Square hole girdling cutter and method for performing holing construction of deep cutting stab-pile wall by utilizing same

A cutting tool and hole ring technology, applied in sheet pile walls, water conservancy projects, excavation, etc., can solve the problems that the construction requirements of pile sheet walls cannot be applied, affect the construction progress of the project, and the construction progress is slow, so as to improve the degree of construction mechanization and construction The effect of fast progress and high safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

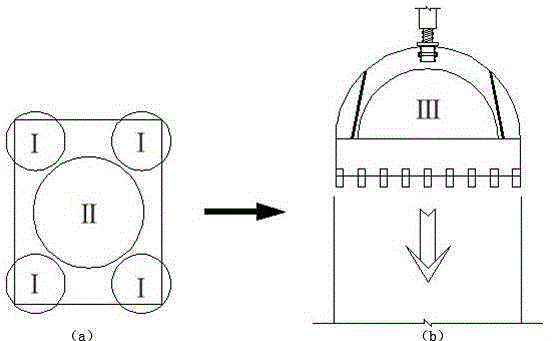

[0032] Some construction road sections have good geological conditions, such as: sandstone interbedded with mudstone geological structure, and the uprightness of the rock and soil is good. During construction, the earth and stone are first excavated to the designed subgrade surface, and the anchorage end of the pile-slab wall is first drilled by a rotary drilling rig, and then used The square hole ring cutting tool finally forms a hole, pours the concrete at the anchorage end, and then casts the concrete at the free end. This method of construction effectively utilizes the characteristics of good uprightness of rock and soil, high degree of mechanization, fast construction progress, good appearance quality, and strong operability.

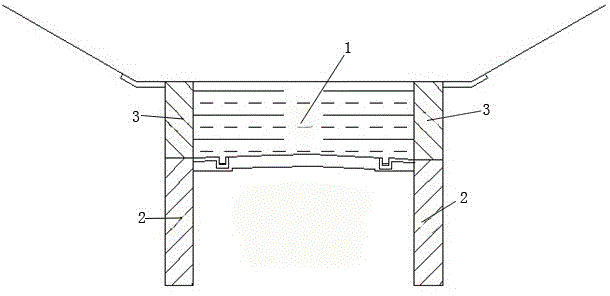

[0033] A rapid construction method for forming holes with ring cutting tools for square holes in pile-slab walls in deep road cuttings, such as figure 1 The construction method shown includes: excavation of earthwork (1), construction at the anchor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com