Seedling transplanter

A technology for transplanting machines and seedlings, which is applied in the field of seedling transplanting machines, can solve the problems of long time consumption, low efficiency, and low transplanting and sowing efficiency of the transplanting machine, so as to shorten the action time and stroke, and avoid the structure being too complicated. , the effect of improving the speed of transplanting and inserting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

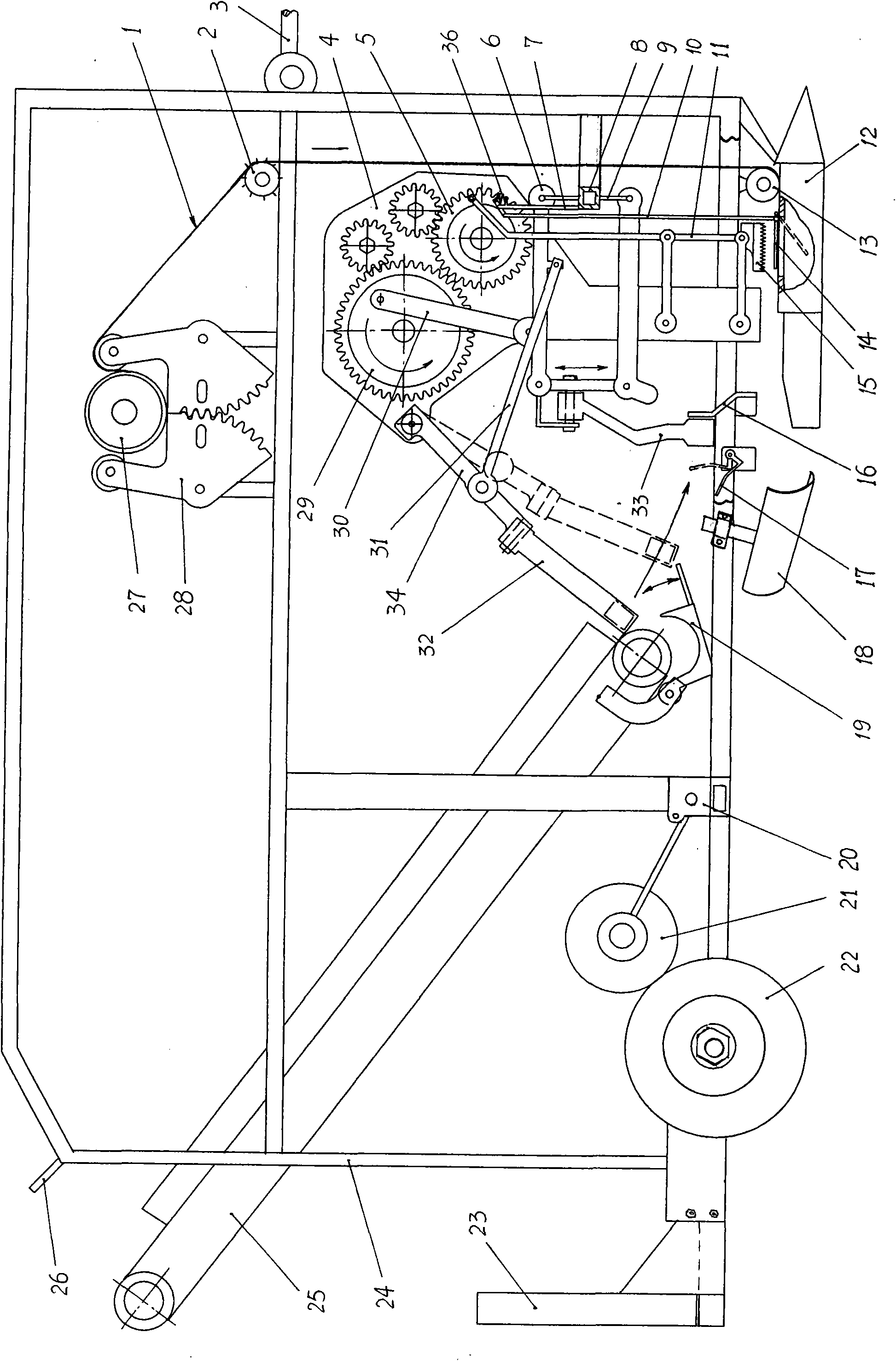

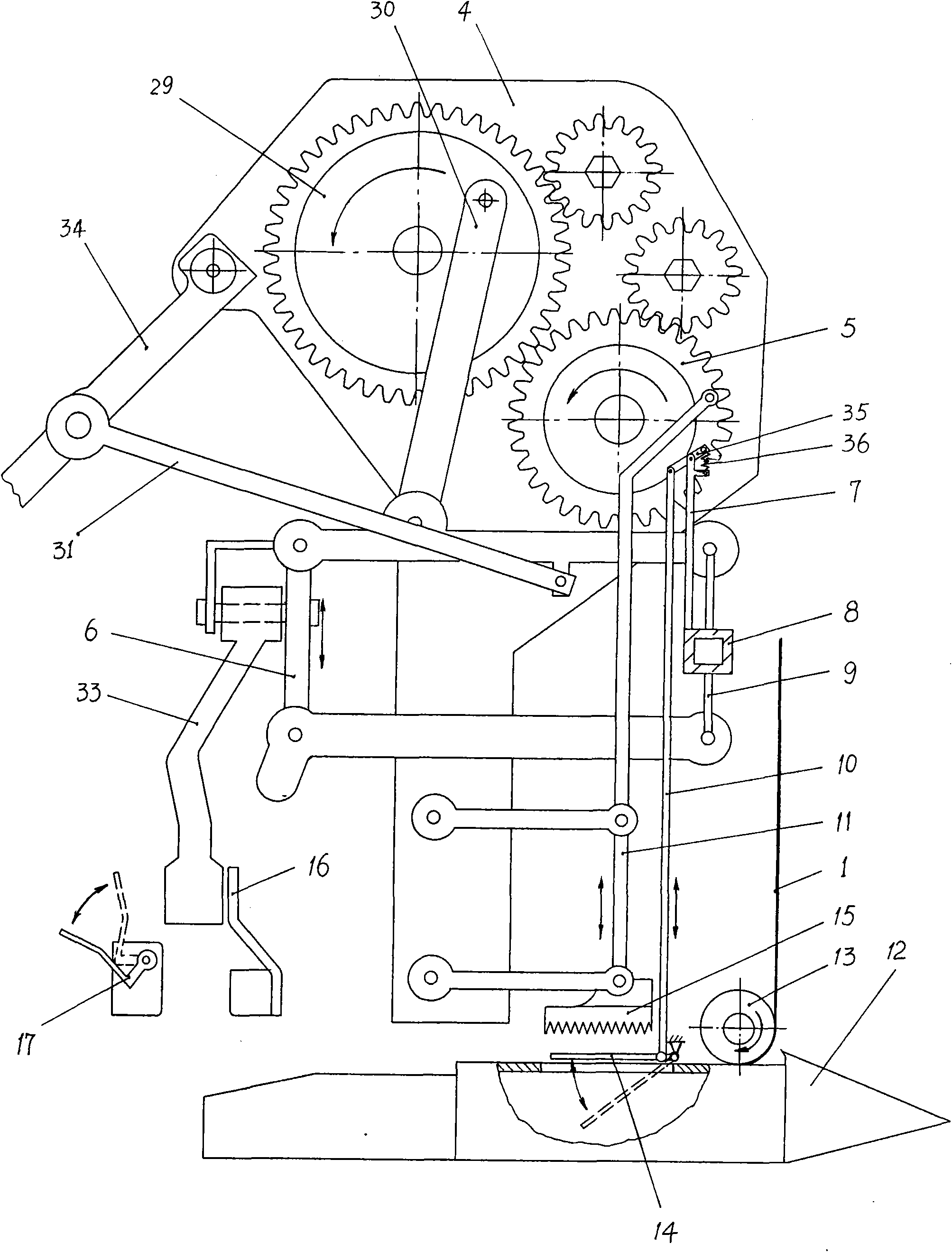

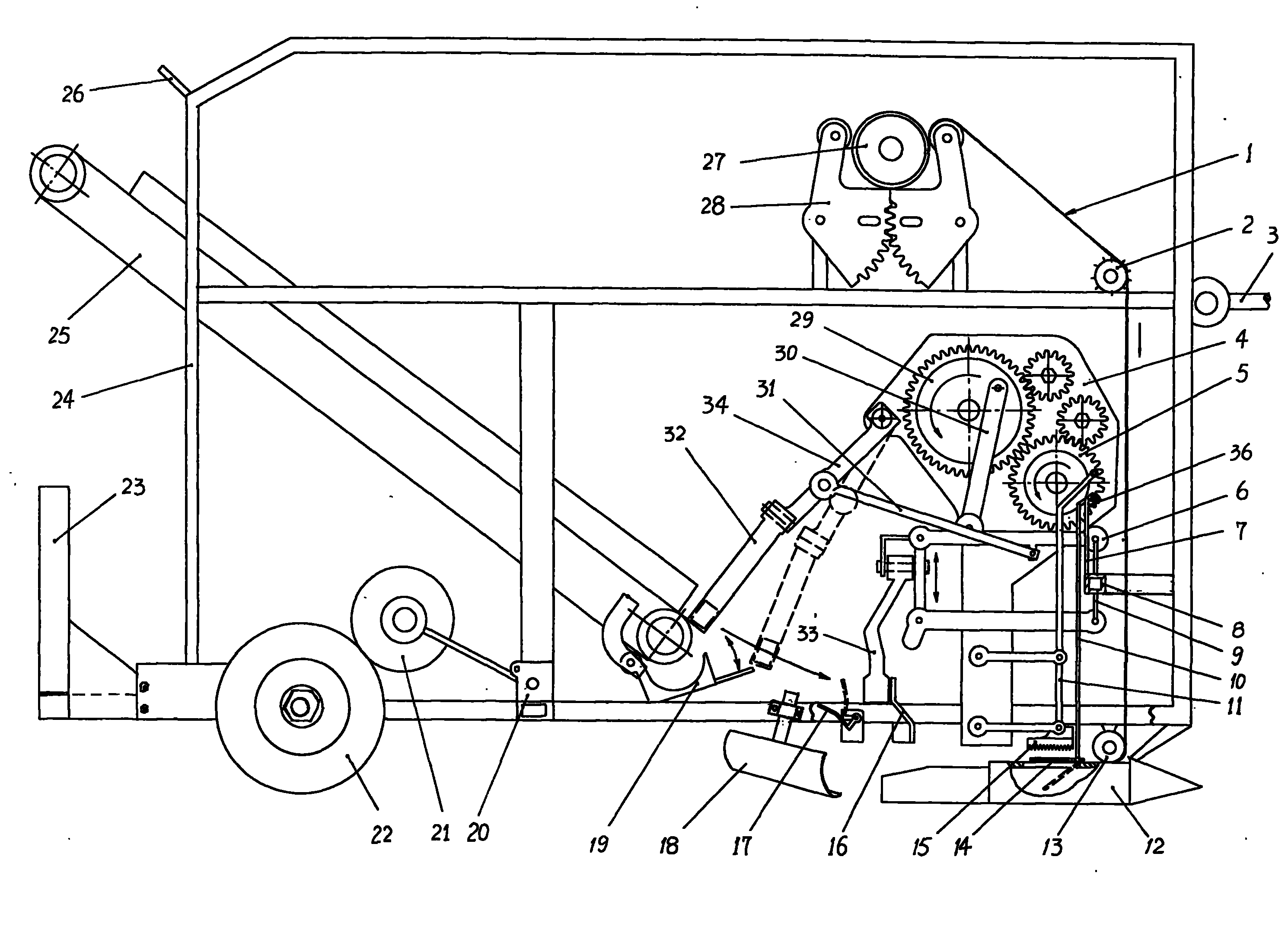

[0022] Such as figure 1 Shown, this seedling transplanting mechanism has a three-dimensional frame 24 of frame type, and front and rear respectively two walking wheels 22 are housed in frame 24 bottoms, and ditch opener 12 is housed on the bottom beam frame of frame 24, Coverer 18 is housed on both sides of the bottom beam frame. The simple cover device is a ploughshare tilted inwards, although other existing structures can of course be used. The seedling pot conveying mechanism 25 is obliquely arranged on the rear portion of the frame 24 at a low front and high rear position, and the electric control opening and closing baffle plate 19 is arranged on the end of the seedling pot conveying mechanism 25 transmission passages. On the frame 24 on the top of the seedling pot conveying mechanism, a seedling raising tray bracket 26 is also connected, and the foldable pedal frame 23 is connected to the bottom of the frame 24 rear ends.

[0023] The traction pull bar 3 that traction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com