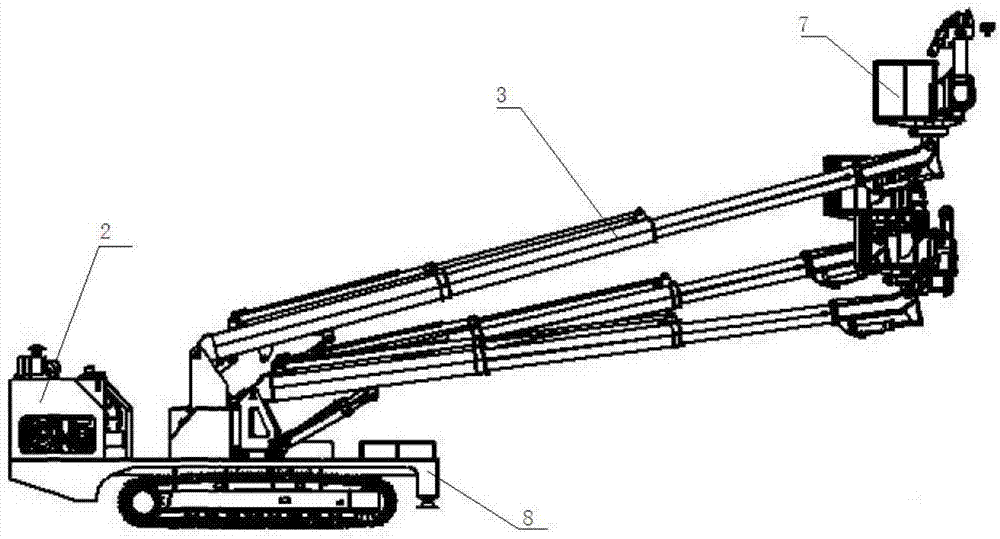

[0020] Embodiment 1: as attached Figure 1~6 As shown, a new type of multi-functional operation trolley for tunnel construction, it includes a chassis 10, a crawler 1 and a power unit 2, the bottom of the chassis 10 has a crawler 1, and the power unit 2 is installed above the tail of the chassis 10 , the front portion of the chassis 10 is equipped with telescopic legs 8, the upper middle of the chassis 10 is provided with a middle working arm 3, and the left and right sides are respectively symmetrically provided with a left working arm 5 and a right working arm 4. The top of the middle working arm 3 has a main hanging basket 7, and the tops of the left working arm 5 and the right working arm 4 are respectively provided with symmetrically arranged side hanging baskets 6; the walking chassis 10 adopts a crawler chassis provided with front supporting legs 8 The structure can better adapt to various harsh working conditions in the tunnel; all actuators are driven by hydraulic pre...

Embodiment 2

[0056] Embodiment 2: as attached Figure 1~6 As shown, a new type of multi-functional operation trolley for tunnel construction, it includes a chassis 10, a crawler 1 and a power unit 2, the bottom of the chassis 10 has a crawler 1, and the power unit 2 is installed above the tail of the chassis 10 , the front portion of the chassis 10 is equipped with telescopic legs 8, the upper middle of the chassis 10 is provided with a middle working arm 3, and the left and right sides are respectively symmetrically provided with a left working arm 5 and a right working arm 4. The top of the middle working arm 3 has a main hanging basket 7, and the tops of the left working arm 5 and the right working arm 4 are respectively provided with symmetrically arranged side hanging baskets 6; the walking chassis 10 adopts a crawler chassis provided with front supporting legs 8 The structure can better adapt to various harsh working conditions in the tunnel; all actuators are driven by hydraulic pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com