Patents

Literature

41results about How to "High degree of construction mechanization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

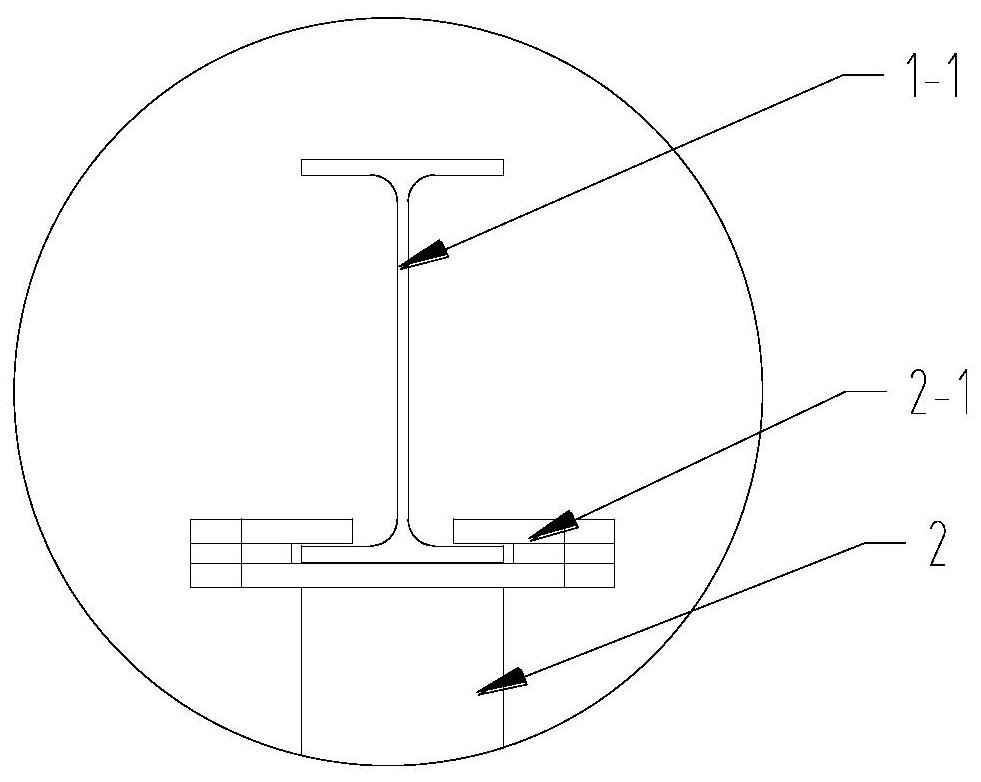

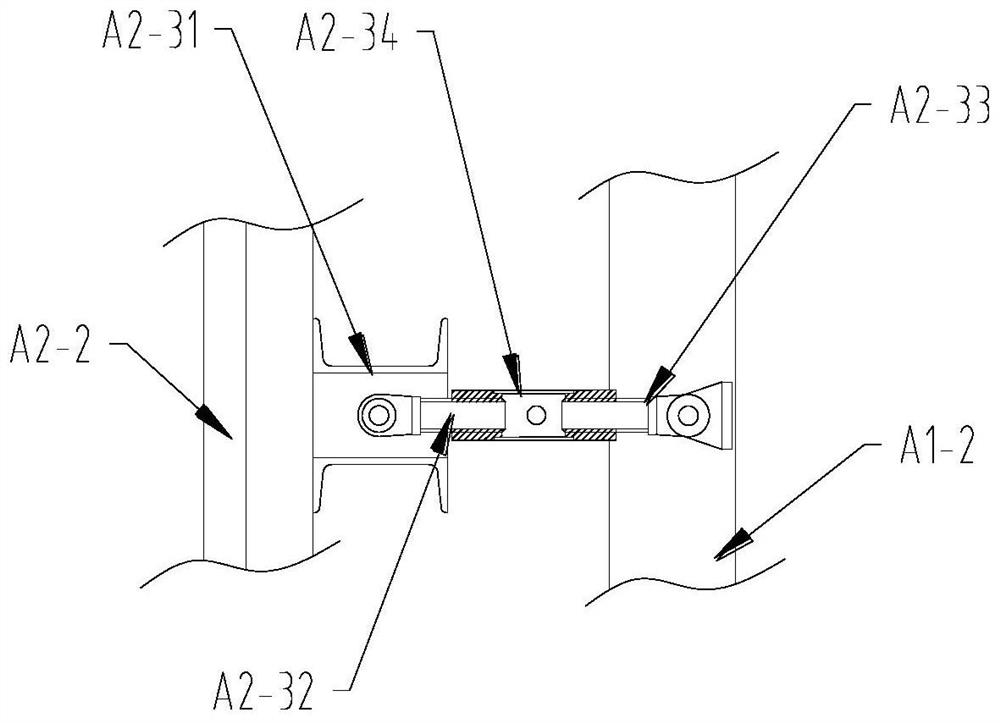

Assembling type connecting aisle structure and construction method thereof

ActiveCN106948833AGuaranteed waterproof performanceReduce disturbanceUnderground chambersTunnel liningBuilding construction

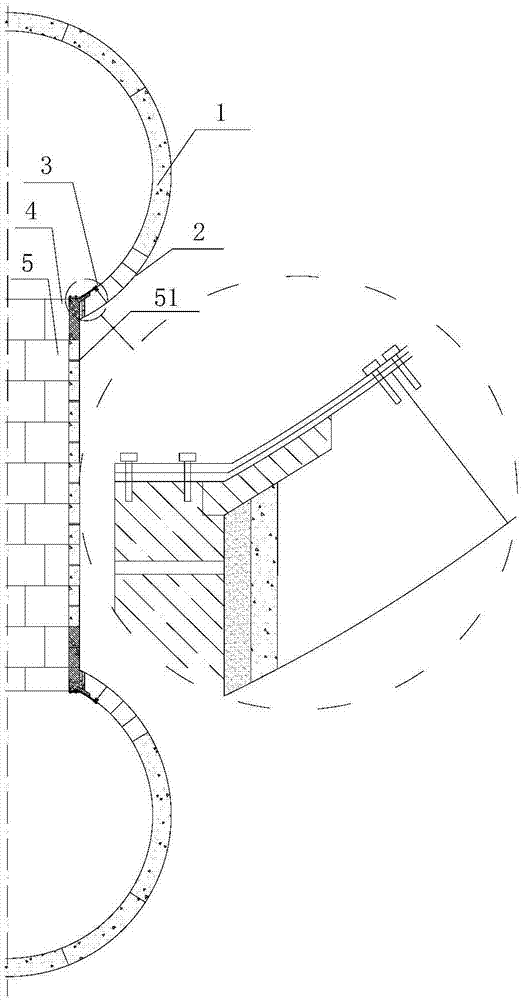

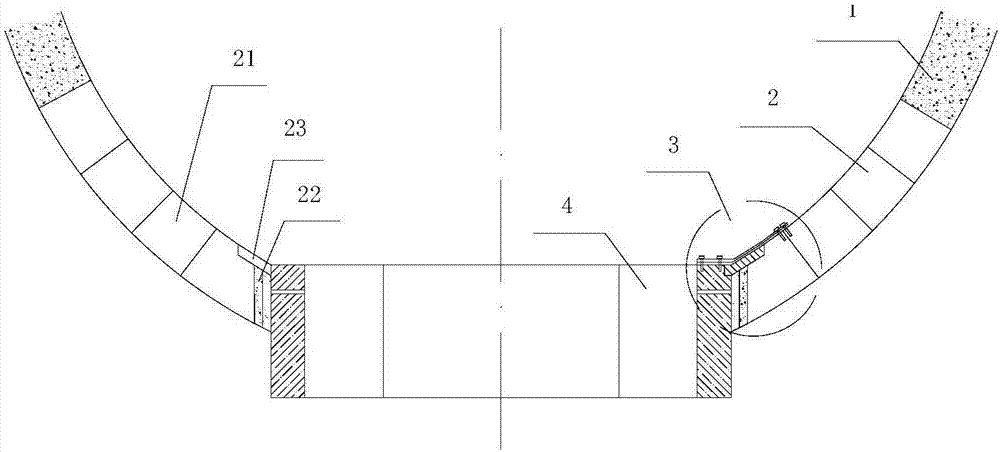

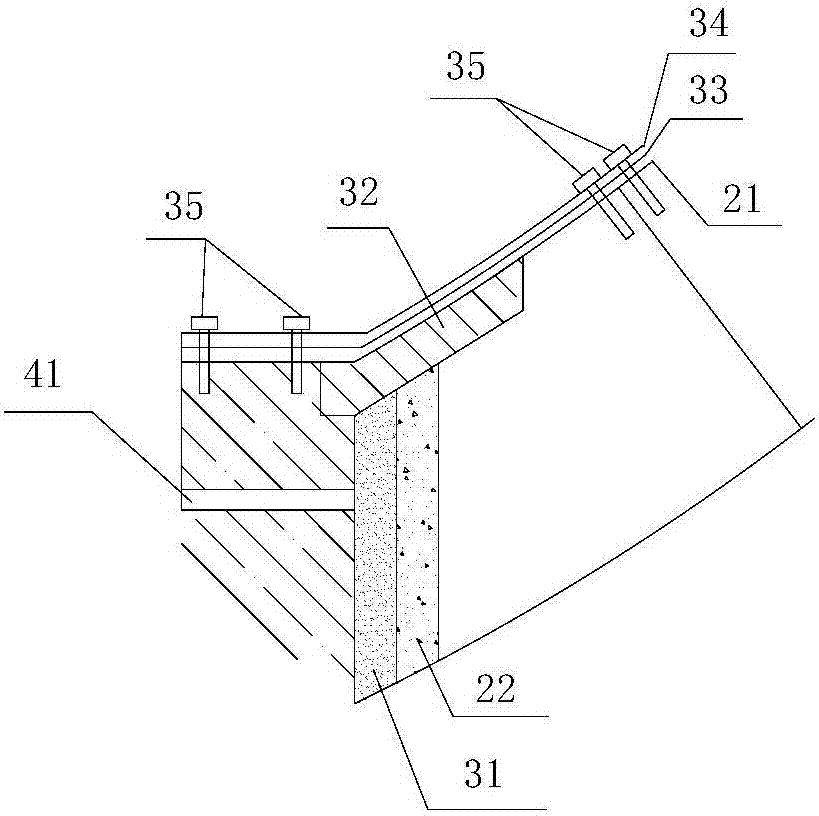

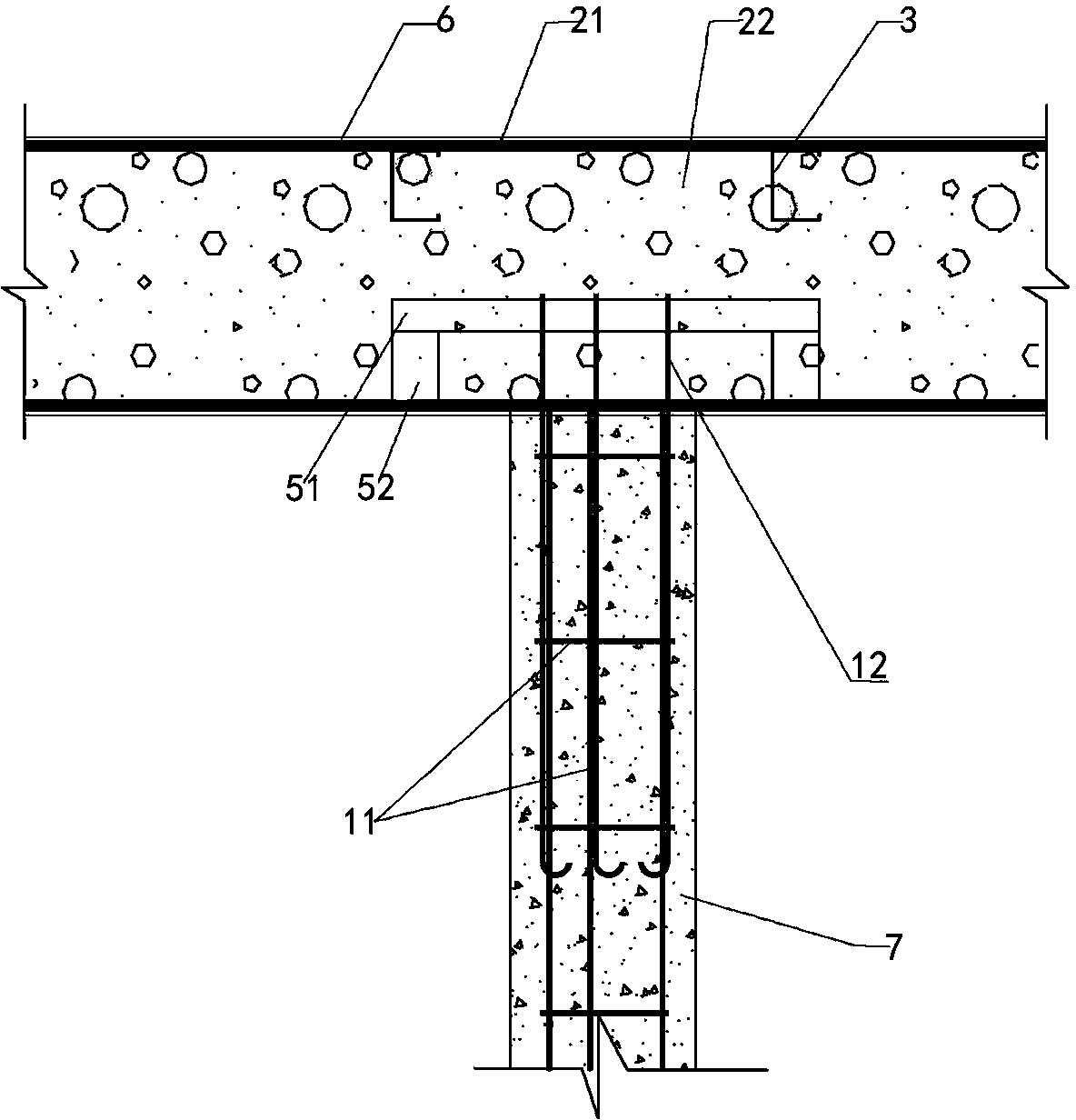

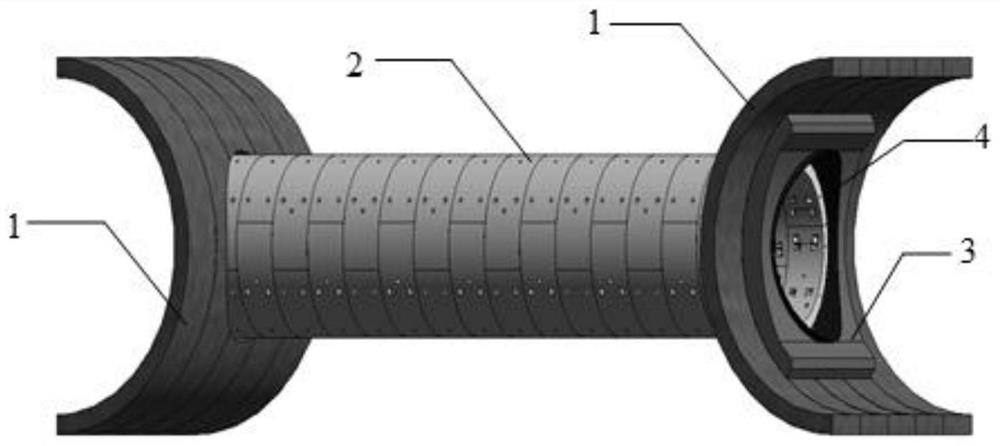

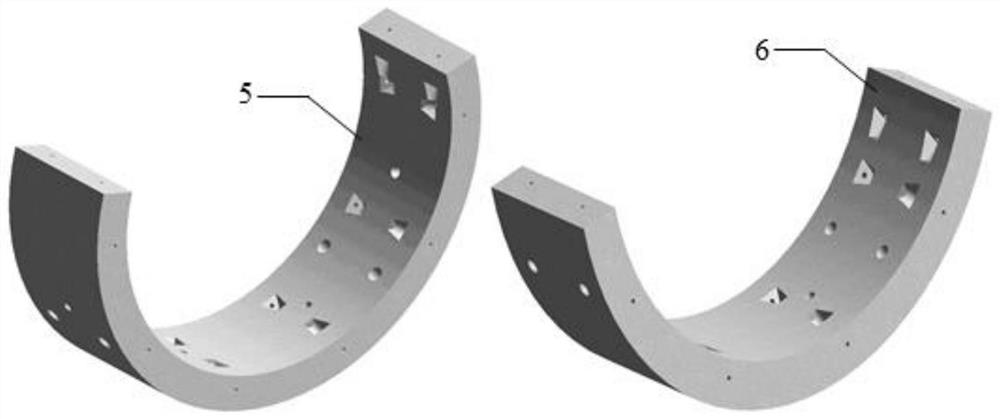

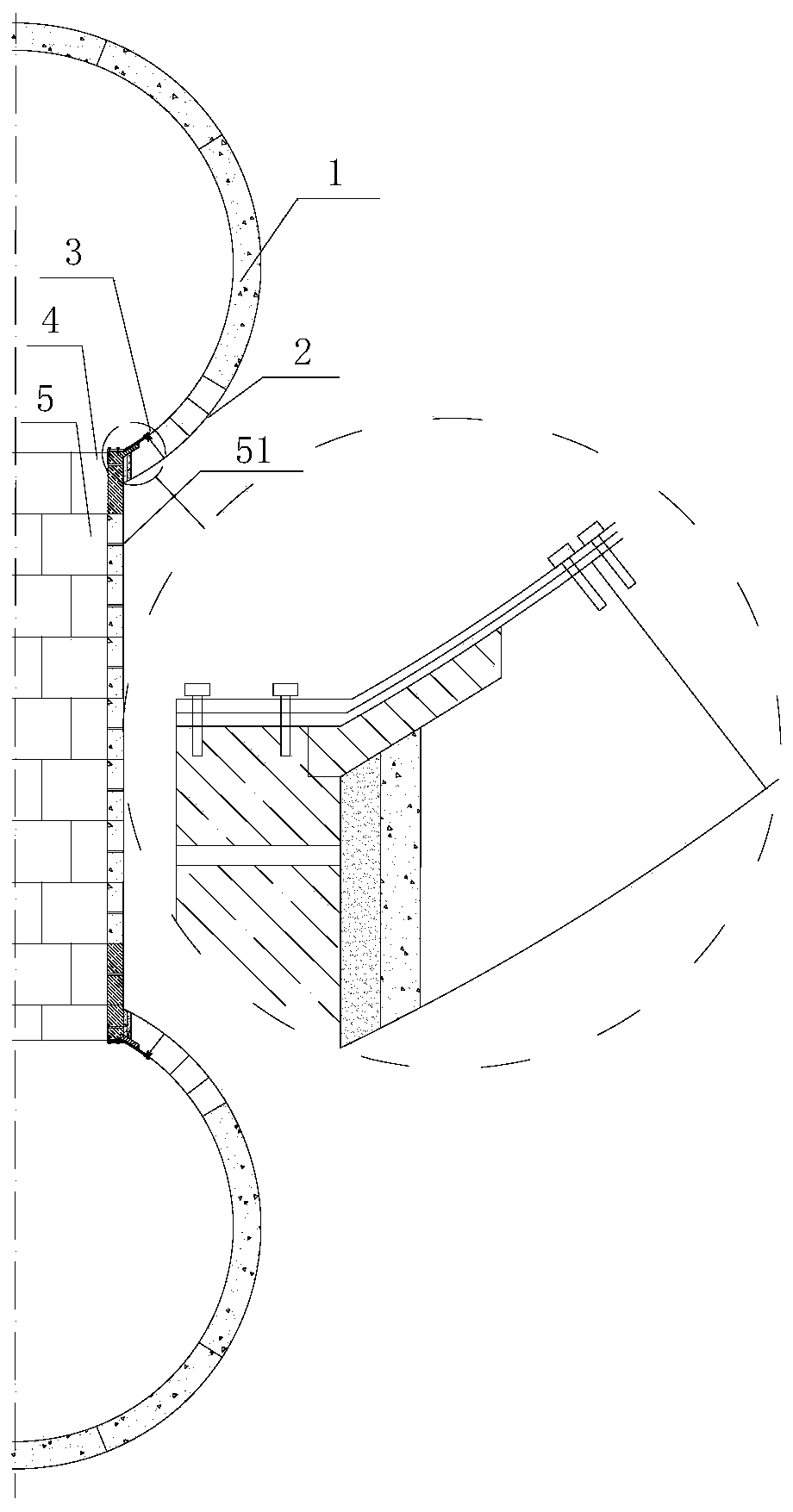

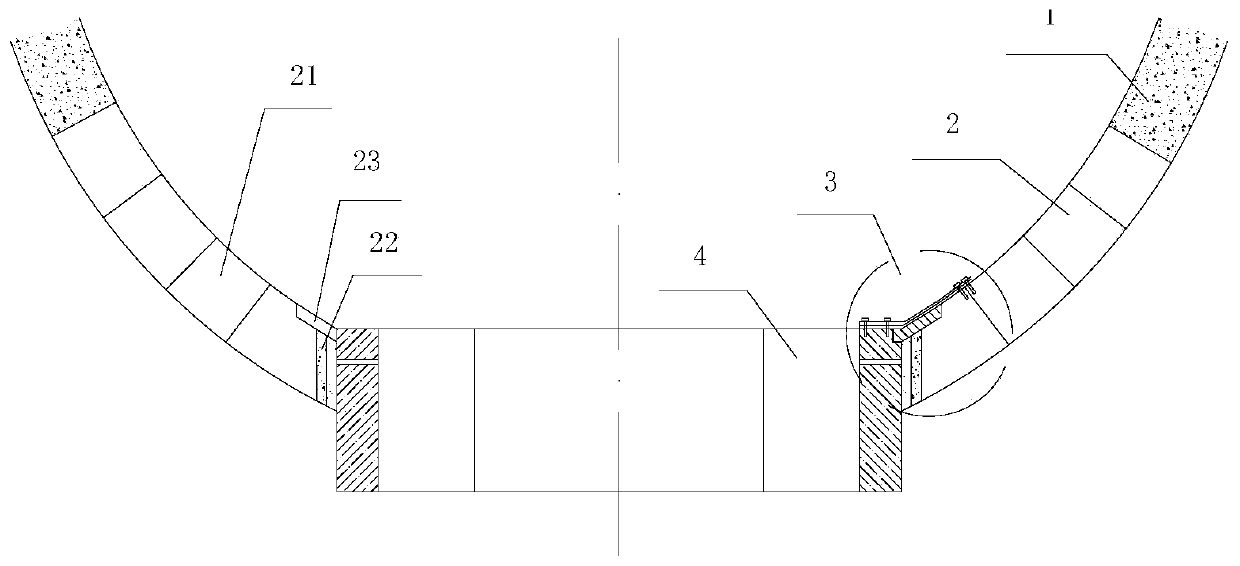

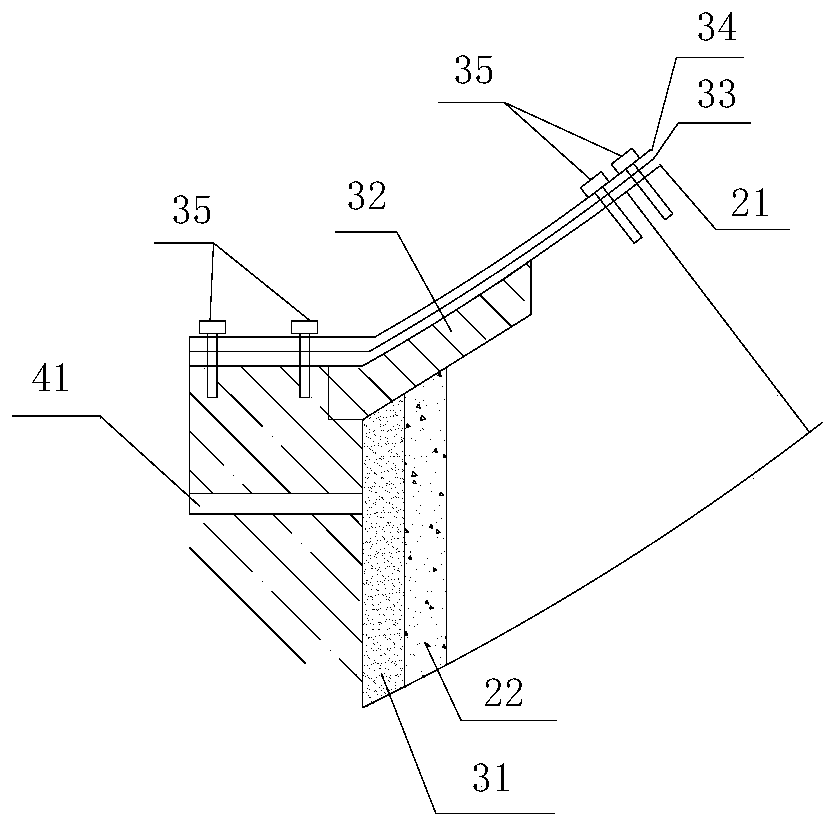

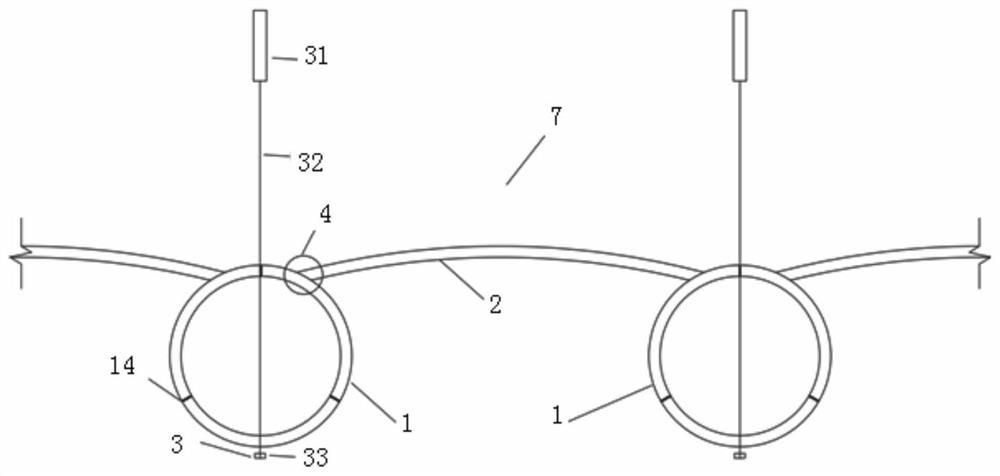

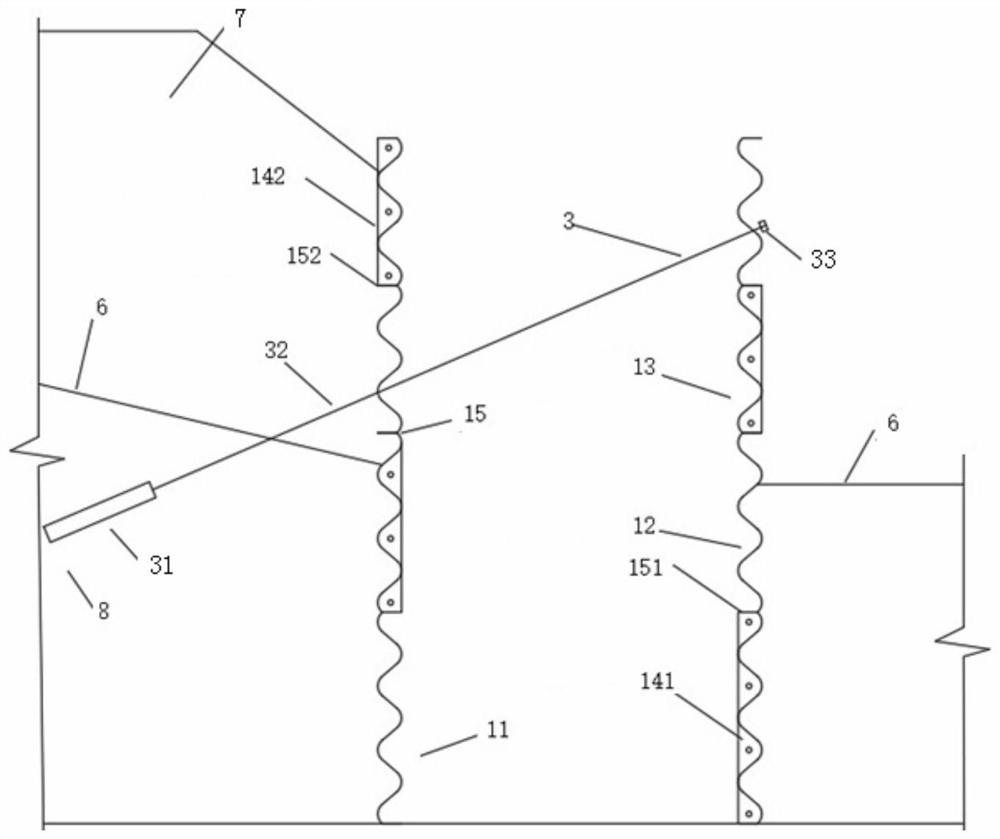

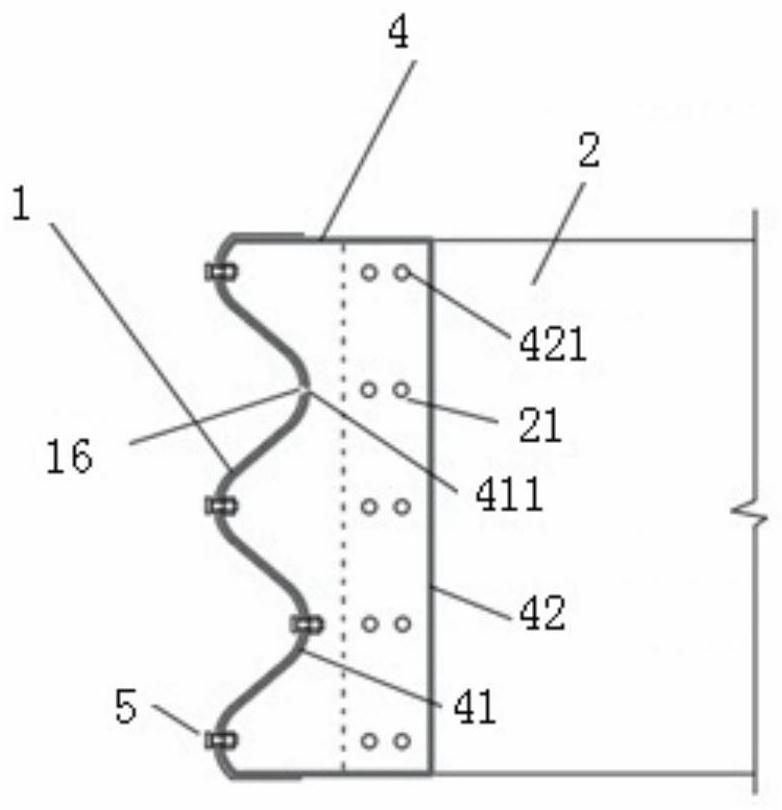

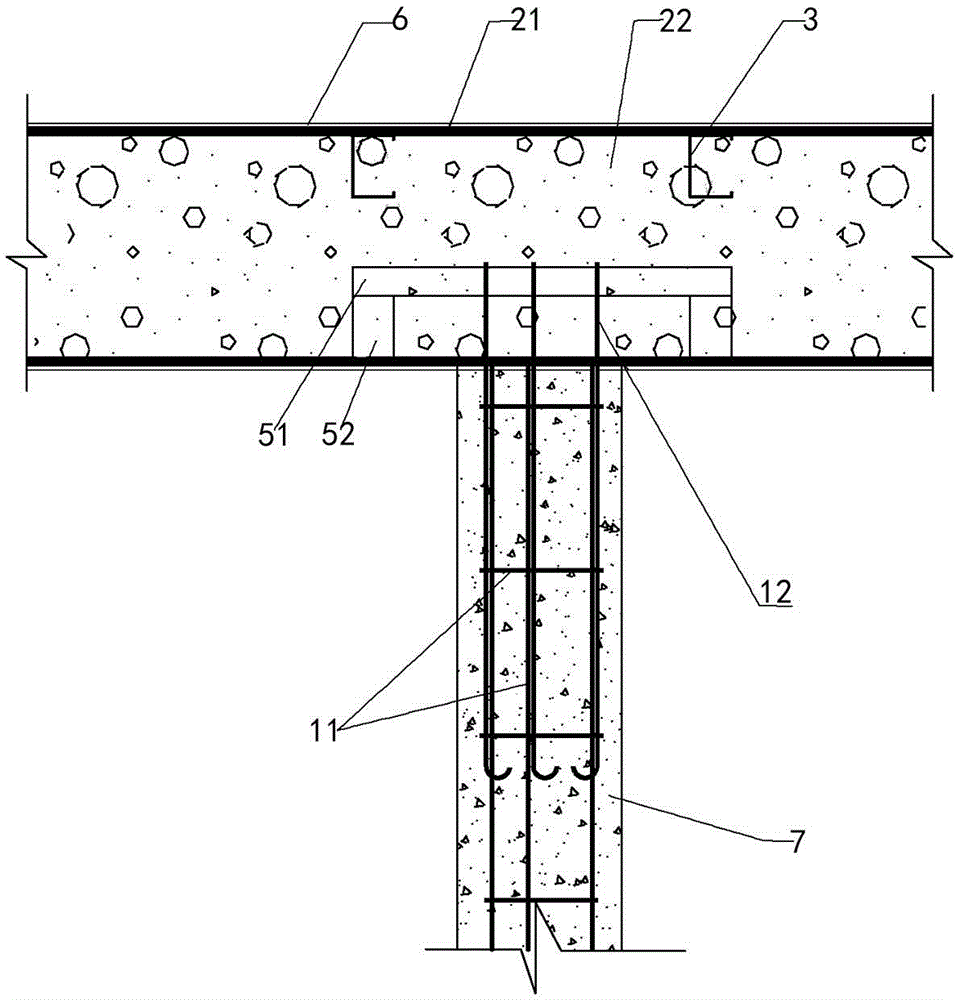

The invention discloses an assembling type connecting aisle structure and a construction method thereof. The assembling type connecting aisle structure is characterized by comprising a shield tunnel concrete segment, a shield tunnel composite segment, an inter-segment connecting system, a connecting aisle steel segment and a connecting aisle concrete segment. The shield tunnel composite segment comprises a composite segment steel segment section, a composite segment concrete segment section and a reserved reinforcing body box, the outer side of the composite segment steel segment section is connected with the shield tunnel concrete segment through connecting bolts in an assembling mode, the inner side of the composite segment steel segment section is integrally connected with the composite segment concrete segment section, and the inner side of the composite segment concrete segment section is connected with the connecting aisle steel segment through the inter-segment connecting system. According to the construction method, the mode of starting with a pipe jacking method and advancing with a shield method is adopted. The assembling type connecting aisle structure and the construction method thereof have the advantages the quality is controllable, the integrality with a shield tunnel is high, and joint waterproofness is high; and the starting problem of narrow and small spaces is solved, and the construction axis of a connecting aisle can also be easily controlled.

Owner:NINGBO UNIV +2

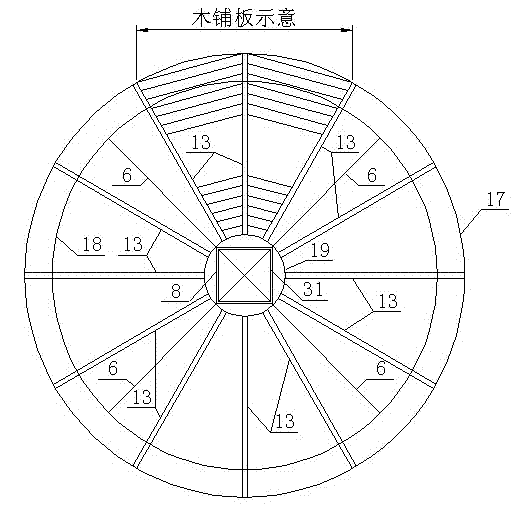

Construction method of circular reinforced concrete chimney cylinder wall and hydraulic sliding mould device

ActiveCN102535843ALess one-time investmentReduce construction costsForms/shuttering/falseworksBuilding material handlingReinforced concreteAssembly disassembly

The invention discloses a construction method of a circular reinforced concrete chimney cylinder wall, and a hydraulic sliding mould device, wherein a hydraulic sliding mould construction method is a rapid construction method of dynamically and continuously molding concrete; loads such as an operation platform and a template are completely supported on a support rod which is stabilized by low-age concrete and has small rigidity; the operation platform and the template are driven to climb along the cylinder wall by a hydraulic jack; and the hydraulic jack climbs on the support rod by an oil path system. The hydraulic sliding mould construction employing the sliding mould as an external cylinder wall and building a lining adopts an ''outside sliding and inside building'' construction process featured by synchronously constructing the external cylinder wall and the lining. The hydraulic sliding mould construction is featured by dynamic continuous construction, having fast construction speed in comparison with mould reverse, symmetrically distributing the hydraulic jack on the circumference of the chimney cylinder wall, forming the template by combining a fixed template with a moveable plate and a contracting and separating template, convenient to assemble and dismount as well as regulate the diameter and the circumference of the combined template structure, capable of gradually decreasing the diameter and the circumference of the combined template structure along with the diameter change of the chimney diameter. The hydraulic sliding mould construction is advantaged in few invested construction operators and convenient management.

Owner:马鞍山钢铁建设集团有限公司

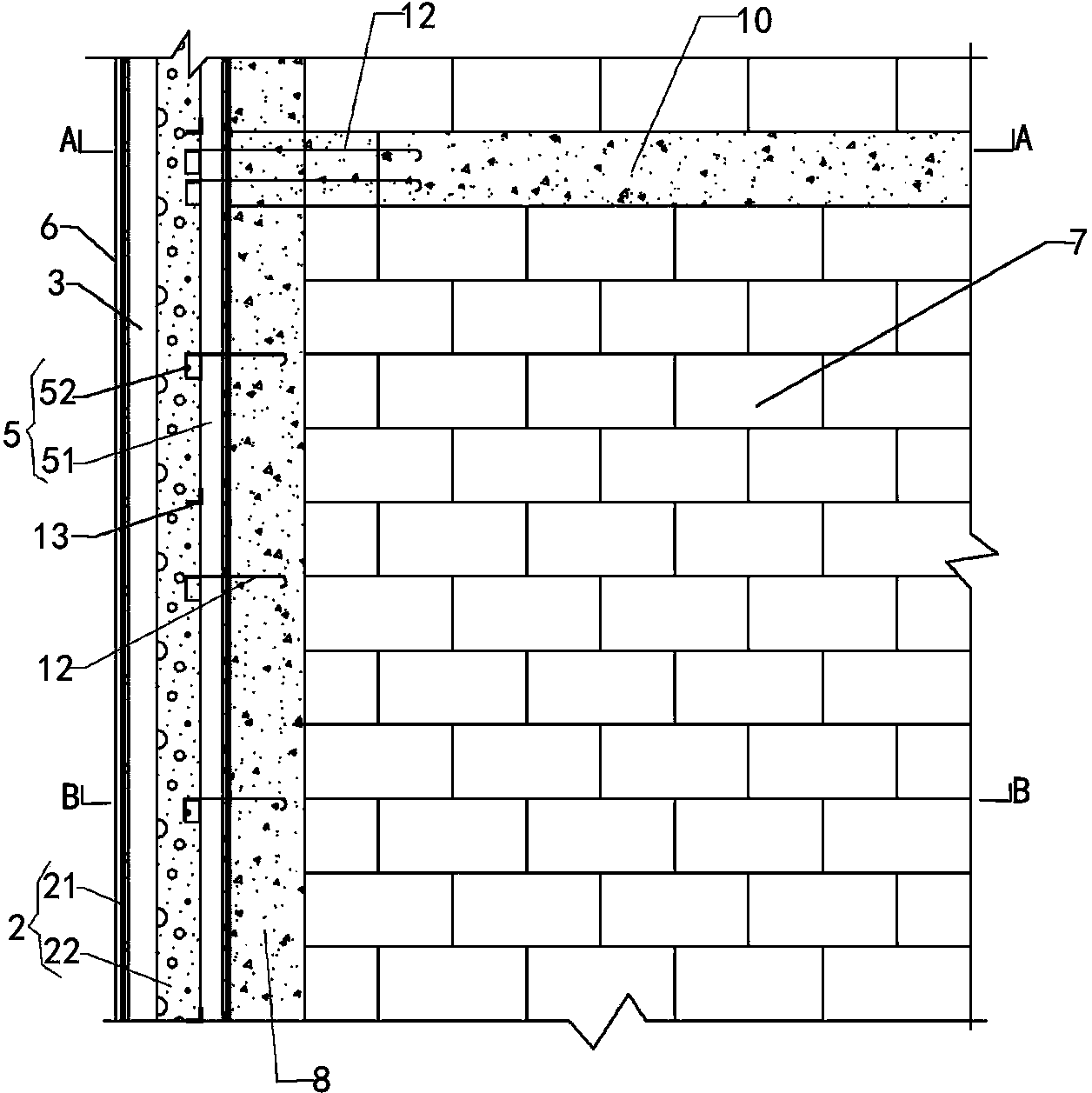

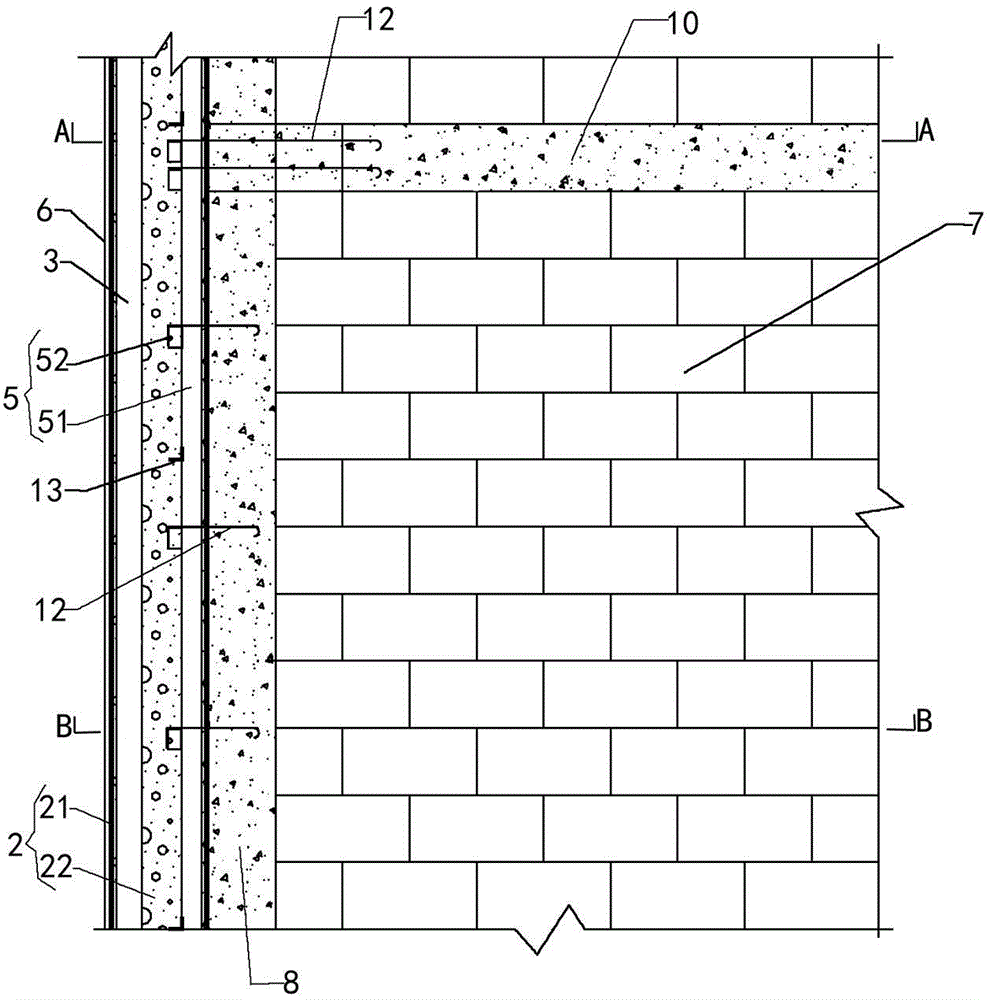

Building envelope inner and outer wall anti-seismic and sound insulation anti-cracking integrated structure and construction method thereof

InactiveCN103883022AImprove insulation effectLow costWallsBuilding material handlingIsolation effectKeel

Disclosed are a building envelope inner and outer wall anti-seismic and sound insulation anti-cracking integrated structure and a construction method of the structure. An outer wall is connected with the outer side of a frame column to form an integrated building envelope surrounding the frame column, one part of the frame column is embedded in the outer wall, the outer wall is a cast-in-place sandwich wall, the outer wall is filled with light porous inorganic core materials, a lightgage steel joist in the core materials is anchored with face plates on the two sides, the outer wall is connected with the inner wall through connecting ribs, and a reinforcing keel is arranged on the connecting portion. According to the structure, containment and heat preservation are integrated, connection between the cast-in-place light inorganic heat preservation composite outer wall and the constructed inner wall is successfully achieved, the good heat preservation, sound isolation and deformation anti-cracking treatment is achieved, industrial wastes are recycled to be used as raw materials to form nonflammable inorganic foam heat preservation slurry, and due to the rich porous structure in the slurry, the slurry has the excellent heat preservation and sound isolation effects. According to the structure and the method, form removal is not required, construction is easy, the forming speed is high, maintenance is not needed, flexible and continuous casting can be achieved, the building construction efficiency is improved by 30 percent, and the cost is reduced by more than 10 percent.

Owner:CHINA CONSTR SECOND ENG BUREAU LTD

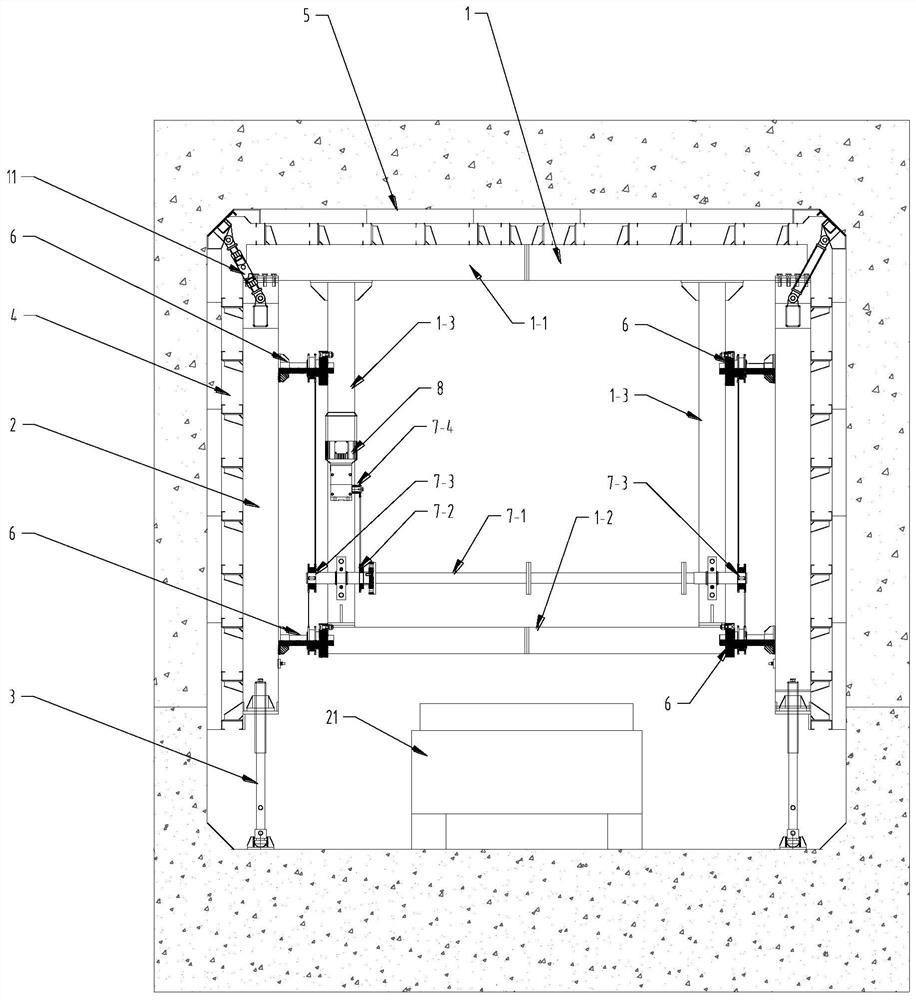

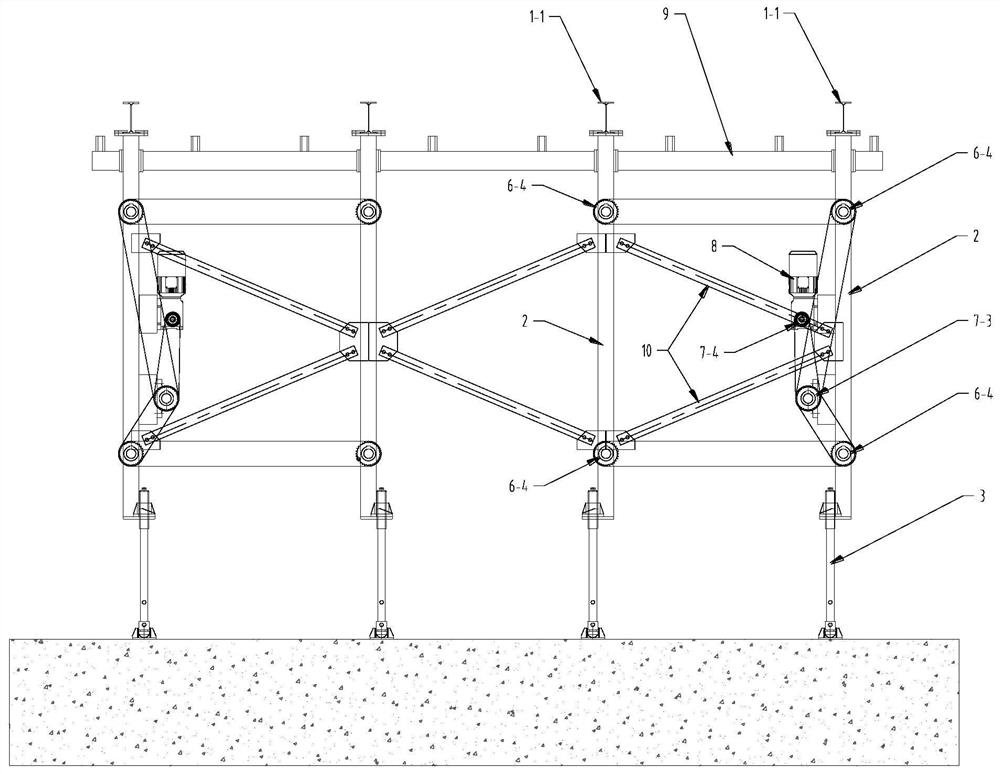

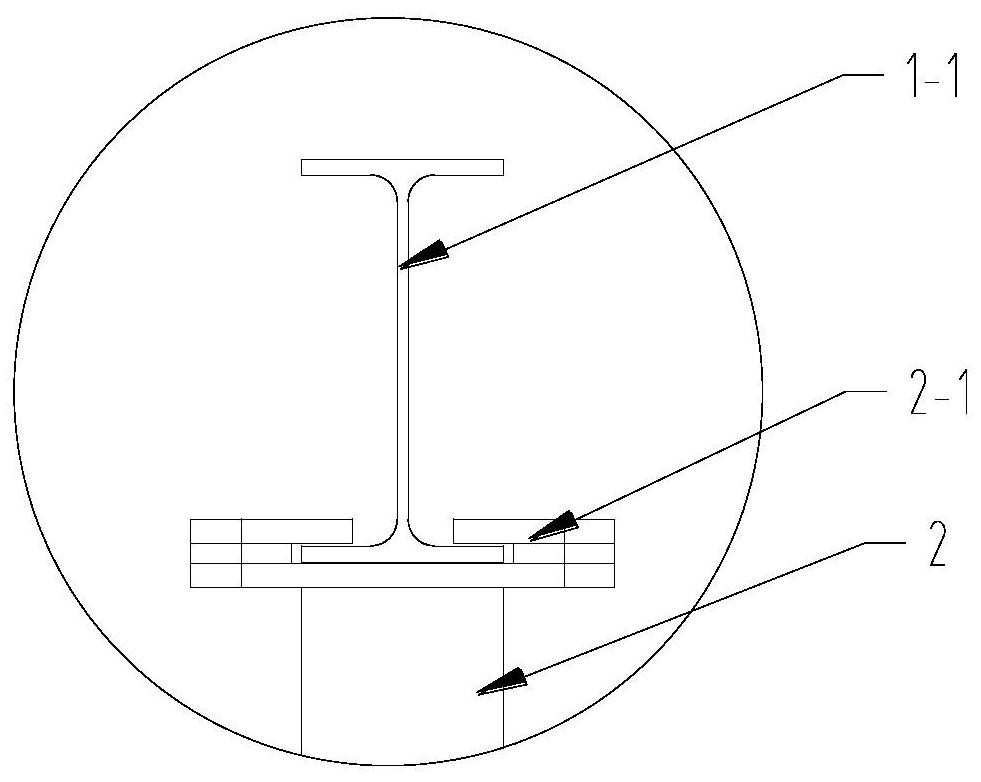

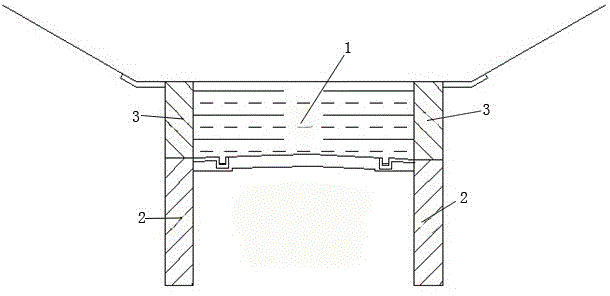

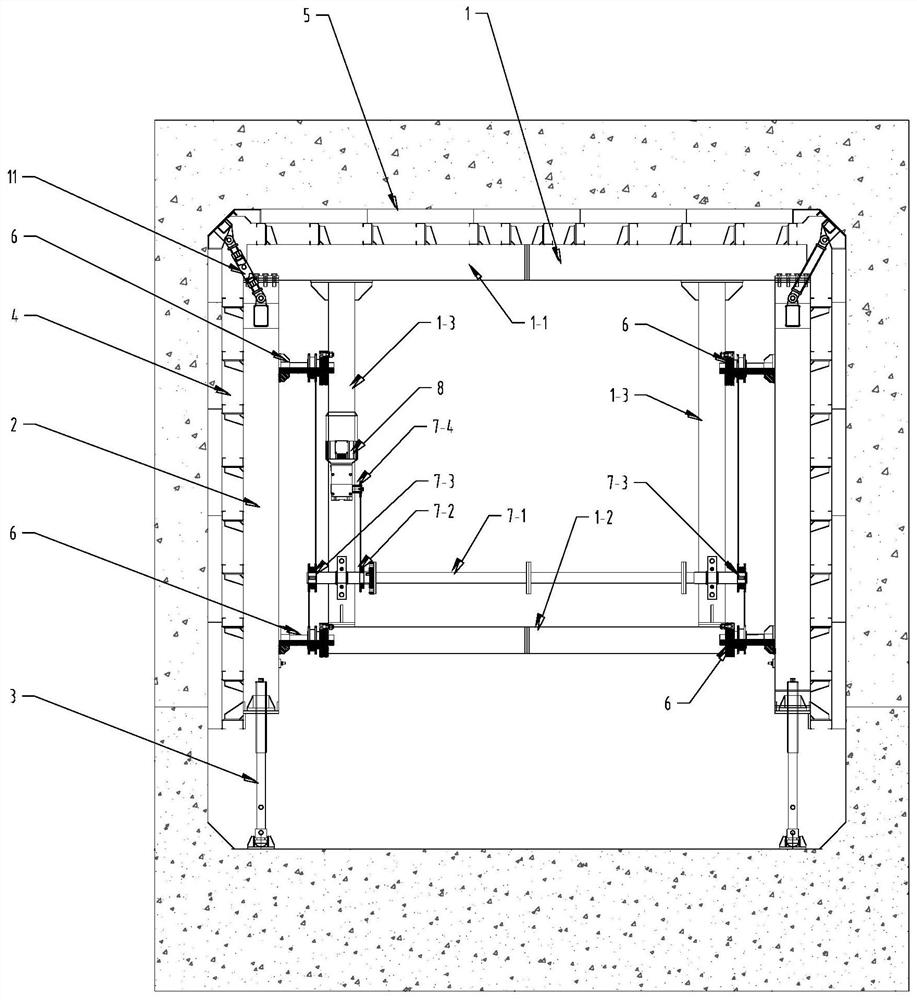

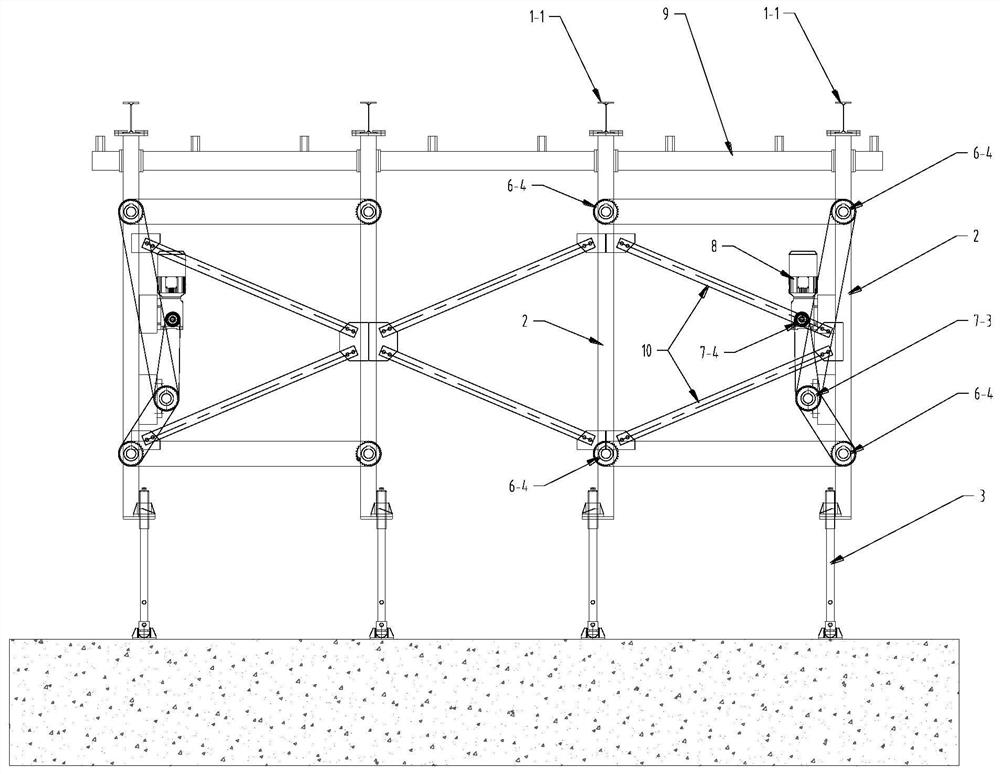

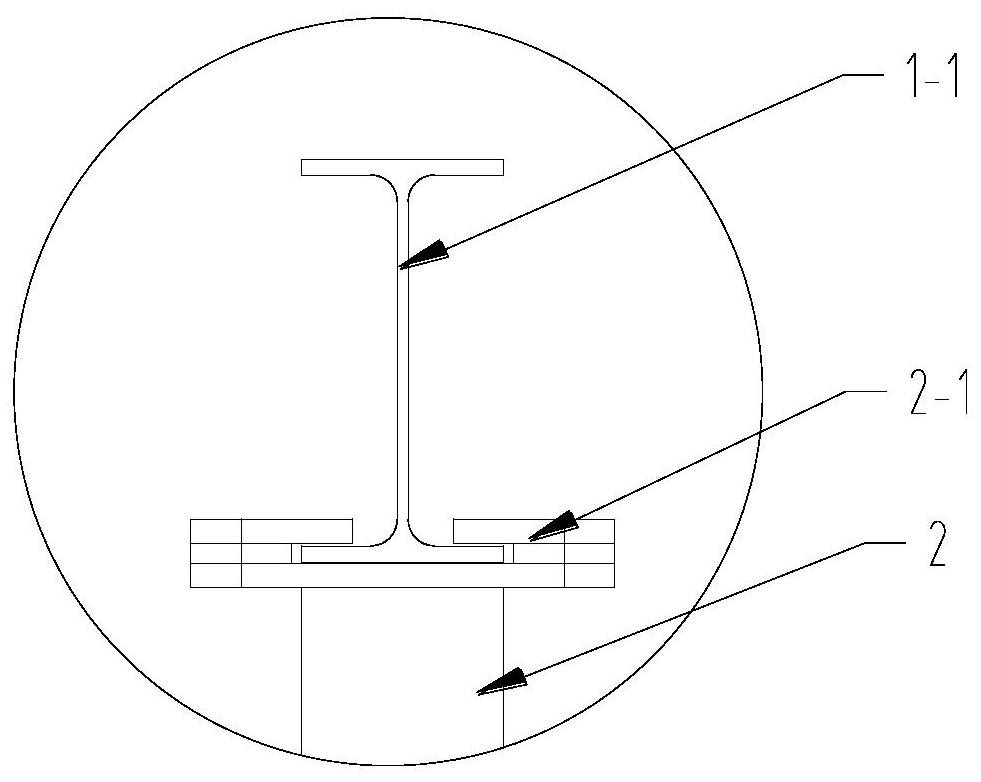

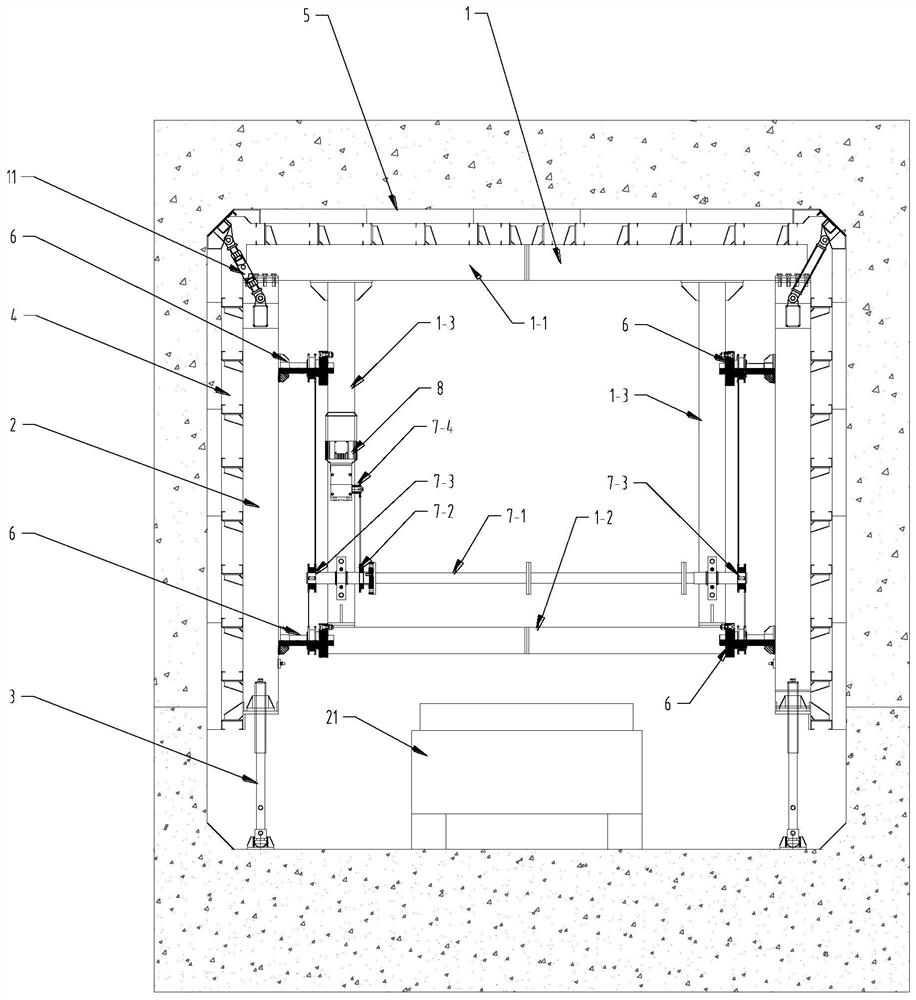

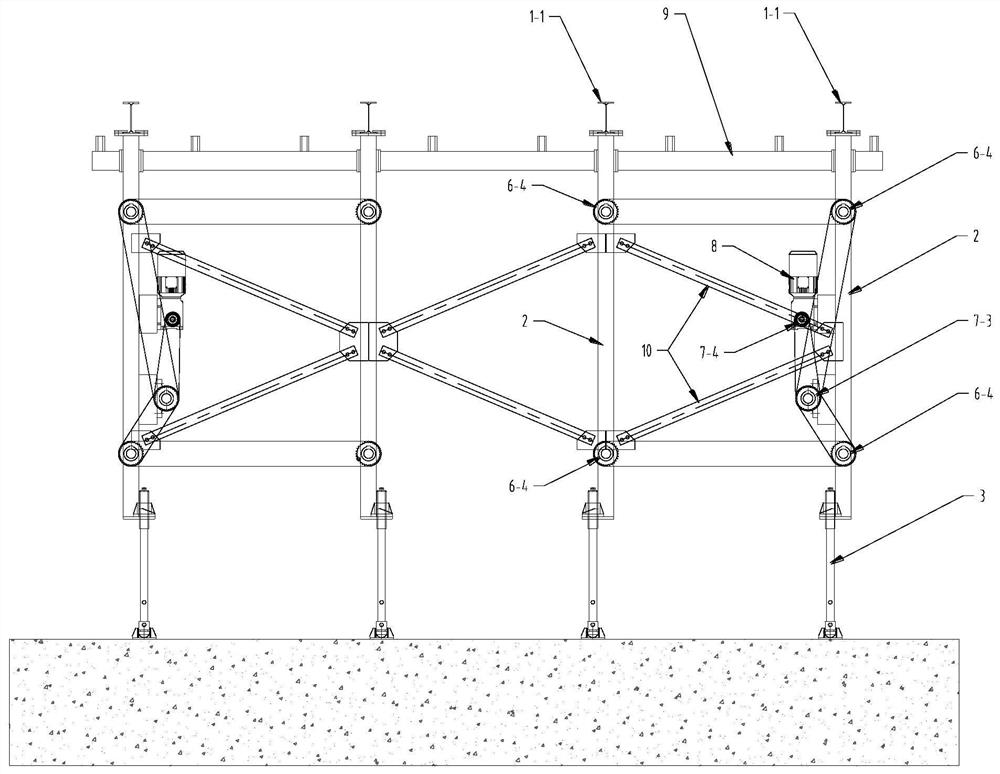

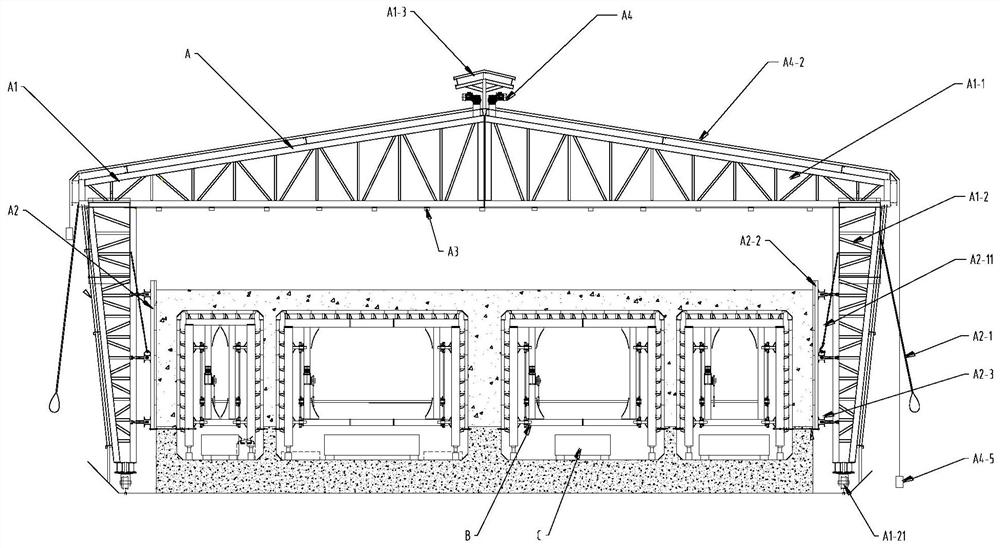

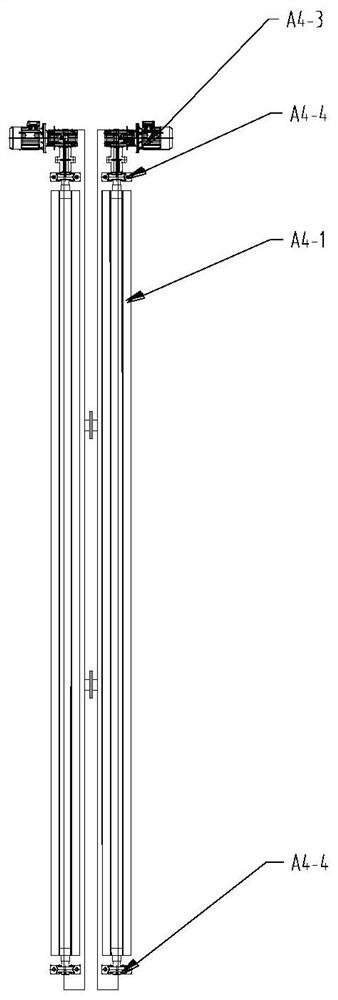

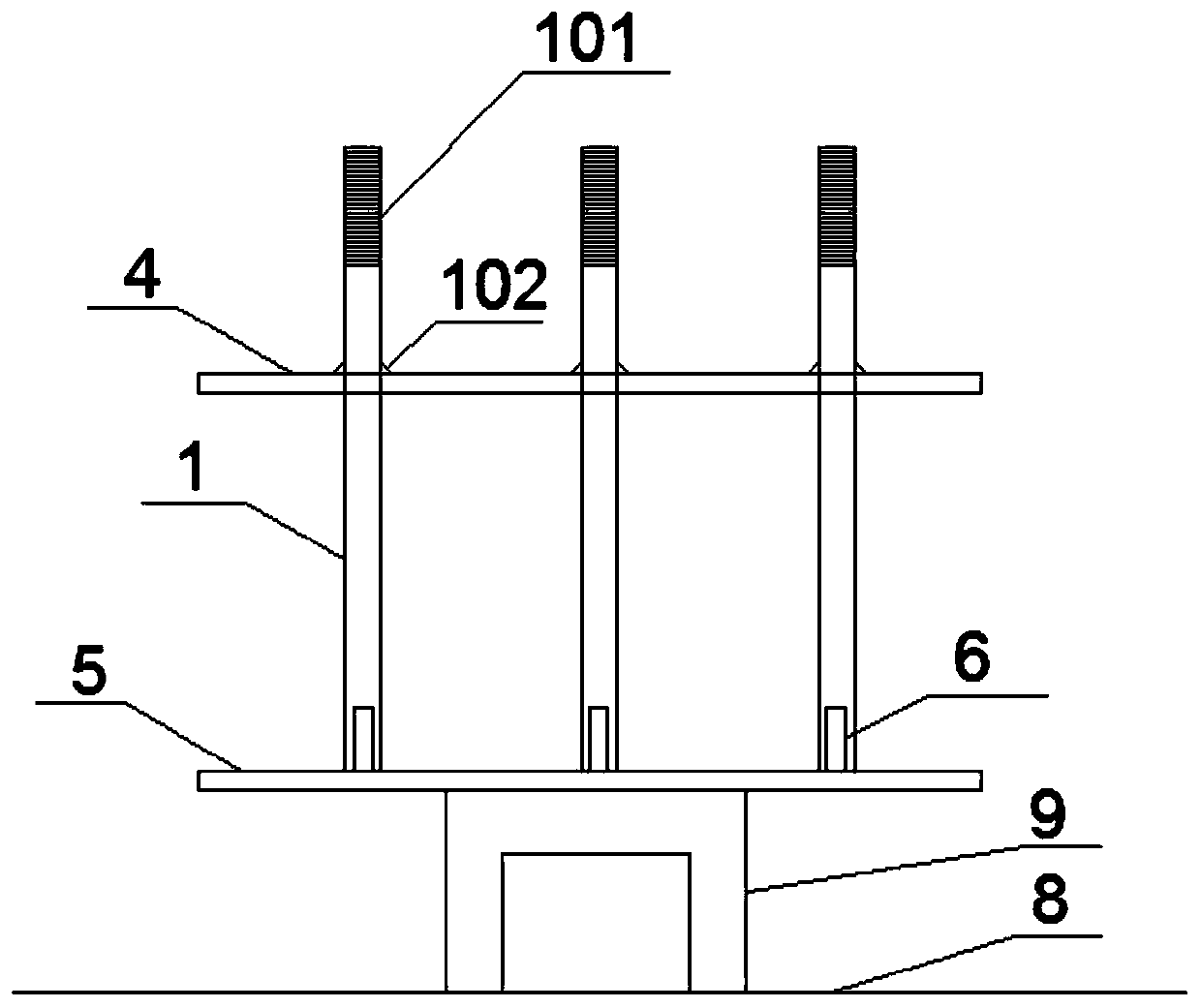

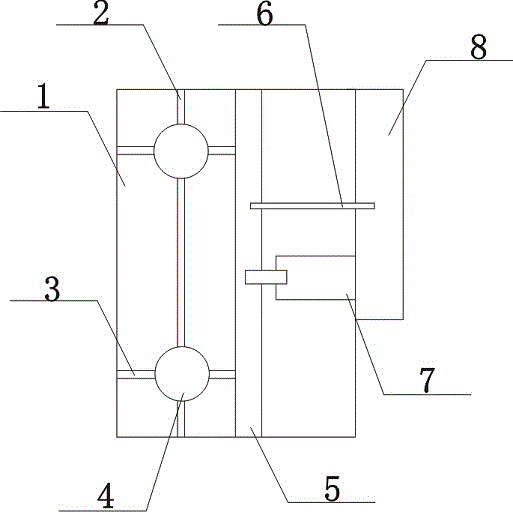

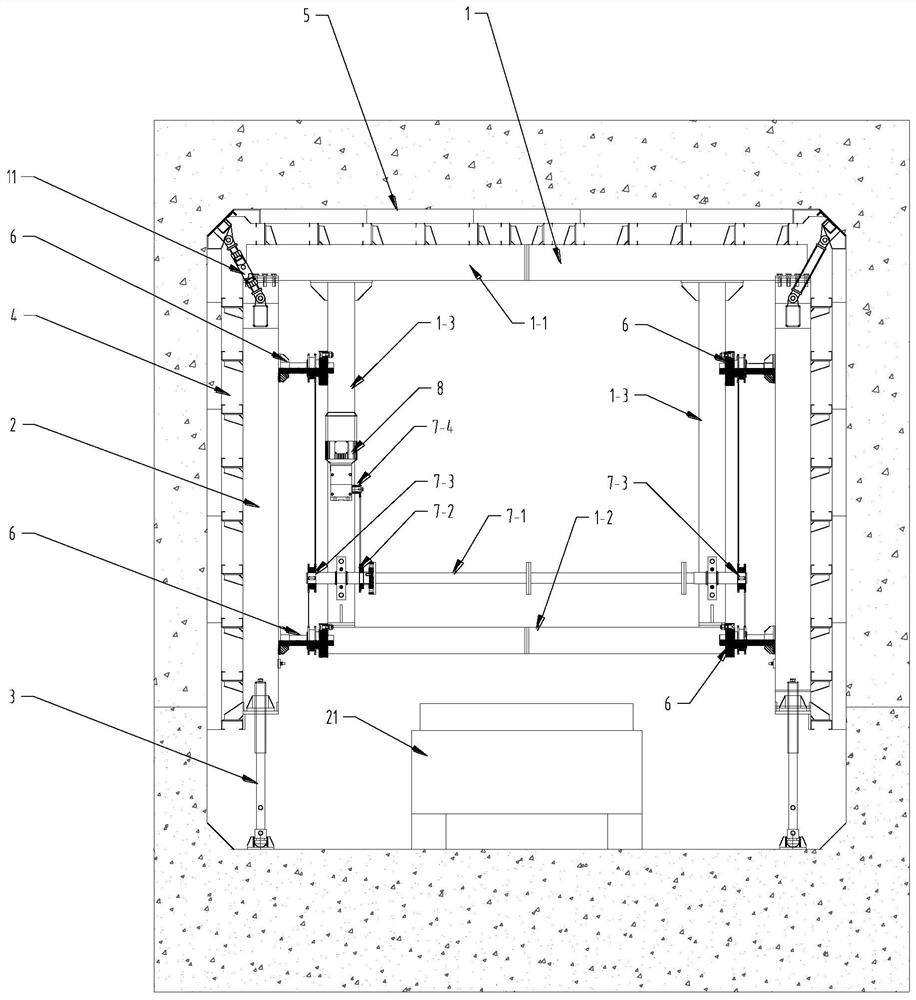

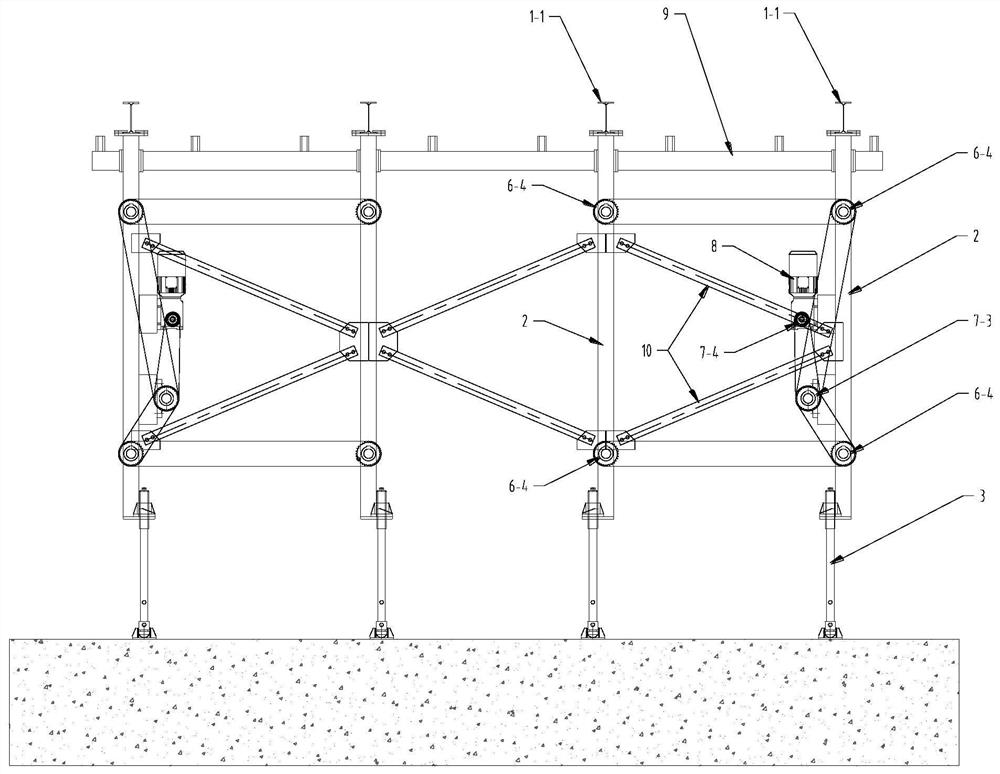

Concrete pipe gallery inner mold in-place and demolding method

ActiveCN111749270ADoes not affect trafficDoes not affect workArtificial islandsForms/shuttering/falseworksArchitectural engineeringPipe

The invention discloses a concrete pipe gallery inner mold in-place and demolding method. The concrete pipe gallery inner mold in-place and demolding method comprises an inner mold frame and a liftingtrolley used for moving the inner mold frame in place, the inner mold frame comprises a portal frame, movable stand columns are arranged on the two sides of the portal frame, side mold plates are installed on the movable stand columns, and the movable stand columns are connected with the portal frame through translation drivers; a top mold plate is mounted at the top of the portal frame; stand column lifting supporting legs are arranged at the bottoms of the movable stand columns, and the height of the whole inner mold frame is adjusted through the stand column lifting supporting legs; and bottom middle supporting legs capable of rising and falling are further arranged at the bottom of the portal frame. During construction, the lifting trolley lifts the inner mold frame to move and be preliminarily in place, the position and the height of the side mold plate are adjusted by combining the inner mold frame, and mold erecting and demolding work is achieved.

Owner:ERCHU CO LTD OF CHINA RAILWAY TUNNEL GRP +1

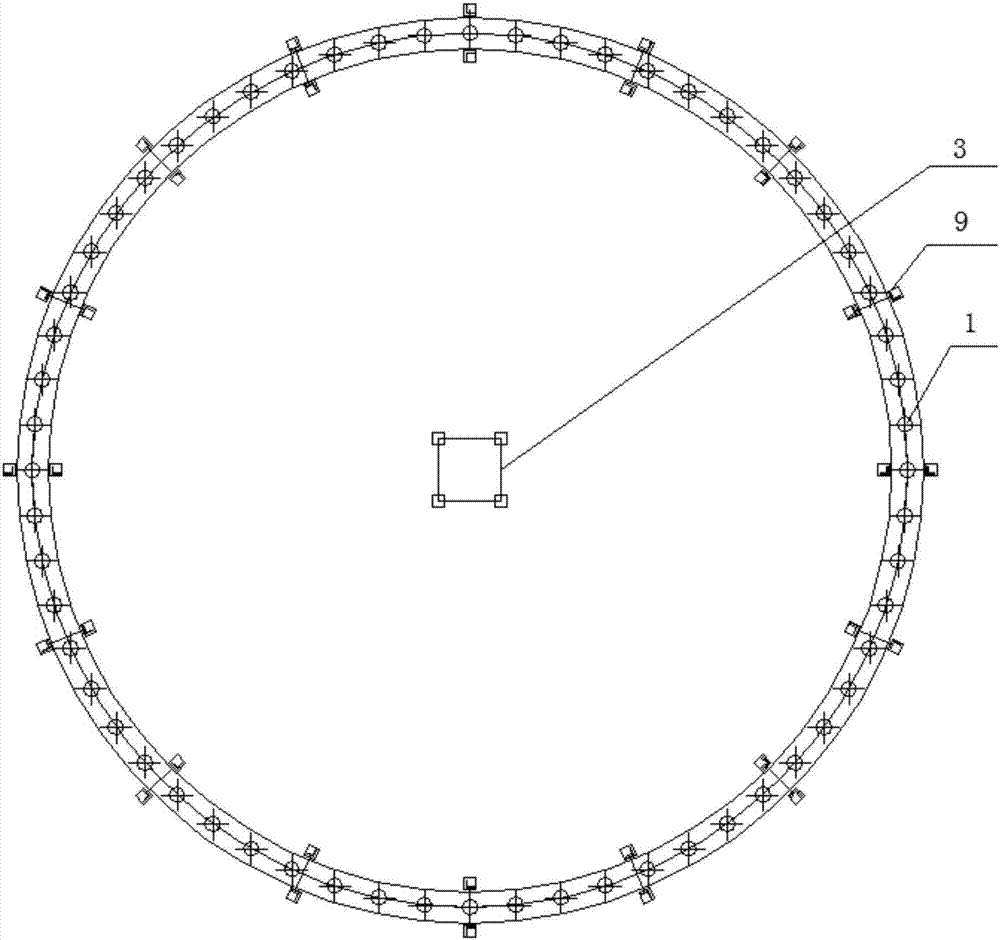

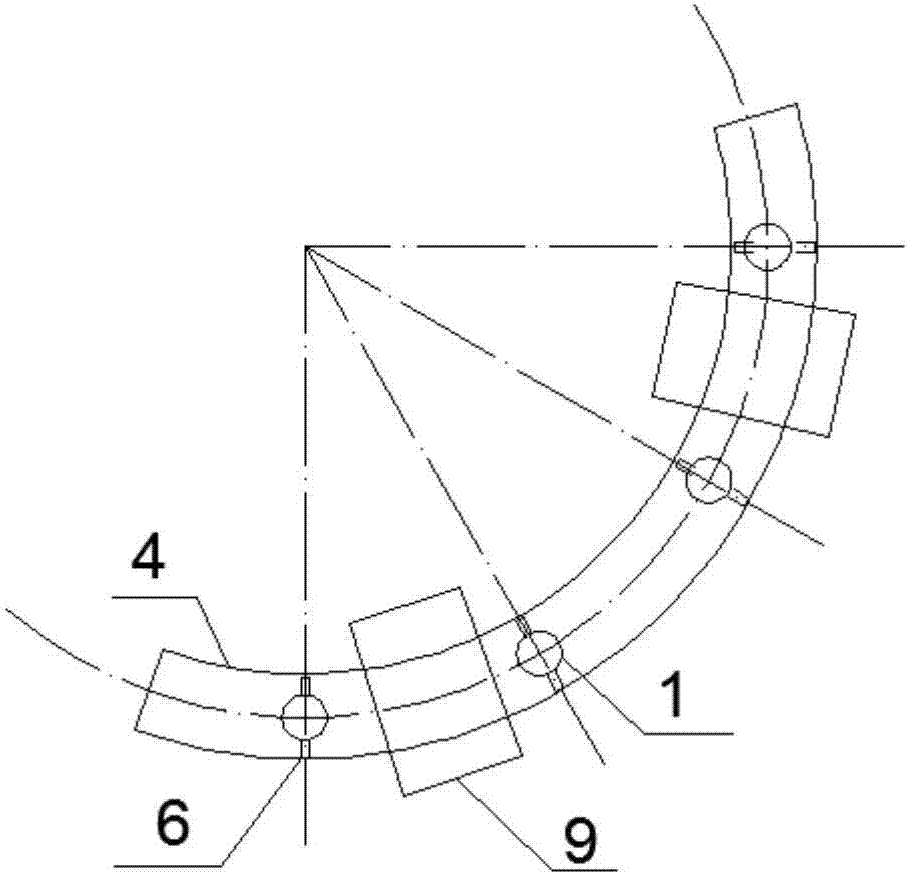

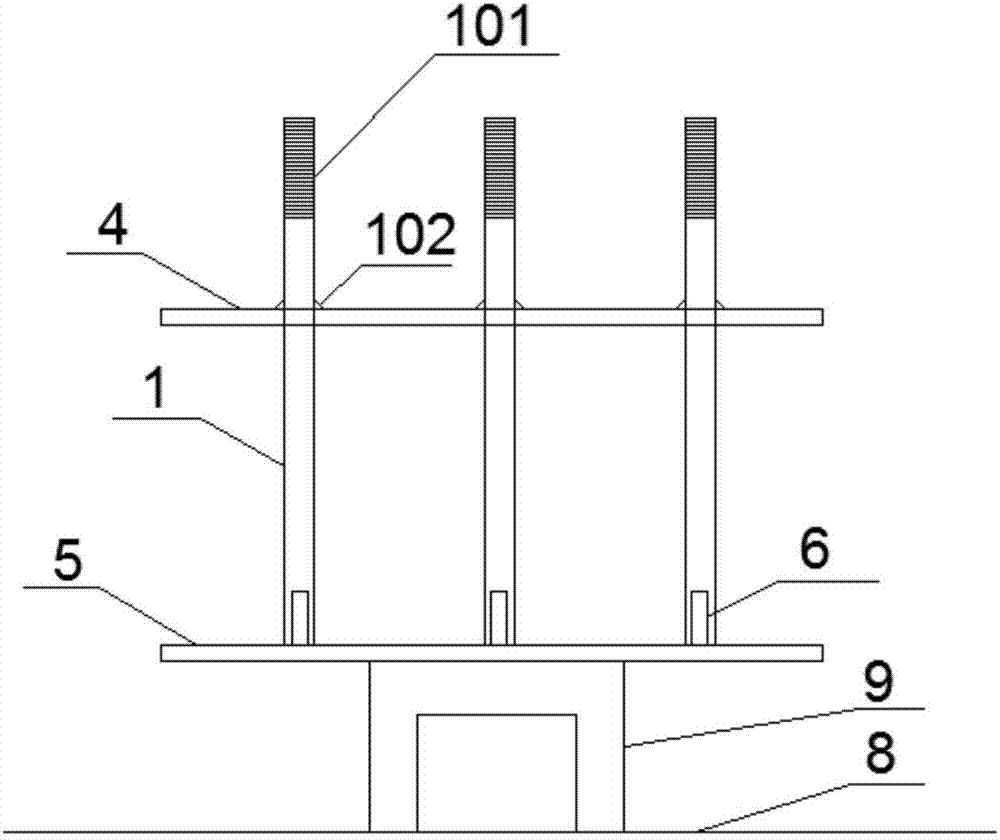

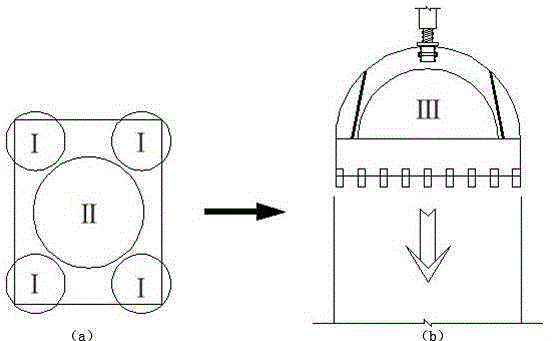

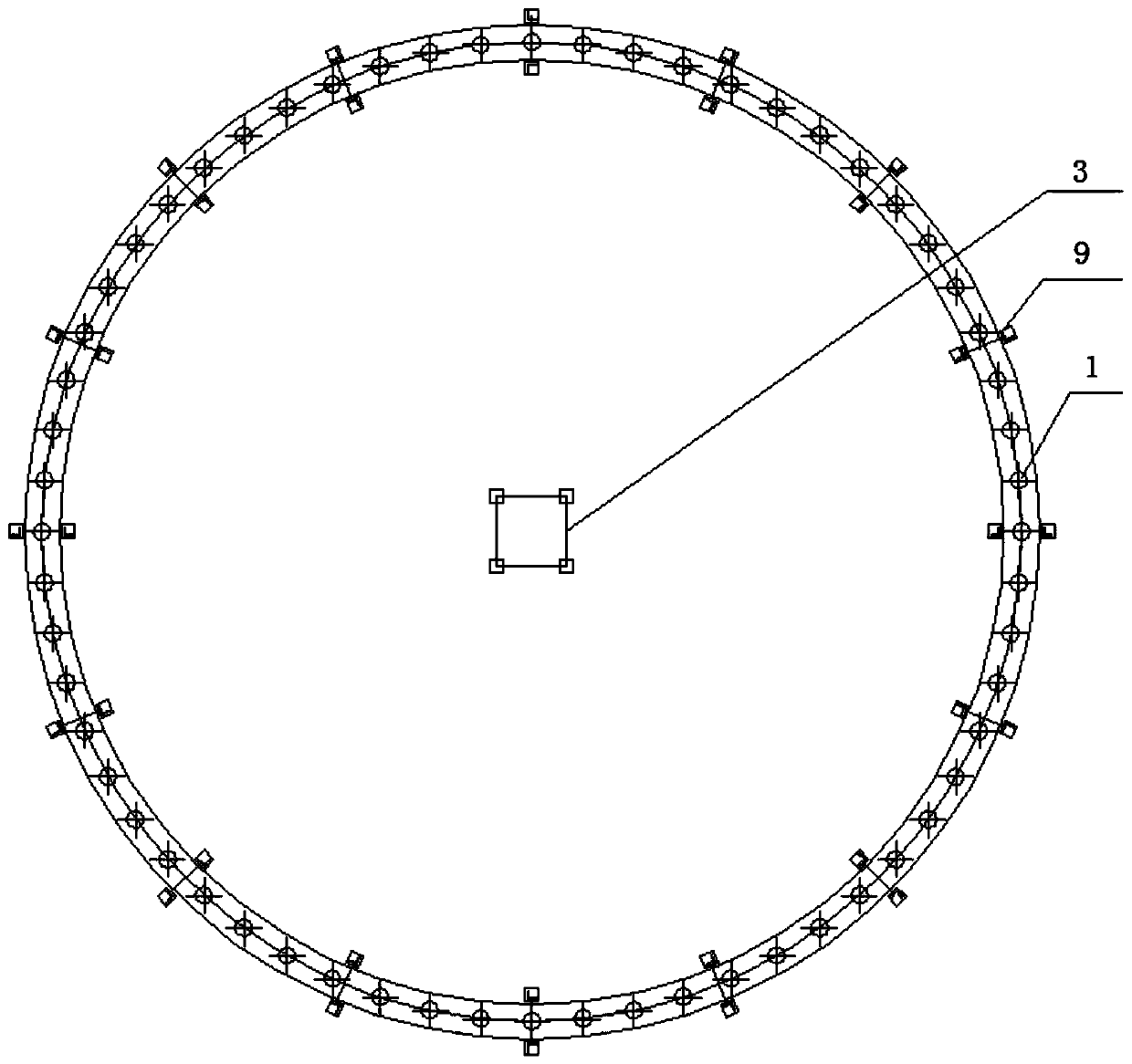

Annular bolt installation method for metallurgical industry furnace body

The invention discloses an annular bolt installation method for a metallurgical industry furnace body, and belongs to the field of metallurgical engineering equipment installation and civil engineering cooperation. For the problems that in the prior art, the device installation is complex, precision is poor and labor hours are consumed, the annular bolt installation method for the metallurgical industry furnace body is provided. The annular bolt installation method includes the following steps that A, a bolt system is manufactured and segmented, and all bolts are divided into multiple symmetrical systems, and each system comprises multiple bolts and fixing anchor plates; B, fixing welding pieces of supporting frames below the bolt systems are embedded in a base concrete cushion layer in advance and poured on the upper surface of the cushion layer; C, each bolt supporting frame is arranged in place along the circumference, the top elevation of each bolt supporting frame is adjusted, and the bolt supporting frames are welded to all embedded parts around the bolt systems in the cushion layer; D, the bolt systems are sequentially installed on the supporting frames, and the top elevation and perpendicularity of the foundation bolts of all the system bodies are fine adjusted; E, the bolt system bodies are welded and installed to form the whole annular bolt system; F, the bolt system bodies are subjected to concrete pouring; and G, acceptance inspection is conducted. The annular bolt installation method is easy to install, high in precision and high in efficiency.

Owner:马鞍山钢铁建设集团有限公司

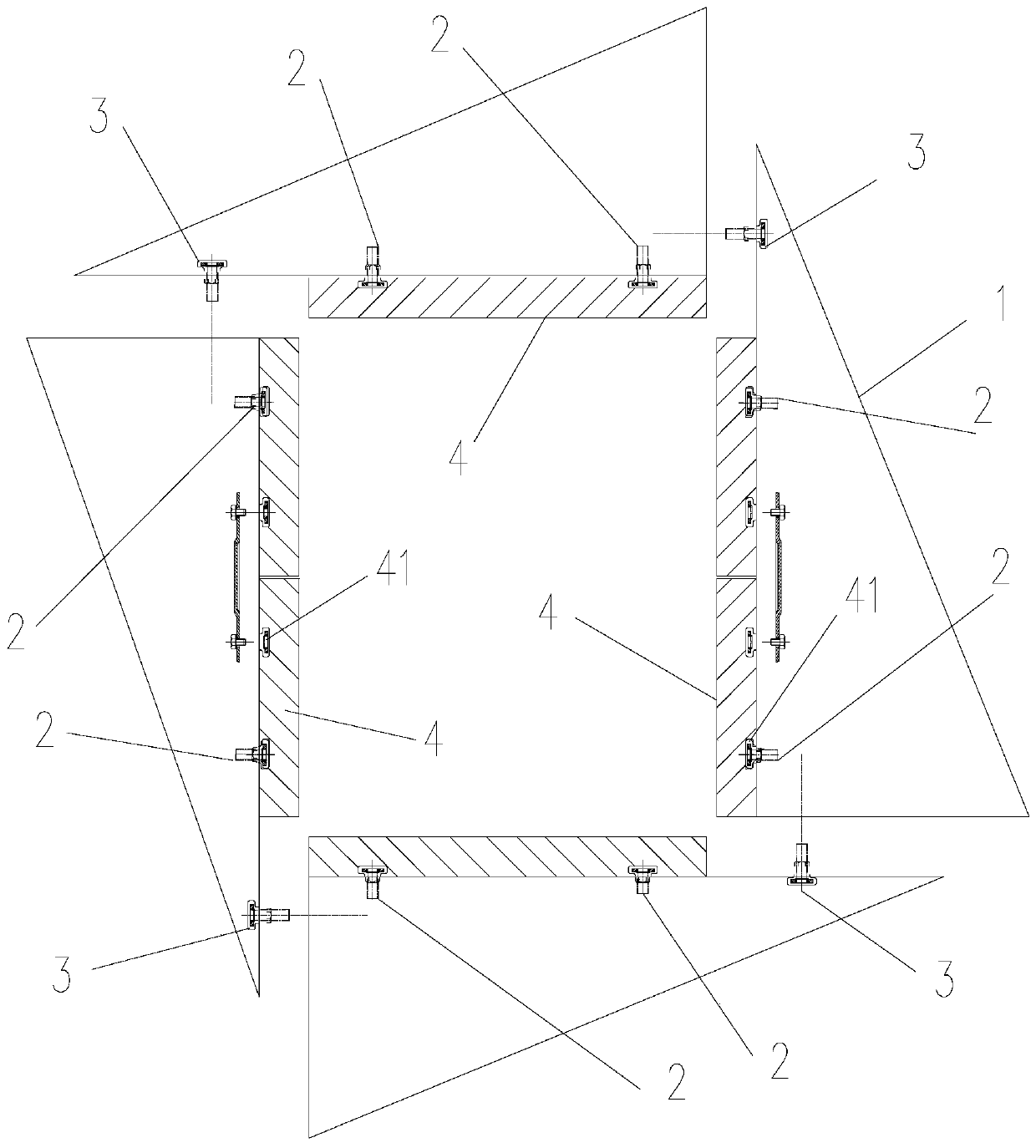

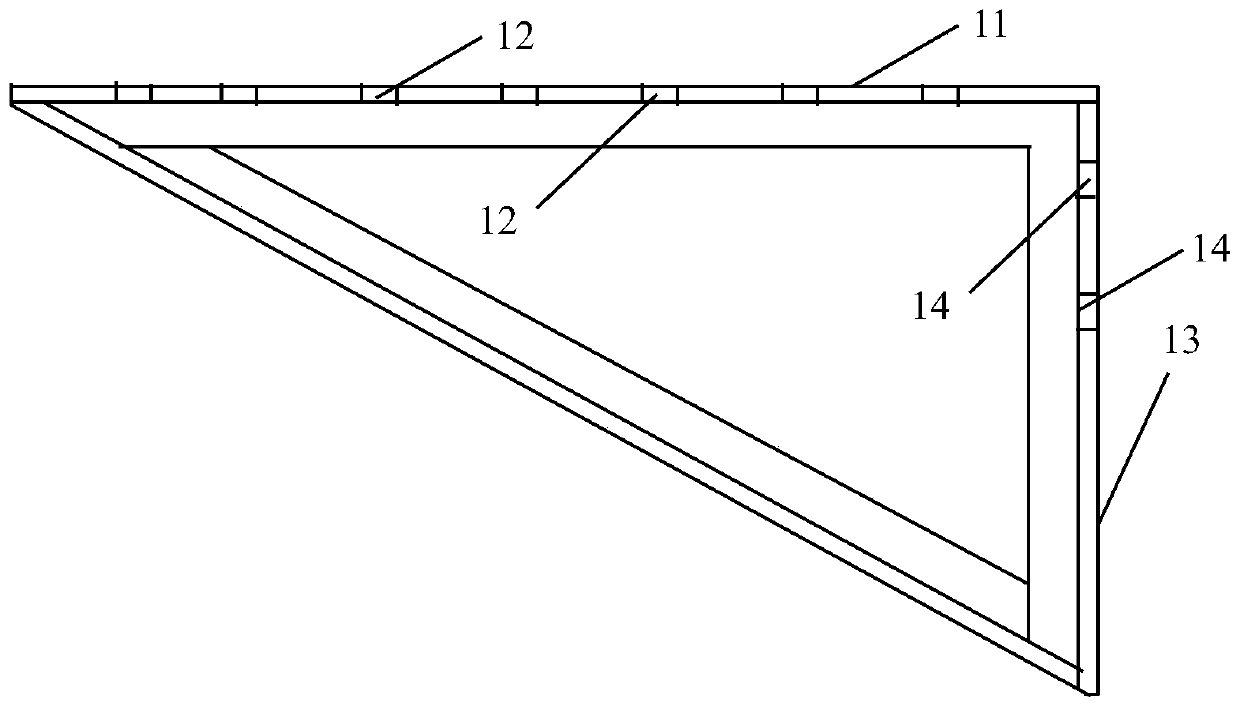

Novel concrete column template device and construction method thereof

PendingCN109853945AImprove construction qualityConstruction quality is safe and reliableForms/shuttering/falseworksAuxillary members of forms/shuttering/falseworksTemplate matchingSteel frame

The invention provides a novel concrete column template device. The novel concrete column template device comprises at least four column hoop pieces, a plurality of first bolt assemblies and a plurality of second bolt assemblies; the column hoop pieces are triangular steel frames, and a plurality of square holes are formed in first straight sides of the triangular steel frames being in contact with concrete column templates; a plurality of long holes are formed in second straight sides of the triangular steel frames; template matching parts are arranged at one ends of first threaded rods of the first bolt assemblies, and the template matching parts are matched with T-shaped grooves of the column templates; and when the column templates are prefabricated and assembled, the column hoop pieces penetrate through the square holes through the multiple first bolt assemblies and are connected with the T-shaped grooves of the column templates onto the column templates in a fastening mode, the column hoop pieces on every two adjacent column templates then penetrate through the square holes through the second bolt assemblies and are connected with the long holes in a fastening mode, and a fastening structure is formed. The invention further provides a construction method of the novel concrete column template device. The application range is wide, the operation is convenient, the working efficiency is high, and the connection is reliable.

Owner:福建博业建设集团有限公司 +2

Square hole girdling cutter and method for performing holing construction of deep cutting stab-pile wall by utilizing same

InactiveCN103334449AEasy to operateImprove securityArtificial islandsExcavationsEngineeringMechanization

The invention discloses a square hole girdling cutter and a method for performing the holing construction of a deep cutting stab-pile wall utilizing the same. The cutter comprises a truss and a square cutter edge thereof; the top of the truss is provided with a pin shaft hole for connecting a drilling rod; and a plurality of cutter bits are welded on the square cutter edge at equal interval. The method comprises the steps of pile position digging, anchoring end construction performed by the cutter, freed end construction and breast board construction. The construction method is simple in operation, fast in construction speed, high in safety factor, economic and reasonable, and capable of improving the degree of mechanization of the construction, and safely, fast and economically finishing the construction in comparison with the traditional construction method under well geological conditions.

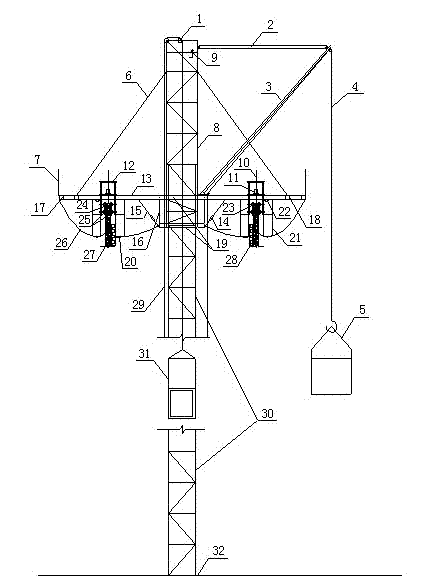

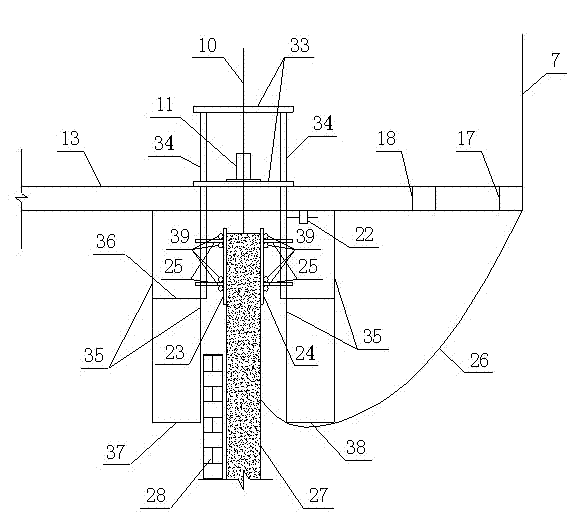

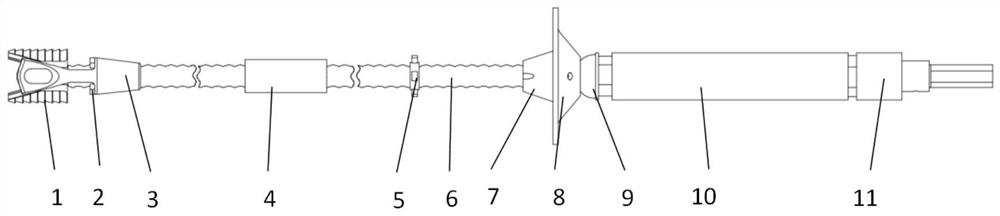

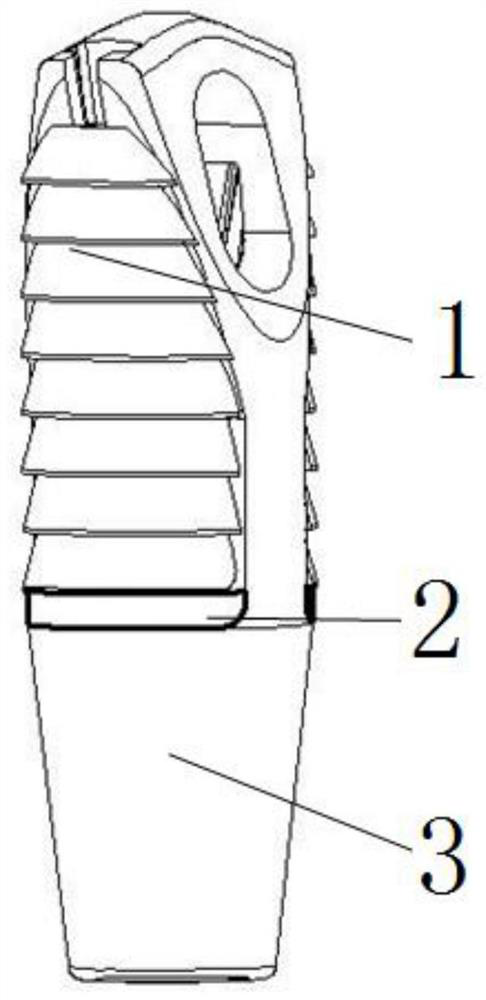

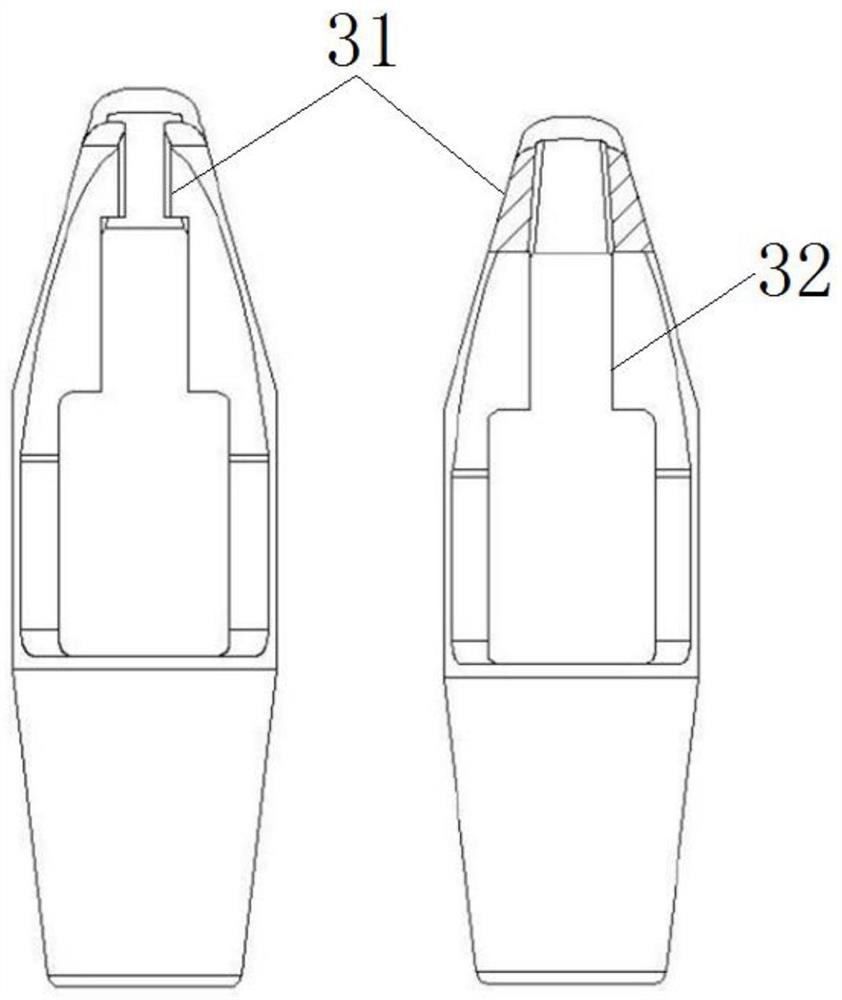

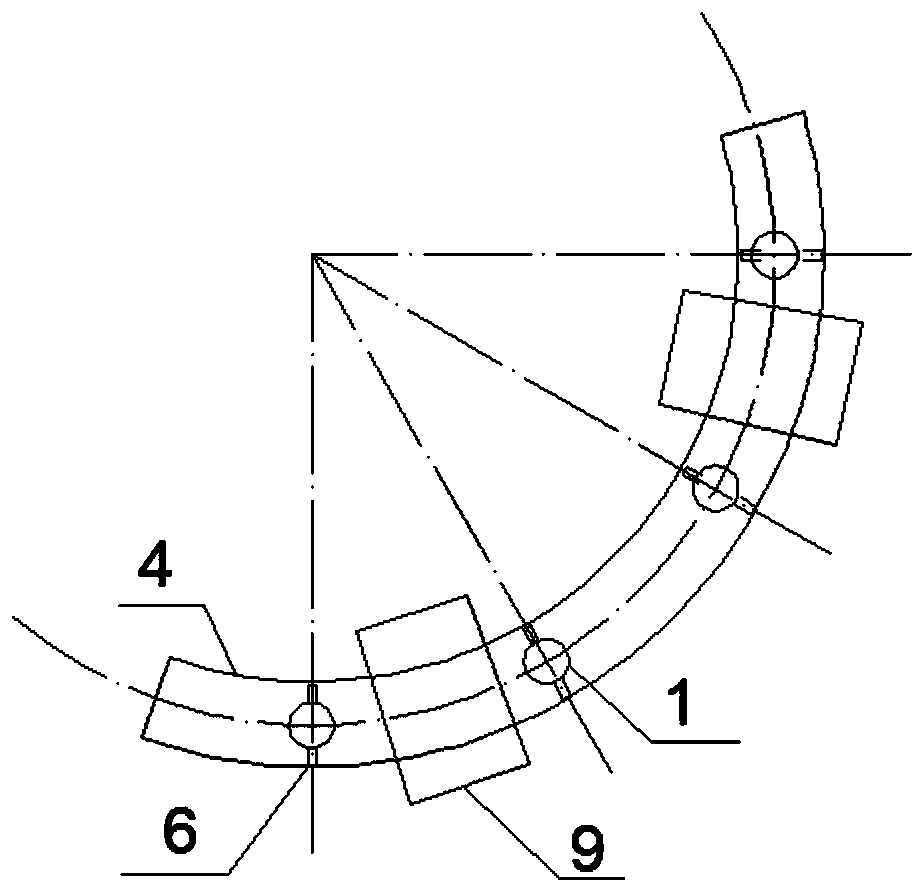

Mechanical method connecting channel construction method using pipe jacking technology

PendingCN113756825AHigh degree of construction mechanizationQuality improvementUnderground chambersTunnel liningSupporting systemArchitectural engineering

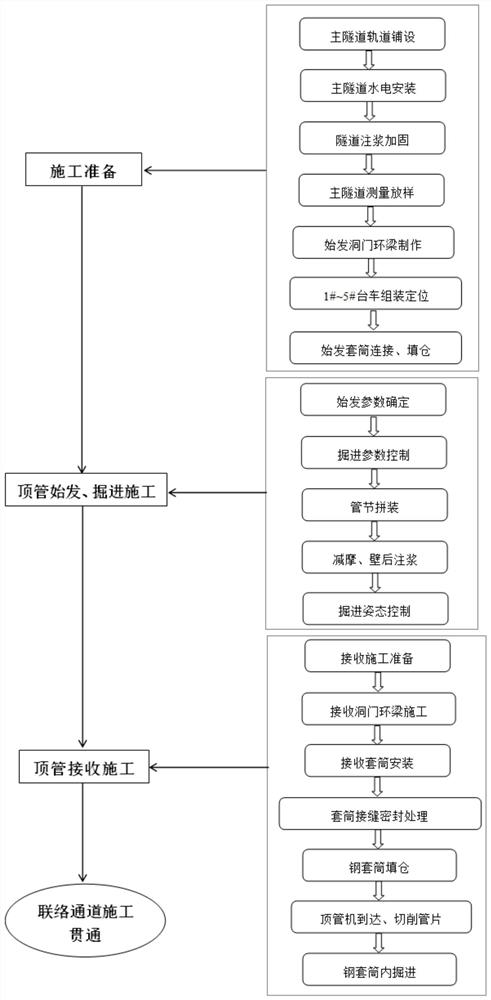

The invention relates to a mechanical method connecting channel construction method using a pipe jacking technology. The method comprises the steps: S1, conducting construction preparation; S2, starting pipe jacking and carrying out tunneling construction; and S3, conducting pipe jacking receiving construction. The method have the beneficial effects that the spliced connecting channel structure and the pipe jacking method construction method have the advantages of high construction mechanization degree, reliable quality, high speed, no soil body pre-reinforcement, low manufacturing cost and small environmental disturbance and the like. A small-diameter earth pressure balance pipe jacking machine and post-corollary equipment are integrally designed with a supporting system in a tunnel, tunneling, pipe piece splicing, deslagging, feeding and grouting in the tunnel construction process are achieved, and full-mechanical operation is achieved. An inner supporting system is provided with an automatic oil pressure adjusting device, the jacking force of a supporting oil cylinder is automatically adjusted along with tunnel stress changes, and automatic service is comprehensively achieved.

Owner:浙江杭海城际铁路有限公司 +2

Reinforcement and rescuing construction method used after landslide and collapse of soil slope

Provided is a reinforcement and rescuing construction method used after landslide and collapse of a soil slope. Firstly, steel bars are inserted at the positions of landslide and collapse of a soil slope; secondly, grouting holes are drilled in soft soil; thirdly, grouting materials are prepared for use; fourthly, the inserted steel bars are transversely bundled into a whole through steel wires, or the inserted steel bars are welded into a whole in an electric welding mode; fifthly, the sunken portion of the collapse is filled with plant fibers and leveled; finally, the prepared grouting materials are injected into the grouting holes and the place filled with the plant fibers at high pressure through a grout injecting machine, and after the grouting materials are solidified, a fixed whole of the soil slope can be formed after landslide and collapse. According to the method, landslide soil does not need to be wiped out; the soft soil is changed into a tight rock-similar body through the grout injecting technology, and the plant fibers and the grouting materials form the stable and tensile concrete whole. Materials can be obtained conveniently; the mechanization degree of construction is high, construction speed is high, and the reinforcing effect is good. The method is suitable for reinforcement and recuing after landslide and collapse of soil slopes around mountainous area highways, railways, bridges and building structures.

Owner:兰泽民

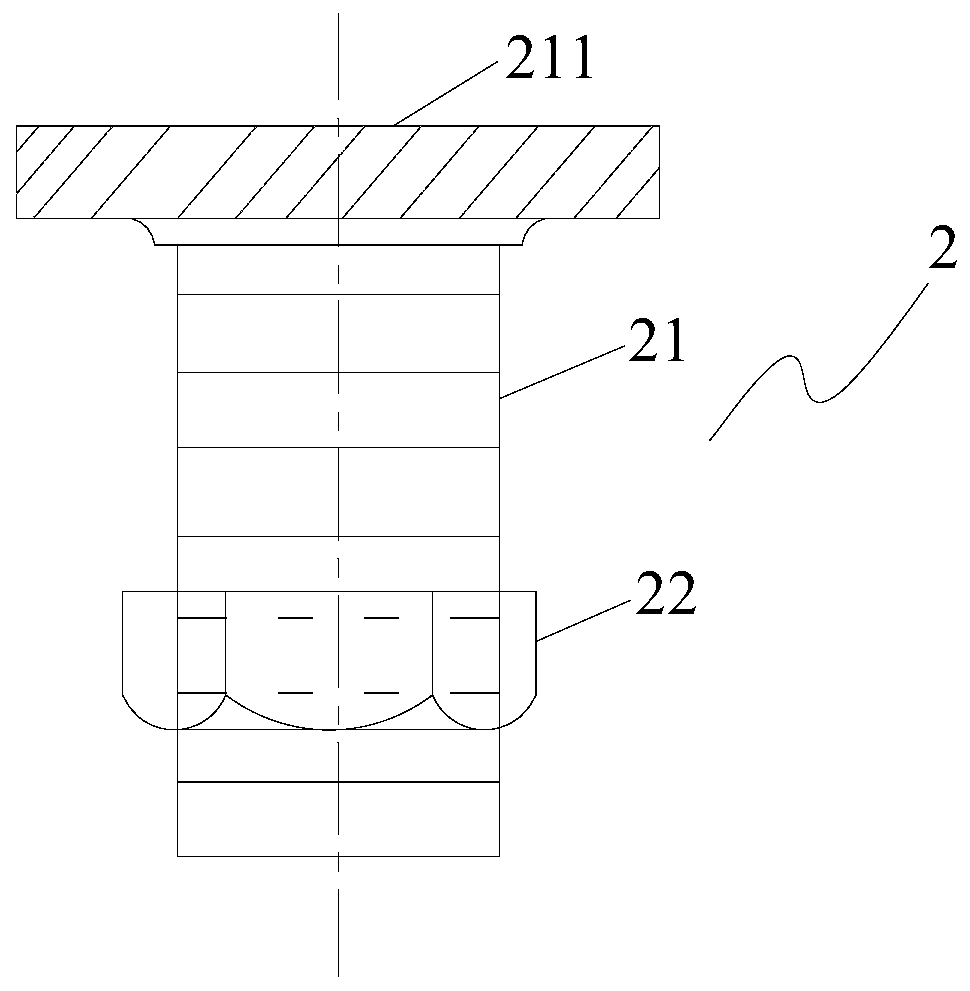

Installation method of caisson

InactiveCN105604078AHigh degree of construction mechanizationReduce the amount of manual workCaissonsStructural engineeringEngineering

The invention discloses an installation method of a caisson. The method is technically characterized by comprising the steps that firstly, a base groove of the caisson is treated to enable the caisson to be effectively connected with a foundation; secondly, after the base groove of the caisson is formed, the position foundation needing to be treated is filled with or leveled with bagged sand according to actual conditions on a construction site, and caisson primary positioning and initial installation are carried out; thirdly, caisson jacking and leveling work is performed, and the caisson is jacked up to be disengaged from a foundation bed; fourthly, the periphery of the caisson is temporarily plugged; fifthly, a booster pump is adopted for carrying out grouting treatment on the bottom of the caisson through a grouting hole preserved in the bottom of the caisson, a caisson foundation is laid after forming, a jacking mechanism is disassembled after mortar forms the strength, and grouting treatment is carried out inside a jacking pipeline; sixthly, a temporary plugging structure on the periphery of the caisson is dug out, and caisson installation is finished. By the adoption of the technical scheme, the construction mechanization degree is high, construction efficiency is improved, the construction cost is reduced, influences on the environment are reduced, and operation safety and environmental protection capability are improved.

Owner:CCCC FIRST HARBOR ENG +1

Assembled communication channel structure and its construction method

ActiveCN106948833BGuaranteed waterproof performanceReduce disturbanceUnderground chambersTunnel liningAisleBuilding construction

The invention discloses an assembling type connecting aisle structure and a construction method thereof. The assembling type connecting aisle structure is characterized by comprising a shield tunnel concrete segment, a shield tunnel composite segment, an inter-segment connecting system, a connecting aisle steel segment and a connecting aisle concrete segment. The shield tunnel composite segment comprises a composite segment steel segment section, a composite segment concrete segment section and a reserved reinforcing body box, the outer side of the composite segment steel segment section is connected with the shield tunnel concrete segment through connecting bolts in an assembling mode, the inner side of the composite segment steel segment section is integrally connected with the composite segment concrete segment section, and the inner side of the composite segment concrete segment section is connected with the connecting aisle steel segment through the inter-segment connecting system. According to the construction method, the mode of starting with a pipe jacking method and advancing with a shield method is adopted. The assembling type connecting aisle structure and the construction method thereof have the advantages the quality is controllable, the integrality with a shield tunnel is high, and joint waterproofness is high; and the starting problem of narrow and small spaces is solved, and the construction axis of a connecting aisle can also be easily controlled.

Owner:宁波用躬科技有限公司 +2

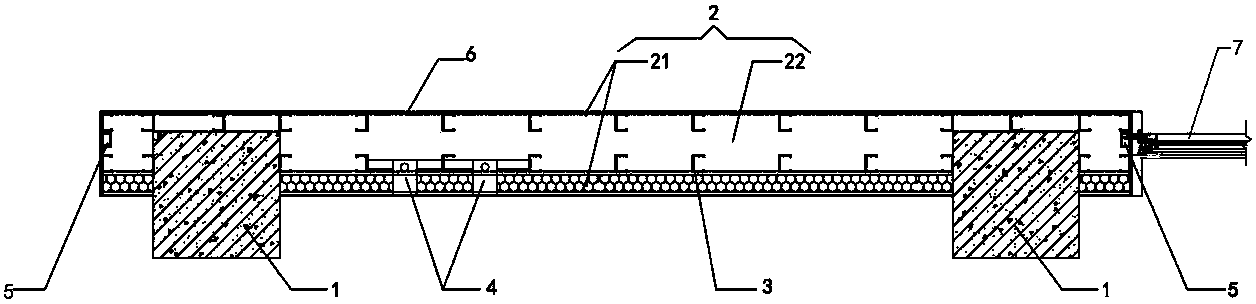

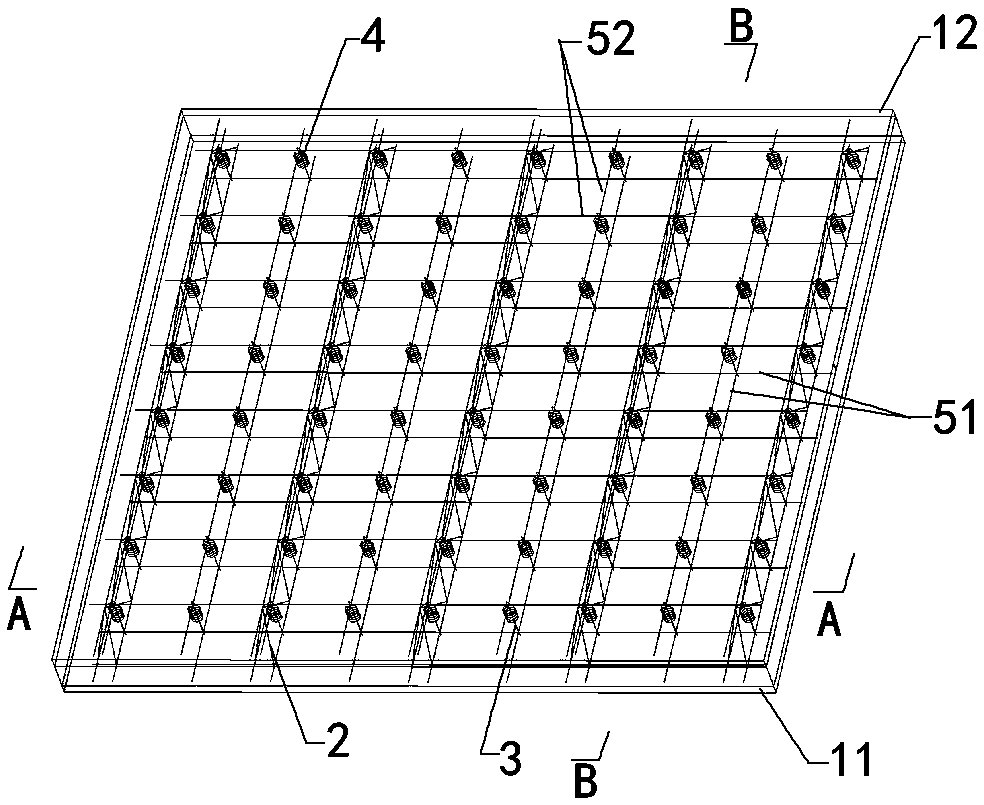

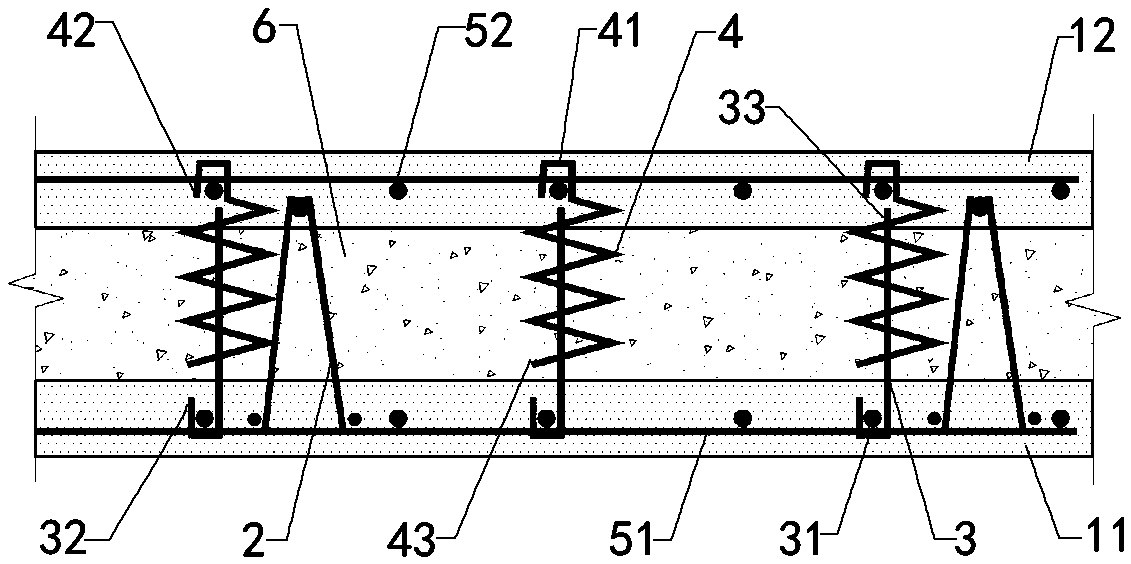

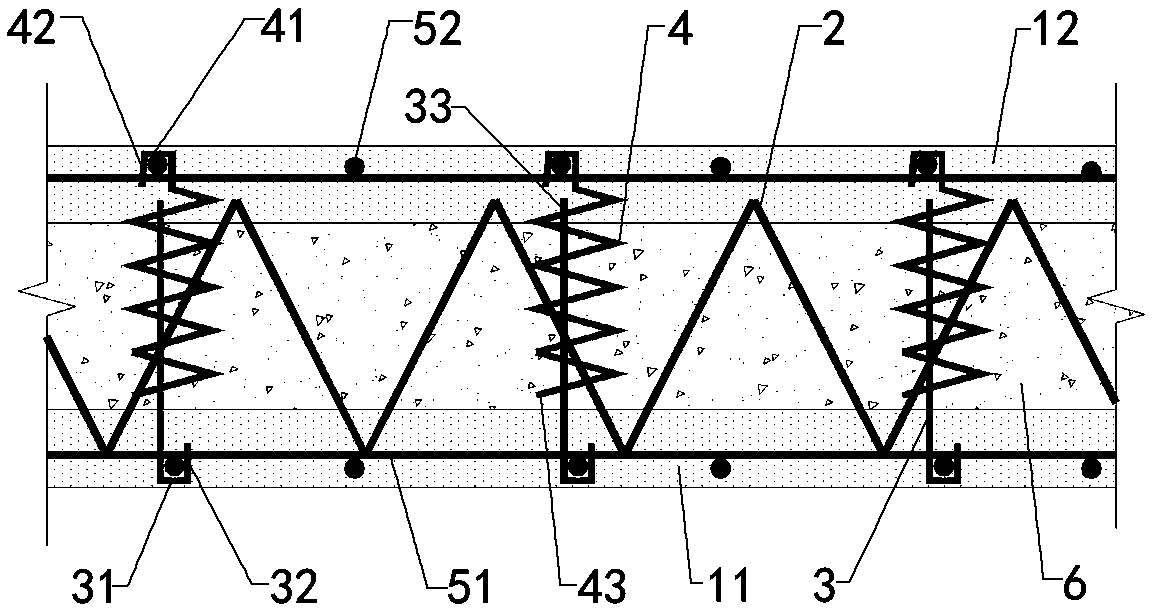

Double-sided superimposed shear wall with bidirectional connecting tensile reinforcements and construction method thereof

The invention relates to the technical field of superimposed shear walls and discloses a double-sided superimposed shear wall with bidirectional connecting tensile reinforcements and a construction method thereof. The superimposed shear wall with the bidirectional connecting tensile reinforcements comprises prefabricated panels on both sides of the shear wall and cast-in-place concrete between thetwo prefabricated panels, and further comprises the connecting tensile reinforcements arranged between the two prefabricated panels; the connecting tensile reinforcements comprise first tensile reinforcements and second tensile reinforcements, wherein the first tensile reinforcements and the second tensile reinforcements are arranged in pairs and overlapped, and are arranged perpendicular to theprefabricated panels. The double-sided superimposed shear wall with the bidirectional connecting tensile reinforcements is simple in structure, beneficial for mechanized and batch production, high inlateral restraint and good in anti-seismic performance.

Owner:CHINA INST OF BUILDING STANDARD DESIGN & RES

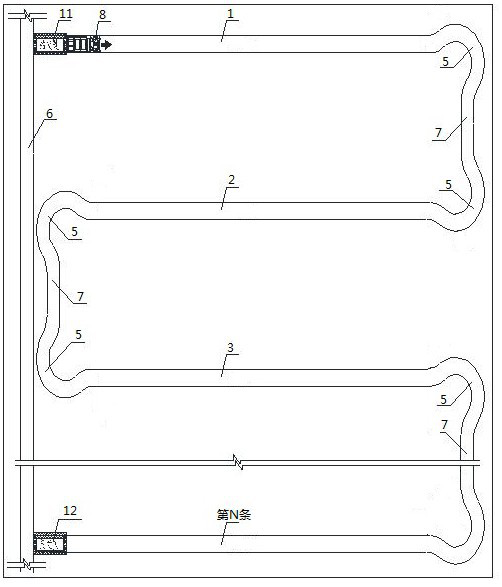

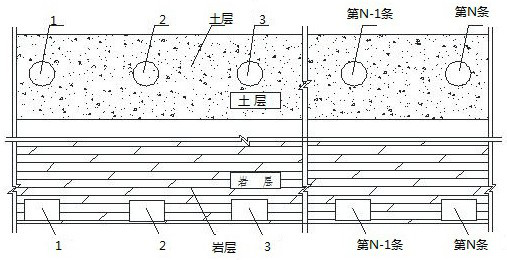

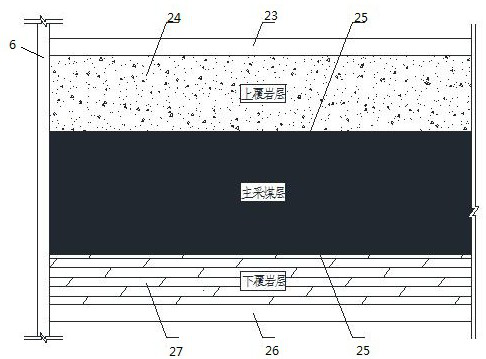

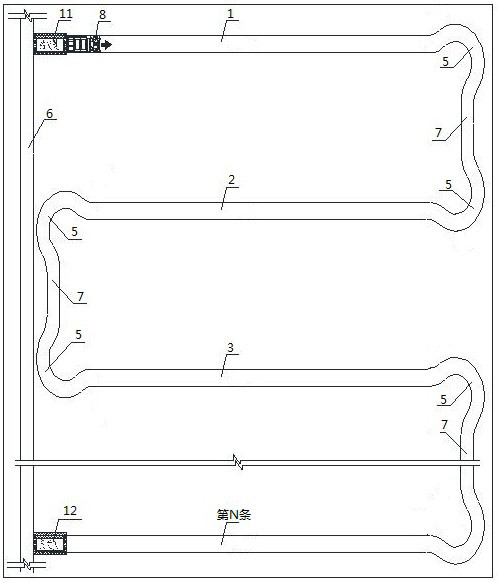

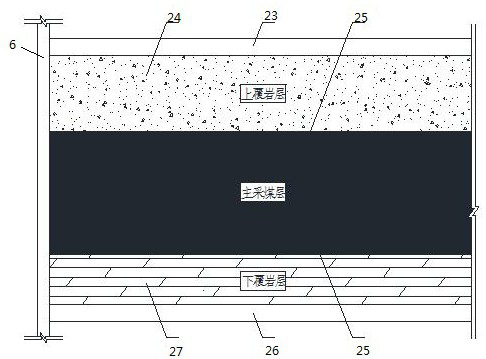

Construction method for continuous tunneling of coal mine TBM and coal mine TBM

The invention discloses a construction method for continuous tunneling of a coal mine TBM and the coal mine TBM. The problem that in the prior art, the working efficiency of rock roadway tunneling islow is solved. The construction method for continuous tunneling of the coal mine TBM comprises the following steps that (1), a main transportation roadway is longitudinally excavated in the one side of an area to be excavated; (2), a starting station and a receiving station which are transversely arranged are constructed at preset positions of the main transportation roadway; and (3) the coal mineTBM is hoisted to the starting station, and then continuous transverse excavation of a first roadway is carried out along a preset route. According to the construction method for continuous tunnelingof the coal mine TBM and the coal mine TBM, a method for the coal mine TBM to carry out small turning radius, reciprocating and continuous ceaseless rock roadway tunneling in a disassembling-free mode is proposed; and by means of the method, the coal mine rock roadway tunneling speed is at least increased by five times or above on the basis of a traditional tunneling speed, and the tunneling method has the advantages of being high in construction mechanization degree, high in tunneling working efficiency, good in roadway forming effect, high in work safety and the like and has high popularization value.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

Use method for inner die rack for pipe gallery construction

InactiveCN111691456ALower the altitudeChange support heightArtificial islandsForms/shuttering/falseworksElectric machineryEngineering

The invention discloses a use method for an inner die rack for pipe gallery construction. The inner die rack comprises a door frame, movable vertical columns, vertical column lifting support legs, side die plates, a top die plate, a translation driver, a transmission assembly and a motor, wherein the movable vertical columns are located at the two transversal sides of the door frame, and the topsof the movable vertical columns and the outer end of a top door beam of the door frame are slidably installed; the side die plates are installed on the movable vertical columns, the top die plate is installed on the top door beam of the door frame, the movable vertical columns are connected with the door frame at the inner sides of the movable vertical columns through the translation driver, and the movable vertical columns are driven to move through the translation driver, so that driving for the translation movement of the side die plates is realized; and one vertical column lifting supportleg is arranged at the bottom of each movable vertical column, and the height of the whole inner die rack is adjusted through the vertical column lifting support legs. During construction, the inner die rack is capable of automatically adjusting the positions of the side die plates and the own height, so that in-place installation working for the side die plates and the top die plate, and die release working are realized.

Owner:ERCHU CO LTD OF CHINA RAILWAY TUNNEL GRP +1

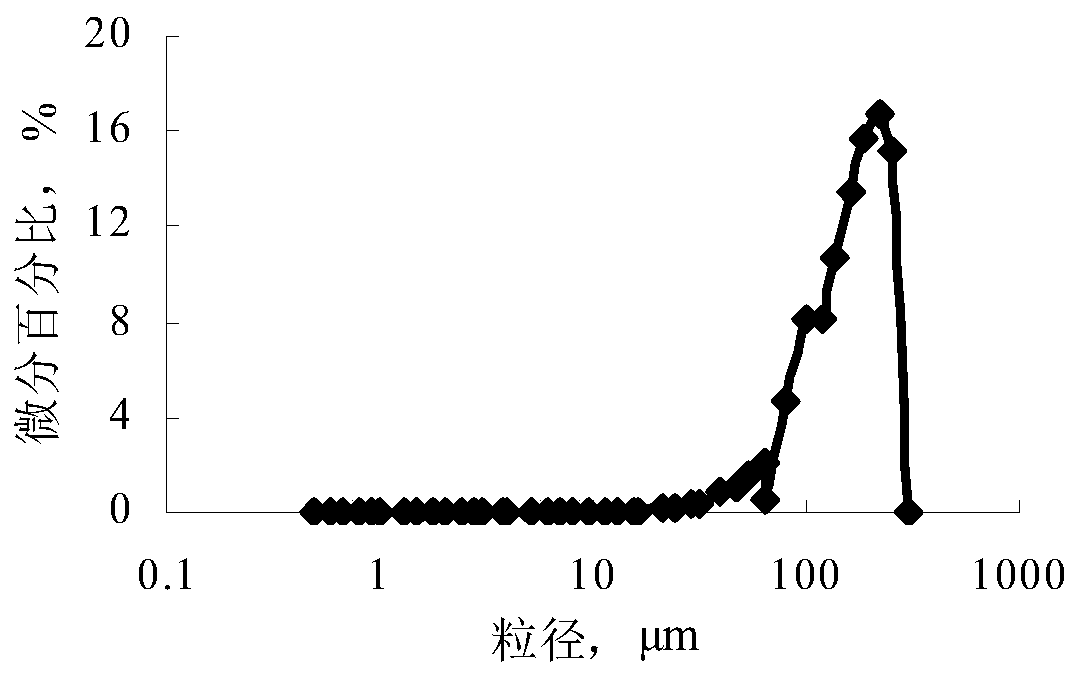

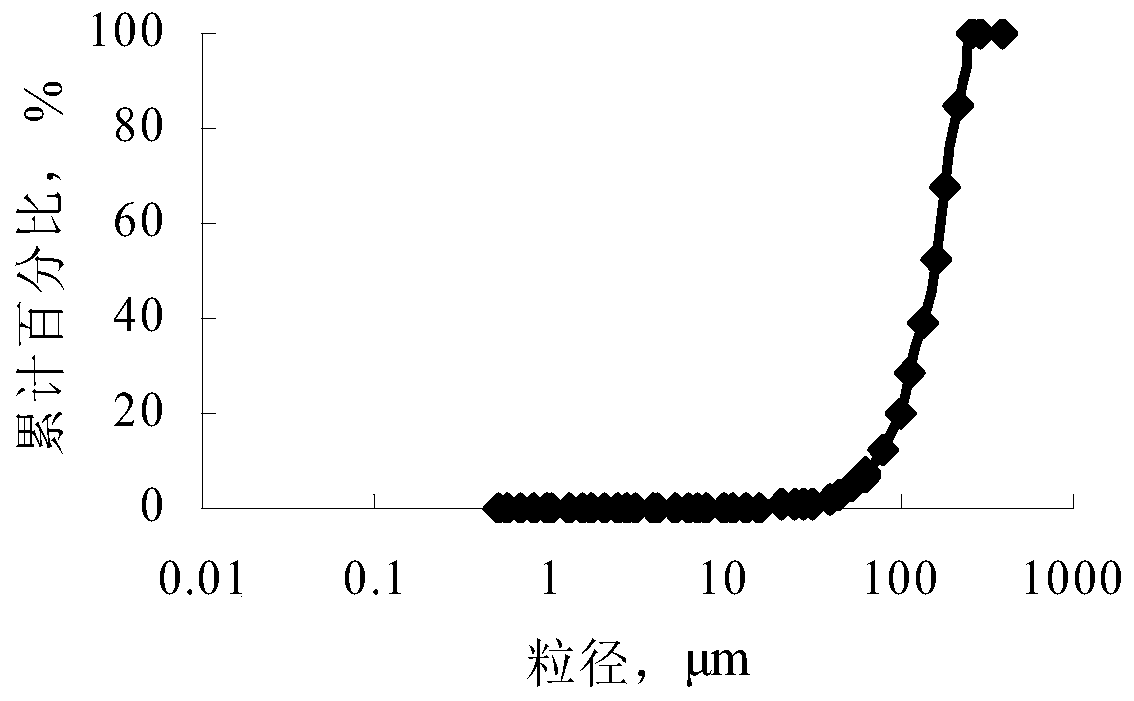

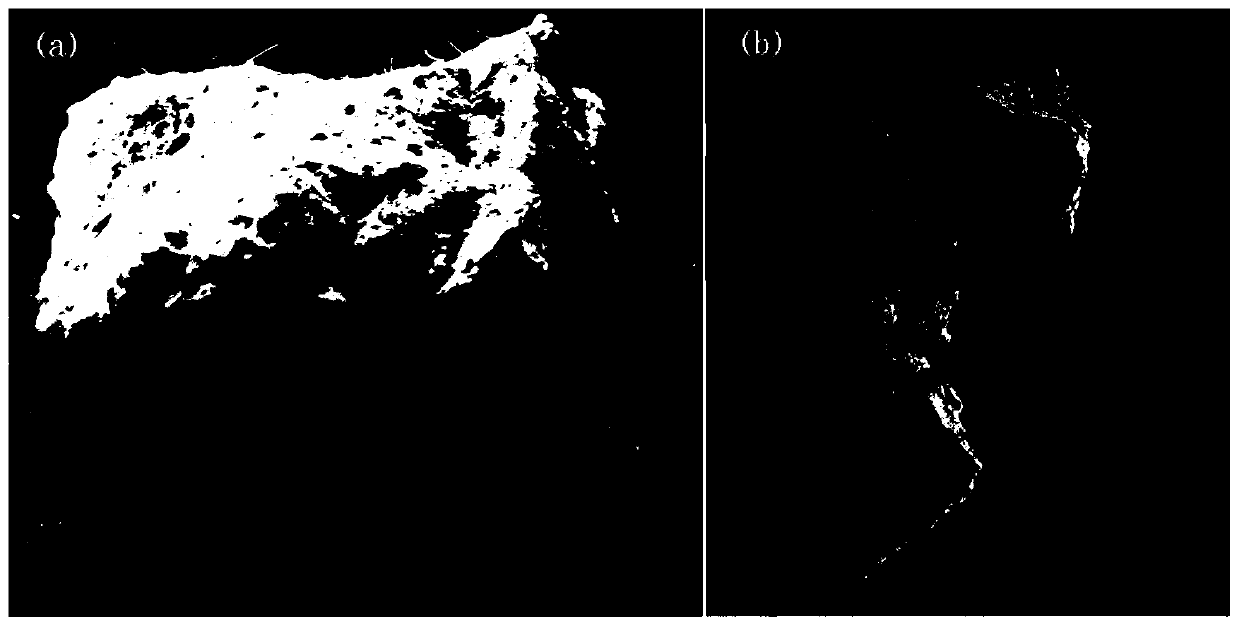

A plugging agent, plugging slurry and plugging construction method for drilling fractured leakage

ActiveCN107722954BRealize pluggingAvoid exacerbating leakageDrilling compositionSealing/packingFiberThermodynamics

The invention relates to a plugging agent and plugging slurry for drilling fractured leakage and a plugging construction method. The plugging agent is prepared from the following components in parts by weight: 80 to 85 parts of cement, 6 to 10 parts of floating beads, 6 to 10 parts of micro-silicon and 1 to 3 parts of asbestos fibers. The plugging agent for the drilling fractured leakage, disclosed by the invention, is characterized in that the cement, the floating beads, the micro-silicon and the asbestos fibers are compounded to form a main body of the plugging agent, wherein the asbestos fibers can be used as a bridge plug for bridging to fractures; the floating beads and the micro-silicon realize filling and plugging effects on the fractures; all the components are coordinated with oneanother, so that the plugging agent easily enters a leakage layer and realizes the comprehensive effects of serving as the bridge plug, bridging, filling and plugging; the plugging agent is especially suitable for the fractured leakage with the width of 3 to 10mm and leakage rate of 5 to 100m<3>; in addition, the plugging agent has the advantages of quick plugging effects, short operation periodand high success rate of plugging leakage.

Owner:中石化石油工程技术服务有限公司 +1

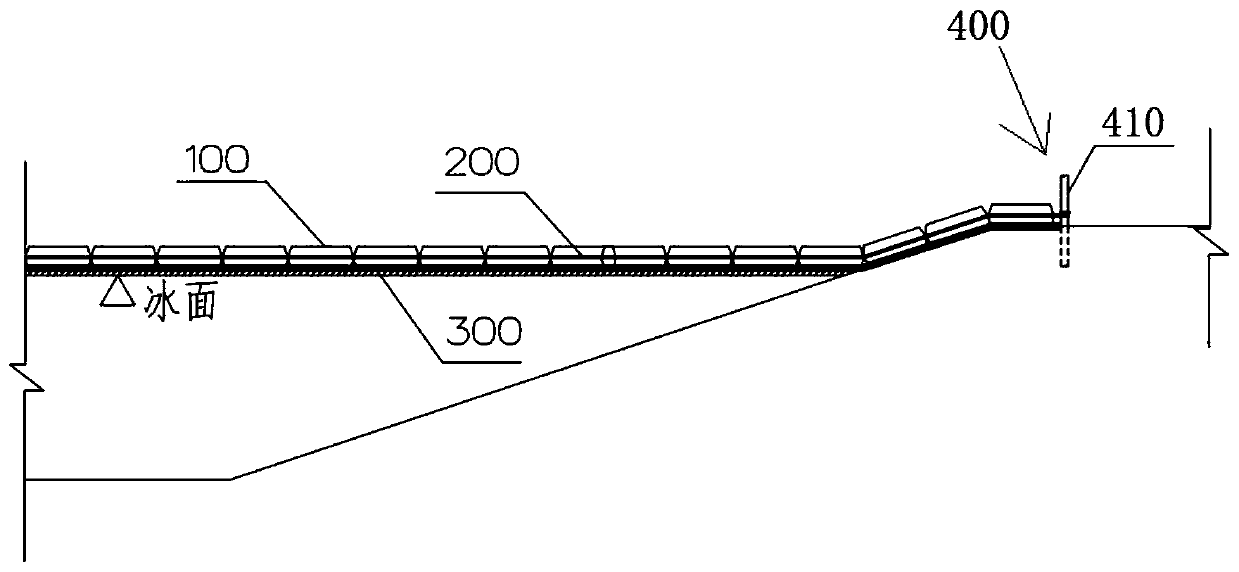

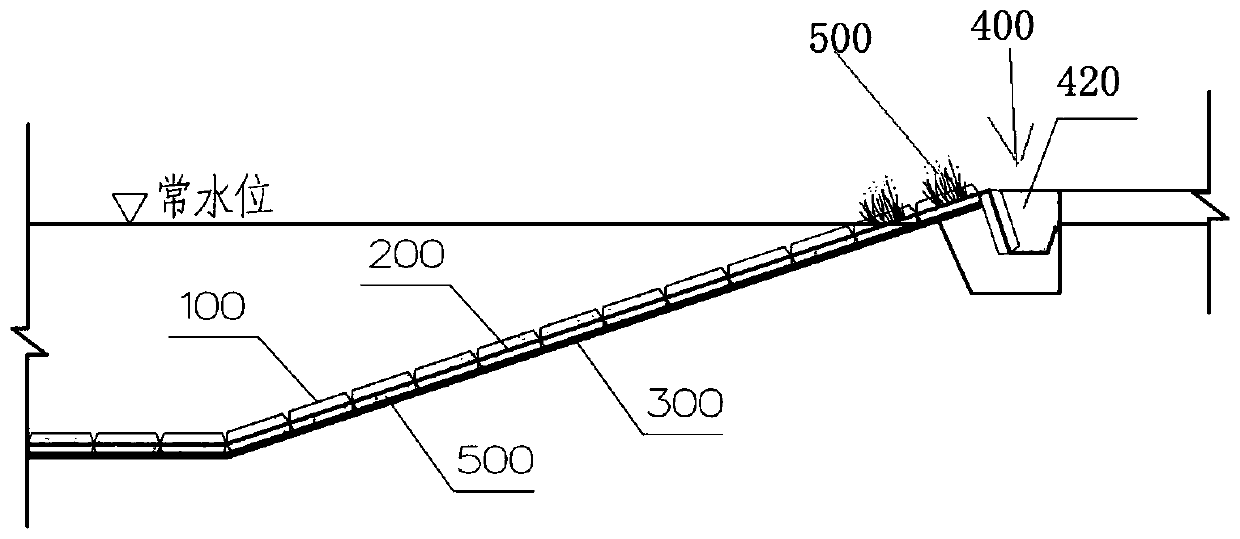

Flexible integral ecological slope protection structure for cold region and construction method of flexible integral ecological slope protection structure for cold region

PendingCN111455931AGood flexibility and integrityStrong ability to adapt to deformationCoastlines protectionReceptacle cultivationEnvironmental resource managementStructural engineering

The invention discloses a flexible integral ecological slope protection structure for a cold region. A method for the flexible integral ecological slope protection structure comprises a plurality of armor blocks being high in intensity and high in impact resistance, which are built on the slope, a pull resisting connecting facility for connecting the armor blocks, a filtering reversing soil protecting facility paved at the bottoms of the armor blocks, a positioning structure arranged to fix the pull resisting connecting facility, and a stuffing material stuffed in the armor blocks. The invention further discloses a construction method of the flexible integral ecological slope protection structure for a cold region.

Owner:SHANGHAI WATER ENG DESIGN & RES INST

High-fill side slope assembly type slope protection device and construction method thereof

PendingCN112211206AAchieve prefabricationEnsure construction safetyExcavationsBulkheads/pilesStructural engineeringGeotechnical engineering

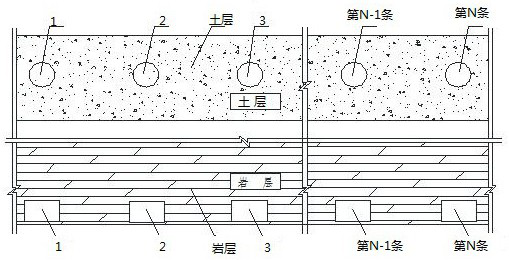

The invention discloses a high-fill side slope assembly type slope protection device and a construction method thereof. The slope protection device is composed of corrugated steel anti-slide piles, corrugated steel breast boards, anchor cables and anti-slide pile-breast board connectors. The corrugated steel anti-slide piles and the corrugated steel breast boards are spliced through the anti-slidepile-breast board connectors, and therefore the corrugated steel anti-slide piles and the corrugated steel breast boards form a whole and jointly resist soil filling pressure loads. The anchor cablespenetrate through the corrugated steel anti-slide piles to be anchored to bed rock, the anti-slide piles are prevented from deforming and toppling over under the load effect of soil filling, and theside slope reinforcing effect is achieved. By means of the device, the problems that existing concrete anti-slide piles and breast boards are large in construction risk, long in period and low in mechanization degree can be effectively solved.

Owner:SHENYANG JIANZHU UNIVERSITY

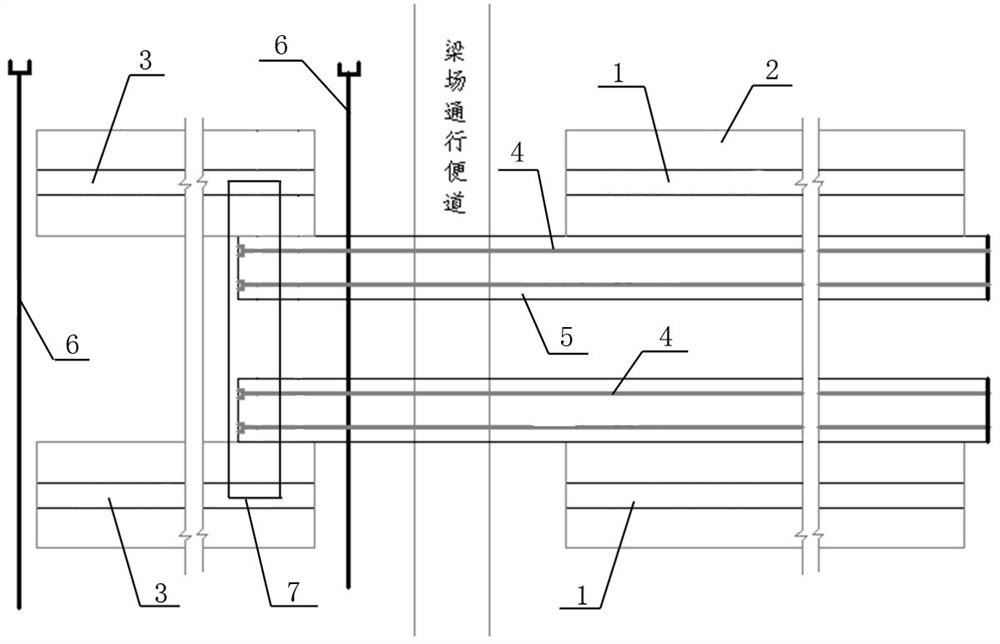

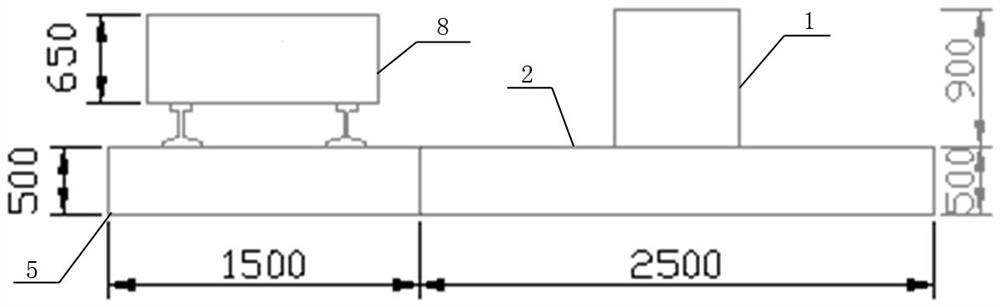

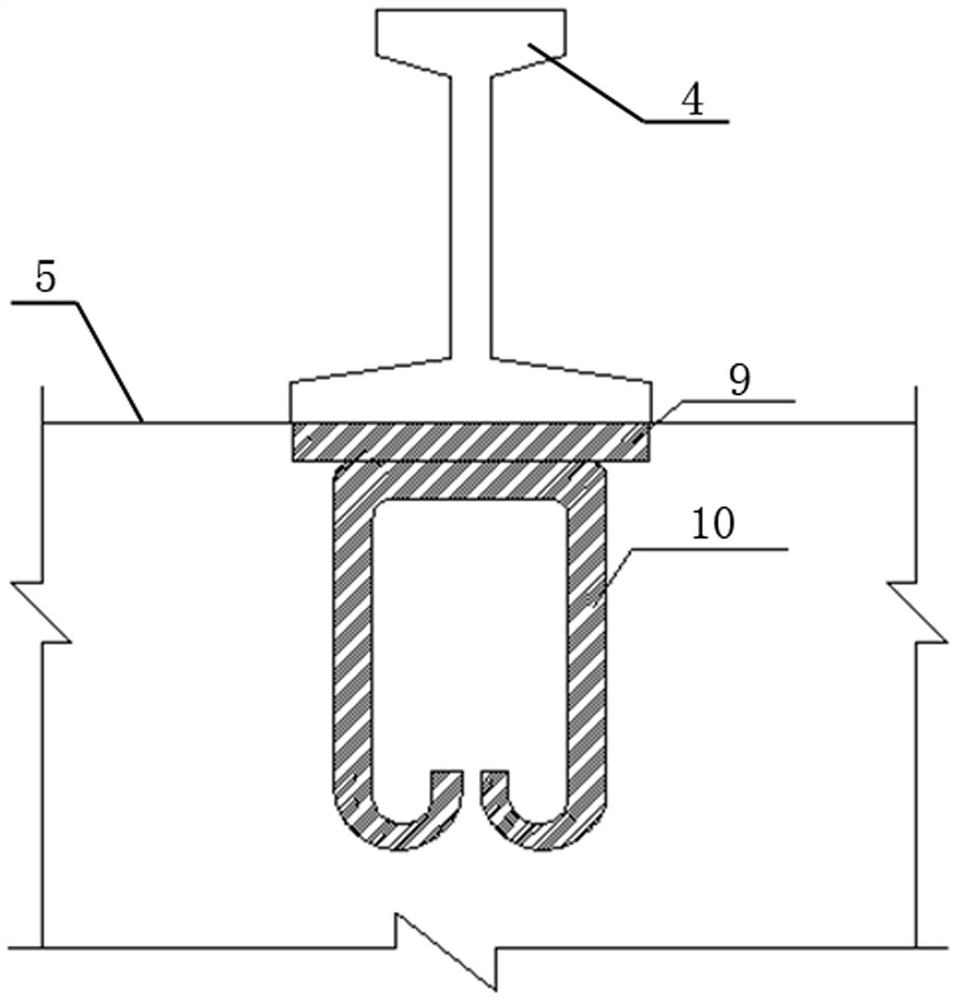

The Construction Method of Transversely Moving the Beam by the Double Track Trolley

InactiveCN110509424BRealize horizontal beam shiftingIncrease storage capacityCeramic shaping apparatusT-beamClassical mechanics

The invention relates to a method for moving a T-beam in a prefabricated beam factory, in particular to a construction method for laterally moving a beam by a double-track trolley. The invention adopts two beam-moving trolleys to move the beam laterally along the track. A jack is installed inside the beam moving trolley, which has the function of automatic lifting. First, move the trolley to just below the T-beam in the longitudinal beam storage area, and start the jack to lift the T-beam away from the original storage beam pedestal. After reinforcement and stability, the trolley pulls the T beam and runs along the transverse track to the transverse beam storage area. Then the jack releases the pressure, the T beam is in place, and the trolley returns to the empty space. The invention realizes horizontal beam shifting, overcomes the problems of cross construction of vertical and horizontal rails and the stability of T beams in the process of beam shifting, makes full use of the field width of the prefabricated beam factory, and improves the beam storage capacity of the prefabricated beam factory.

Owner:CHINA RAILWAY SIXTH GRP CO LTD +1

Reinforcement and emergency construction method after soil slope landslide collapse

Provided is a reinforcement and rescuing construction method used after landslide and collapse of a soil slope. Firstly, steel bars are inserted at the positions of landslide and collapse of a soil slope; secondly, grouting holes are drilled in soft soil; thirdly, grouting materials are prepared for use; fourthly, the inserted steel bars are transversely bundled into a whole through steel wires, or the inserted steel bars are welded into a whole in an electric welding mode; fifthly, the sunken portion of the collapse is filled with plant fibers and leveled; finally, the prepared grouting materials are injected into the grouting holes and the place filled with the plant fibers at high pressure through a grout injecting machine, and after the grouting materials are solidified, a fixed whole of the soil slope can be formed after landslide and collapse. According to the method, landslide soil does not need to be wiped out; the soft soil is changed into a tight rock-similar body through the grout injecting technology, and the plant fibers and the grouting materials form the stable and tensile concrete whole. Materials can be obtained conveniently; the mechanization degree of construction is high, construction speed is high, and the reinforcing effect is good. The method is suitable for reinforcement and recuing after landslide and collapse of soil slopes around mountainous area highways, railways, bridges and building structures.

Owner:兰泽民

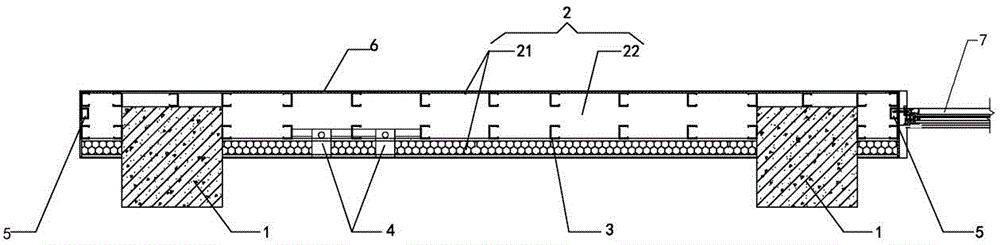

Lining equipment for pipe gallery construction

PendingCN111636477AChange support heightSimple structureArtificial islandsUnderground chambersElectric machineryStructural engineering

The invention discloses lining equipment for pipe gallery construction. The lining equipment comprises an inner mold frame and a lifting trolley for moving the inner mold frame in place; the inner mold frame comprises a door frame, movable stand columns, stand column lifting and supporting legs, side mold plates, a top mold plate, translation drivers, a transmission assembly and a motor; the movable stand columns are positioned on the two lateral sides of the door frame; the tops of the movable stand columns are slidably arranged on the outer end of a top door beam of the door frame; the sidemold plates are installed on the movable stand columns; the top mold plate is installed on the top door beam of the door frame; the movable stand columns are connected with the door frame at the innerside of the movable stand columns through the translation drivers; the movable stand columns are driven to move in a translation manner through the translation drivers, so that the side mold plates are driven to do translation movement; each stand column lifting and supporting leg is arranged at the bottom of the corresponding movable stand column; and the height of the whole inner mold frame isadjusted through the stand column lifting and supporting legs. During construction, the lifting trolley lifts the inner mold frame to move and to be preliminarily in place, and the positions of the side mold plates and the height of the inner mold frame are adjusted by combing with the inner mold frame, so that mold setting and demolding are achieved.

Owner:ERCHU CO LTD OF CHINA RAILWAY TUNNEL GRP +1

A construction method for pipe gallery

ActiveCN111733872BAuxiliary pouring and maintenanceImprove construction efficiency and qualityArtificial islandsUnderwater structuresRainy weatherSystems engineering

The invention discloses a construction method for a pipe gallery. The construction method adopts an outer formwork trolley, an inner formwork frame and a lifting trolley for moving the inner formwork set; the outer formwork trolley, the inner formwork set and the The combined use of lifting trolleys can effectively assist the operations at each stage of construction, realize the automatic positioning and automatic demoulding of the inner side formwork, inner top formwork and outer formwork, effectively reduce the labor intensity of workers, ensure the quality of concrete pouring, and improve the quality of pouring. It improves the degree of mechanization of the construction of the pipe gallery; at the same time, it has the function of rainproof operation, which effectively solves the difficulty of manual construction in rainy weather and reduces the risk of construction in rainy days. The structure is simple, the design is reasonable, the function is rich, and the movement is convenient, and it is suitable for the concrete construction of the pipe gallery.

Owner:中铁隧道集团二处有限公司 +1

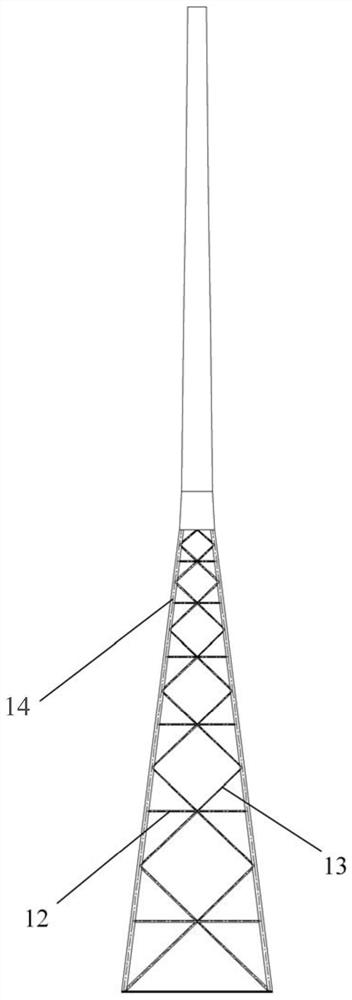

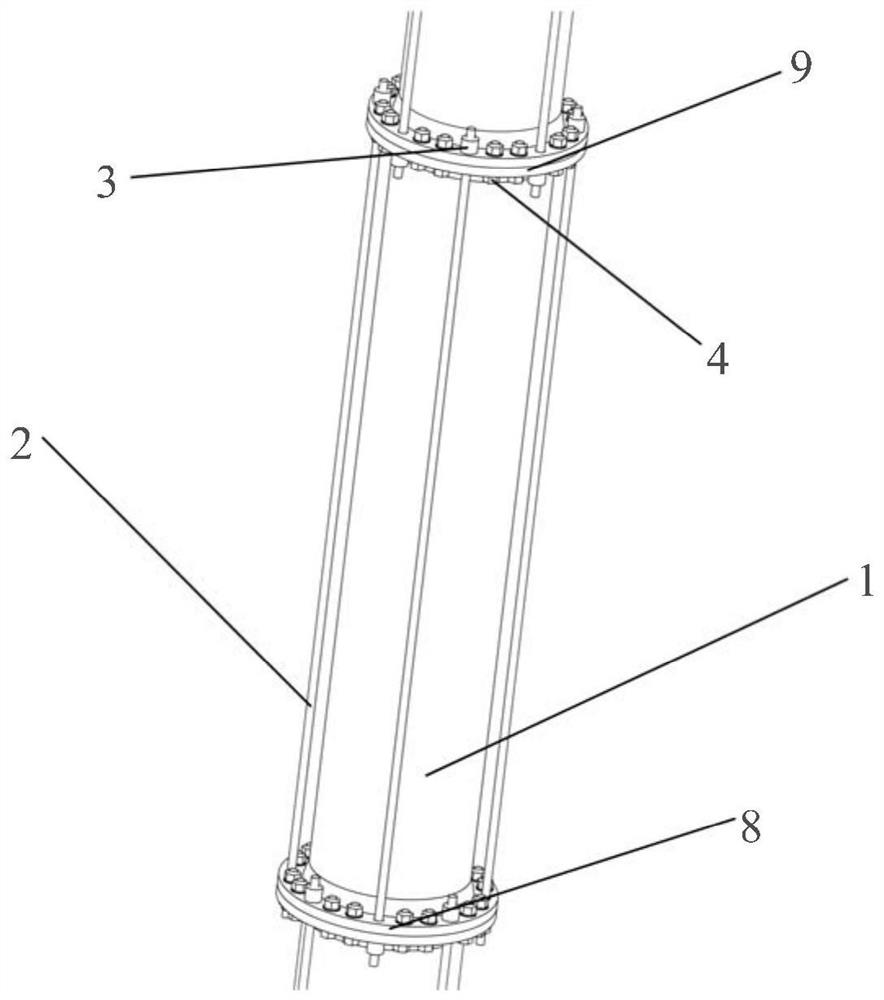

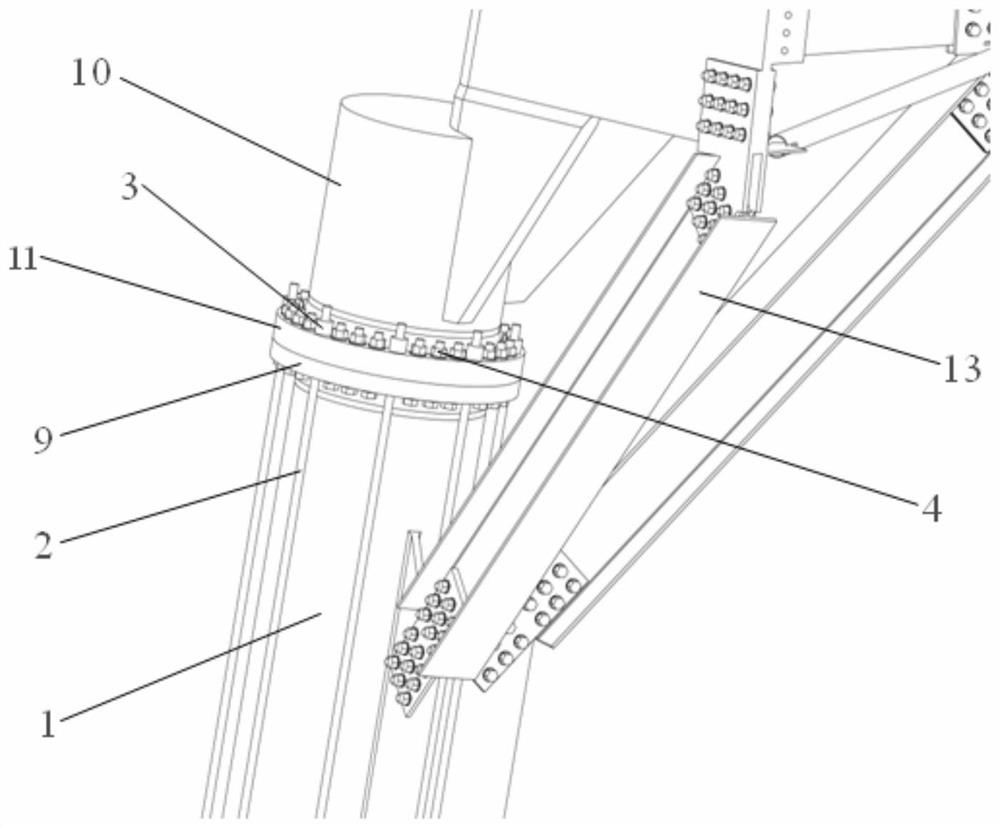

Framework type external prestress anti-fatigue steel tower structure

InactiveCN112283045AImprove fatigue lifeAvoid affecting the ultimate carrying capacityWind motor supports/mountsMachines/enginesPre stressArchitectural engineering

The invention discloses a framework type external prestress anti-fatigue steel tower structure. The framework type external prestress anti-fatigue steel tower structure comprises a plurality of steelpipe columns, wherein the steel pipe columns are connected into a tower column through flanges and bolts from bottom to top; an upper end flange plate and a lower end flange plate are arranged at thetop end and the bottom end of each steel pipe column respectively; a prestress anchor cable is arranged outside each steel pipe column; an upper anchor point of the prestress anchor cable outside eachsteel pipe column penetrates through the upper end flange plate of the steel pipe column and the lower end flange plate of the adjacent previous steel pipe column and is fixed above the lower end flange plate of the adjacent previous steel pipe column through an anchor head; and a lower anchor point of the prestress anchor cable outside each steel pipe column penetrates through the lower end flange plate of the steel pipe column and the upper end flange plate of the adjacent next steel pipe column and is fixed below the upper end flange plate of the adjacent next steel pipe column through ananchor head. According to the steel tower structure, the prestress anchor cables are mounted outside the steel pipe columns, so that the steel tower structure is simple and convenient to mount and convenient to maintain.

Owner:QINGDAO HUA STRONG ENERGY TECH CO LTD

A construction method for coal mine tbm continuous roadway digging and coal mine tbm

ActiveCN111794760BFlexible turningImprove excavation efficiencyTunnelsContinuous/uninterruptedMining engineering

The invention discloses a coal mine TBM continuous roadway excavation construction method and a coal mine TBM, which solves the problem of low work efficiency of rock roadway excavation in the prior art. The present invention is a construction method for coal mine TBM continuous roadway excavation, the steps are as follows: S1: Excavate the main transport roadway longitudinally on one side of the area to be excavated; Station and receiving station; S3: Hoist the coal mine TBM to the starting station, and then carry out continuous lateral excavation of the first rock roadway along the preset route. The present invention proposes a method for coal mine TBM to carry out small turning radius, reciprocating, continuous uninterrupted rock roadway excavation without dismantling the machine. The method makes the coal mine rock roadway excavation speed at least on the basis of the existing traditional roadway speed. Increased by more than five times, the roadway digging method has many advantages such as high degree of construction mechanization, high excavation work efficiency, good roadway forming effect, high operation safety, etc., and has high promotion value.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

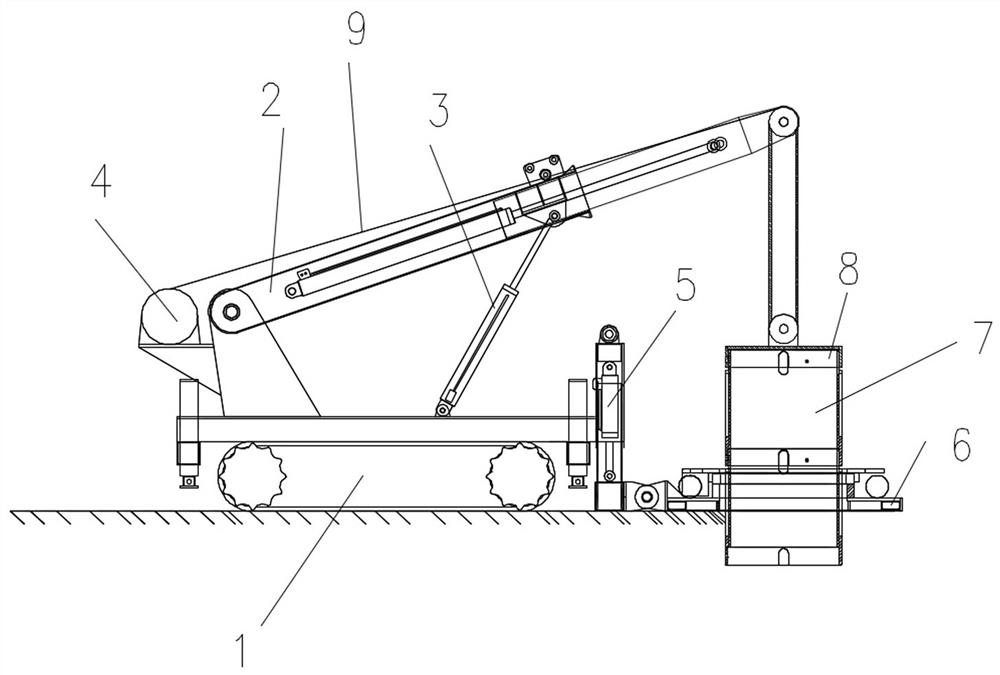

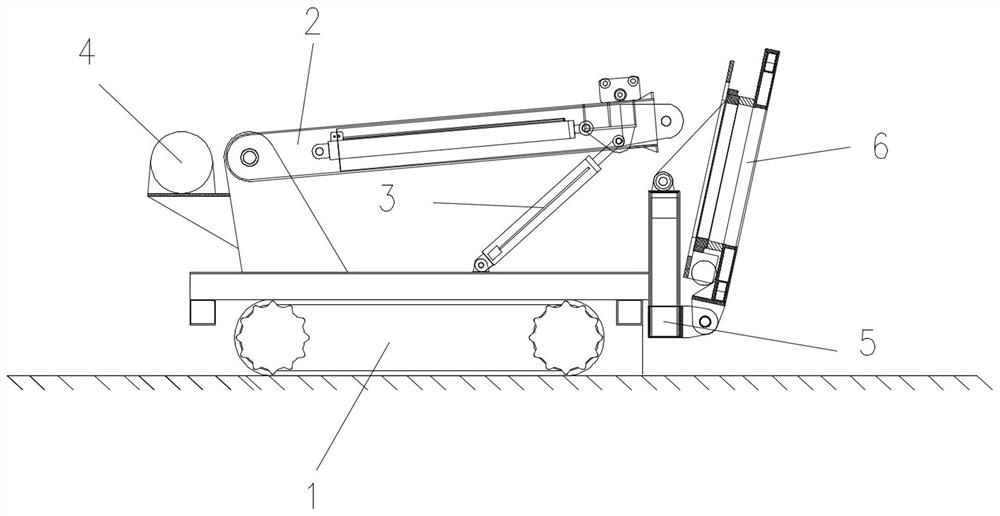

Tube drawing bench for construction in underground narrow space and construction method

The invention discloses a tube drawing bench for construction in an underground narrow space and a construction method. The tube drawing bench comprises a traveling system and a tube drawing system, wherein the traveling system comprises a traveling chassis, a main arm, a lifting arm and a tube drawing winch, the tube drawing system comprises a tube twisting disc retracting and releasing structure, a tube twisting disc, a protective cylinder and a protective cylinder receiving disc, the protective cylinder receiving disc is connected with the main arm through a connecting rope, the tail end of the connecting rope is connected to the tube drawing winch, the protective cylinder is connected to the bottom end of the protective cylinder receiving disc, the tube twisting disc is connected to the tube twisting disc retracting and releasing structure, and the tube twisting disc retracting and releasing structure is arranged outside the traveling chassis. According to the tube drawing bench, the sectionally-arranged protective cylinders are matched with the main arm with the shortened length, so that the overall height of the tube drawing bench is reduced, the construction requirement for tube drawing in an underground narrow space is met, the tube twisting disc is arranged to repeatedly twist the protective cylinder in the pulling-out process to reduce the friction force during lifting, and the protective cylinder is stably and efficiently pulled out under the combined action of filing and upward pulling.

Owner:BCEG CIVIL ENG

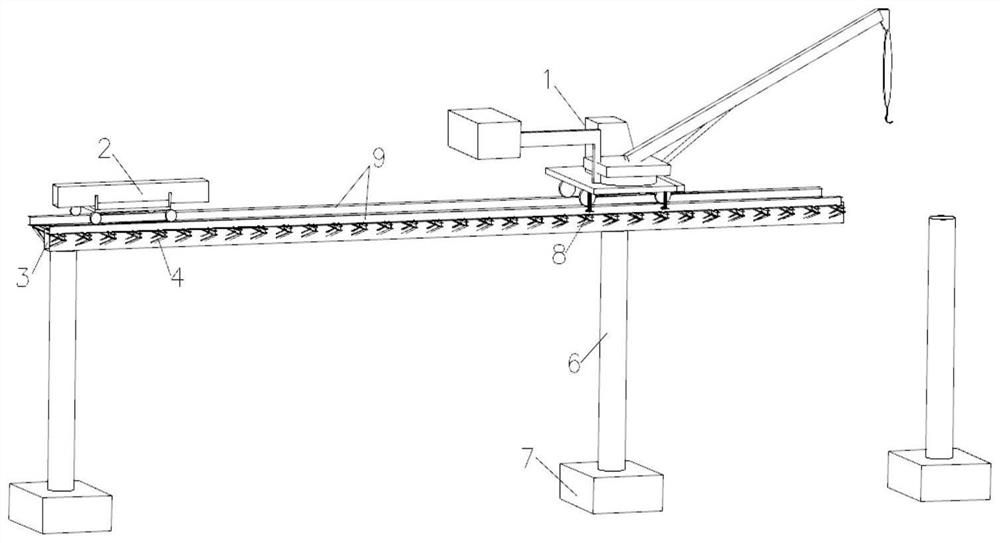

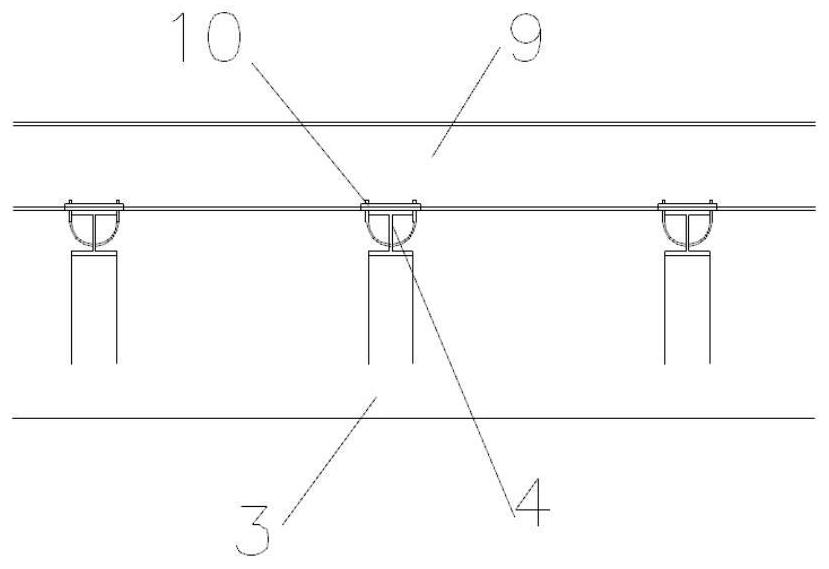

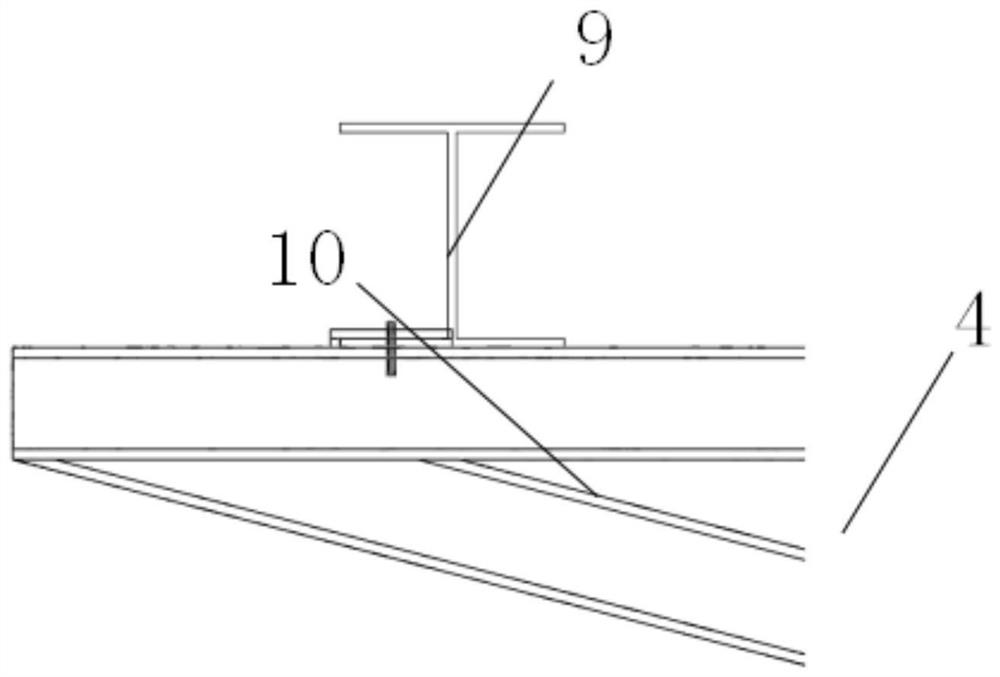

Mountain pedestrian path excavation-free mechanical construction method

PendingCN114427199AImprove construction safety and qualityHigh degree of construction mechanizationBridge structural detailsFoundation engineeringTrackwayArchitectural engineering

An excavation-free mechanical construction method for a mountain pedestrian path comprises the steps that a bridge deck starting section footpath and a bridge deck track are installed at an entrance of a construction section, and a bridge deck crane and a beam transporting trolley are installed on a bridge deck of the starting section. The bridge deck crane is driven to the top of the pre-installed steel pipe crossing column, and the bridge deck crane is anchored; the remote control beam transporting trolley transports the components to the operation range of the bridge deck crane from the entrance through the bridge deck track, and the bridge deck crane lifts the components from the beam transporting trolley for steel pipe column installation; then sequentially installing a middle-span section steel beam, a column top section steel beam, a secondary component and a track; according to the method, the installed mountainous region pedestrian path bridge floor is used as an equipment hoisting operation foundation and a driving transportation channel, so that the influence of the original natural environment is avoided, and the purpose that the whole line is mechanically constructed without excavating and damaging a mountain body is achieved.

Owner:中建五局第三建设有限公司

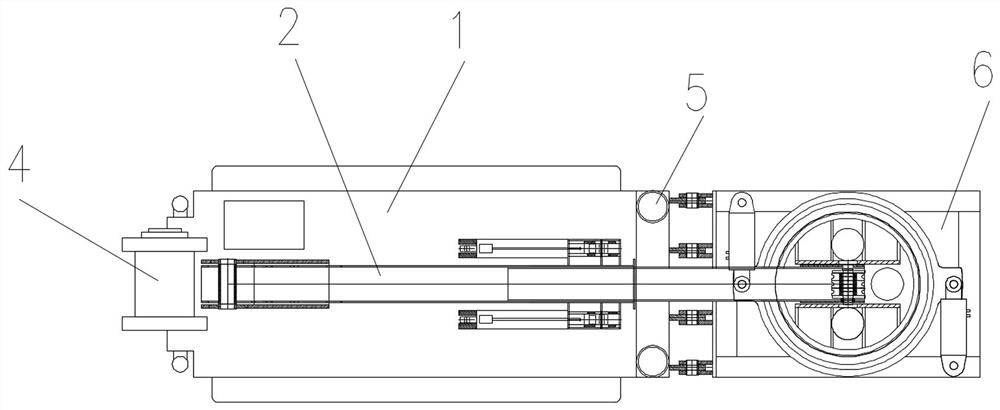

Extended anti-stripping prestressed hollow grouting anchor rod and its supporting method

The invention discloses an extended anti-stripping prestressed hollow grouting anchor rod and its supporting method, which comprises an anchor head and an anchor rod body. Block expansion shell clips, wedge-shaped grooves and T-line grooves are symmetrically arranged on the wedge head in the expansion shell, and wedge-shaped wings and T-line wings respectively matched with wedge-shaped grooves and T-line grooves are arranged on the expansion shell clips , a grout stopper, a backing plate, a spherical nut and a prestressing device are sequentially arranged at the end of the anchor rod body. The present invention can effectively prevent the occurrence of the phenomenon that the expansion shell clip is pulled away from the anchor rod and falls off from the inner wedge head of the expansion shell when the pretightening force is applied; the present invention installs one or more The fixer for fixing the position of the anchor body and the anchor hole can overcome the problem that the super-long anchor rod is not easy to be centered; the present invention applies prestress by mechanical means, effectively overcoming the defects in the prior art of simply relying on manpower to apply prestress.

Owner:CHINA RAILWAY LONGCHANG MATERIALS

A kind of metallurgical industry furnace body ring bolt installation method

ActiveCN107489163BImprove efficiencyImprove installation accuracyFoundation engineeringMetallurgical industryCushion

The invention discloses an annular bolt installation method for a metallurgical industry furnace body, and belongs to the field of metallurgical engineering equipment installation and civil engineering cooperation. For the problems that in the prior art, the device installation is complex, precision is poor and labor hours are consumed, the annular bolt installation method for the metallurgical industry furnace body is provided. The annular bolt installation method includes the following steps that A, a bolt system is manufactured and segmented, and all bolts are divided into multiple symmetrical systems, and each system comprises multiple bolts and fixing anchor plates; B, fixing welding pieces of supporting frames below the bolt systems are embedded in a base concrete cushion layer in advance and poured on the upper surface of the cushion layer; C, each bolt supporting frame is arranged in place along the circumference, the top elevation of each bolt supporting frame is adjusted, and the bolt supporting frames are welded to all embedded parts around the bolt systems in the cushion layer; D, the bolt systems are sequentially installed on the supporting frames, and the top elevation and perpendicularity of the foundation bolts of all the system bodies are fine adjusted; E, the bolt system bodies are welded and installed to form the whole annular bolt system; F, the bolt system bodies are subjected to concrete pouring; and G, acceptance inspection is conducted. The annular bolt installation method is easy to install, high in precision and high in efficiency.

Owner:马鞍山钢铁建设集团有限公司

The construction method of the integrated structure of anti-seismic, sound insulation and anti-crack of the inner and outer walls of the enclosure structure

InactiveCN103883022BImprove insulation effectLow costWallsBuilding material handlingIsolation effectKeel

Disclosed are a building envelope inner and outer wall anti-seismic and sound insulation anti-cracking integrated structure and a construction method of the structure. An outer wall is connected with the outer side of a frame column to form an integrated building envelope surrounding the frame column, one part of the frame column is embedded in the outer wall, the outer wall is a cast-in-place sandwich wall, the outer wall is filled with light porous inorganic core materials, a lightgage steel joist in the core materials is anchored with face plates on the two sides, the outer wall is connected with the inner wall through connecting ribs, and a reinforcing keel is arranged on the connecting portion. According to the structure, containment and heat preservation are integrated, connection between the cast-in-place light inorganic heat preservation composite outer wall and the constructed inner wall is successfully achieved, the good heat preservation, sound isolation and deformation anti-cracking treatment is achieved, industrial wastes are recycled to be used as raw materials to form nonflammable inorganic foam heat preservation slurry, and due to the rich porous structure in the slurry, the slurry has the excellent heat preservation and sound isolation effects. According to the structure and the method, form removal is not required, construction is easy, the forming speed is high, maintenance is not needed, flexible and continuous casting can be achieved, the building construction efficiency is improved by 30 percent, and the cost is reduced by more than 10 percent.

Owner:CHINA CONSTR SECOND ENG BUREAU LTD

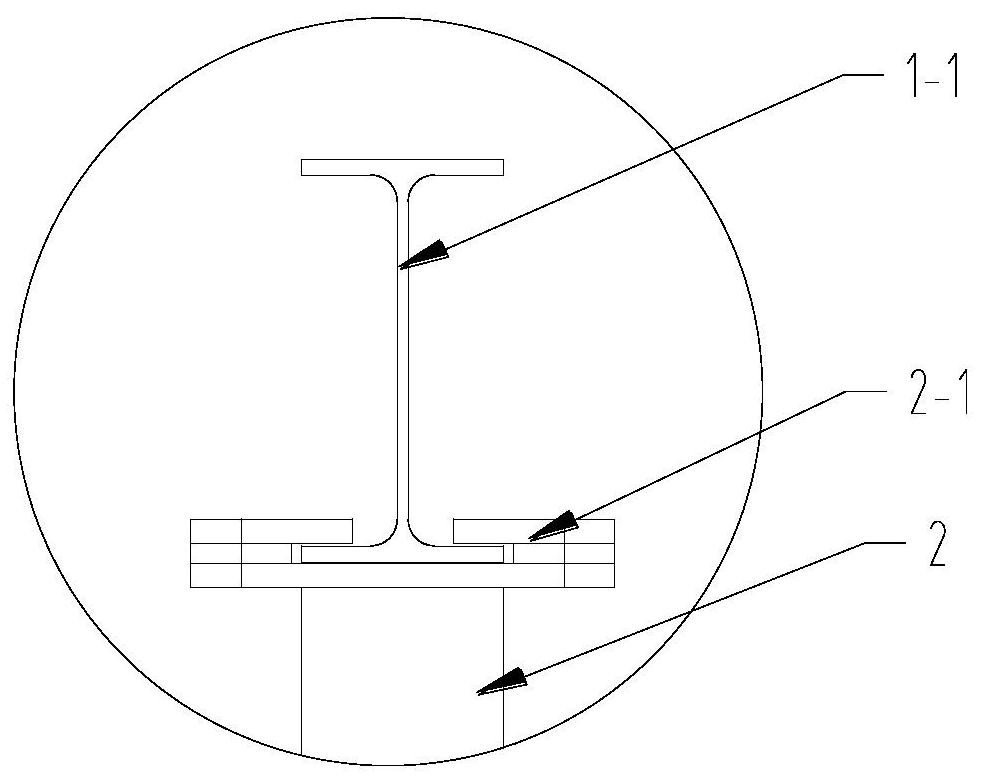

beam foundation structure

InactiveCN104762986BLight weightHigh degree of construction mechanizationFoundation engineeringArchitectural engineeringEngineering

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER +6

Mechanical equipment for concrete pipe gallery construction

PendingCN111636478AChange support heightSimple structureArtificial islandsUnderwater structuresArchitectural engineeringMechanical equipment

The invention discloses mechanical equipment for concrete pipe gallery construction. The mechanical equipment comprises an inner form formwork and a lifting trolley used for moving the inner form formwork in place, wherein the inner form formwork comprises a portal frame, movable stand columns are arranged on the two sides of the portal frame, side form plates are installed on the movable stand columns, the movable stand columns are connected with the portal frame through translation drivers, a top form plate is mounted at the top of the portal frame, stand column lifting supporting legs are arranged at the bottoms of the movable stand columns, the height of the whole inner form formwork is adjusted through the stand column lifting supporting legs, and a bottom middle supporting leg capable of rising and falling are further arranged at the bottom of the portal frame. During construction, the lifting trolley lifts the inner form formwork to move and be preliminarily in place, the positions of the side form plates and the height of the lifting trolley are adjusted by combining the inner form formwork, and form erecting and form removing work is achieved.

Owner:ERCHU CO LTD OF CHINA RAILWAY TUNNEL GRP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com