A kind of metallurgical industry furnace body ring bolt installation method

A ring bolt, metallurgical industry technology, applied in infrastructure engineering, construction and other directions, can solve the problems of time-consuming, complicated installation, poor accuracy, etc., to achieve the effect of less time-consuming, reduced project cost, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

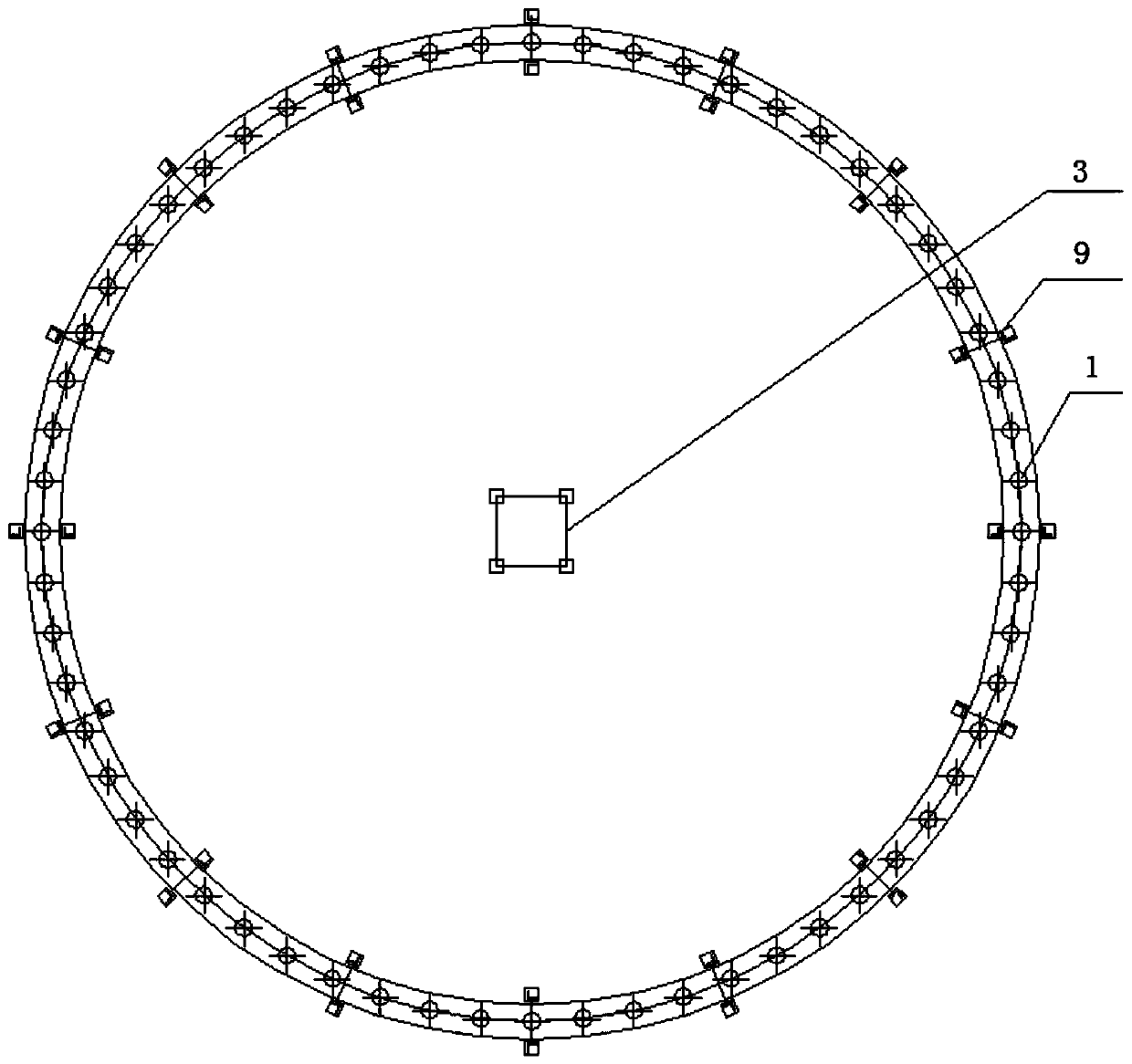

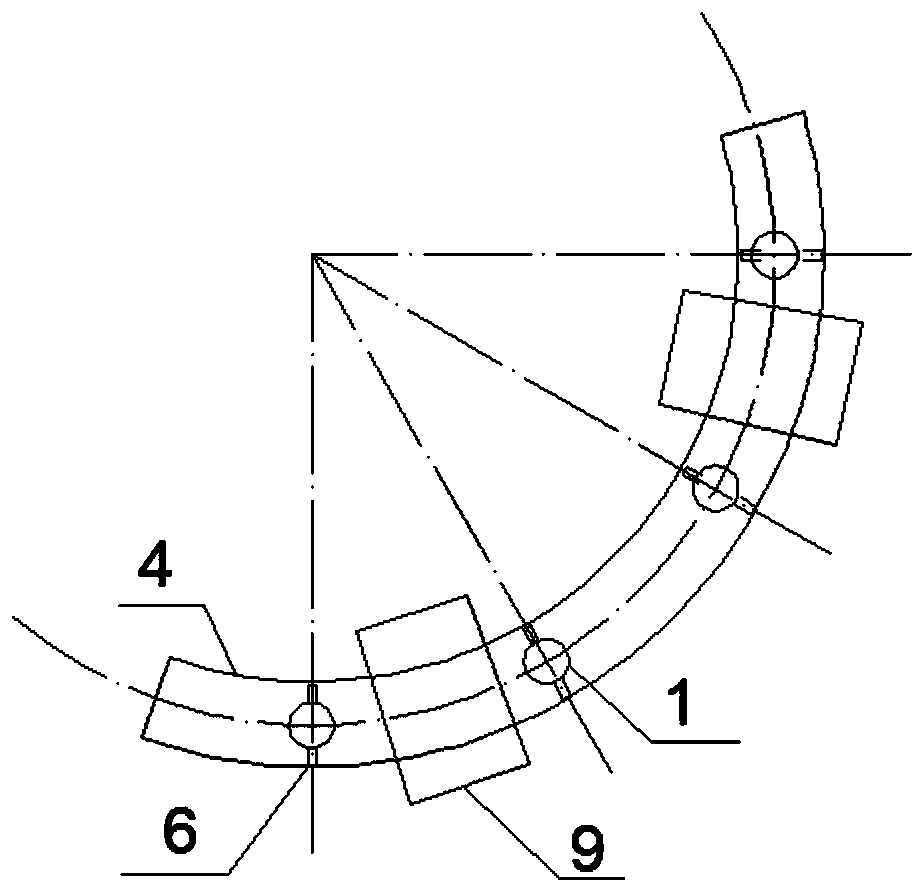

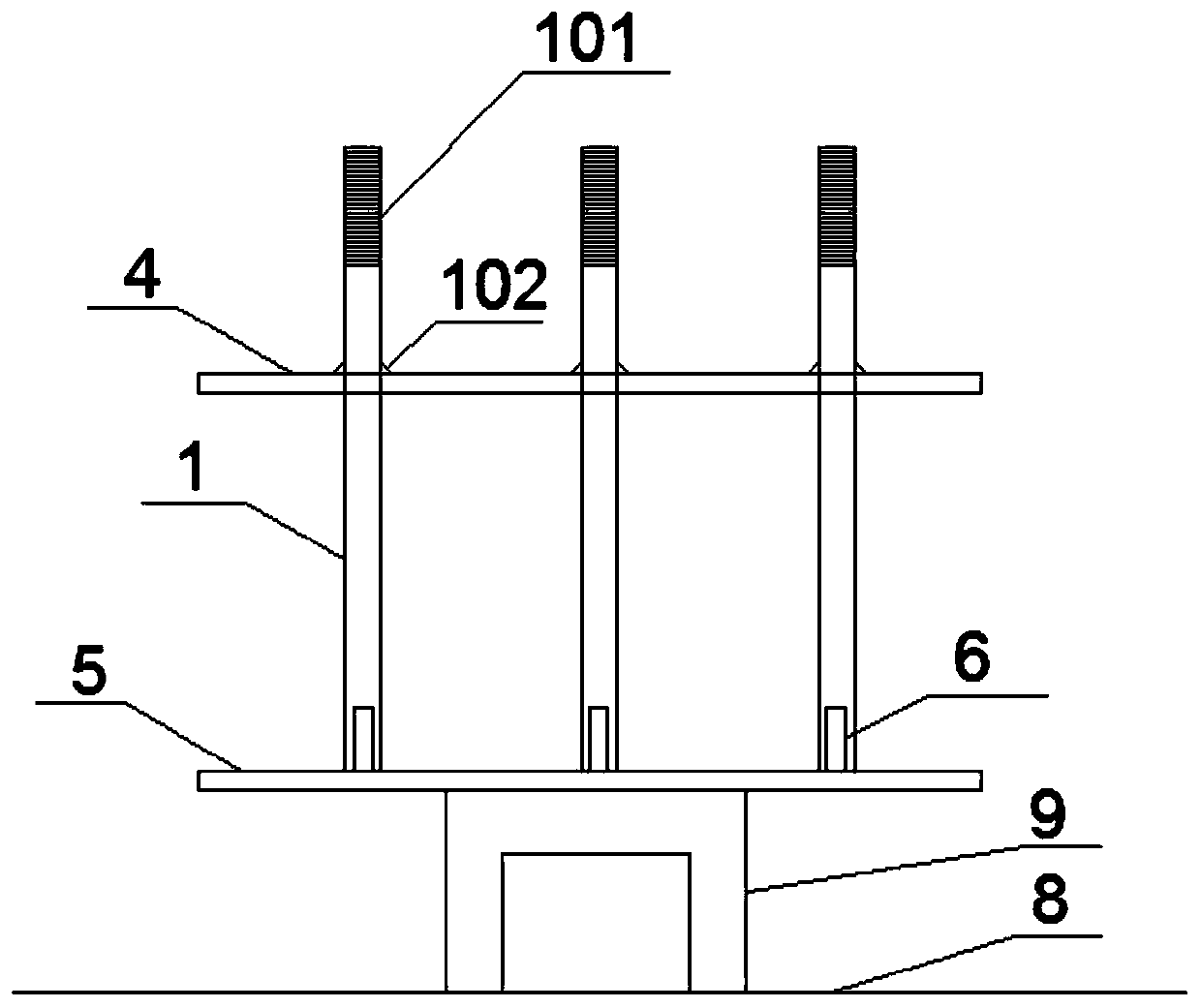

[0051] Such as figure 1 , 2 As shown in , 3, the method of this scheme is to process the large-diameter bolts arranged in a ring into several wholes through the upper and lower anchor plates of the bolts for block processing, and use the upper and lower ring plates to connect, the overall stability is good, and the bottom of the bolt anchor plate is used A technique in which a support frame is used to complete the installation process. This scheme is suitable for the installation of large-diameter, high-precision pre-embedded bolts on the foundations of blast furnaces, hot blast furnaces, desulfurization towers, and CDQ ovens in metallurgical engineering.

[0052] The present invention divides n bolts into several parts, such as figure 2 , 3 , each part is connected together by the upper fixed ring plate 4 and the lower fixed ring plate 5 in a ring, the self-weight of the large-diameter anchor bolt 1 can improve its stability, and the quality of a single one often reaches ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com