Two-stage compression refrigerating system

A two-stage compression and refrigeration system technology, applied in refrigerators, compressors, refrigeration components, etc., can solve the problems of uneconomical volume ratio of high and low pressure cylinders, inflexible energy regulation of refrigeration systems, and large temperature fluctuations in cold storage, etc., to achieve improved The effect of high efficiency, flexible adjustment and small temperature fluctuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

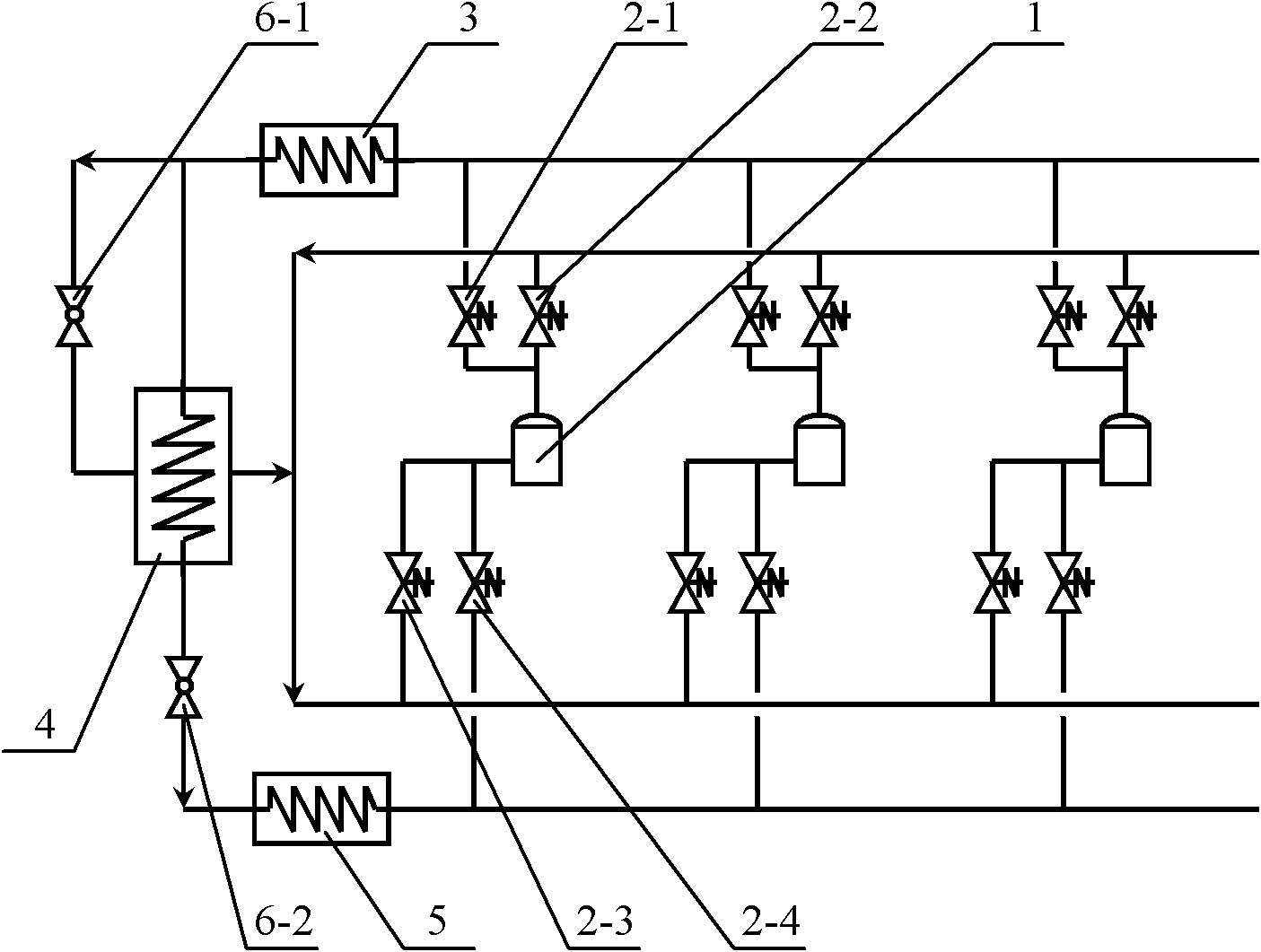

[0019] figure 1 It is a schematic diagram of a two-stage compression refrigeration system with one-stage throttling and incomplete cooling in the middle of the present invention, including multiple refrigeration compressors 1, condenser 3, evaporator 5, and intercooler 4. The intercooler is a shell-and-tube heat exchange or plate heat exchanger. The discharge end of each refrigeration compressor 1 is respectively connected with the first electromagnetic valve 2-1 and the second electromagnetic valve 2-2, and the suction end of each refrigeration compressor is respectively connected with the third electromagnetic valve 2-3 and the second electromagnetic valve 2-3. Four solenoid valves 2-4, the first solenoid valve 2-1 connected to each refrigeration compressor is connected in parallel to the inlet of the condenser 3, and the second solenoid valve 2-2 connected to each refrigeration compressor is connected in parallel to the middle The shell side outlet of the cooler 4 is conne...

Embodiment 2

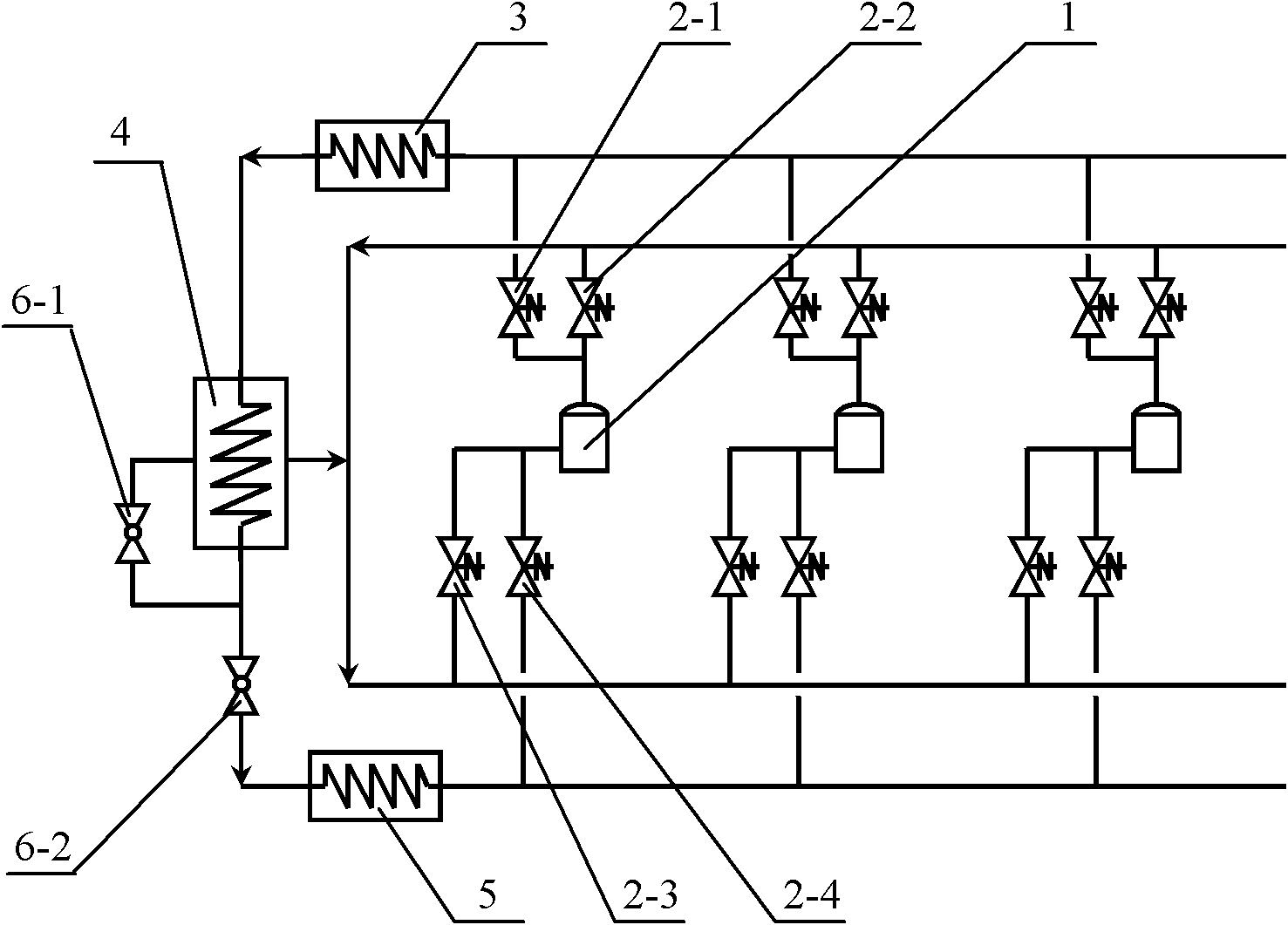

[0029] figure 2It is a schematic diagram of another two-stage compression refrigeration system with one-stage throttling and incomplete cooling in the middle of the present invention. The connection mode of the first throttling valve is different, and the other structures are exactly the same as in Embodiment 1.

[0030] It includes multiple refrigeration compressors 1, condensers 3, evaporators 5, and intercoolers 4, and the intercoolers are shell-and-tube heat exchangers or plate heat exchangers. The discharge end of each refrigeration compressor 1 is respectively connected with the first electromagnetic valve 2-1 and the second electromagnetic valve 2-2, and the suction end of each refrigeration compressor is respectively connected with the third electromagnetic valve 2-3 and the second electromagnetic valve 2-3. Four solenoid valves 2-4, the first solenoid valve 2-1 connected to each refrigeration compressor is connected in parallel to the inlet of the condenser 3, and th...

Embodiment 3

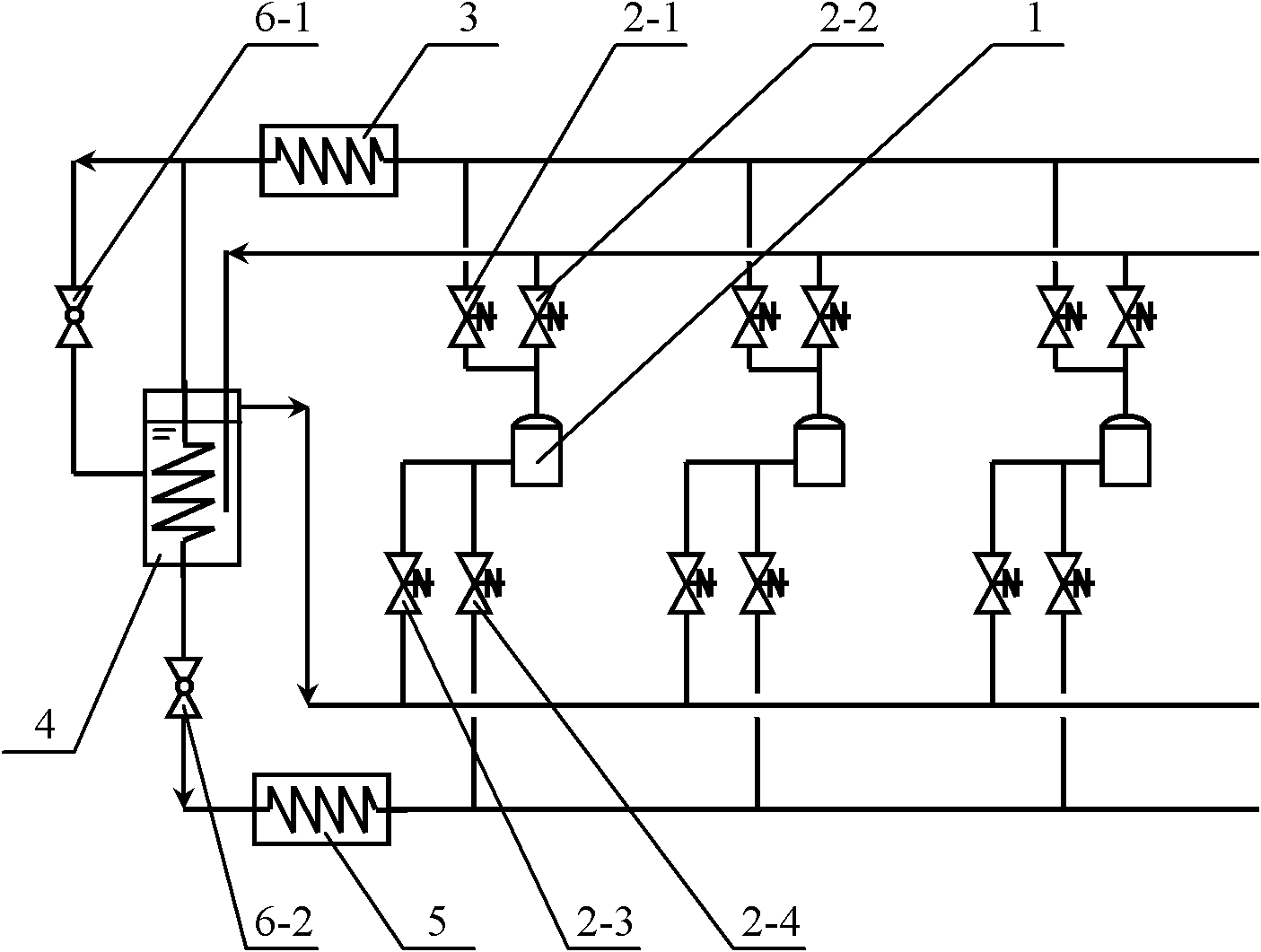

[0039] image 3 It is a schematic diagram of a two-stage refrigeration compression system with one-stage throttling and complete cooling in the middle, including multiple refrigeration compressors 1, condenser 3, evaporator 5, and intercooler 4. The intercooler is a shell-and-tube type with a liquid surface Heat Exchanger. The discharge end of each refrigeration compressor is respectively connected with the first electromagnetic valve 2-1 and the second electromagnetic valve 2-2, and the suction end of each refrigeration compressor is respectively connected with the third electromagnetic valve 2-3 and the fourth electromagnetic valve 2-3. Solenoid valve 2-4, the first solenoid valve 2-1 connected to each refrigeration compressor is connected in parallel to the inlet of the condenser 3, and the second solenoid valve 2-2 connected to each refrigeration compressor is connected in parallel to the intermediate cooling The shell side interface below the liquid surface of the device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com