Framework type external prestress anti-fatigue steel tower structure

An in vitro prestressing and anti-fatigue technology, which is applied in infrastructure engineering, wind turbines, and the configuration of installation/support of wind turbines, etc., can solve problems such as cumbersome construction and installation, save time, inhibit the development of microscopic and macroscopic cracks, Simple to use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Referring to the accompanying drawings, a detailed description will be given of a frame-type externally prestressed anti-fatigue steel tower structure provided by the present invention in conjunction with an embodiment.

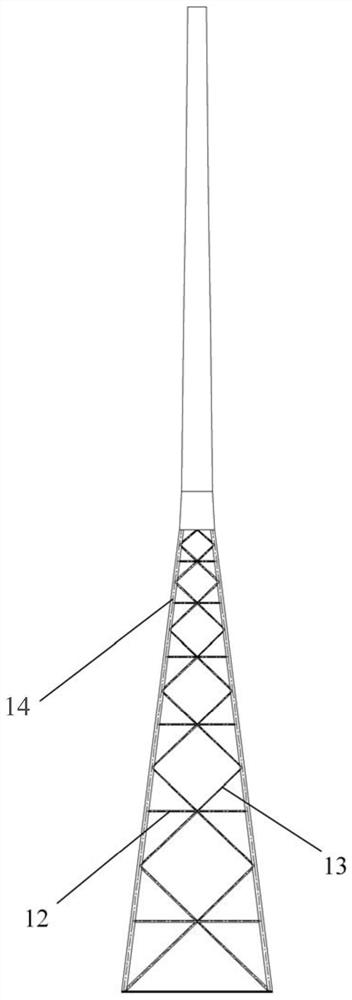

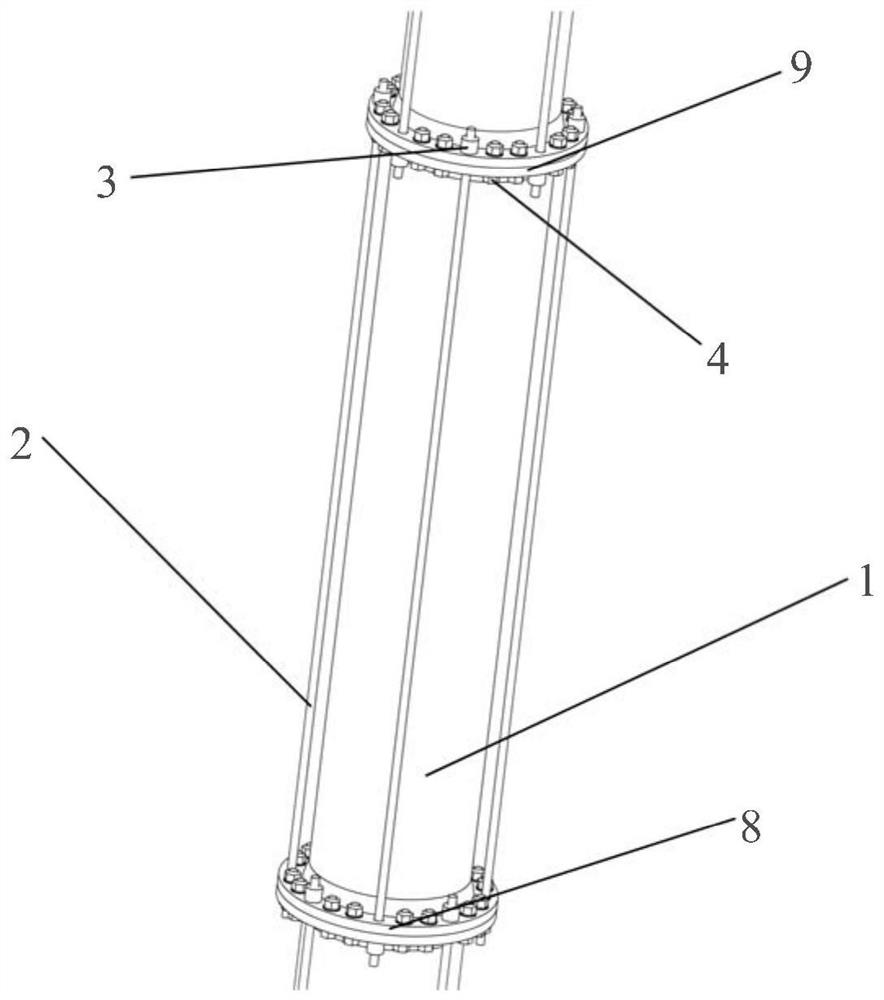

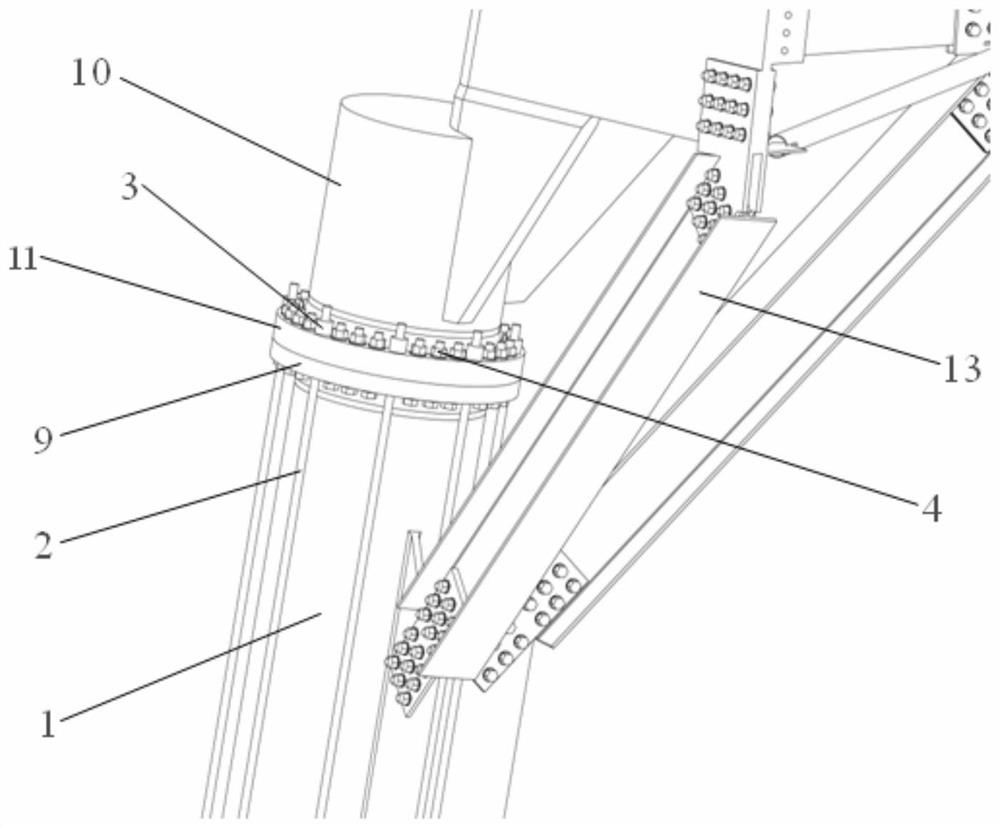

[0023] refer to Figure 1-5 , a frame type externally prestressed anti-fatigue steel tower structure, including several sections of steel pipe columns 1, cross bars 12 and oblique bars 13, each section of steel pipe columns 1 is connected from bottom to top by flanges and bolts 4 to form a tower column 14, There are four tower columns 14, horizontal bars 12 are horizontally fixed on adjacent tower columns 14, oblique bars 13 are cross-fixed on adjacent tower columns 14, and steel pipe columns 1, cross bars 12 and oblique bars 13 are connected to form a steel tower shelf. Specifically, the top and bottom ends of each section of steel pipe column 1 are respectively provided with an upper end flange plate 9 and a lower end flange plate 8, and each sectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com