Method for quickly installing section steel beam plate under top-down cover-excavation

A technology of cover-excavation reverse operation and installation method, which is applied in the field of steel plate installation and steel beam, which can solve the problems of thick steel plate, difficulty in on-site assembly, and high welding requirements, so as to facilitate installation and adjustment, and improve construction efficiency and quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The present invention is further described below with reference to the drawings, and the scope of the invention is not limited to the following:

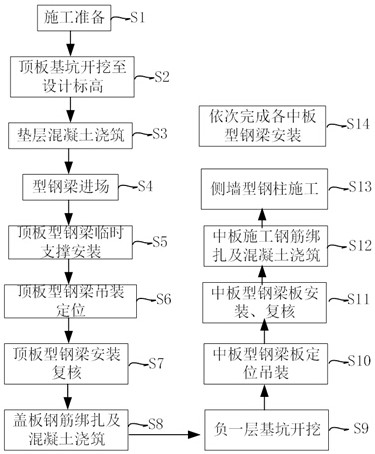

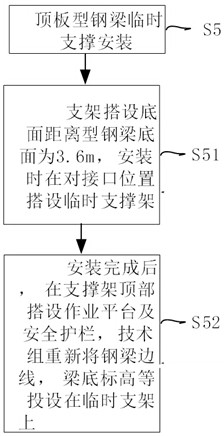

[0062] like Figure 1 ~ 8 As shown, a rapid installation method of the type steel beam under the cover retrorefold conditions, including the following steps;

[0063] Step S1: Construction preparation. Construction preparation includes through design, understanding of engineering and main design intentions, engineering site conditions and positioning conditions, main building interrelations and axis size, high grounds on the ground, and design for measurement accuracy requirements. Through the drawings, the calculation of the discharge data is performed, and the calculation of data is determined by different people to use different methods, and the calibration is performed to reduce the appearance of accidental errors. Understand the construction site layout and construction progress in advance, ensure the deepening, processing, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Verticality | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com