Novel concrete column template device and construction method thereof

A technology of concrete column and construction method, which is applied in the direction of formwork/formwork/work frame, connection parts of formwork/formwork/work frame, preparation of building components on site, etc. problems such as low force and concrete penetration, to achieve the effect of safe and reliable construction quality, convenient construction operation and improved construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

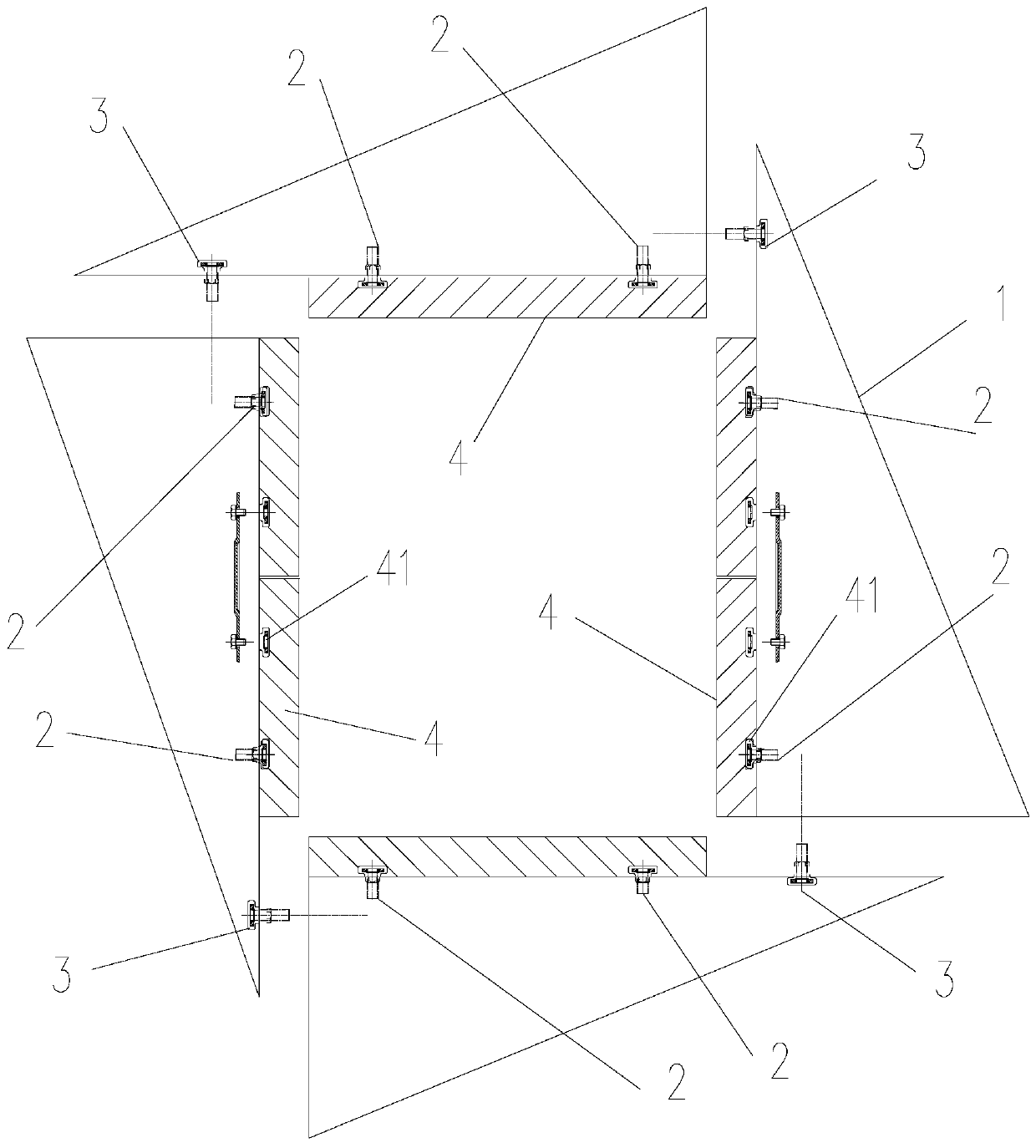

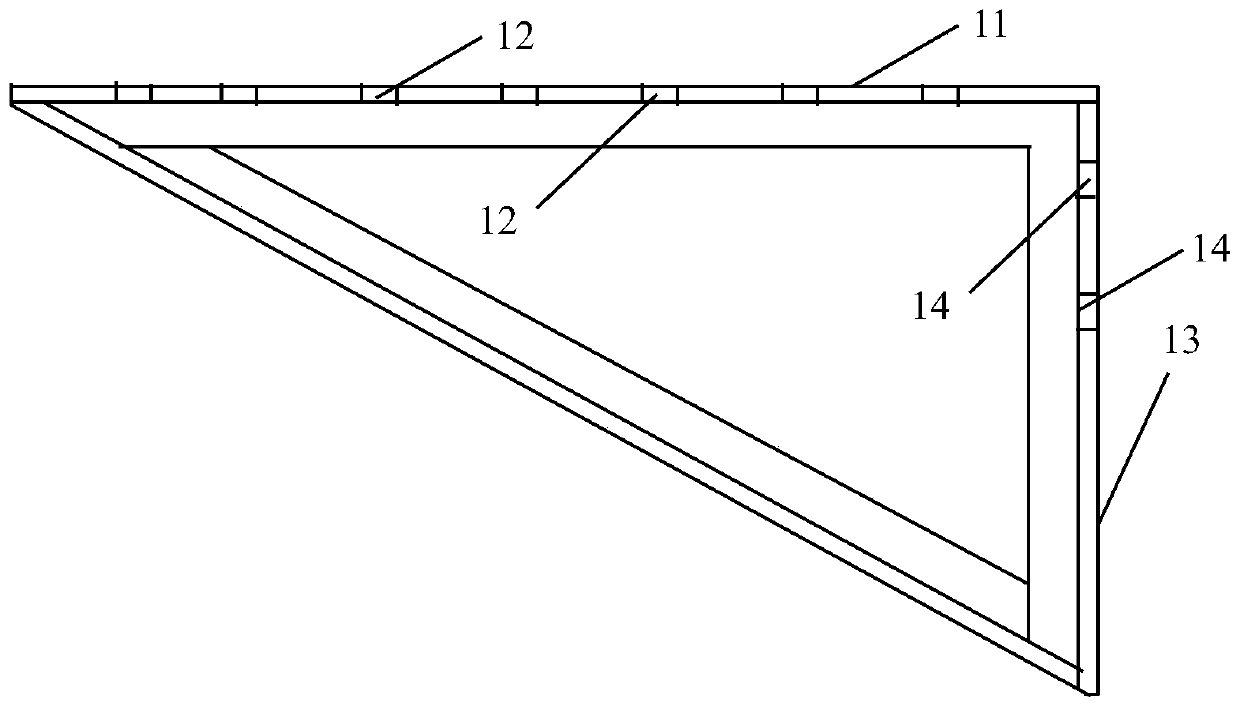

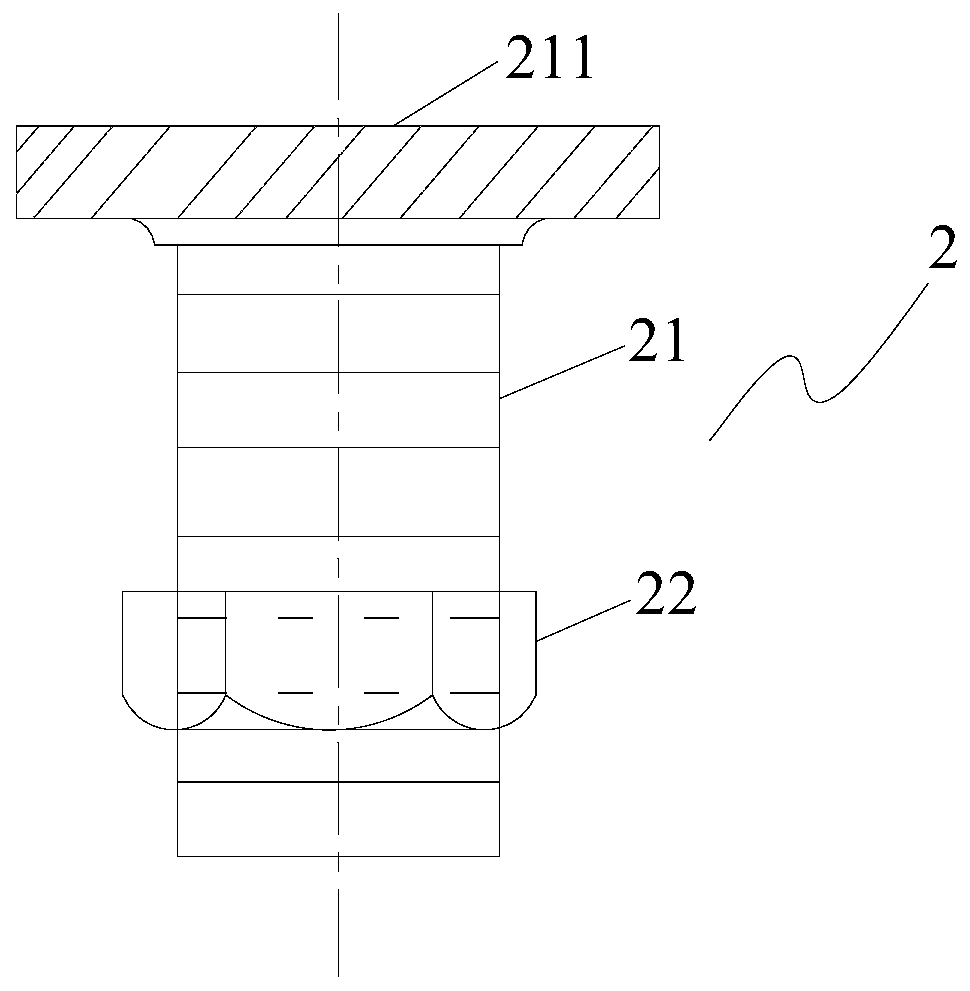

[0023] see Figure 1 to Figure 3 As shown, a novel concrete column formwork device of the present invention includes at least four column hoops 1, a plurality of first bolt assemblies 2 and a plurality of second bolt assemblies 3; the column hoops 1 are triangular steel frames, A plurality of square holes 12 are provided on the first straight side 11 of the triangular steel frame in contact with the concrete column template 4; a plurality of elongated holes 14 are provided on the second straight side 13 of the triangular steel frame; the first bolt One end of the first screw 21 of the assembly 2 is provided with a formwork matching part 211, which matches the T-shaped groove 41 of the column formwork; when the column formwork 4 is prefabricated and assembled, the column hoop 1 is passed through a plurality of first bolts The component 2 passes through the square hole 12 and is connected to the T-shaped groove 41 of the column formwork 4 and fastened on the column formwork 4, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com