Tooth collision prevention mechanism of relay driving fuel transfer device

A technology of fuel transfer device and driving gear, applied in the direction of transmission device, transmission device parts, friction transmission device, etc., can solve the problems of shortage and long transportation path, and achieve the effect of reducing impact, easy processing and installation, and reliable mechanism structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

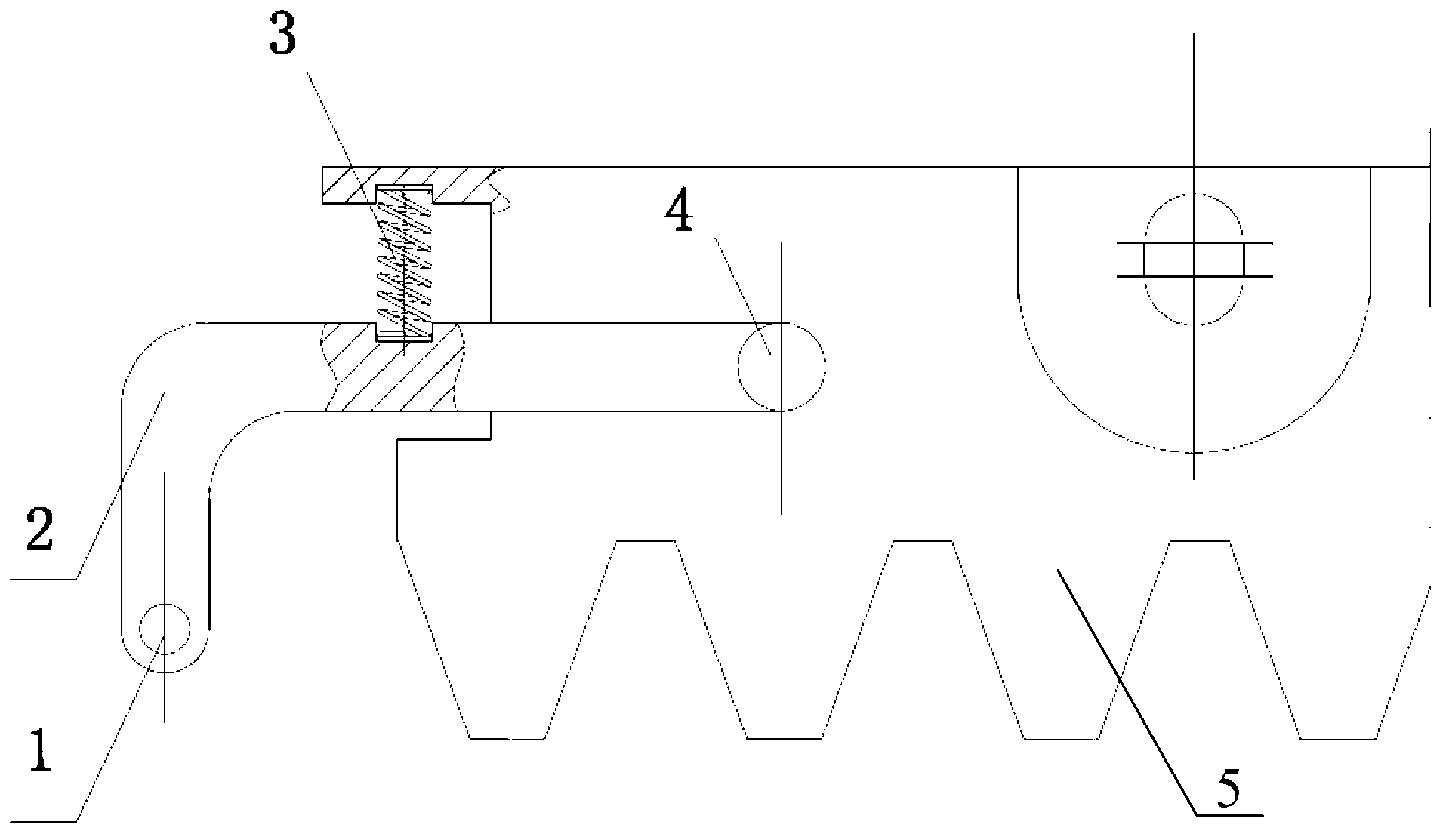

[0018] Such as figure 1 As shown, the anti-collision gear mechanism of the relay-driven fuel transfer device provided by the present invention includes four main parts. The ram 2 is connected to the rack on the transport trolley of the relay-driven fuel transfer device through the pin 4 arranged at one end of the ram 2 and the spring 3 arranged on the upper part of the ram 2, and the ram 2 can use the pin 4 as the rotation axis Rotate, the pin shaft 4 is used to limit the trajectory of the striker 2. The front lower end of the bumper 2 is provided with a roller 1, and the roller 1 is in contact with the relay drive gear to change the friction in the relay drive process from sliding friction to rolling friction.

[0019] When the relay drive starts, the roller 1 which is arranged at the lower end of the bumper 2 contacts with the relay drive gear. Due to the existence of the initial velocity, the contact force makes the striker 2 rotate around the pin 4 .

[0020] The upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com