A construction method for pipe gallery

A construction method and pipe gallery technology, applied in artificial islands, water conservancy projects, infrastructure projects, etc., can solve the problems of difficult control of the concrete quality of the pipe gallery, consuming manpower and material resources, and complicated construction conditions, so as to solve the problems of manual construction difficulties, Improve construction efficiency, assist pouring and curing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] In order to enable those skilled in the art to better understand the solution of the present invention, the technical solution of the present invention will be further described below in conjunction with specific examples.

[0055] A construction method for a pipe gallery. The construction method uses an outer formwork trolley A, an inner formwork frame B and a lifting trolley C for moving the inner formwork formwork.

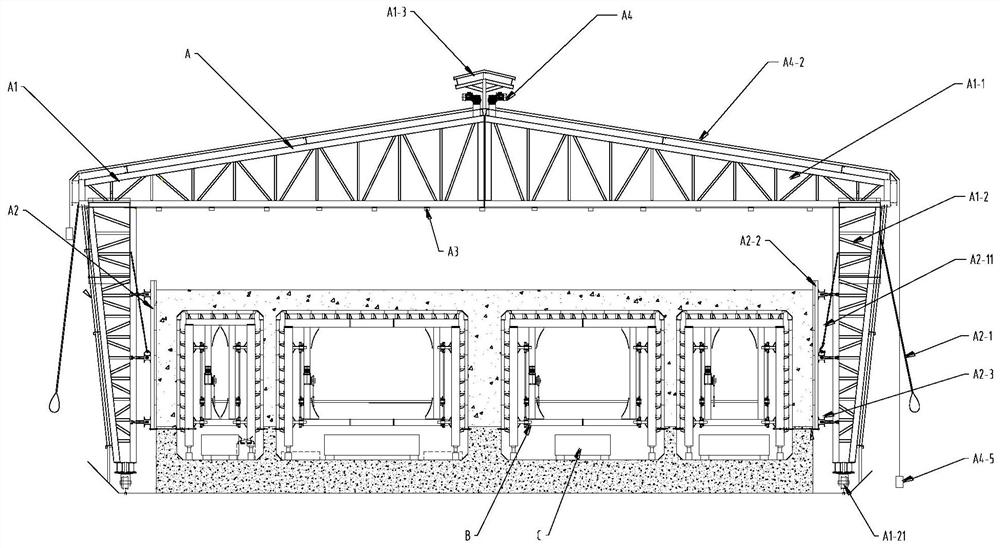

[0056] 1. See attached Figure 1-4 , the following specifically introduces the outer mold trolley A.

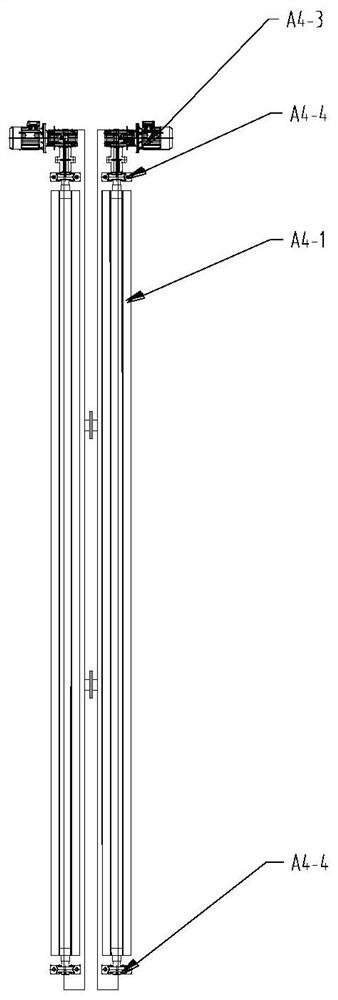

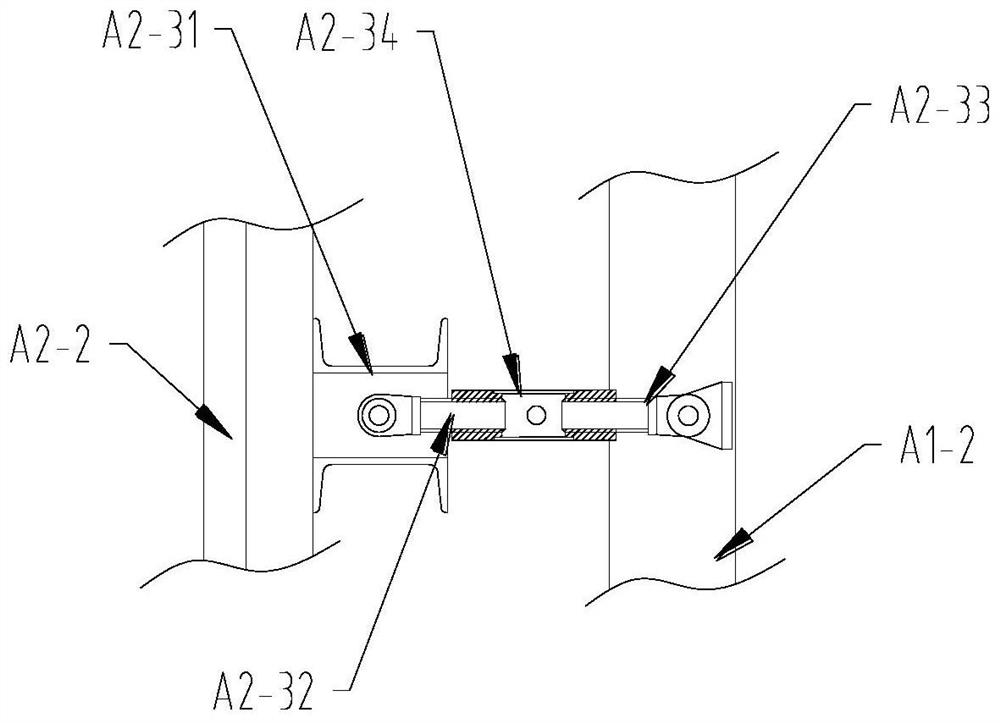

[0057] The outer mold trolley includes a scaffolding A1, an outer mold mechanism A2, a spray maintenance mechanism A3 and a rainproof mechanism A4.

[0058] The scaffold A1 is composed of several heel longitudinal beams and several heel beams welded together. The scaffold A1 includes a top scaffold A1-1 and two side scaffolds A1-2. The spacing is greater than the width of the pipe gallery, the top scaffold A1-1 is connected to the top of the two side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com