Arc rectification system and its arc rectification device

A technology of electric arc and arc torch, which is applied in the field of non-melting inert gas tungsten shielded welding arc rectification system and its arc rectification device, which can solve the problems of reducing work efficiency, slowing down the swing speed, increasing the process, etc., and achieves the convenience of energy adjustment , stable arc voltage, and the effect of light overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Embodiments of the present invention will now be described with reference to the drawings, in which like reference numerals represent like elements.

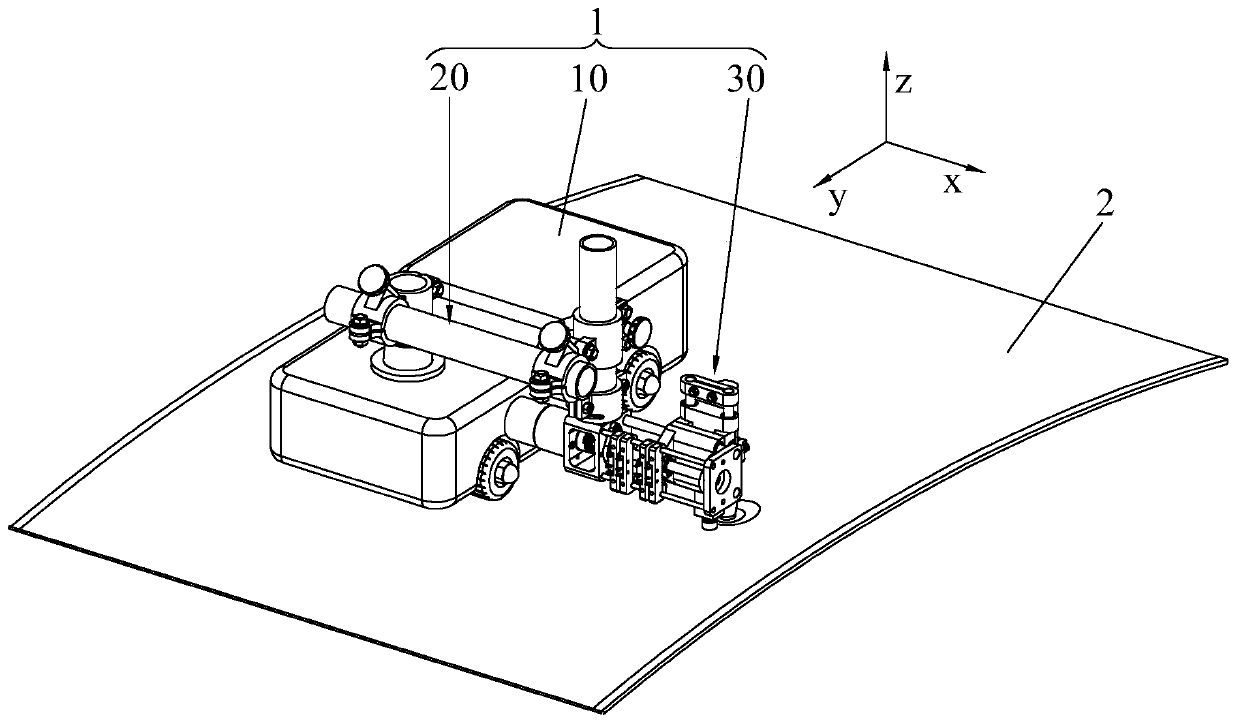

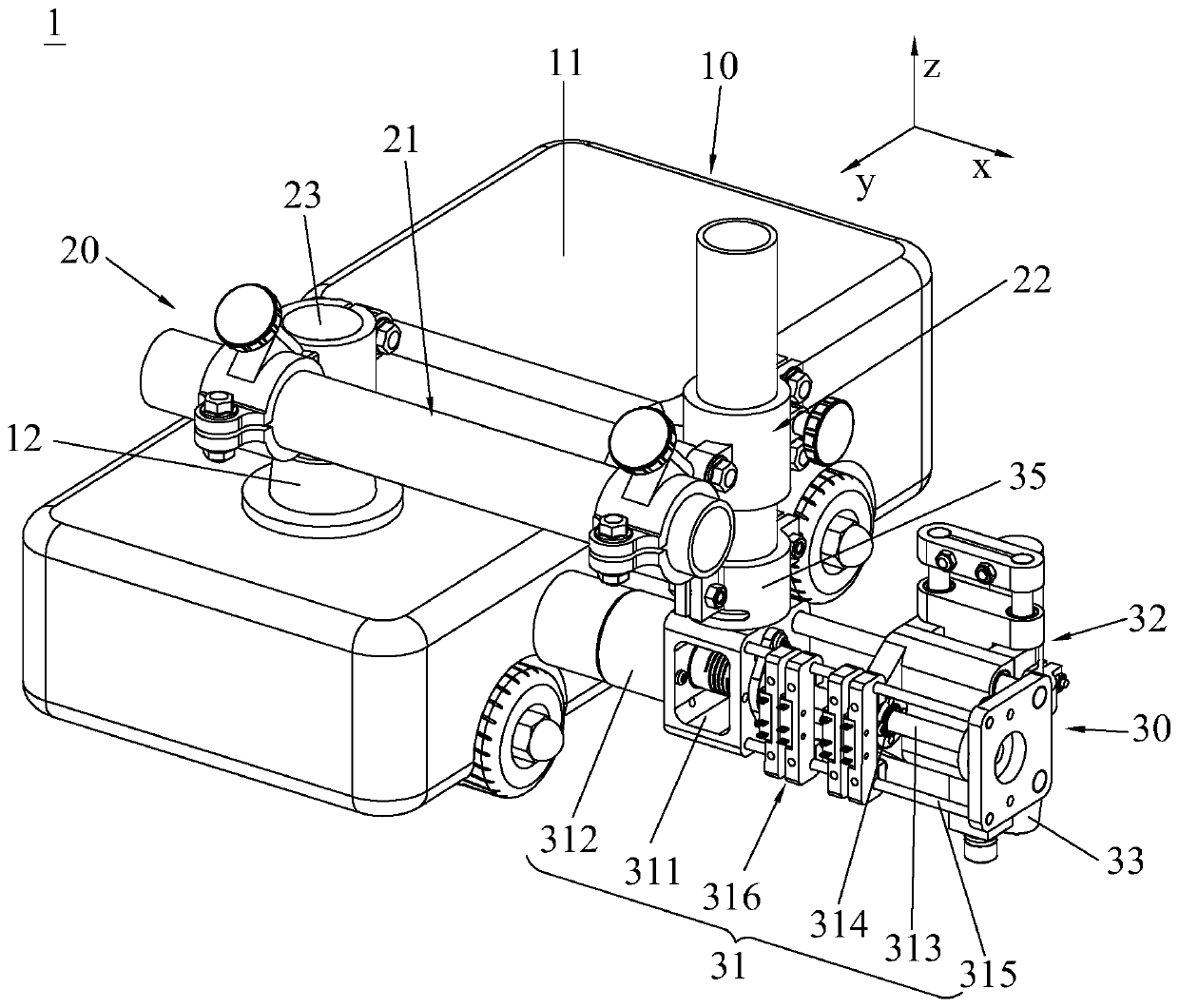

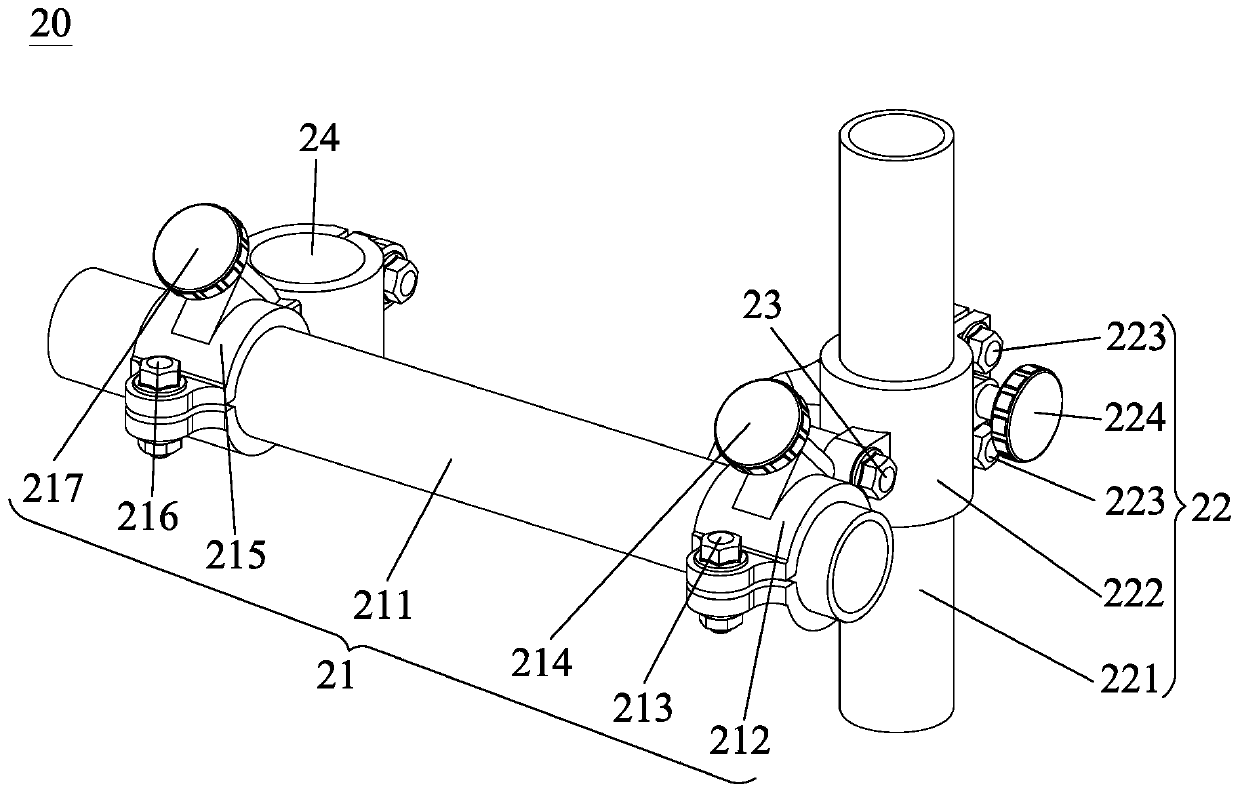

[0044] see first figure 1 As shown, the arc straightening system of the present invention includes an arc straightening device 1 and a part 2 to be straightened after welding. Wherein, the part 2 to be corrected is a welded hull aluminum alloy thin plate, which has a curved surface structure, but is not limited thereto. The arc straightening device 1 is a non-melting inert gas tungsten shielded welding (TIG) arc straightening device, the arc swing speed can be controlled in sections, the swing amplitude is constant, the distance between the arc and the surface of the workpiece 2 to be straightened is constant, and it can run automatically , so it is especially suitable for correcting the welding deformation of aluminum alloy thin-walled hulls. On the basis of ensuring the surface quality of the hull, it can correct the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com