Construction method of circular reinforced concrete chimney cylinder wall and hydraulic sliding mould device

A technology of reinforced concrete and construction method, which is applied in the fields of formwork/formwork/work frame, preparation of building components on site, construction, etc., which can solve the problem of large shaking of the central hanging cage, slow lifting speed of the central hanging cage, and vertical transportation of construction materials. Insecurity and other problems, to achieve the effect of small construction space, few participants in the war, and conducive to disassembly, transportation and reuse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

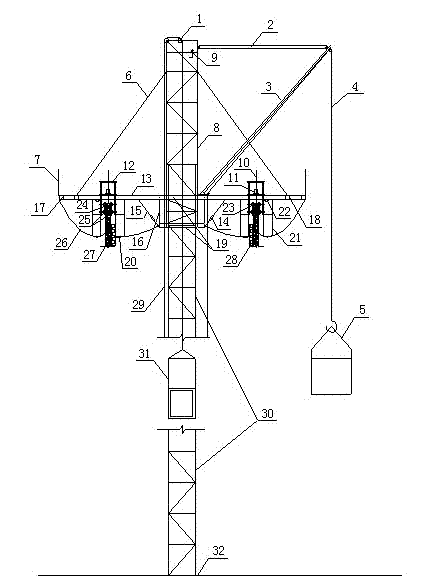

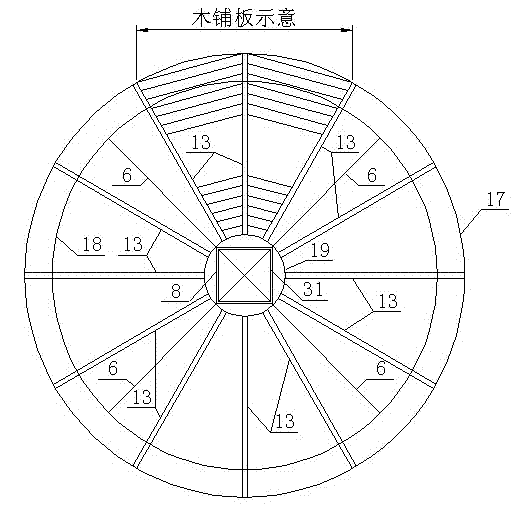

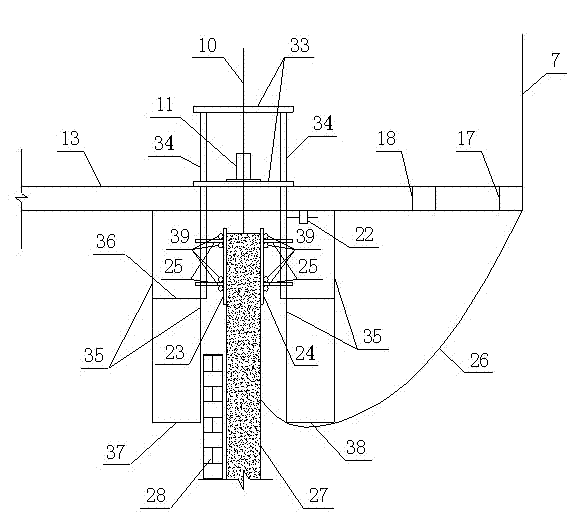

[0022] As shown in the figure, the fixed derrick steel plate embedded parts 32 are pre-embedded in advance on the chimney foundation constructed by conventional inverted moulds, and the fixed derrick 29 is erected. The fixed derrick 29 is made of angle steel sections, connected by high-strength bolts, and the lower end of the fixed derrick is welded and fixed at On the steel plate embedded part 32, the upper end of the fixed derrick extends into the ascending derrick 8 and is higher than the construction operation platform by a certain height; the conventional inverted mold is used to construct the chimney wall 27 of a certain height, and the support rod 10 is pre-embedded in the wrong head by 25% In the chimney tube wall 27 that has been constructed, the supporting rod 10 is generally made of Φ48mm×3.5mm steel pipes, which are connected by welding. The number of supporting rods 10 is determined in advance according to the design of the slipform construction device; the hydraulic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com