Continued ironmaking device based on melting reduction

The technology of a heat exchange device and an air extraction device is applied in the non-blast furnace ironmaking field of metallurgy to achieve the effects of reducing production costs, facilitating comprehensive utilization of energy and reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

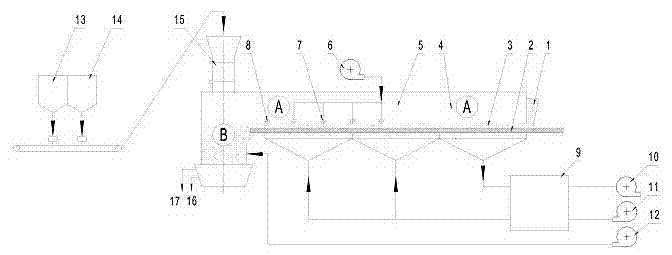

[0029]As shown in the figure, the pre-reduction furnace A and melting furnace B are designed to communicate with the hearth, and the hearth 2 can adopt various horizontal or small-inclination moving beds, such as vibrating beds, chain beds, etc. Feeding bin 1 will be mixed with carbonaceous reducing agent (coal, coke, petroleum coke, etc.) Carbon-containing iron oxide pellets (blocks) charge 3 are made, and sent to the hearth 2 after drying (or directly). The thickness of the material layer on the hearth 2 is about 100 mm to 300 mm, and the furnace material 3 moves on the hearth 2 to the direction of the melting furnace. The hearth 2 in the preheating zone 4 is equipped with a grate, and the lower part of the hearth 2 in the preheating zone 4 is equipped with an exhaust box connected with the flue gas treatment system 9. Pass through the furnace charge 3 material layer, directly heat the furnace charge 3, dry and preheat the furnace charge 3, and then enter the heat exchange ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com