Assembled communication channel structure and its construction method

A communication channel and assembled technology, which is applied in tunnels, shaft equipment, earthwork drilling and mining, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

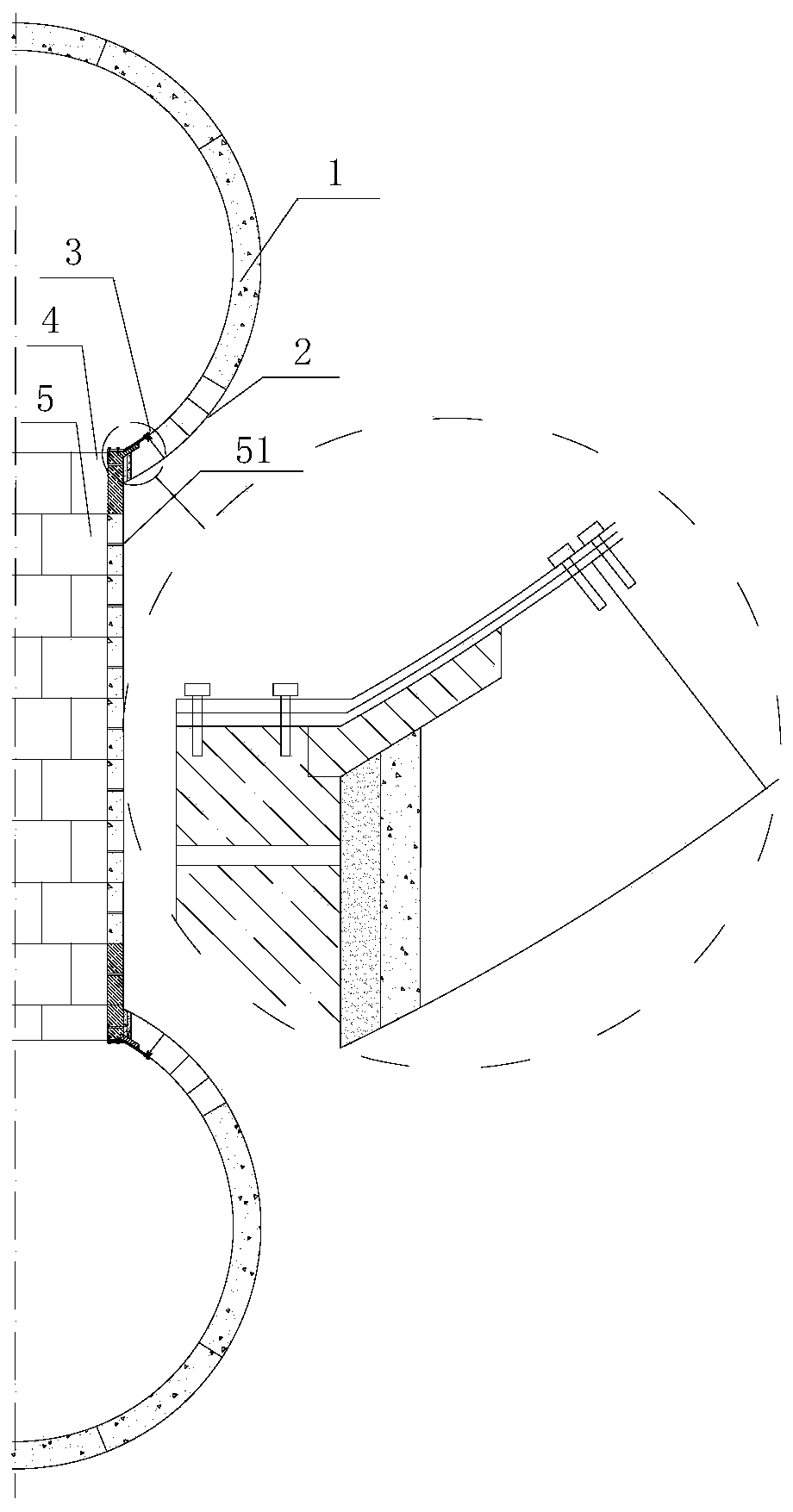

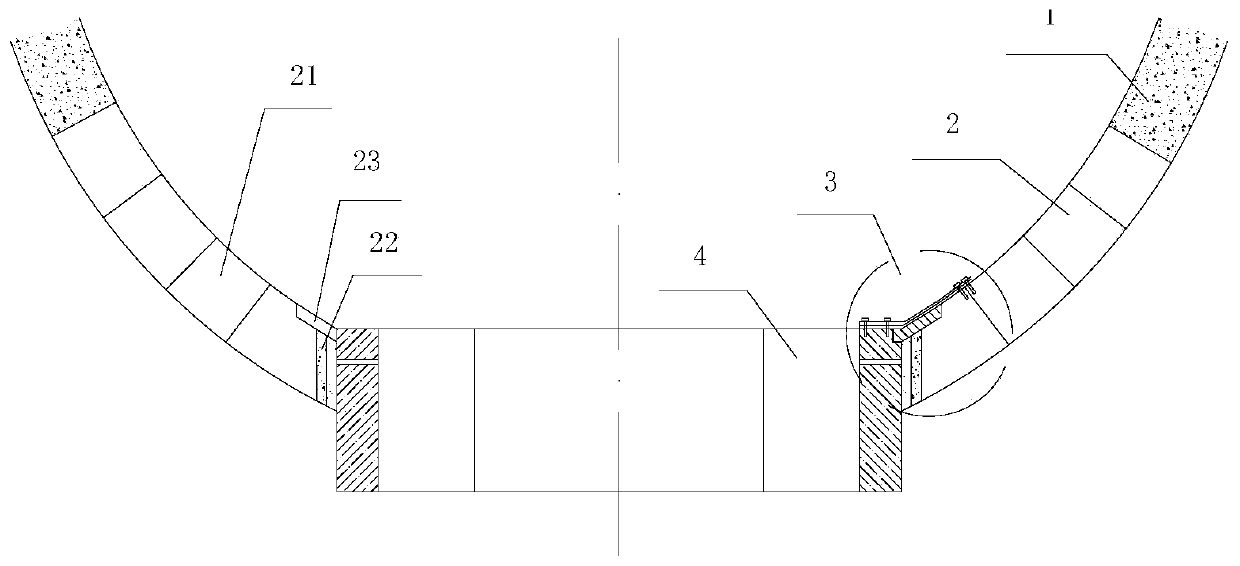

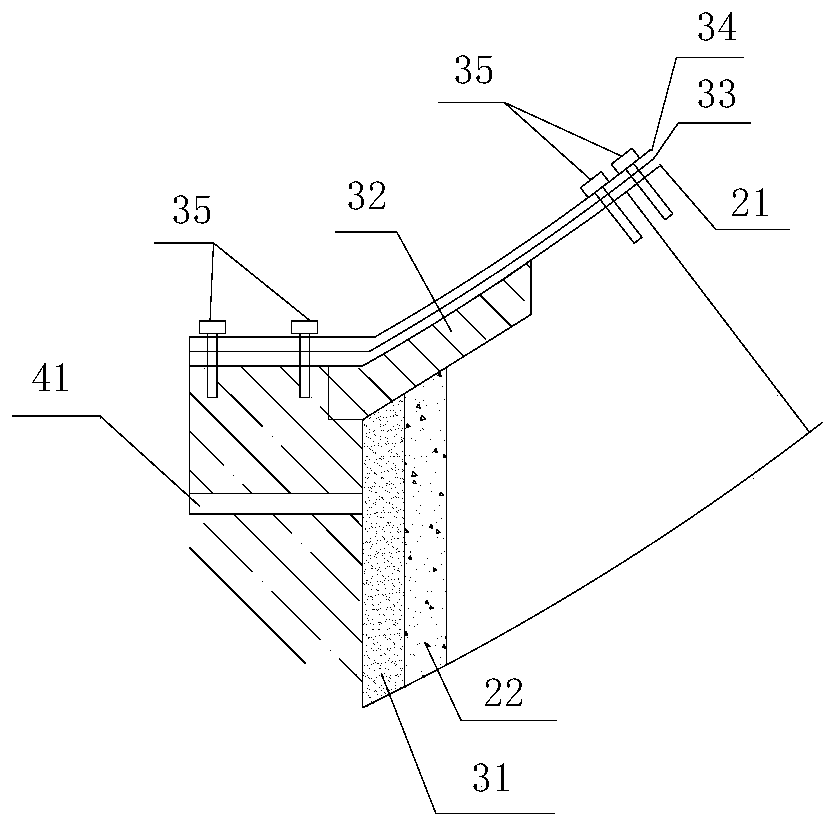

[0091] The structure of the assembled communication channel of the present invention is as follows: figure 1 , figure 2 and Figure 4 As shown, it is mainly composed of the following structures: shield tunnel concrete segment 1, shield tunnel composite segment 2, segment connection system 3, communication channel steel tube segment 4 and communication channel concrete segment 5;

[0092] The shield tunnel composite segment 2 includes a composite segment steel pipe segment 21, a composite segment concrete segment 22 and a reserved reinforcement box 23, and the outer side of the composite segment steel tube segment 21 is connected to the shield tunnel concrete segment 1 through a connecting bolt 17 Assembled and connected and its inner side is integrally connected with the composite segment concrete pipe segment 22, the inner side of the composite segment concrete pipe segment 22 is connected with the steel pipe segment 4 of the communication channel through the inter-segment ...

Embodiment 2

[0099] A construction method of an assembled communication channel structure of the present invention comprises the following steps:

[0100] a , Step 1, positioning the axis 6 of the contact channel;

[0101] b , Step 2, erecting the mobile prestressed support system 7;

[0102] c , Step 3, the starting airtight cabin 9 is installed synchronously with the shield machine 8;

[0103] d , Step 4, install the sealed receiving system 10 of the shield machine;

[0104] e , Step 5, the push-type reaction frame 11 on the originating side is installed;

[0105] f , Step 6, start excavation by shield machine jacking method;

[0106] g , Step 7, grouting and plugging the gap between the steel pipe section 4 of the connecting passage on the departure side and the composite segment 2 of the shield tunnel;

[0107] h , Step 8, the tunneling construction of the shield tunneling machine with shield tunneling method;

[0108] i , Step 9, the shield machine enters the tunnel to r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com