Anti-rust intelligent manufacturing equipment for hardware machining

A technology of mechanical processing and intelligent manufacturing, applied in the cleaning method using tools, cleaning method using gas flow, cleaning method and utensils, etc. The effect of compatibility, improving efficiency, and convenient processing and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to further understand the features, technical means, and specific objectives and functions of the present invention, the present invention will be described in further detail below with reference to the accompanying drawings and specific embodiments.

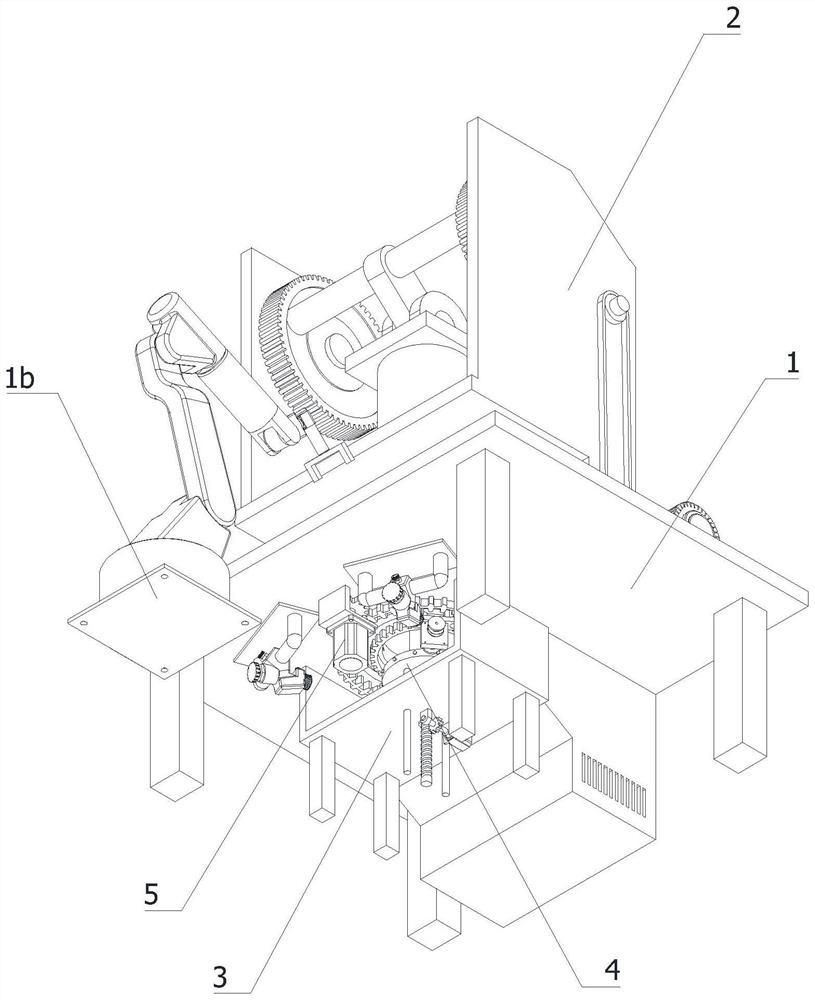

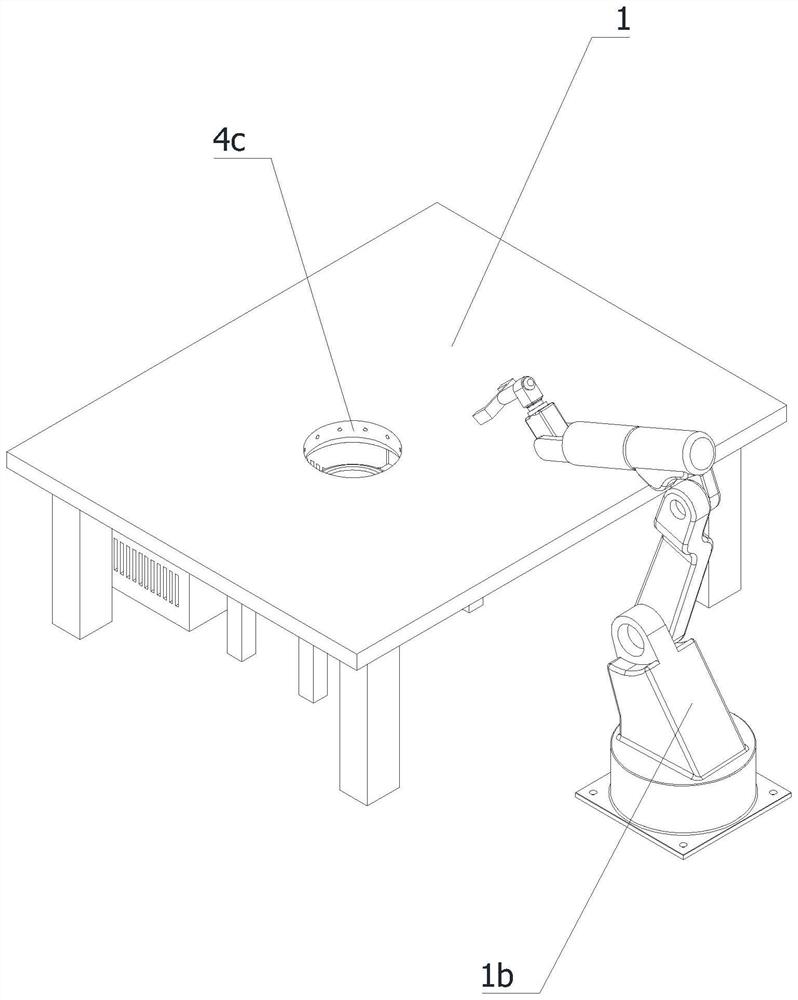

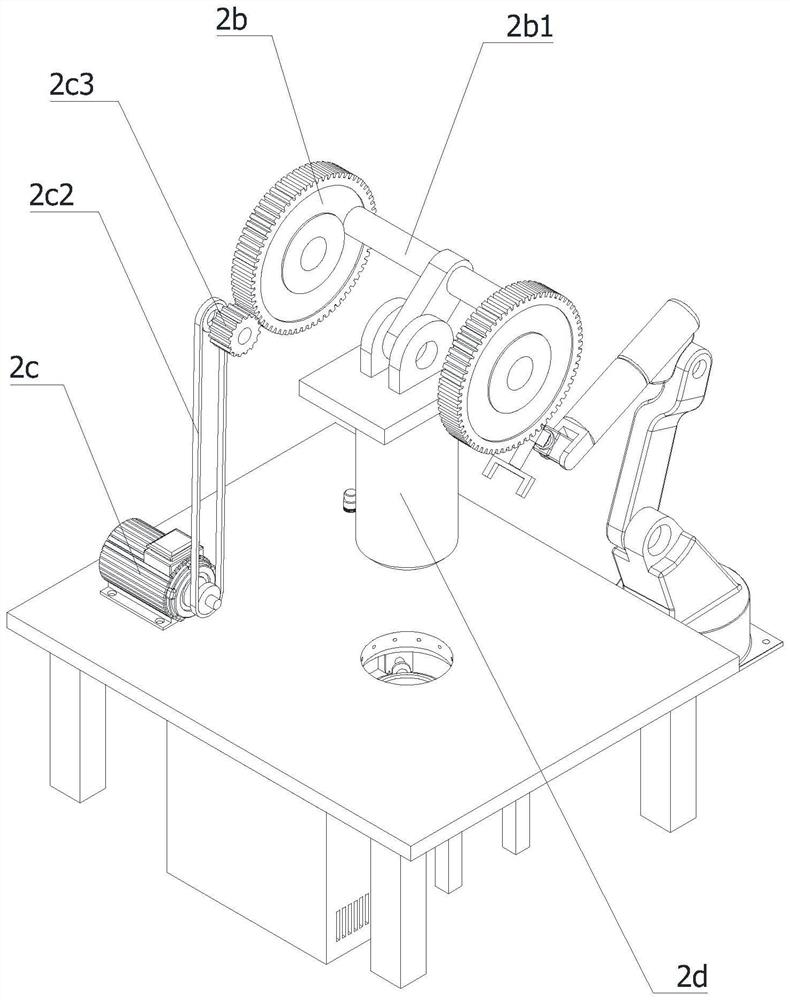

[0042] like Figure 1-13 shown:

[0043] A rust-proof intelligent manufacturing equipment for hardware machining, comprising a frame 1 and a stamping assembly 2, the stamping assembly 2 is located above the frame 1, and a disc-shaped material receiving table 4 is arranged below the stamping assembly 2 , the lifting assembly 3 for driving the material receiving table 4 to lift on the frame 1 and the anti-rust mechanism 5 for anti-rust treatment of the blank of the tubular hardware, the anti-rust mechanism 5 includes the annular slide rail 5a, The drive assembly 5b, the first brush head assembly 5c and the second brush head assembly 5d, the annular sliding rail 5a is located on the frame 1 and is arranged around t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com