Mechanical method connecting channel construction method using pipe jacking technology

A communication channel and construction method technology, applied in tunnels, tunnel linings, earthwork drilling and mining, etc., can solve the problems of difficulty in comprehensive promotion, high cost, and inability to synchronize grouting, etc., to achieve automatic services, reliable quality, and small environmental disturbances Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

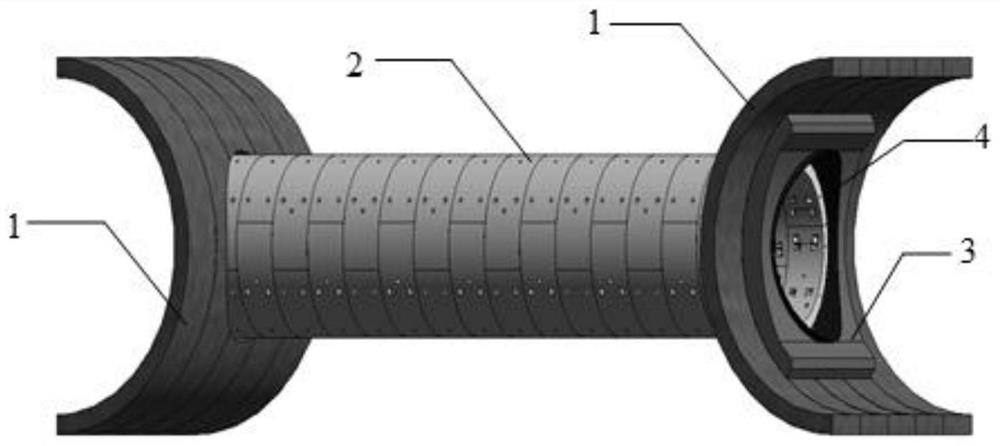

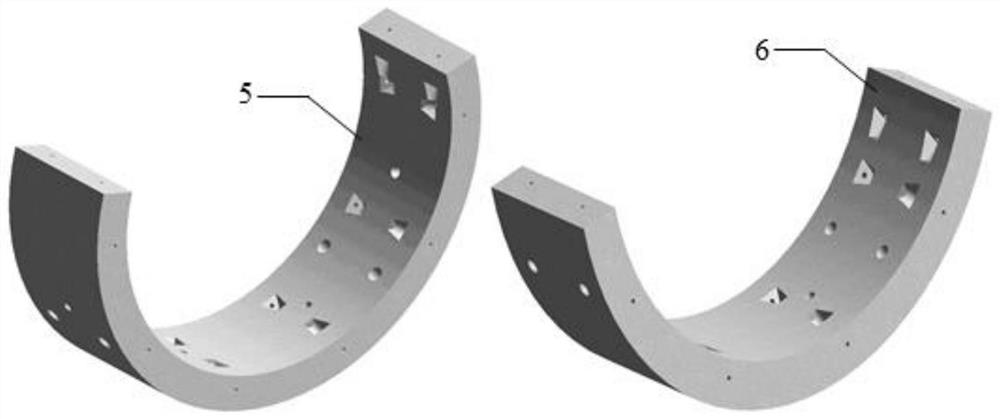

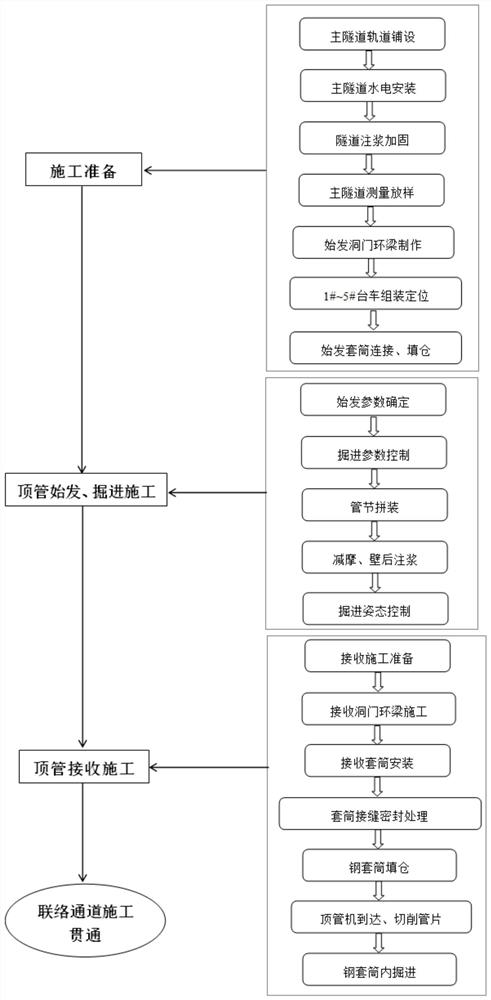

[0071]Embodiment 1 of the present application provides a mechanical method of connecting channel construction method using pipe jacking technology, including construction preparation, pipe jacking initiation, excavation construction and pipe jacking construction, wherein the construction preparation stage includes track laying in the main tunnel 1, hydropower Installation, grouting reinforcement of the main tunnel, production of ring beams at the door of the starting tunnel, 1# back supporting trolley, 2# rear supporting trolley, 3# rear supporting trolley (including starting sleeve and main engine), 4# rear supporting platform Car, 5# rear supporting trolley (including receiving sleeve) assembly positioning and sleeve connection, starting and receiving sleeve filling; pipe jacking starting and tunneling construction stages include starting parameter control, tunneling parameter control, pipe joint Assembly, anti-friction grouting, post-wall grouting, attitude control; pipe jac...

Embodiment 2

[0152] The length of the left line of the shield section between Yuhang High-speed Railway Station and Xucun Town Station of Hanghai Intercity Railway Project is 3126.22m, the starting mileage: ZDK0+437.570, the end mileage: ZDK3+563.487, and the long chain is 0.303m; the right line length of the shield section between Yuhang and Xucun is 3126.555m , starting mileage: YDK0+437.570, end mileage: YDK3+563.847, long chain 0.278m. The minimum curve radius of the line is 800m, the maximum curve radius is 4000m, the buried depth of the tunnel is 7.6m~25m, the line spacing is 10.8~16m, and the maximum longitudinal slope is 28‰. In this section, three mechanical communication channels are set up at left DK0+785.000 (right DK0+787.798), right DK1+237.420 (left DK1+239.019), and right DK1+800.000 (left DK1+801.599).

[0153] like Figure 4 As shown, the center mileage of 1# communication channel 7 is left DK0+785.000 (right DK0+787.798), the main tunnel rail surface is -22.647 (-22.689...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com