Patents

Literature

84results about How to "Reduce construction safety hazards" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

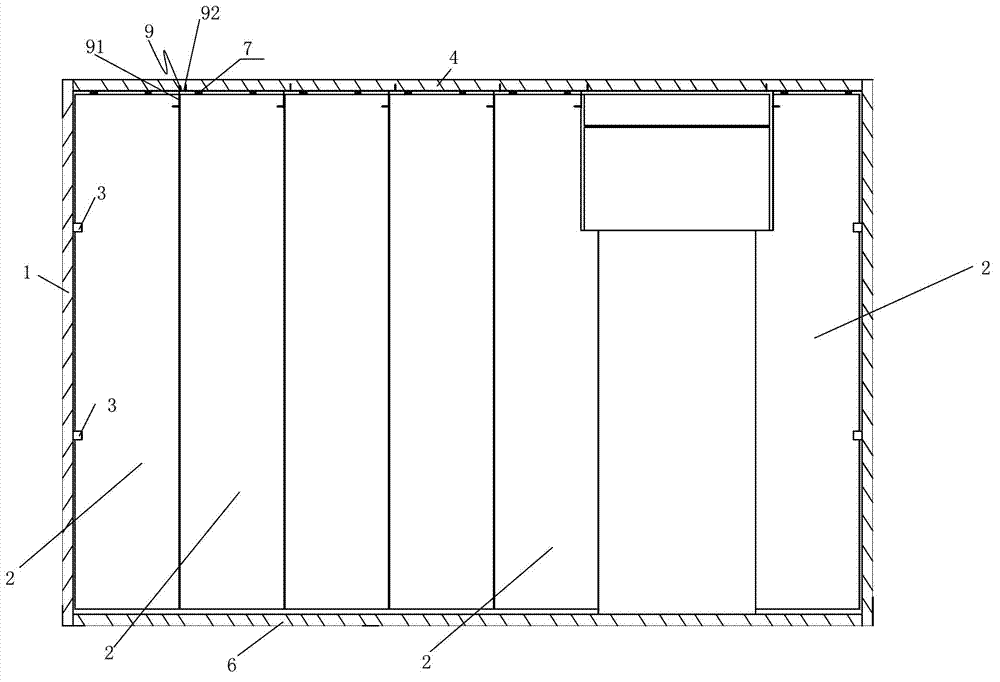

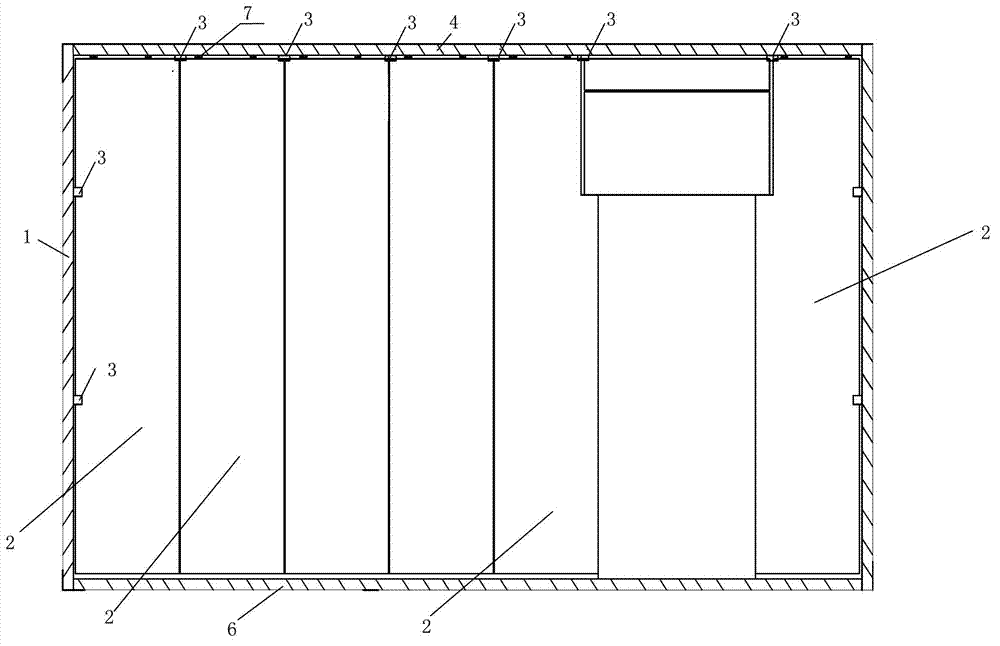

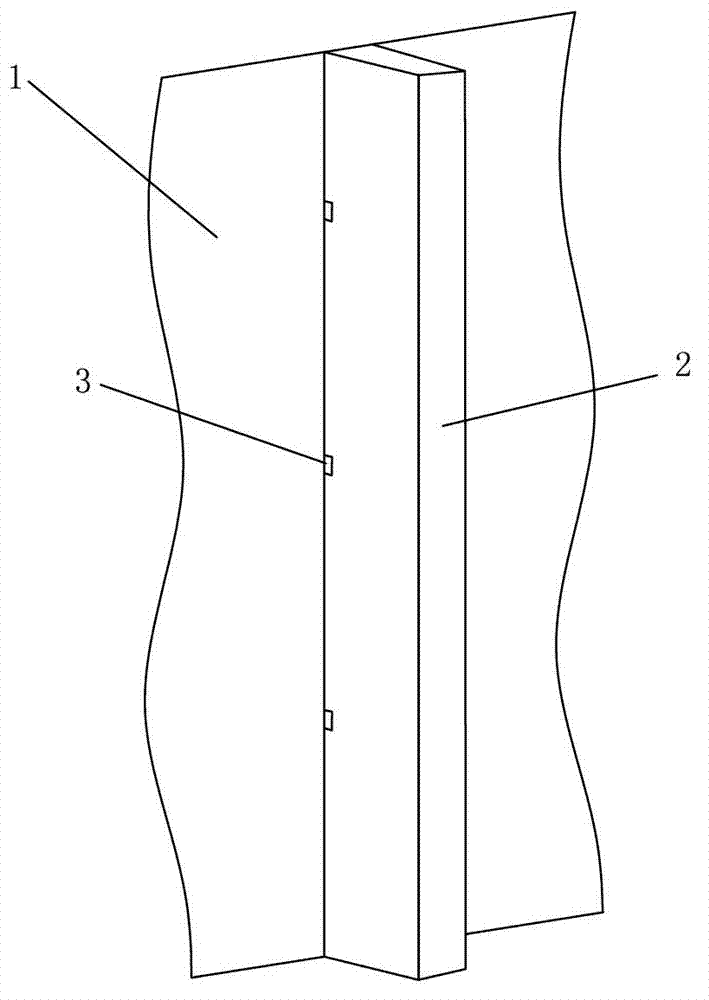

Installation technology of inner separation wall body

InactiveCN102777041ARapid positioningGuaranteed flatnessWallsBuilding material handlingStructural engineeringEngineering

Owner:中山建华墙体材料有限公司

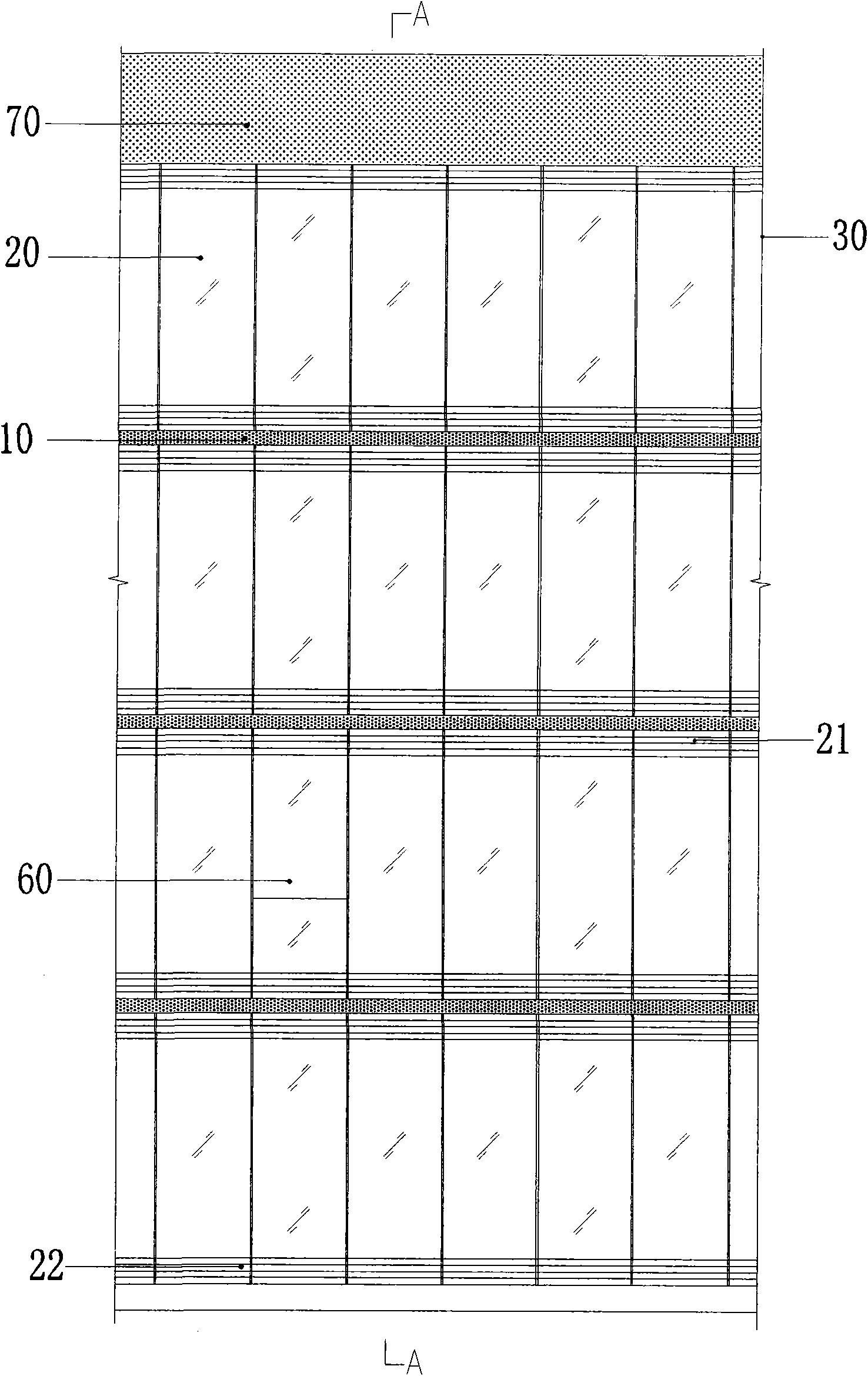

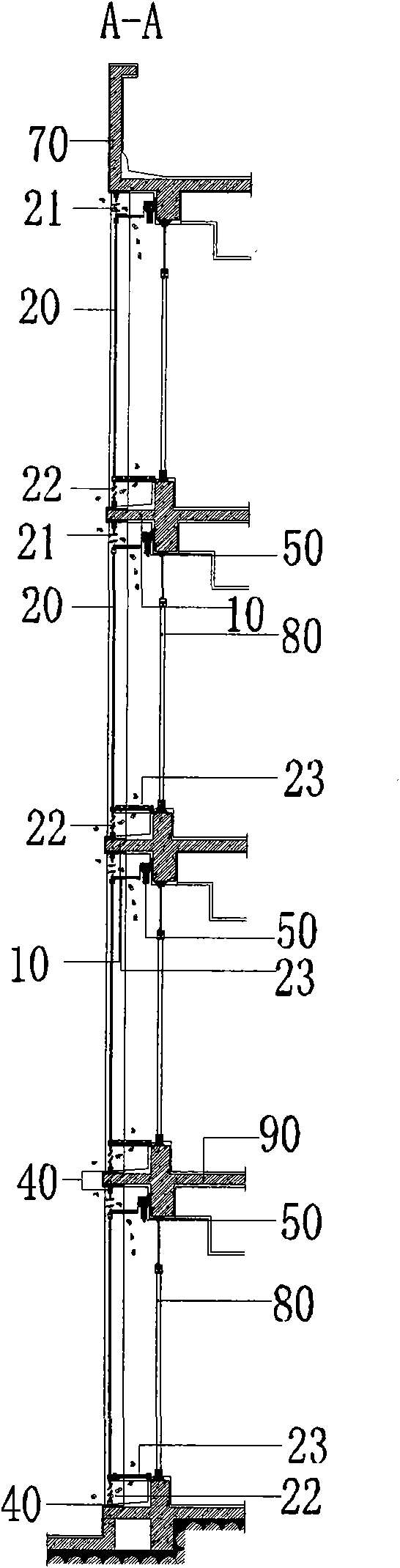

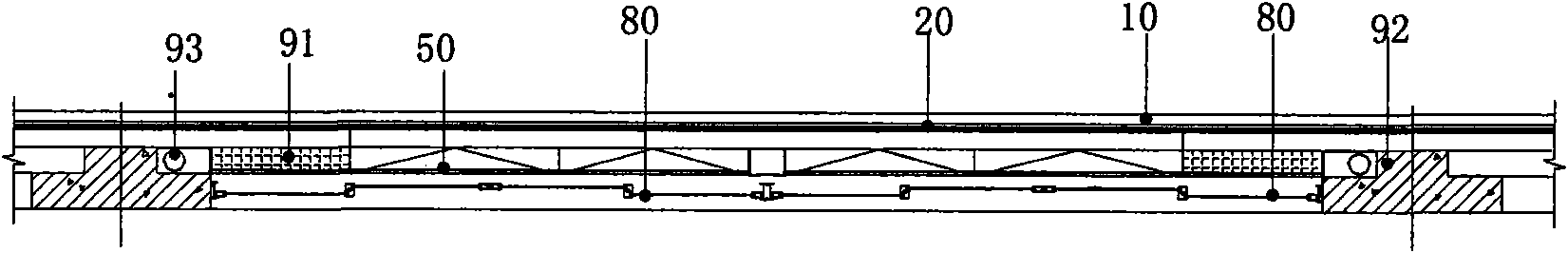

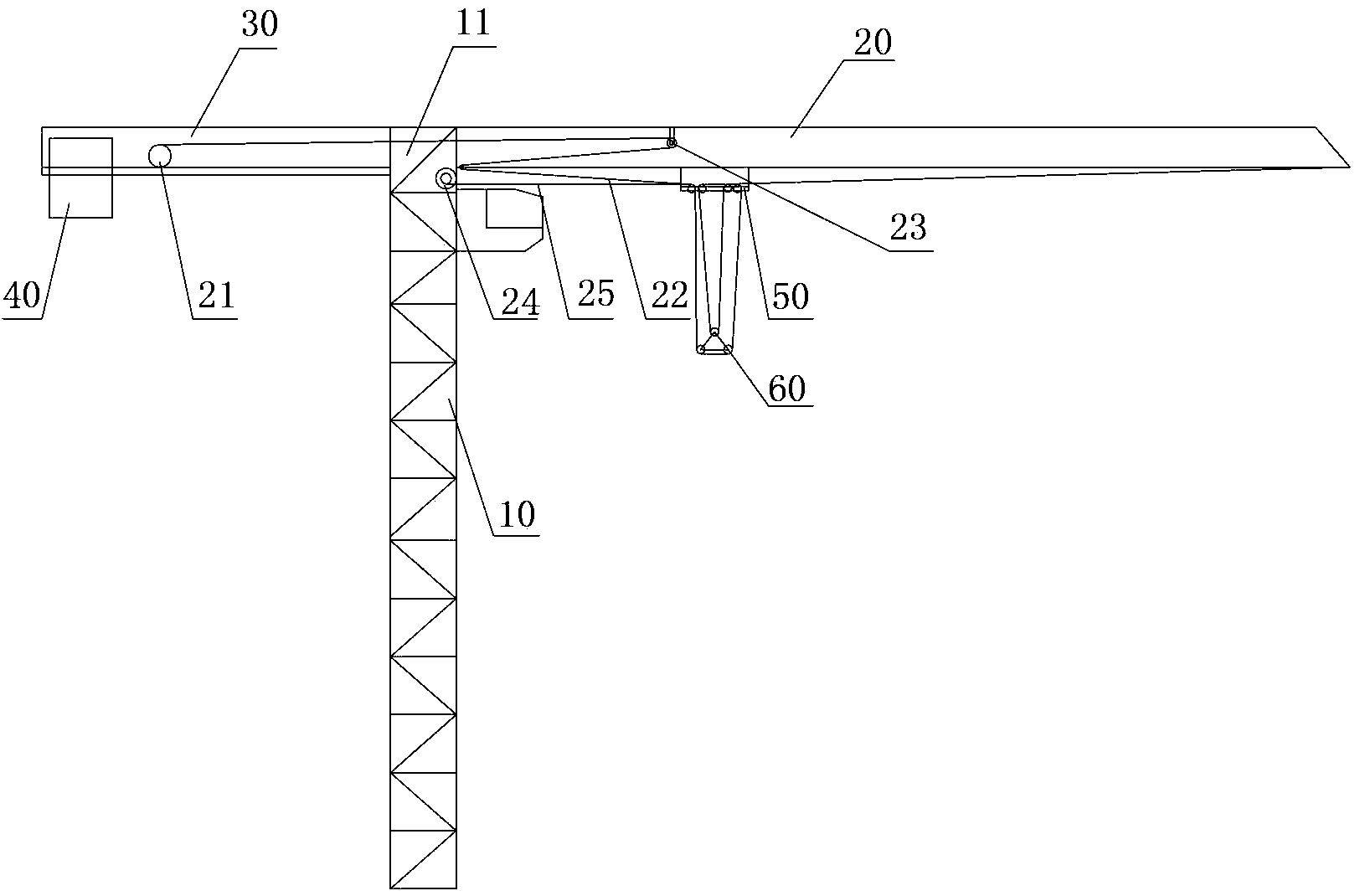

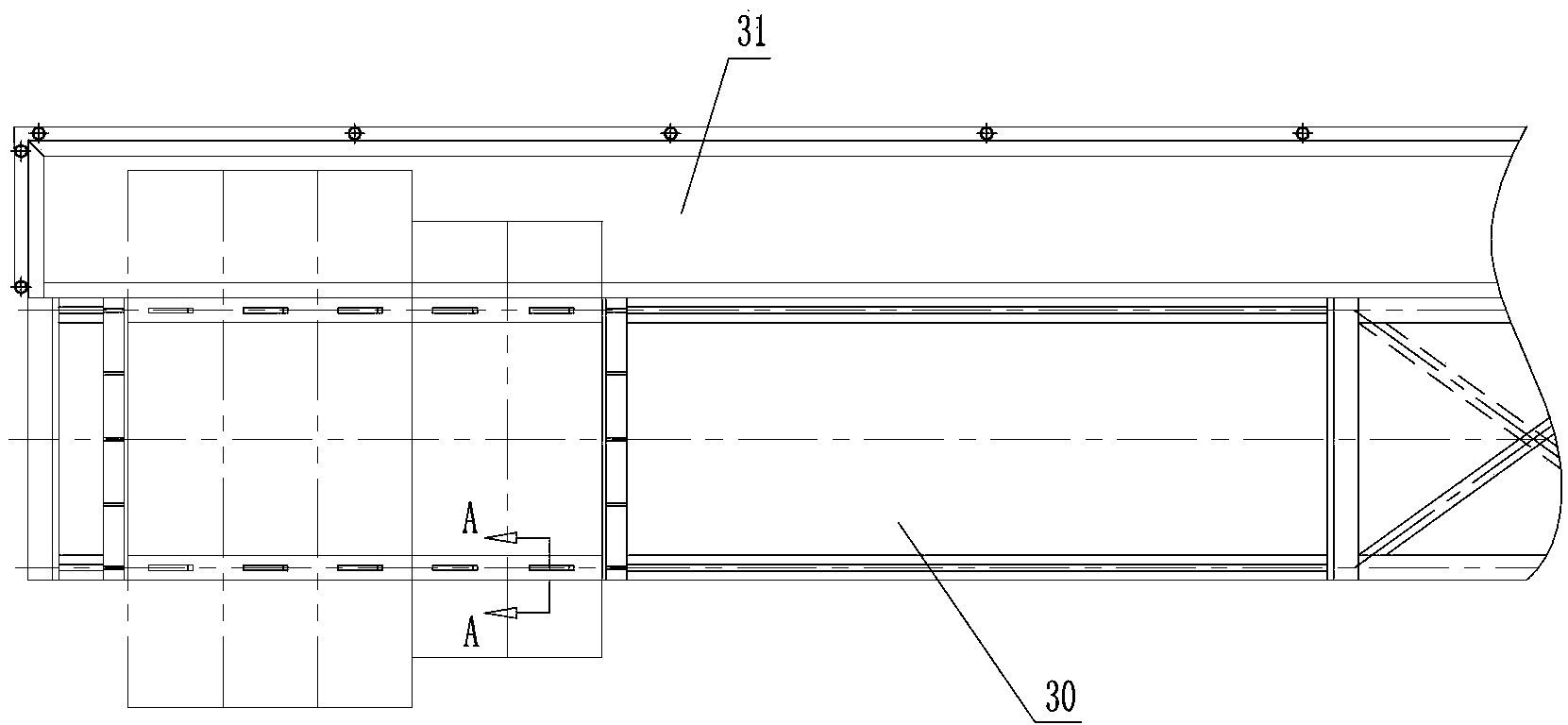

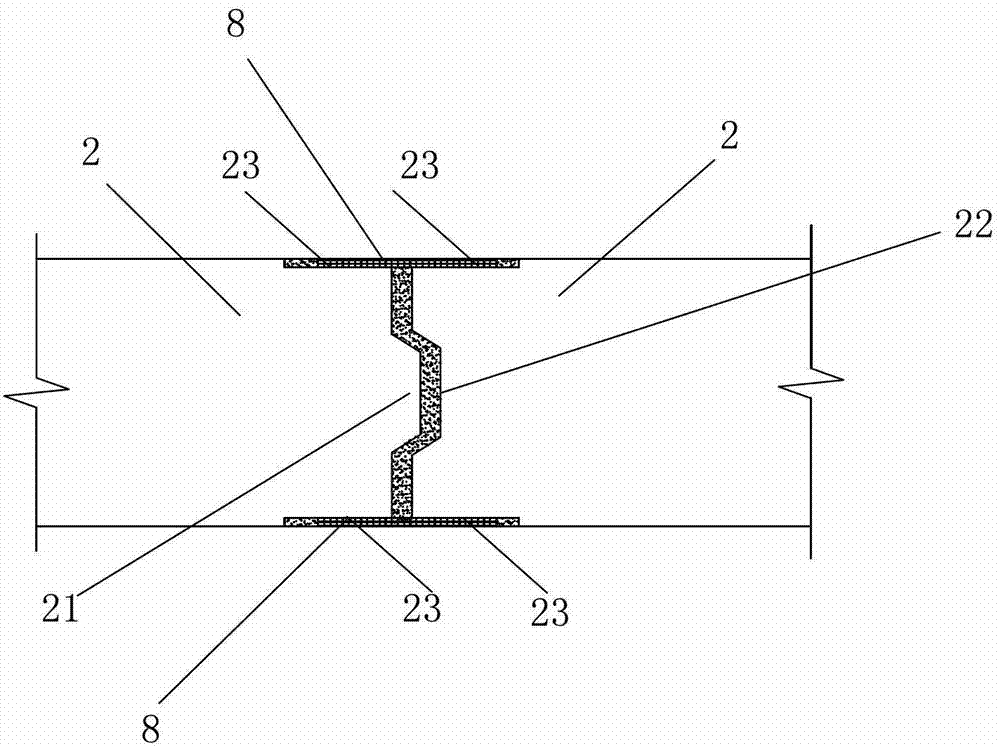

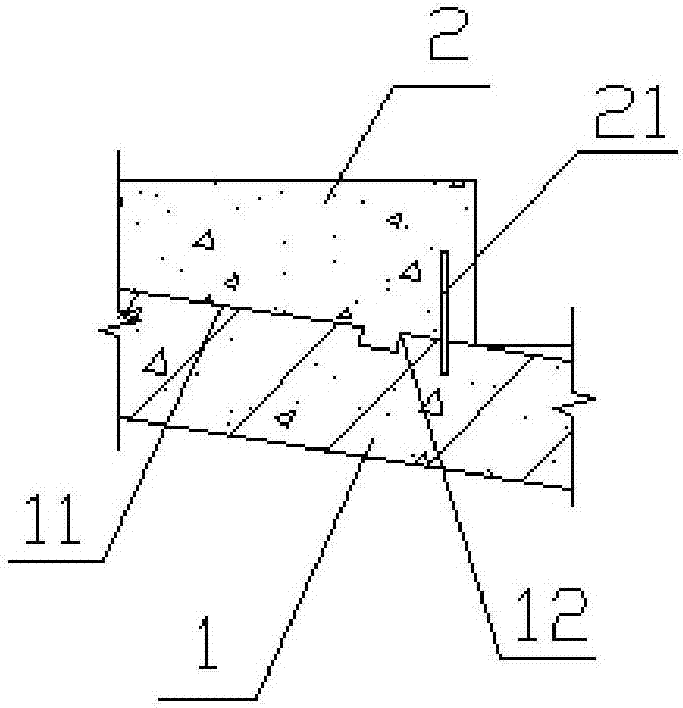

Safe and economic double curtain wall borne by building structure

InactiveCN101603341AIncrease the usable areaLow maintenanceWallsLighting and heating apparatusArchitectural engineeringBuilding construction

The invention provides a safe and economic double curtain wall borne by a building structure. The curtain wall comprises horizontal support plates (10) which extend along a supporting member of a window of an inner curtain wall in each layer in the building structure, wherein an outer curtain wall (20) is positioned and fixed on the upper surface of the horizontal support plate (10); an upper exhaust ventilation port (21) and a lower inlet ventilation port (22) are arranged above and under the outer curtain wall (20) respectively; and each layer is independent in space. The curtain wall saves materials on structure and connection, saves occupied space, high cost, complicated construction and fussy steel structure, improves the utilization area of the building, reduces the cost, shortens construction period, reduces long-term maintenance cost, has time and manpower saving, simple structure, low construction cost, high safety, convenient maintenance, low cost and the like, leads easy layer to circulate independently, reduces the problem of heat concentration on higher floor, and is integrated with sun-shading, heat insulating, sound insulating, warming, energy saving, heat preserving, dust proofing, mosquito and insect preventing, ventilating and other energy-saving environment-friendly functions in the whole system.

Owner:SHENZHEN FUCHENG TECH DEV +1

Tower crane and adjusting method for trimming moment of tower crane

The invention relates to a tower crane and an adjusting method for trimming moment of the tower crane. The tower crane comprises a tower body, a rotary tower column, a crane boom, a balance arm, and a balance weight arranged on the balance arm; the adjusting method comprises the following steps: acquiring load moment of the tower crane; determining target trimming moment of the tower crane according to the load moment; determining a target position of the balance weight on the balance arm according to the target trimming moment; moving the balance weight to the target position. According to the technical scheme provided by the invention, the target trimming moment required by the tower crane is determined through acquiring load moment of the tower crane, then the balance weight is adjusted to a corresponding target position, compared with the prior art, the trimming moment of the tower crane can be adjusted timely, so that a stress state of the tower crane is improved, the service life of the tower crane is prolonged, and potential safety hazards in construction are reduced.

Owner:ZOOMLION HEAVY IND CO LTD

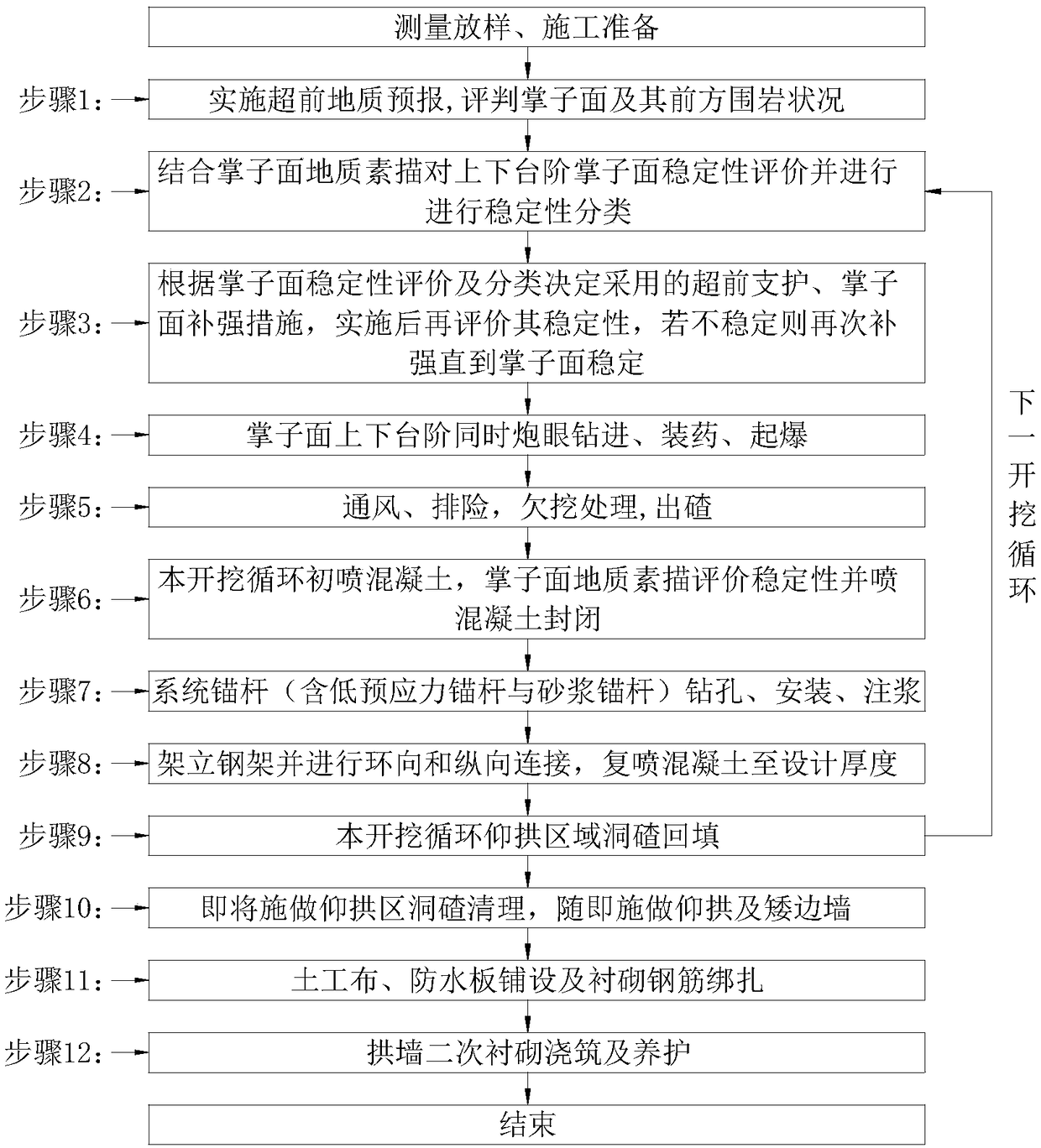

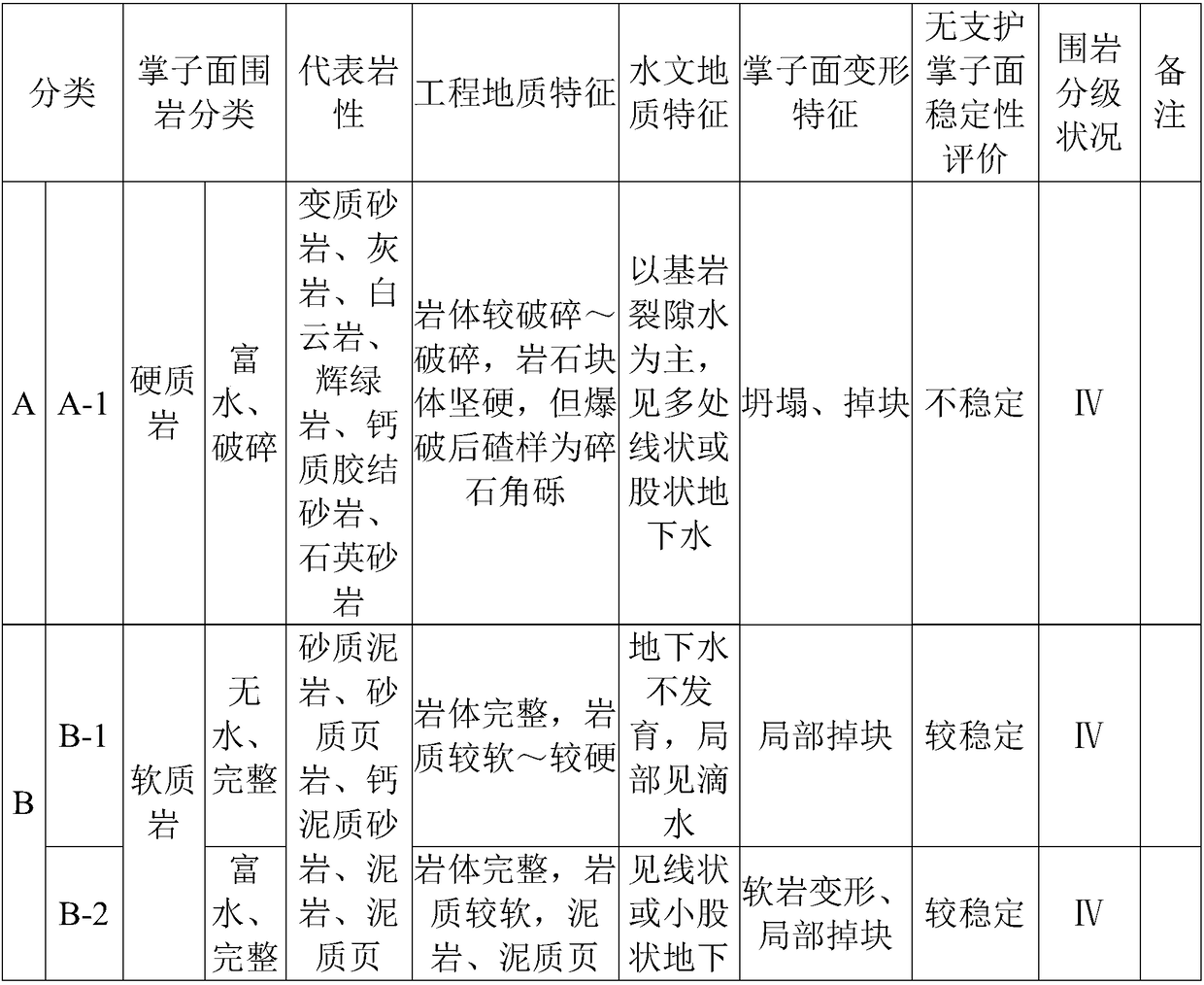

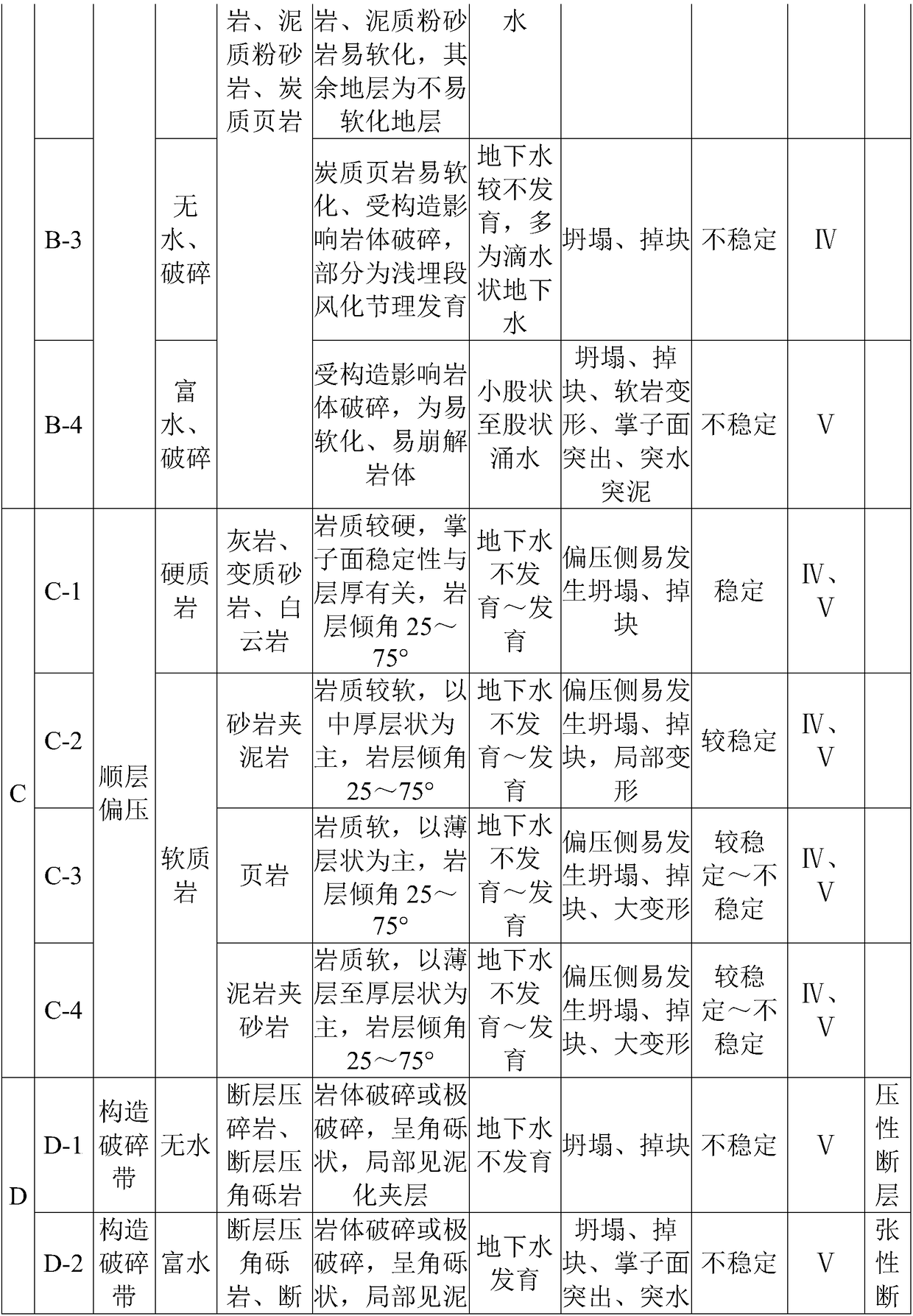

Mini step excavation method suitable for IV-V level of surrounding rocks of large-section tunnel

The invention discloses a mini step excavation method suitable for IV-V level of surrounding rocks of a large-section tunnel. A tunnel face is divided into upper and lower steps, the height of the lower step ranges from 5m to 8m, and advanced geologic prediction is implemented; the tunnel face stability is evaluated and classified; whether to implement advanced support and tunnel face reinforcement is decided, and a processing method is used till the tunnel face is stable; a drill jumbo drills blast holes and fill an explosive in the full section of the tunnel face, whole detonation is carriedout, and the vertical length difference between the upper and lower steps ranges from 3m to 5m; ventilation, danger removing, under-excavation handling and slag removing are carried out on the tunnelface; the tunnel face after excavation is sketched geologically, the stability of the tunnel face is determined, a wet spraying manipulator sprays an early high-strength concrete preliminarily, and the tunnel face is enclosed; an arc centering installation trolley erects a steel frame and implements annular and vertical connection, and concrete is sprayed again to reach a design thickness; an inverted arc area of a present excavation cycle is back filled with hole slag, and work of next cycle is carried out; a movable inverted arch trestle is used to pour the inverted arc and sidewall with basic concrete; earthwork cloths and waterproof boards are laid, and lining steel bars of an arch wall are lashed; and the lining of the arch wall is poured and maintained.

Owner:武九铁路客运专线湖北有限责任公司 +4

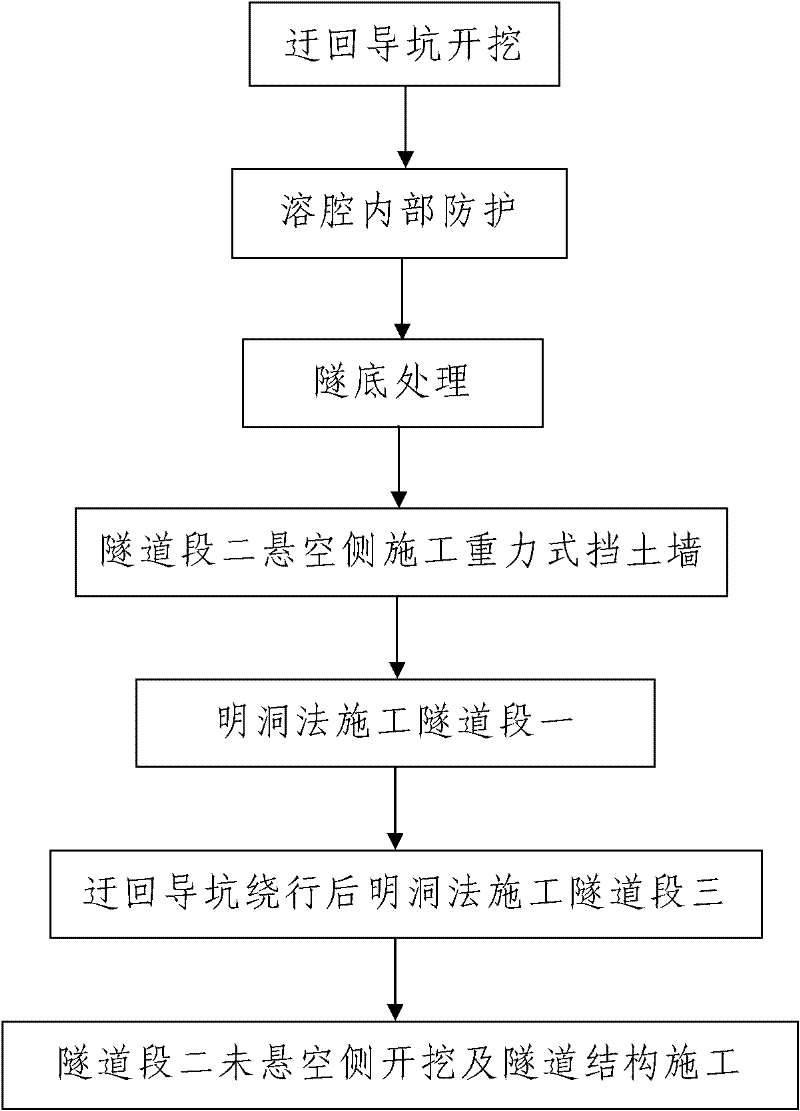

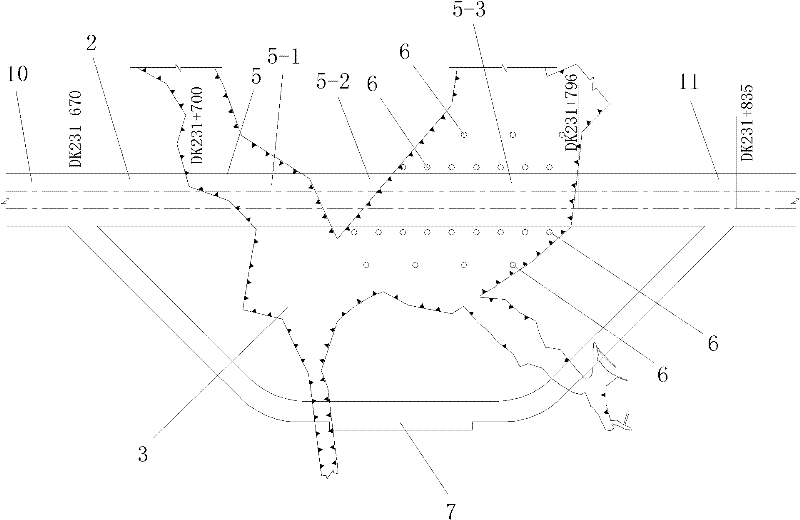

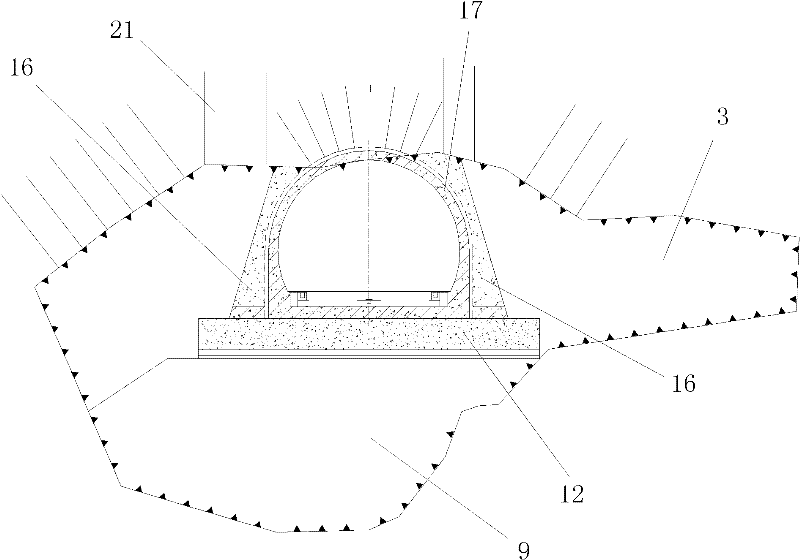

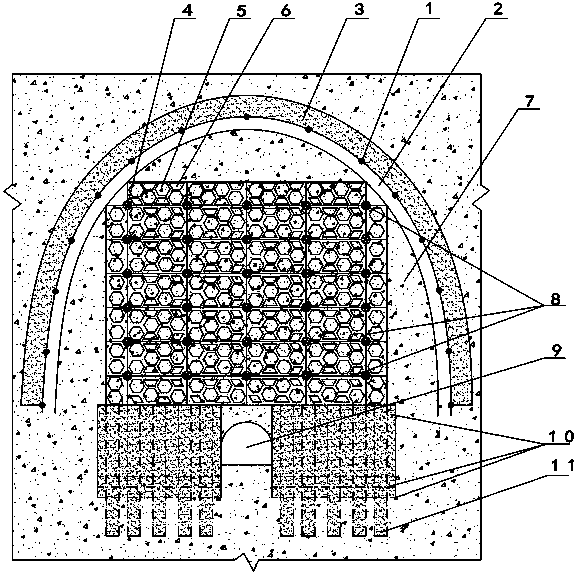

A large-scale solution cavity treatment method for karst tunnels

ActiveCN102296961AReasonable designSimplify construction stepsUnderground chambersTunnel liningLarge distanceKarst tunnel

The invention discloses a karst tunnel large-scale cavern processing method. A cavern traversing tunnel section penetrating through a cavern comprises a tunnel section I, a tunnel section II and a tunnel section III according to the distribution positions, wherein two sides of the tunnel section I are suspended in midair and the top of the tunnel section I is at a smaller distance away from a cavern top plate, one side of the tunnel section II is suspended in midair, and two sides of the tunnel section III are suspended in midair and the top of the tunnel section III is at a larger distance away from the cavern top plate. The processing method comprises the steps of: 1, excavating a bypass pilot tunnel; 2, protecting inside of the cavern; 3, processing the bottom of the tunnel: filling the cavern below the tunnel section I with rock residues and grouting for reinforcing, and then distributing an armoured concrete slab girder, filling the cavern below the tunnel section III with concrete and then distributing an armoured concrete slab girder, filling the cavern below the tunnel section II with hard fillers; 4, constructing a gravity retaining wall at the suspending side of the tunnel section II; 5, constructing the tunnel section I with an open cut tunnel process; 6, constructing the tunnel section III with the open cut tunnel process after the bypass pilot tunnel bypasses; and 7, constructing the tunnel section II. The karst tunnel large-scale cavern processing method has the advantages of reasonable design, convenience for construction, safe and reliable construction process and short construction period, good processing effect on the large-scale cavern.

Owner:CHINA RAILWAY 20 BUREAU GRP

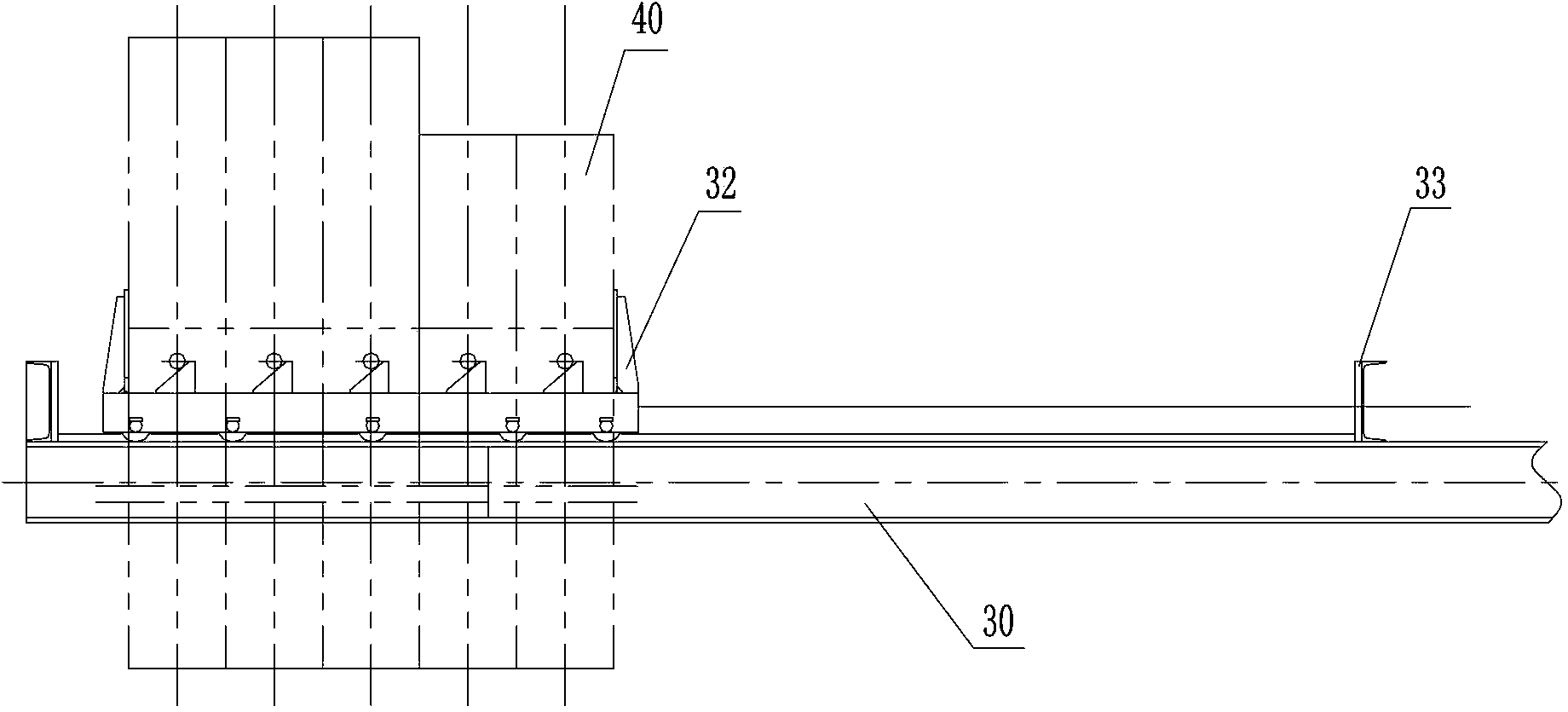

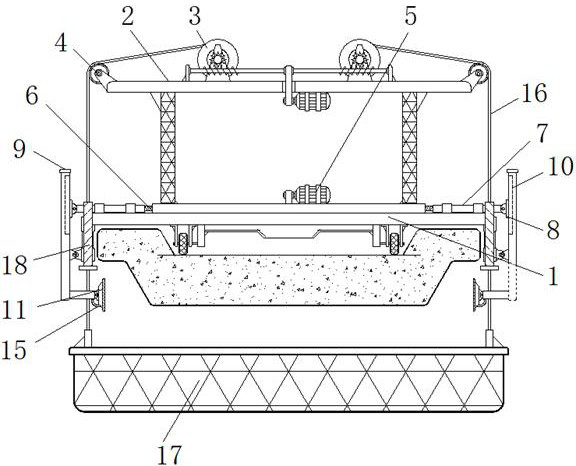

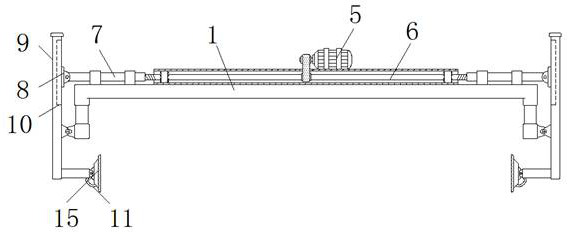

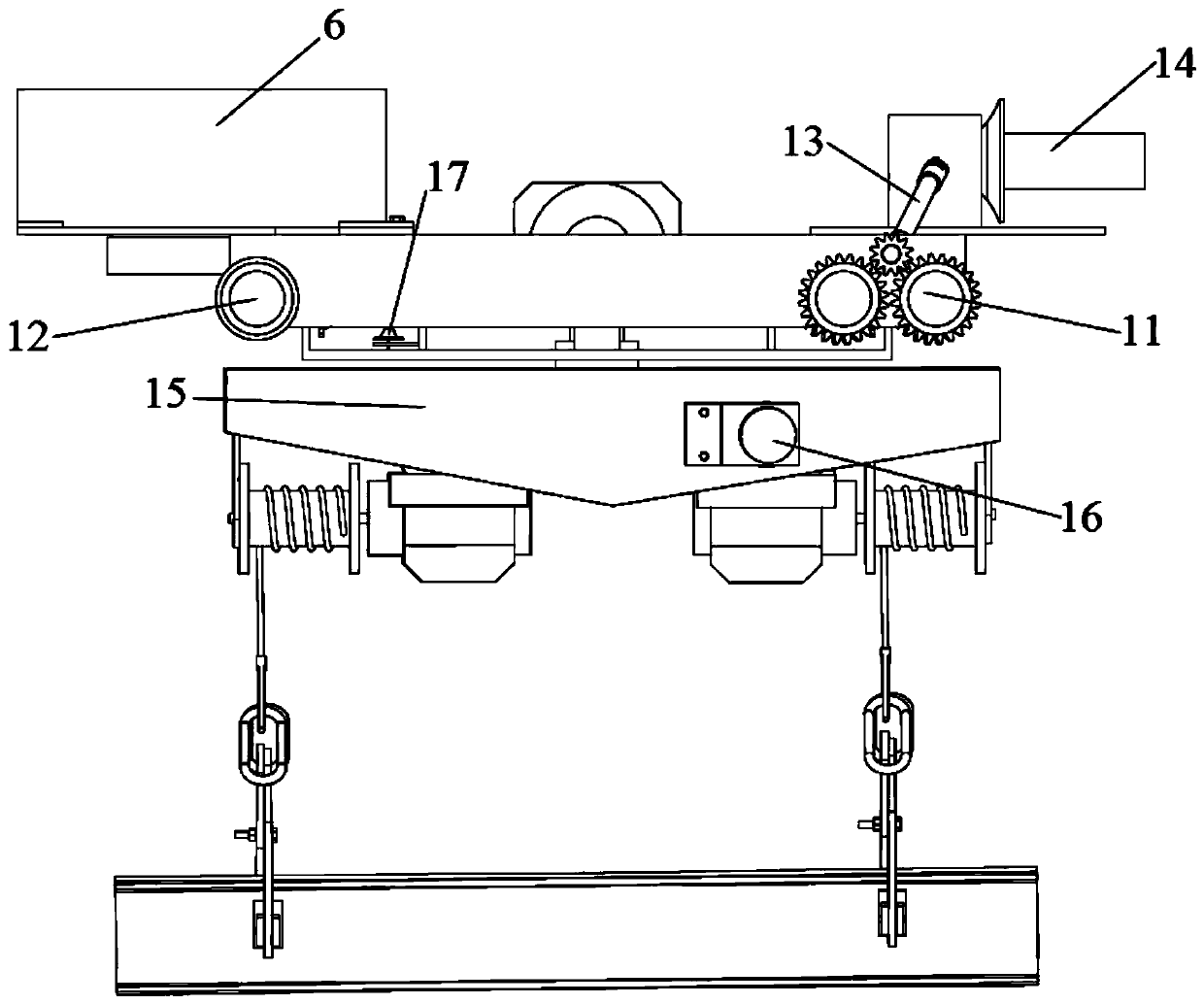

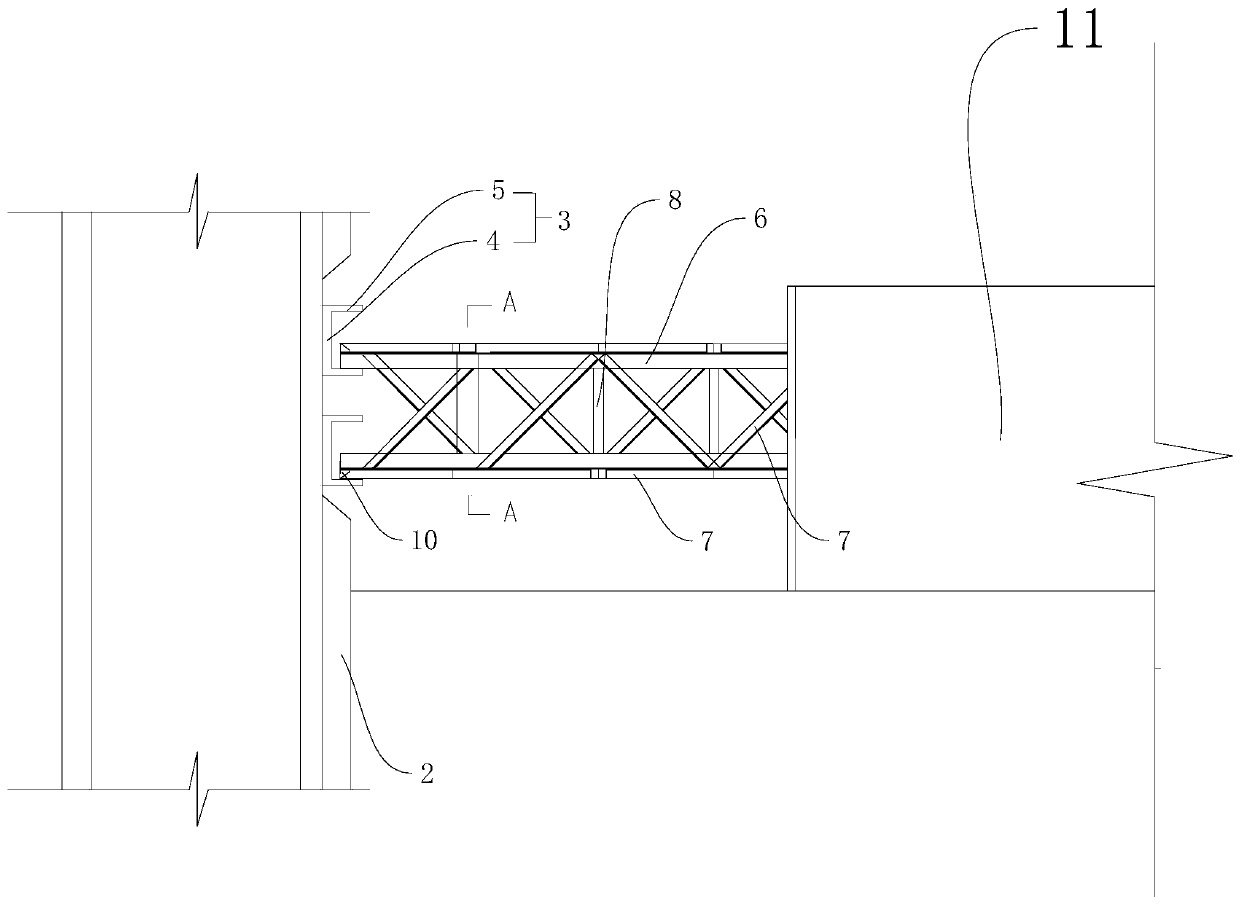

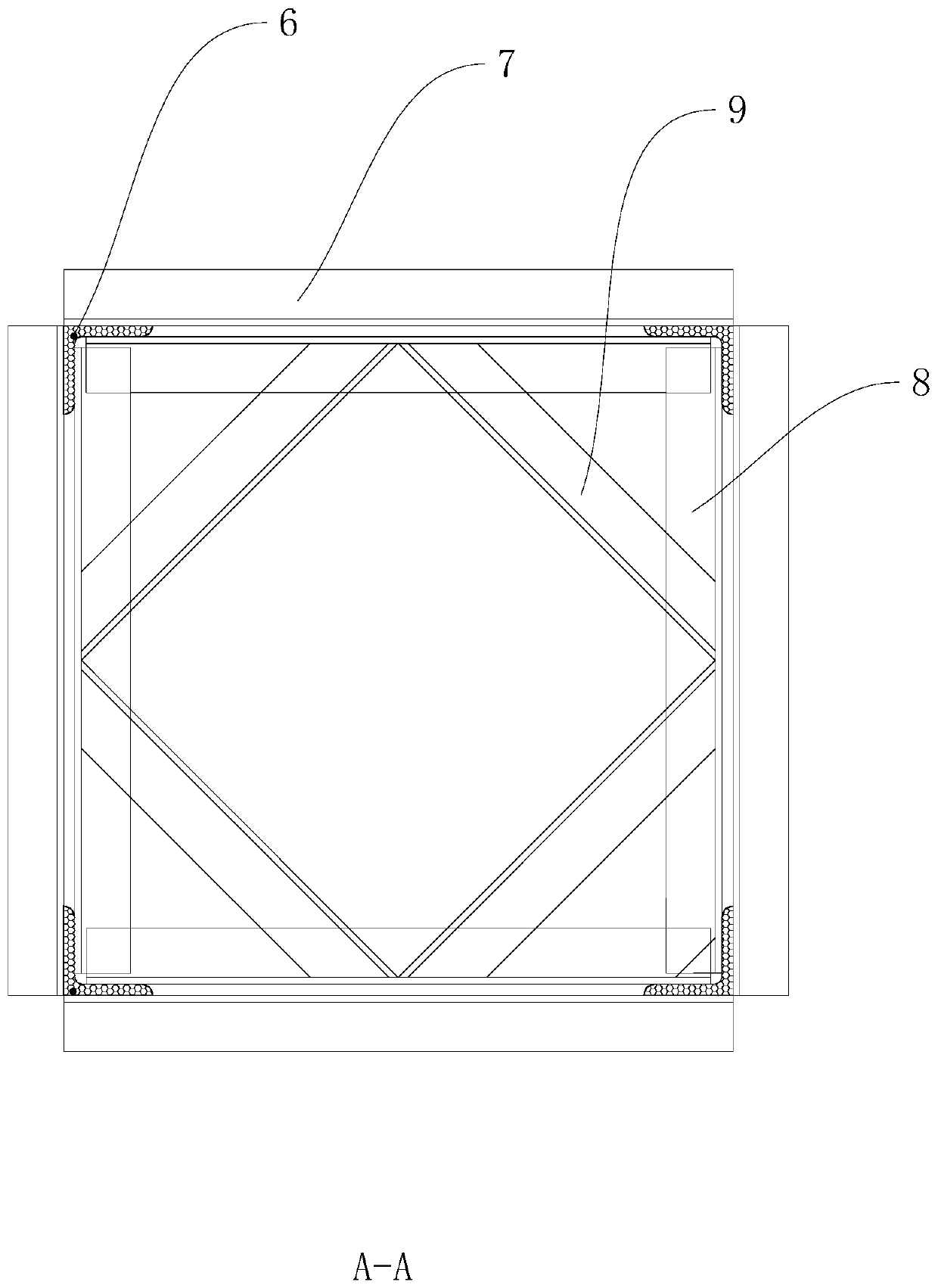

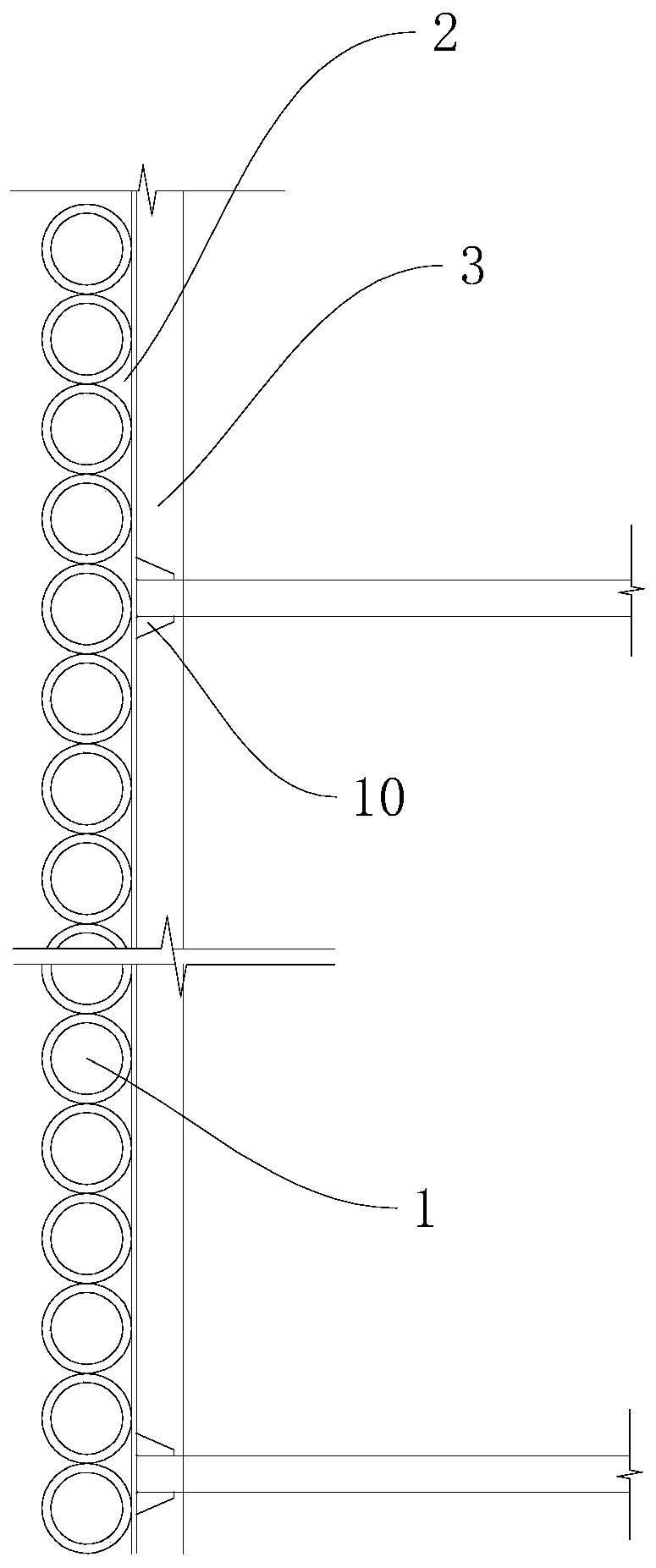

Novel track layer for urban rail traffic engineering and its construction method

PendingCN107642012AEasy to operateEasy to driveRailway track constructionIndustrial engineeringUrban rail

The invention relates to the engineering technology science and particularly relates to a novel track layer for urban rail traffic engineering and its construction method. The device comprises a lifting walking work trolley, a connection truss beam, a track walking mechanism and a supporting structure; horizontal stretching and vertical supporting structures of the lifting walking trolley are operated firstly so as to lift the whole novel track layer to the height of a track hanging and dismounting material; a hoisting trolley lifts up the track material to leave a flat trunk and a material pad; the novel track layer is forwards walked to the installing position of a track section, and then the track material is dismounted; a steel track is connected and the track section is mounted to temporarily support and fix the newly installed track section; the track is walked towards the track section hoisting position in next time to arrive at the unloading place, then the track section is hoisted to the next cycle. The device is simple in structure, convenient to operate, and low in cost; meanwhile, the safety during the working process is ensured and the efficiency is improved.

Owner:CHINA RAILWAY SHANGHAI ENGINEERING BUREAU GROUP CO LTD +1

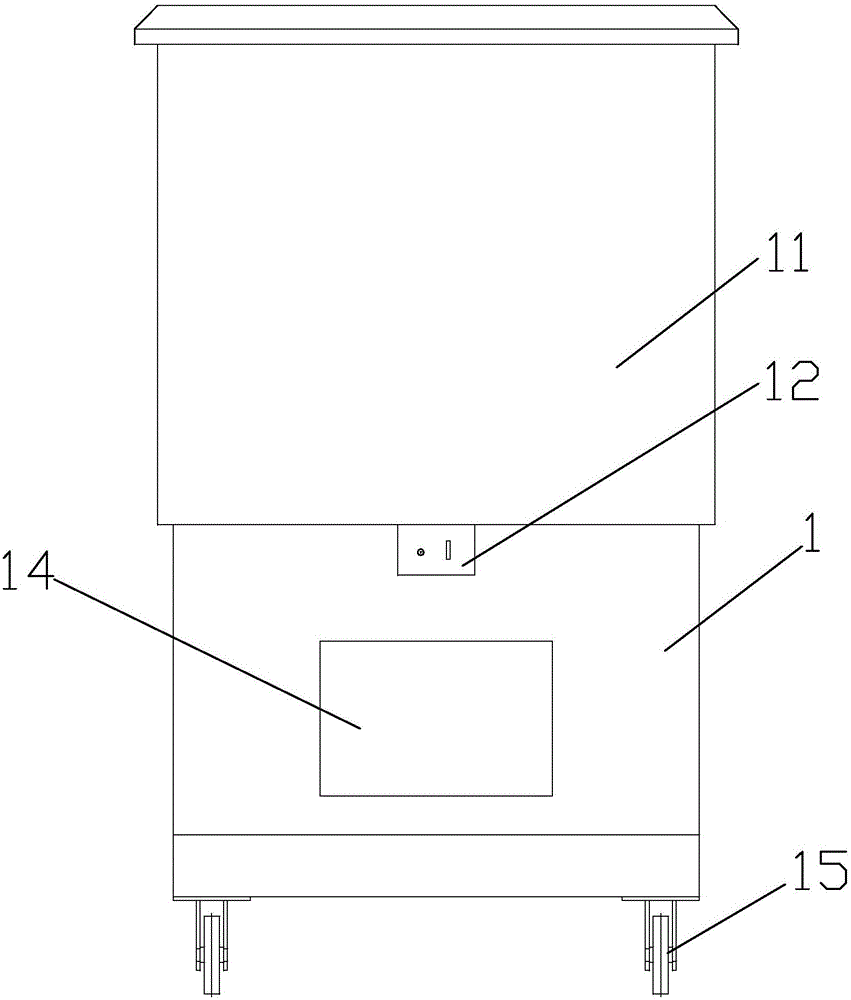

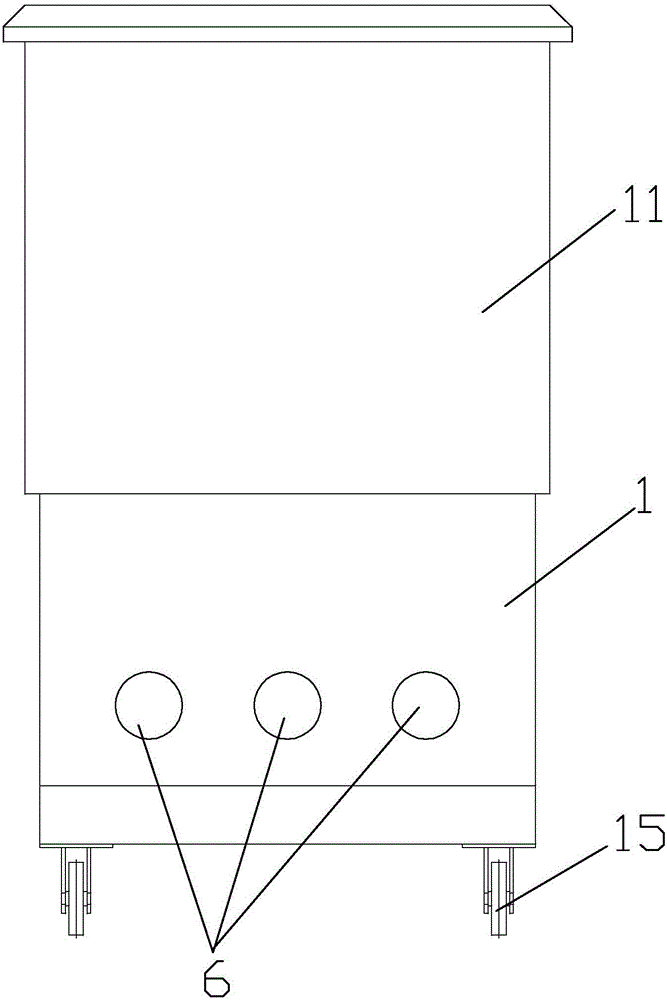

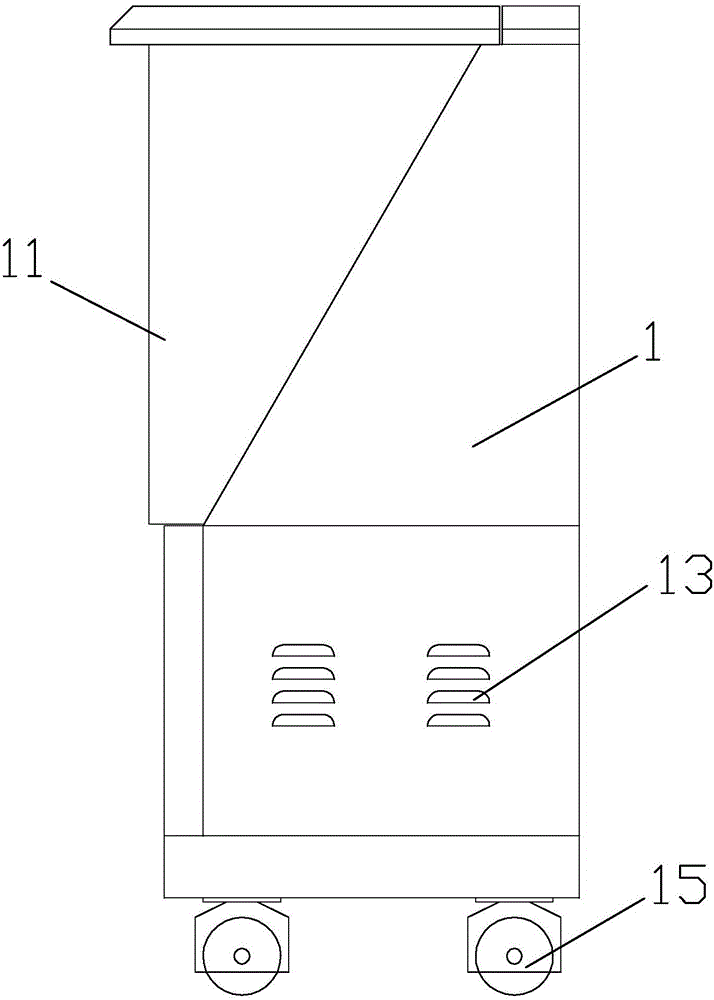

Rapid plugging/pulling cable branching box

ActiveCN105071335AReduce laying distanceSolve the problem of long-distance layingCable junctionsElectricityInsulation layer

The invention provides a rapid plugging / pulling cable branching box. The branching box comprises a box body, three insulators, three copper bars, three connection wires, three T-shaped cable terminals, three straight line adapters and an insulation separation plate, wherein the insulators, the copper bars, the connection wires and the T-shaped cable terminals are arranged in the box body. Each of the straight line adapters comprises a conductive rod, an insulation layer, a rapid clamping head and a housing. One end of each of the straight line adapters is electricallyconnected with one T-shaped cable terminal in the box body correspondingly. The straight line adapters, the T-shaped cable terminals, the connection wires and the copper bars form a three-phase electric access. In use, the copper bars are correspondingly connected with three phase wires A, B and C of a ring main unit incoming cable. The straight line adapters are quickly clamped with rapid joints of three bypass cable joints via the rapid clamping heads. The branching box is simple in structure, low in cost and convenient to achieve. Laying distances of flexible bypass cables can be greatly reduced in use, so a difficulty in remote laying of power supply points and flexible bypass cables is solved and rush repair efficiency is increased.

Owner:CHANGZHOU POWER SUPPLY OF JIANGSU ELECTRIC POWER +3

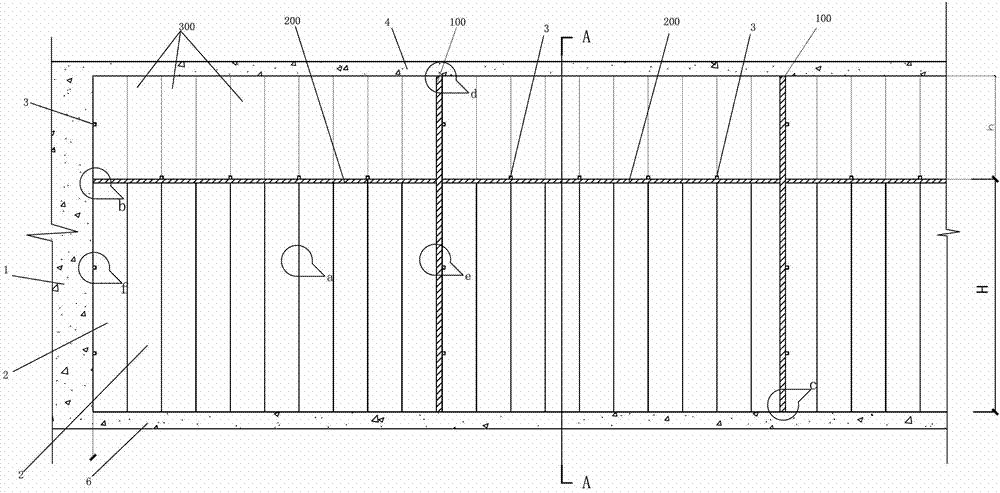

Installation technology of connecting board type inner separation wall

InactiveCN102777042AImprove stabilityImprove labor efficiencyWallsBuilding material handlingStructural engineeringEngineering

The invention discloses an installation technology of a connecting board type inner separation wall. The installation technology comprises the following steps of: locating, despoiling, installing vertical metal supporting columns, installing horizontal metal supporting columns, installing wallboards in lower installation spaces and installing connecting boards with the height being lower than that of the wall boards in upper installation spaces. According to the installation technology disclosed by the invention, the space between beam boards and floor boards are separated into multiple lower installation spaces and multiple upper installation spaces through horizontal metal supporting beams and vertical metal supporting beams, the wall boards are arranged in the lower installation spaces, the connecting boards are arranged in the upper installation spaces, thus the labor efficiency is greatly increased, and the firm performance of a wall body is enhanced.

Owner:中山建华墙体材料有限公司

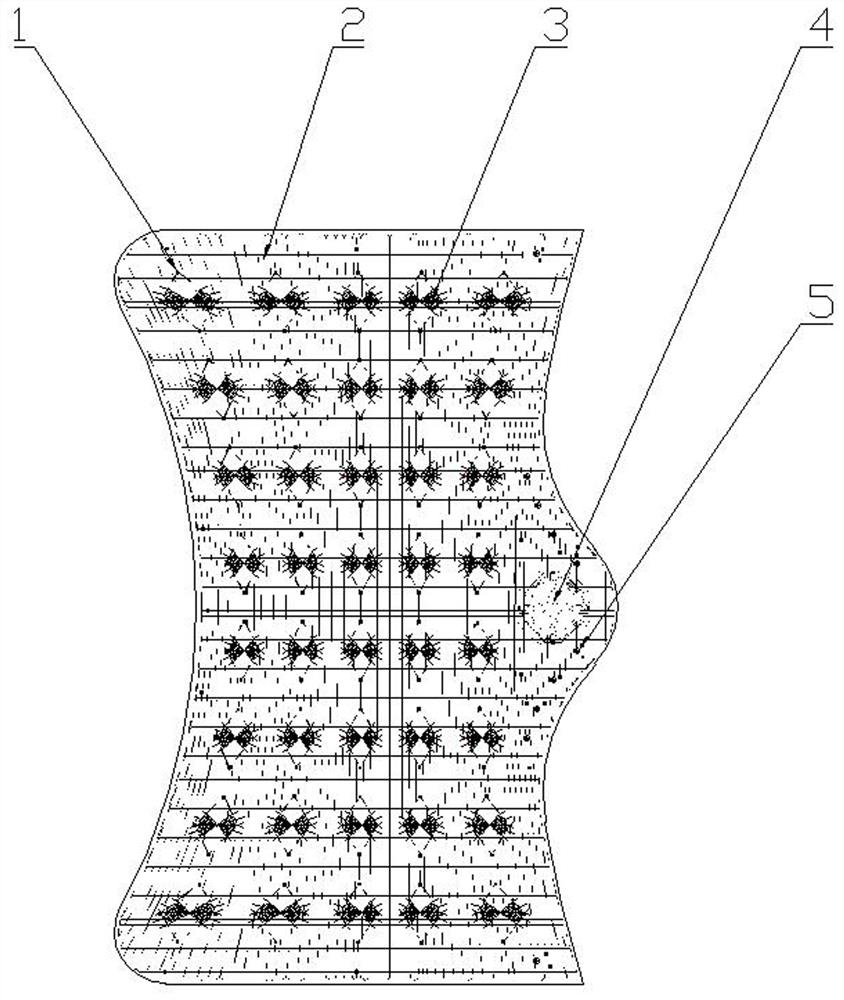

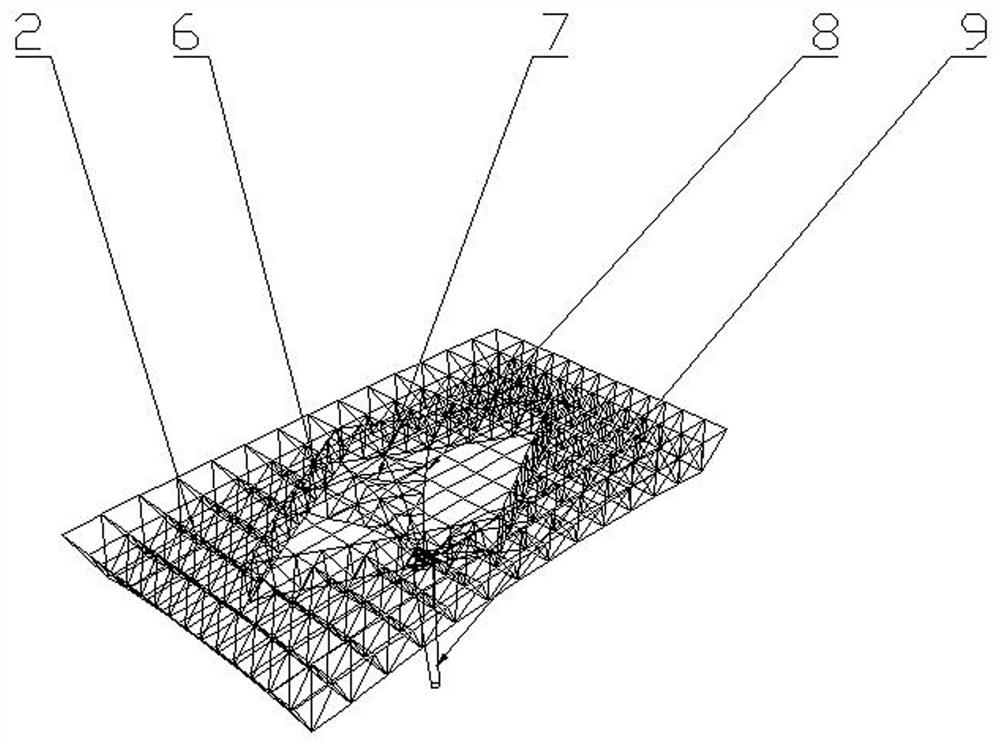

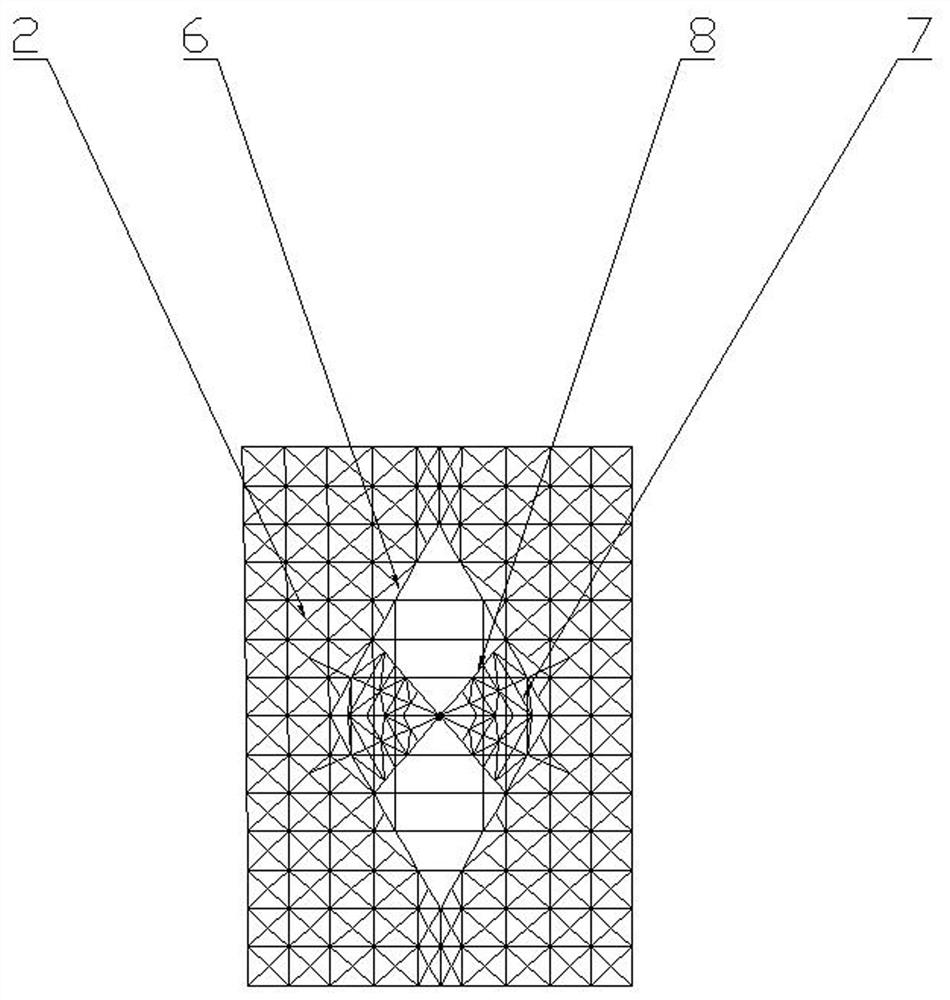

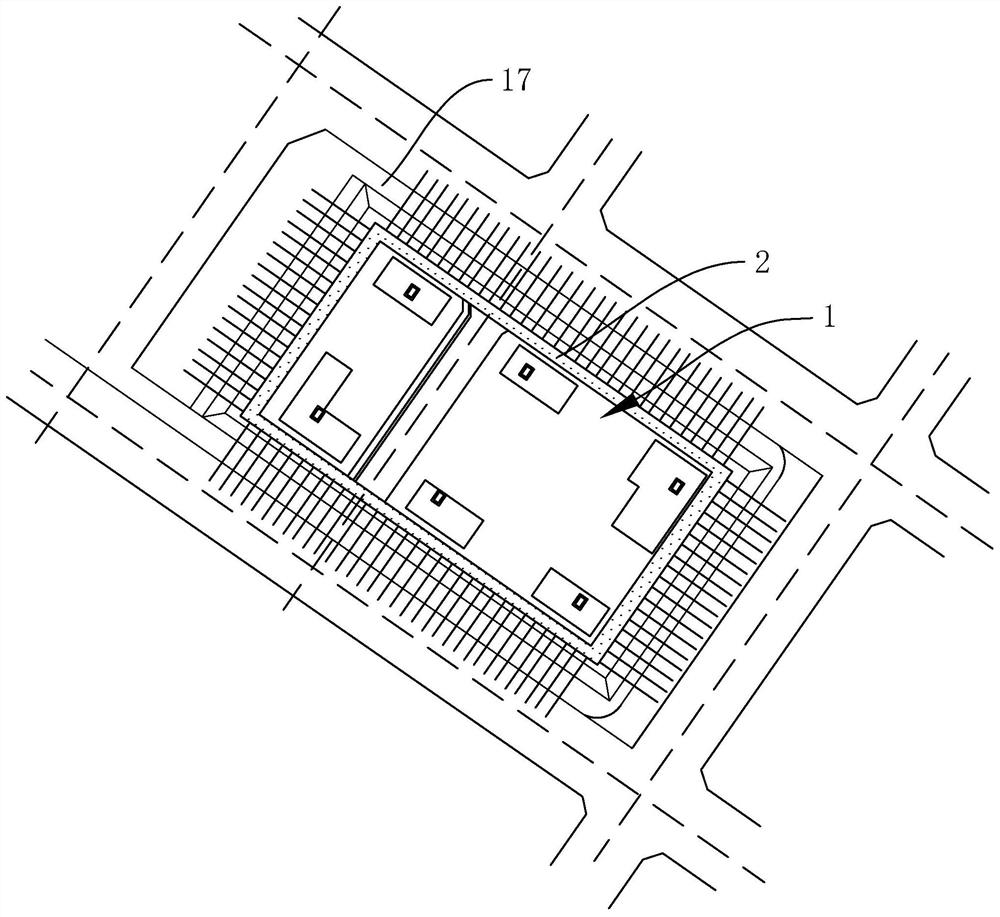

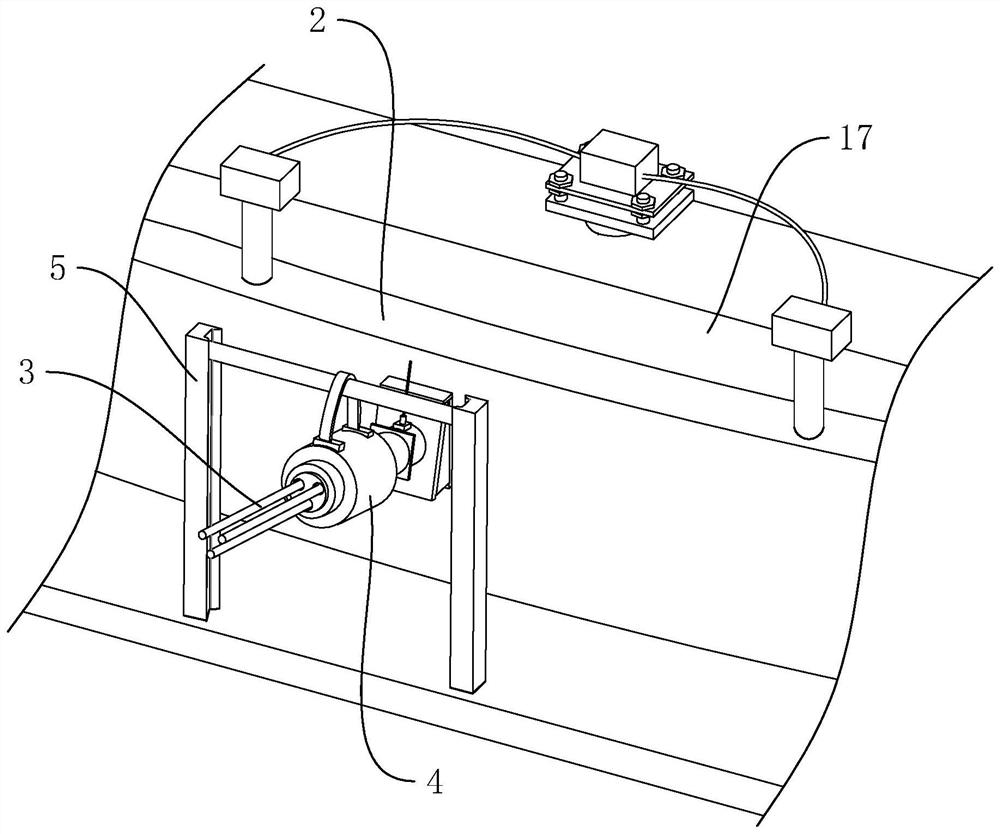

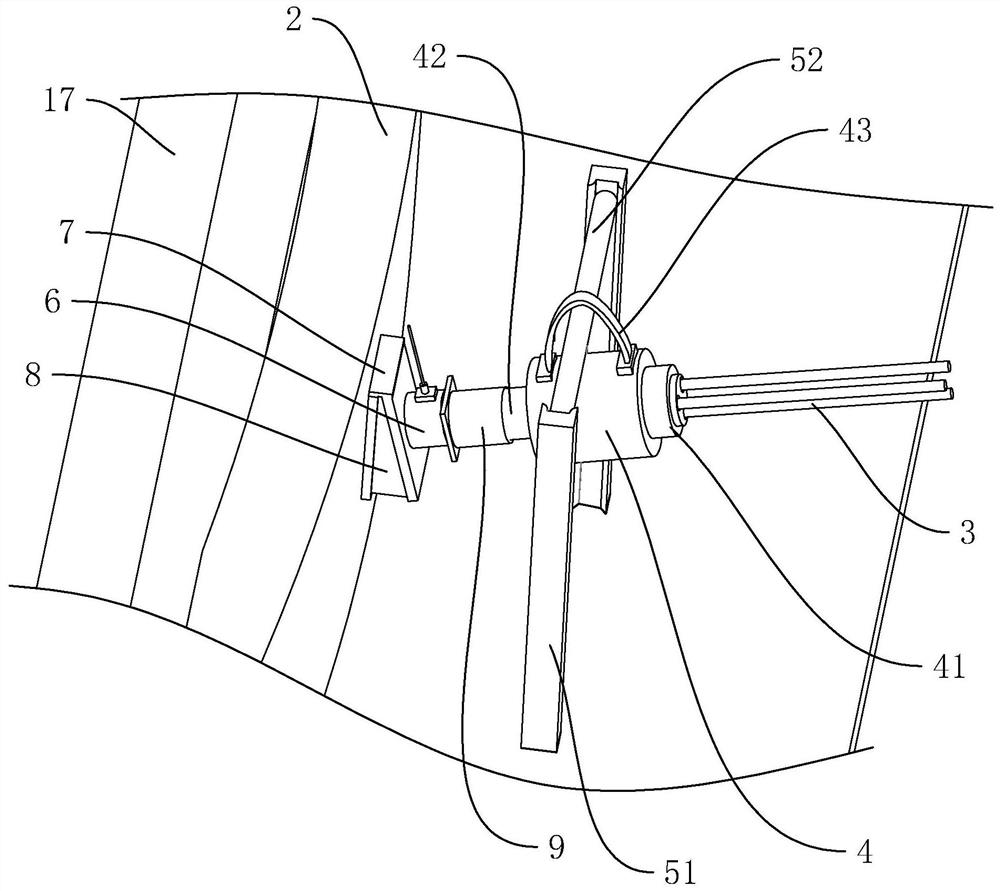

Forked column and curved surface grid integrated steel structure roof and installation method thereof

InactiveCN113047503AImprove structural stabilityShort construction periodBuilding roofsStrutsAgricultural engineeringMechanical engineering

The invention relates to a forked column and curved surface grid integrated steel structure roof and an installation method thereof, and belongs to the technical field of steel structures. The steel structure roof comprises a plurality of lotus grain column assemblies which are distributed in a rectangular array at equal intervals; the lotus grain column assemblies are arranged on one sides of the lotus grain column assemblies; peripheral roof net racks are arranged between the lotus grain column assemblies and between the lotus grain column assemblies and the lotus grain column assemblies; each lotus grain column assembly comprises a supporting column; a plurality of forked columns are arranged between the two ends of the supporting column and the peripheral roof net racks; supporting column edge sealing trusses are arranged between the forked columns and the peripheral roof net racks; each lotus grain column assembly comprises a lotus grain column; and lotus grain column edge sealing trusses are arranged between the lotus grain columns and the peripheral roof net racks. The forked column and curved surface grid integrated steel structure roof has the characteristics of good structural stability, short construction period and high efficiency. Therefore, construction potential safety hazards are reduced, and installation convenience is improved.

Owner:浙江东南网架股份有限公司

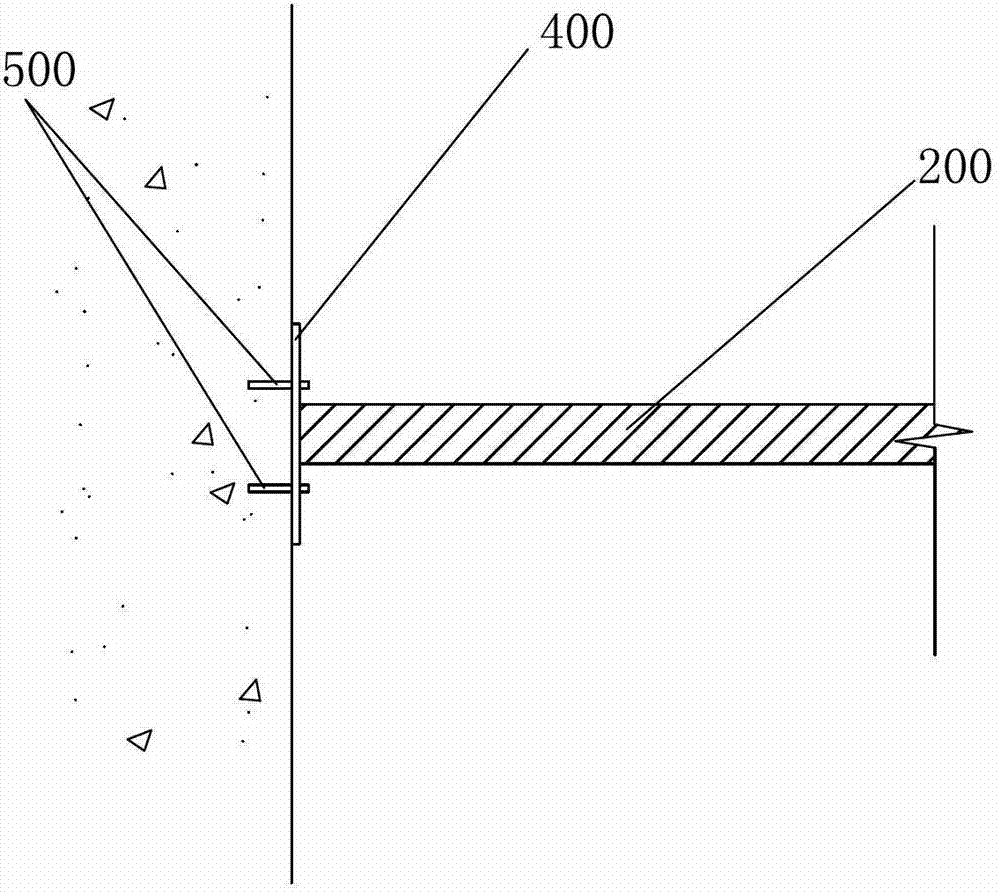

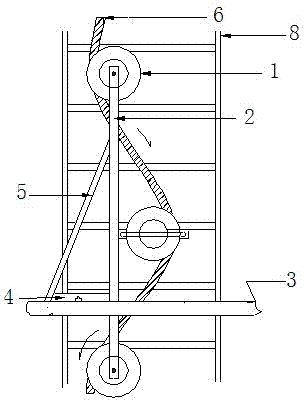

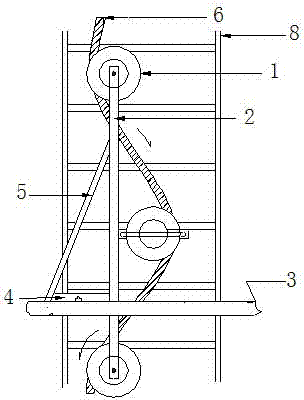

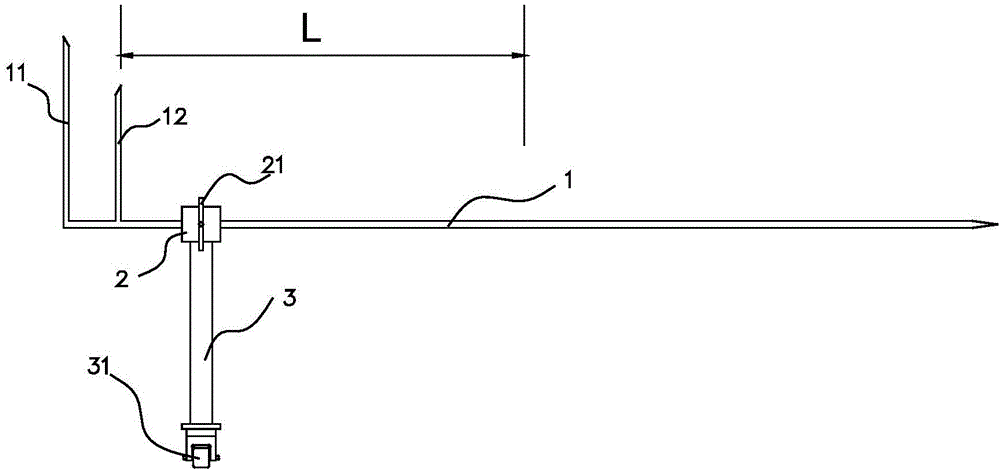

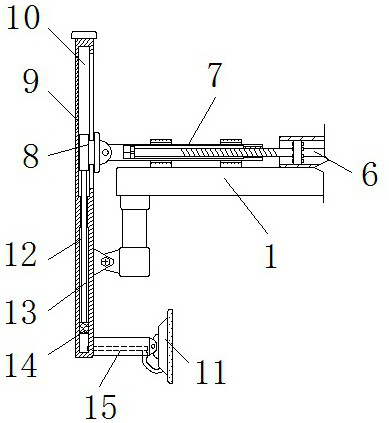

Auxiliary device capable of paying off cable from top to bottom in building construction and cable paying off method

ActiveCN102332691APay-off process safetyReduce construction safety hazardsArrangements using take-up reel/drumApparatus for laying cablesFloor slabEngineering

The invention discloses an auxiliary device capable of paying off a cable from top to bottom in building construction and a cable paying off method. The auxiliary device comprises at least three fixed pulleys, the fixed pulleys are fixedly arranged on a vertical strut and are respectively located at different heights, at least one fixed pulley can be regulated left and right relative to the vertical strut; and a horizontal cross rod is arranged on the vertical strut, and an inclined pull rod is arranged between the other end of the horizontal cross rod and the vertical strut. The cable paying off method disclosed by the invention comprises the following steps of: (1) fixing the auxiliary device on a floor slab, and mounting the vertical strut in a wire hole; and (2) enabling one end of the cable to round all the fixed pulleys from top to bottom, then starting paying off, regulating the fixed pulley which can be regulated at left and right as required in a cable paying off process to change horizontal distance between the fixed pulley and adjacent fixed pulleys, thus paying off speed of the cable can be controlled. According to the invention, labour is saved in the cable paying off process, a falling speed is easy to control, the whole cable paying off process is very safe, and potential safety hazards in construction are reduced.

Owner:中建五局安装工程有限公司

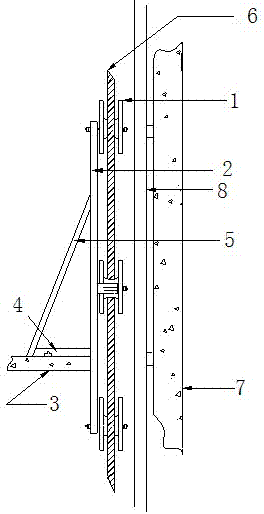

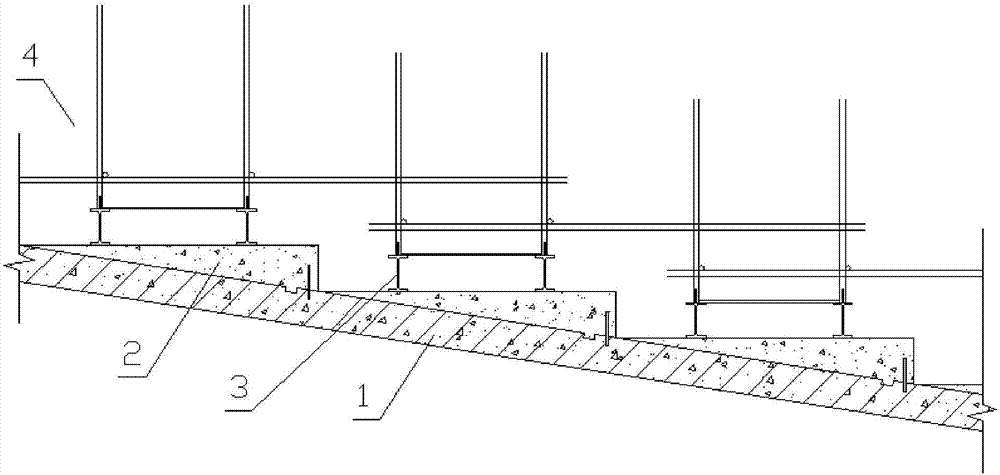

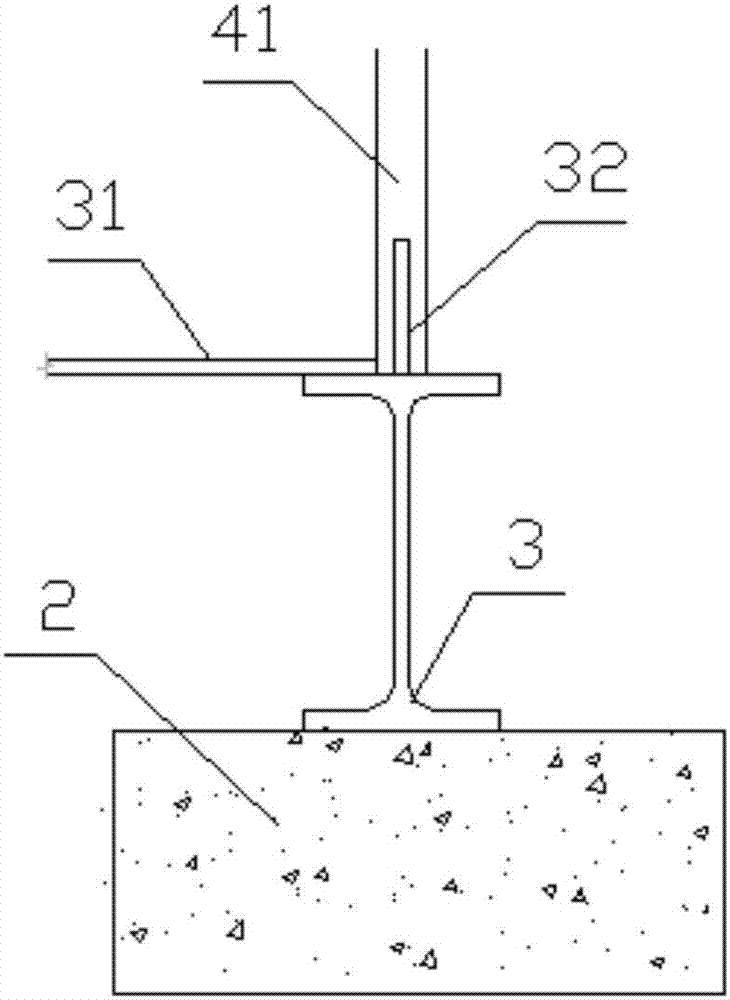

Concrete slant component upper supporting system and construction method for same

InactiveCN106917508AImprove stabilityEliminate destructionForms/shuttering/falseworksShoresSupporting systemSurface layer

The invention discloses a concrete slant component upper supporting system and a construction method for the same. The concrete slant component upper supporting system is built on a completed reinforced concrete slant component and comprises a plurality of concrete steps arranged on a slope of the reinforced concrete slant component; the slope of the reinforced concrete slant component is provided with anti-shearing slots and vertical insertion ribs cast with the concrete steps; each concrete step is provided with elongated I-shaped steel; a supporting rack is built over the I-shaped steel; and supporting stand columns of the supporting rack are supported on the I-shaped steel. With arrangements of the concrete steps and the increase of the I-shaped steel, concentrated force of the supporting rack can be converted into uniform-distribution force, so damage to a top plate surface layer can be eliminated; and a cross section of each stand column is evenly stressed, so perpendicularity can be guaranteed and local stability of the column member can be enhanced.

Owner:ZHONGTIAN CONSTR GROUP

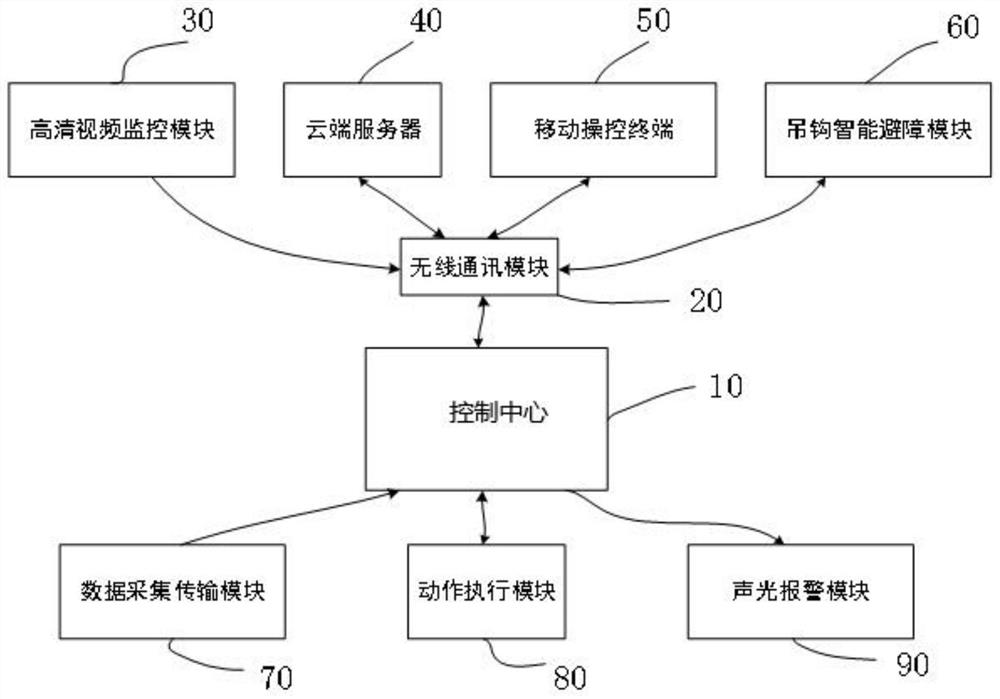

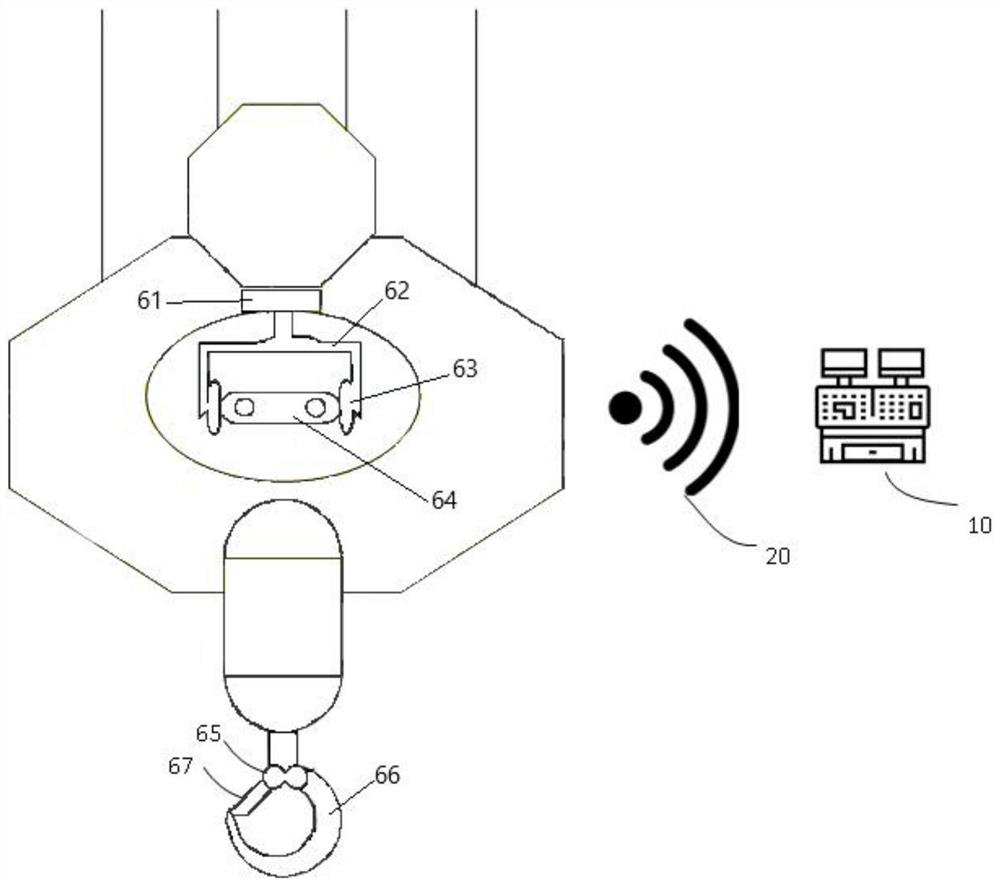

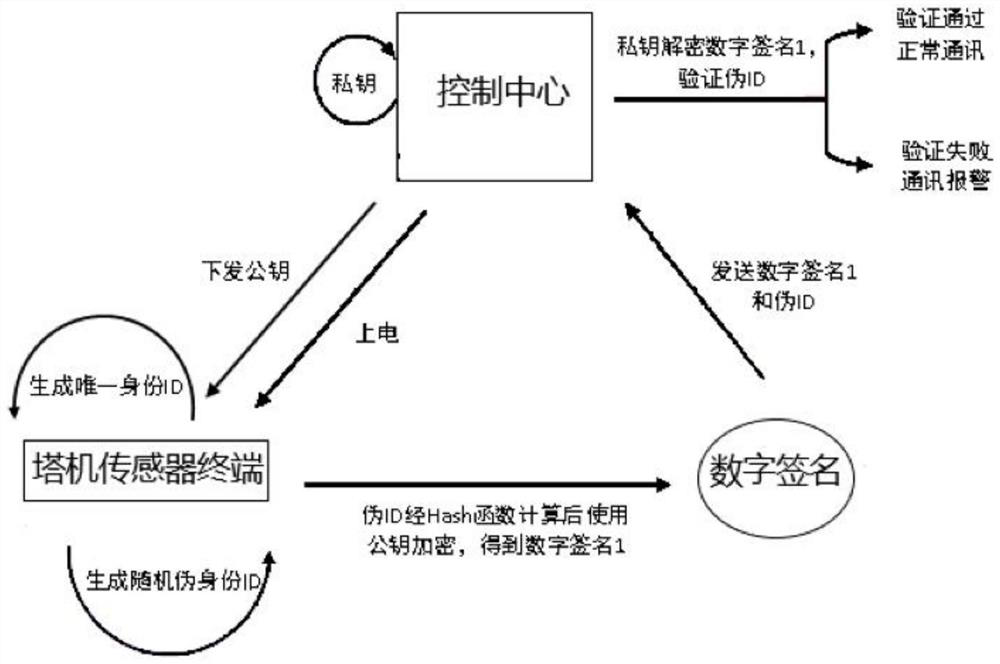

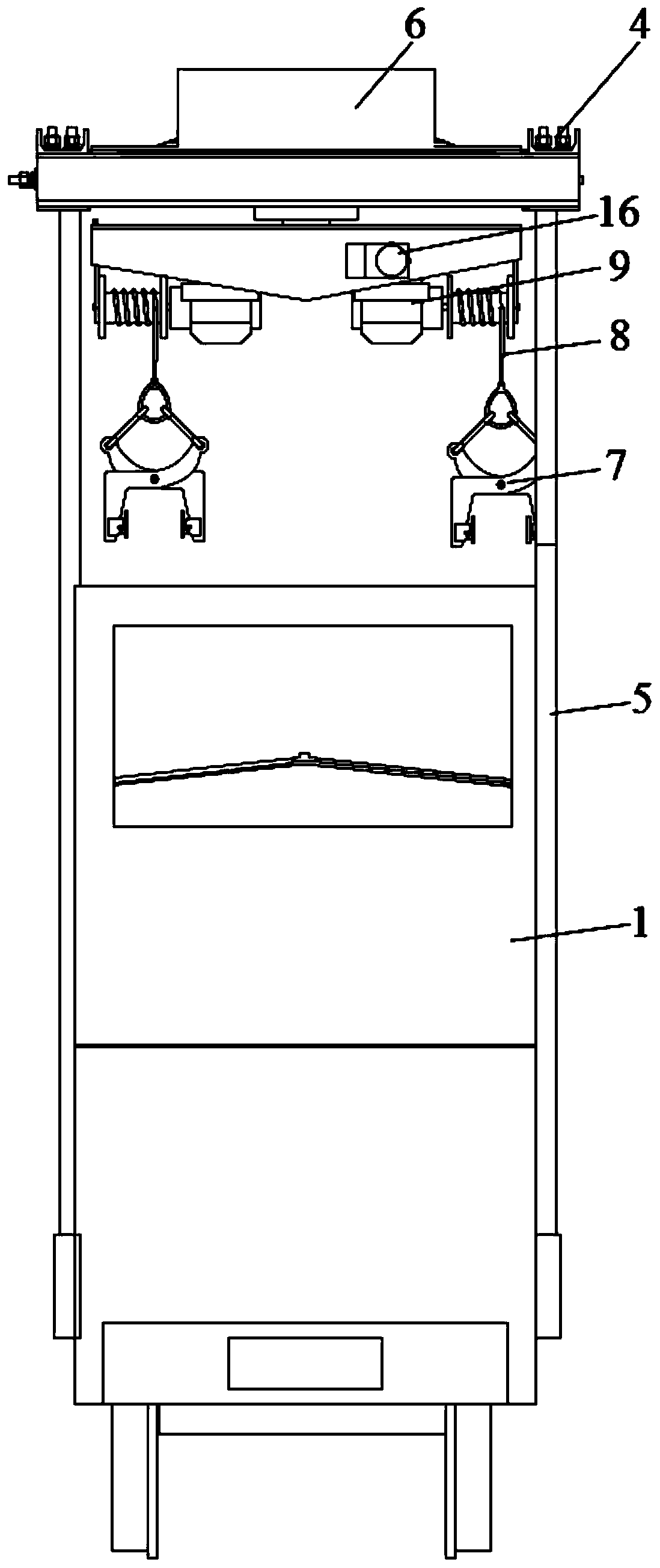

Intelligent control system for tower crane

PendingCN112777497AReduce labor costsImprove the efficiency of hoisting operationsCranesSafety gearVideo monitoringData acquisition

The invention discloses an intelligent control system for a tower crane, and belongs to the field of construction engineering machinery. The control system comprises a control center, a wireless communication module, a cloud server, a mobile control terminal, a high-definition video monitoring module, a lifting hook intelligent obstacle avoidance module, a data acquisition and transmission module, an action execution module and an alarm module, the cloud server, the mobile control terminal, the high-definition video monitoring module and the lifting hook intelligent obstacle avoidance module are connected with the control center through the wireless communication module, and the data acquisition and transmission module, the action execution module and the alarm module are connected with the control center. According to the intelligent control system for the tower crane, the core components of the tower crane are integrated through information technology means and are not detachable, so that intelligent operation and intelligent obstacle avoidance within the calibration range of the tower crane are realized, the labor cost of tower crane operation is reduced, the potential safety hazard of construction is further reduced, and the hoisting operation efficiency of the tower crane is improved.

Owner:GUANGXI CONSTR ENG GROUP CONSTR MACHINERY MFG

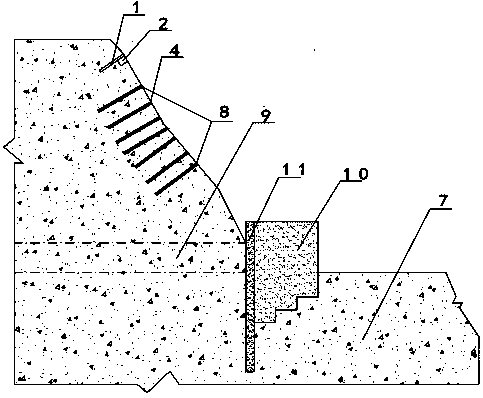

Supporting treatment construction method for high and steep side slopes of tunnel portal bedding strong weathered rocks

ActiveCN109610481AIncreased risk of landslidesGood drainageExcavationsReinforced concreteEngineering

The invention discloses a supporting treatment construction method for high and steep side slopes of tunnel portal bedding strong weathered rocks. The method comprises the following steps: (1) densely-arranged steel pipe piles which are distributed in an approximate semicircular arc mode are arranged outside a design boundary of a main slope, U-shaped drainage grooves are constructed and formed along the inner sides of the densely-arranged steel pipe piles, geogrids are paved within the range of 1-2 m along the outer sides of the densely-arranged steel pipe piles, and a layer of concrete is sprayed to the surfaces of the grids; (2) an anchor cable frame beam structure is arranged on the surface of the side slope on the inner sides of the densely-arranged steel pipe piles, a concrete layerslightly higher than a frame beam is built along the inner side of each frame, and hollow polygonal edge blocks are evenly arranged in the frames; (3) a plurality of reinforced concrete piles are evenly arranged on the left side and the right side of the tunnel portal design boundary at intervals; and (4) a foundation pit is excavated along the outer side of the reinforced concrete piles, and a reinforcement cage is built along the foundation pit and around the reinforced concrete piles to form a retaining wall structure. The method can effectively solve the problem of treatment of the high and steep side slopes of the bedding strong weathered rocks, and has the advantages of efficient construction, safe structure and the like.

Owner:XIANGTAN UNIV

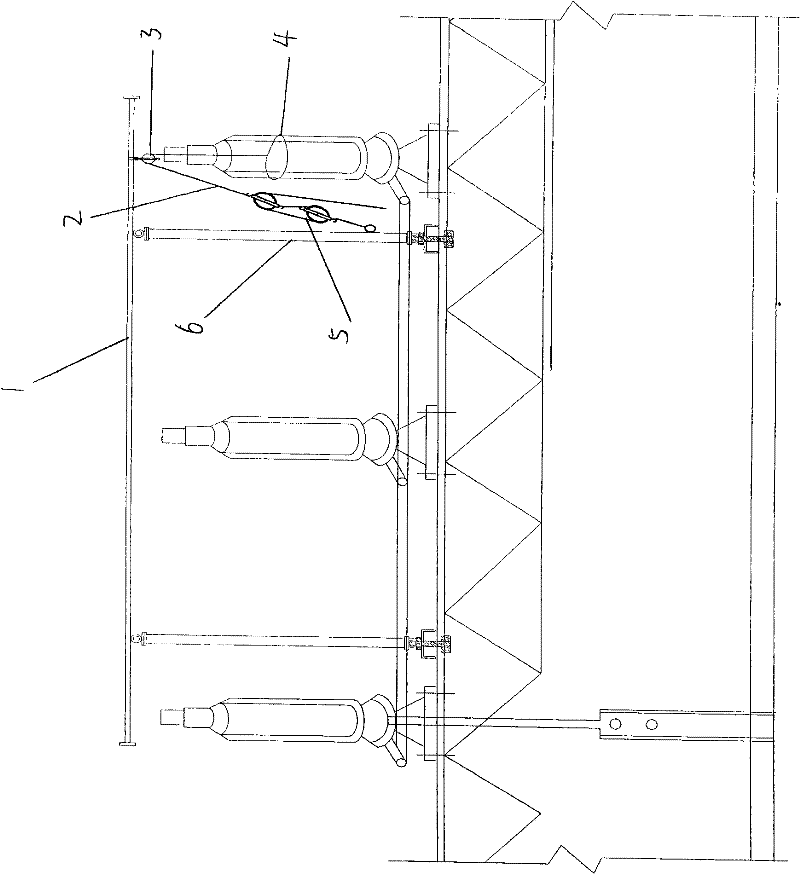

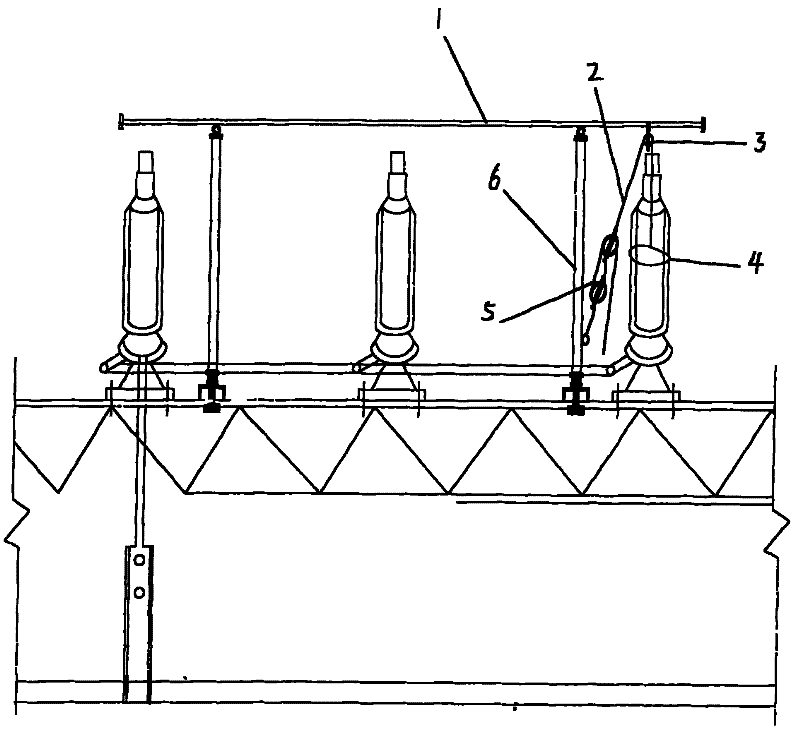

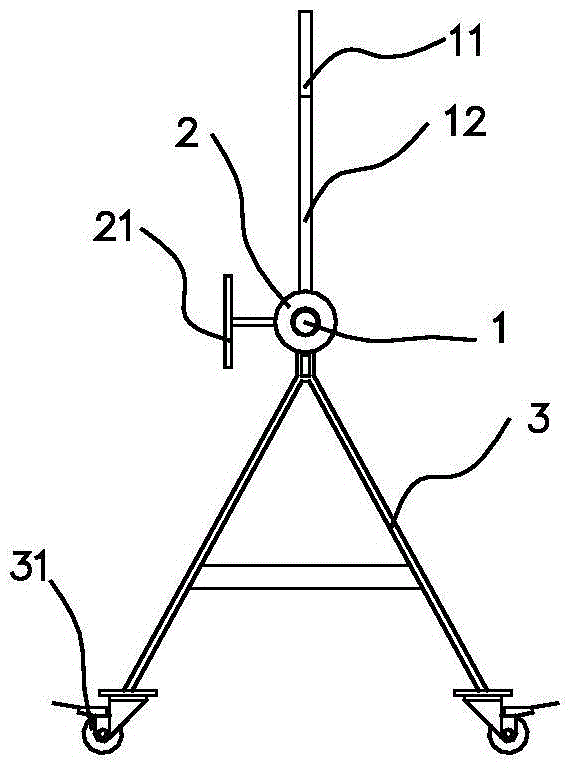

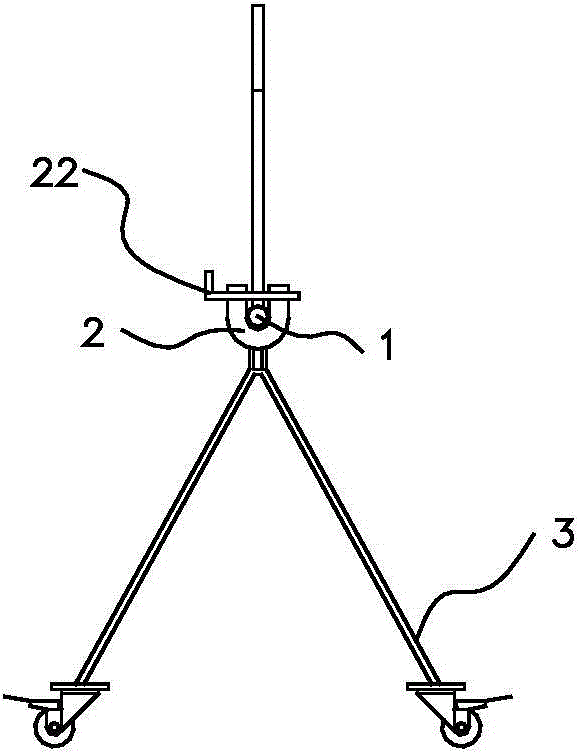

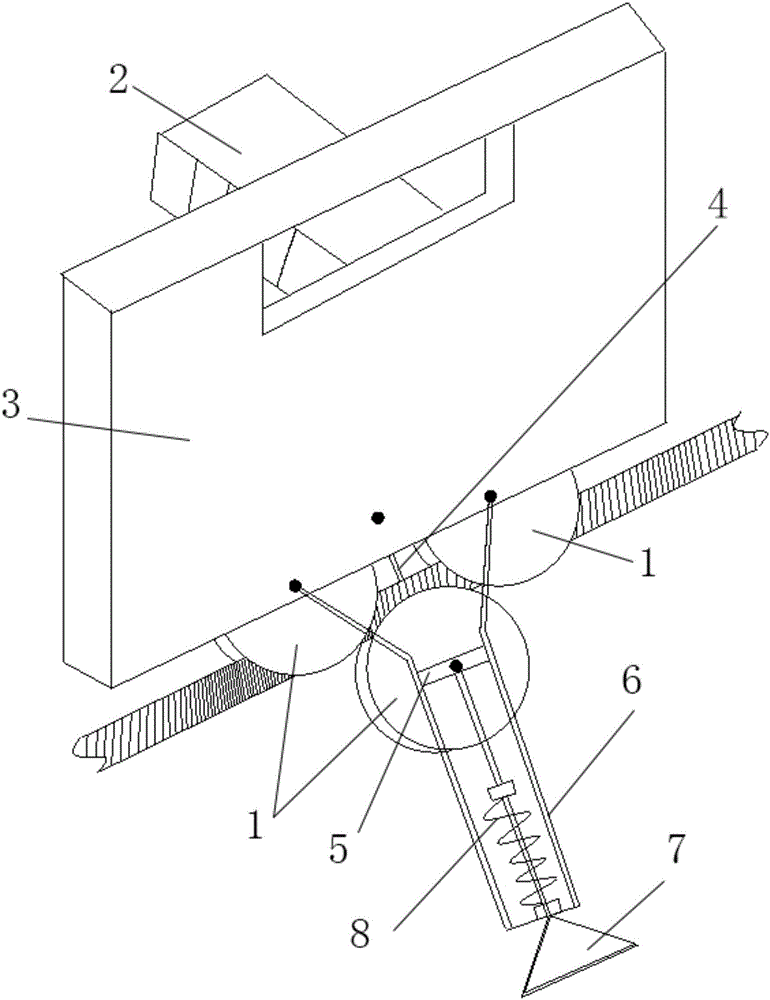

Disconnecting switch overhaul lifting appliance

InactiveCN102447222AEasy to useReduce construction safety hazardsPortable liftingSwitchgearPulleyArchitectural engineering

The invention discloses a disconnecting switch overhaul lifting appliance, and aims to design a disconnecting switch overhaul lifting appliance which is safe and convenient to use. The disconnecting switch overhaul lifting appliance provided by the invention has the technical scheme that the disconnecting switch overhaul lifting appliance comprises a guide rope and a pulley block; a fixed pulley is arranged at the top of a lifting appliance rack; a support rod of the lifting appliance rack is fixedly connected with the pulley block; the guide rope penetrates through each pulley on the pulley block and penetrates through the fixed pulley; and one end of the guide rope is provided with a rope sleeve. The pulley block is provided with a fixed pulley and a movable pulley. The disconnecting switch overhaul lifting appliance has simple structure, use efficiency can be improved effectively, and potential safety hazards of construction workers can be reduced.

Owner:XINXIANG POWER SUPPLY COMPANY STATE GRID HENAN ELECTRIC POWER

Special tool for maintenance of corrugated beam barrier of highway

InactiveCN105625218APlay a plastic rolePlay a repairing roleRoadway safety arrangementsShortest distanceEngineering

The invention discloses a special tool for maintenance of a corrugated beam barrier of a highway and relates to the technical field of barrier maintenance. By the adoption of the special tool for maintenance of the corrugated beam barrier of the highway, the situation that the barrier bounces and injures people in the dismantling process can be avoided, and a repairing function and a short-distance transferring function are achieved. The special tool for maintenance of the corrugated beam barrier of the highway comprises a main rod and a traveling support. A long cross arm and a short cross arm are arranged at the front end of the main rod, wherein the long cross arm is located at the top end of the main rod, and the short cross arm is located behind the long cross arm, in parallel to the long cross arm and is provided with a gap. A movable supporting structure is arranged at the top end of the traveling support. The main rod is provided with a supporting section. The supporting section of the main rod is arranged on the movable supporting structure. According to the special tool for maintenance of the corrugated beam barrier of the highway, the main rod is arranged to be in an F shape, and a corrugated beam protective plate right can be placed in the gap between the long cross arm and the short cross arm. During dismantling, the long cross arm at the end of the main rod is clamped on the back side of a corrugated beam, the short cross arm is clamped on the front side of the corrugated beam, and even if the barrier bounces elastically when screws are separated from the barrier and stand columns are installed, the situation that the barrier bounces and injures people is avoided under the restraint of the short cross arm. Meanwhile, a clamping opening formed by the F shape can also have shaping and repairing effects on the corrugated beam protective plate which deforms slightly.

Owner:江苏高速公路工程养护有限公司

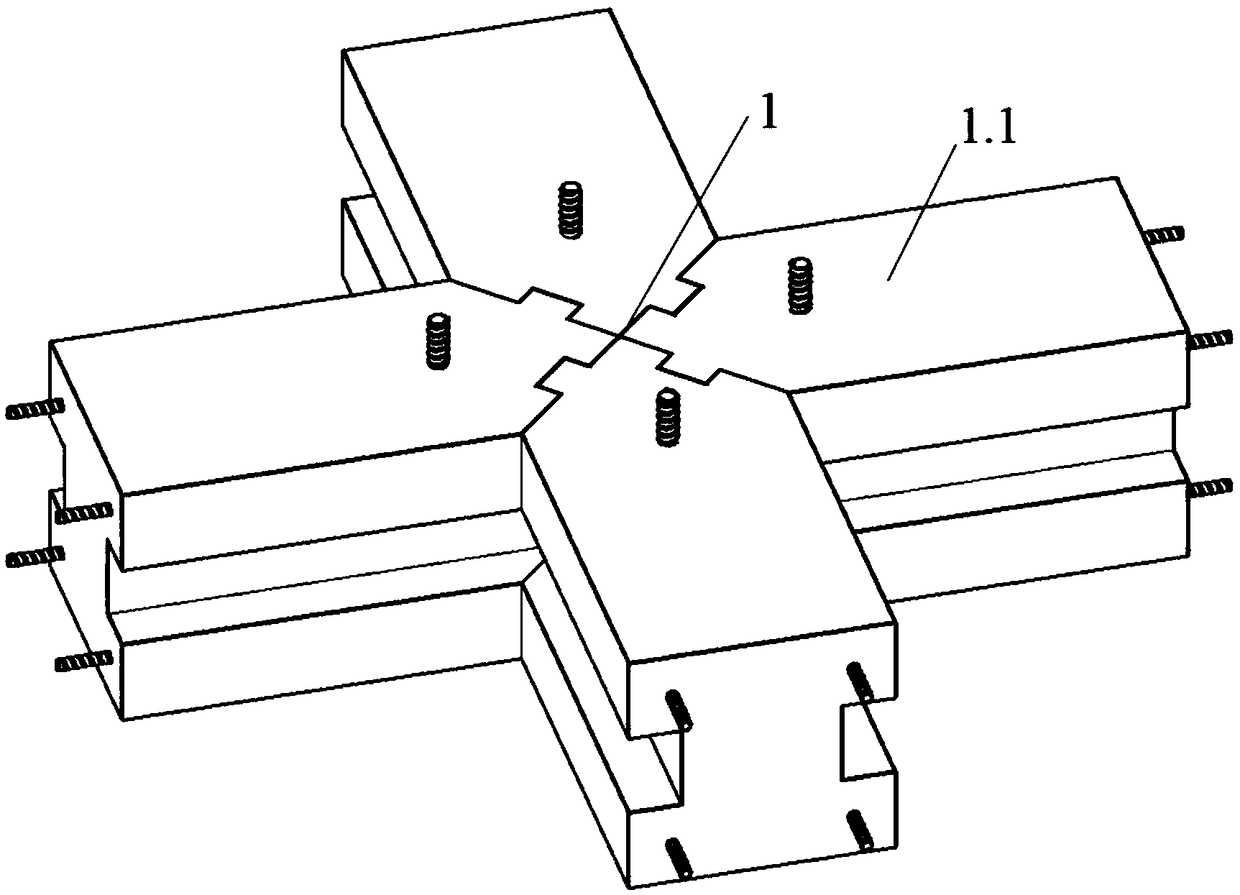

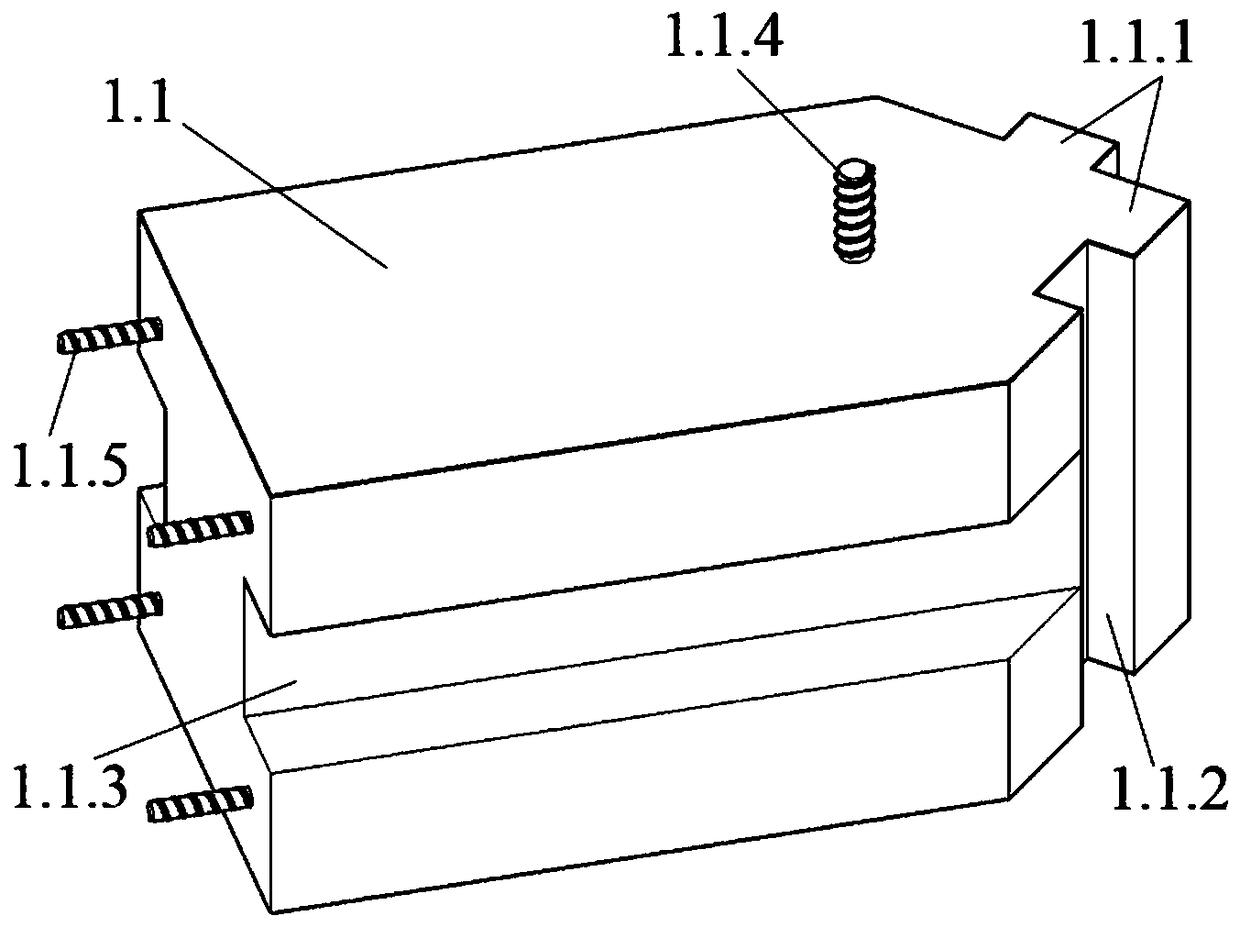

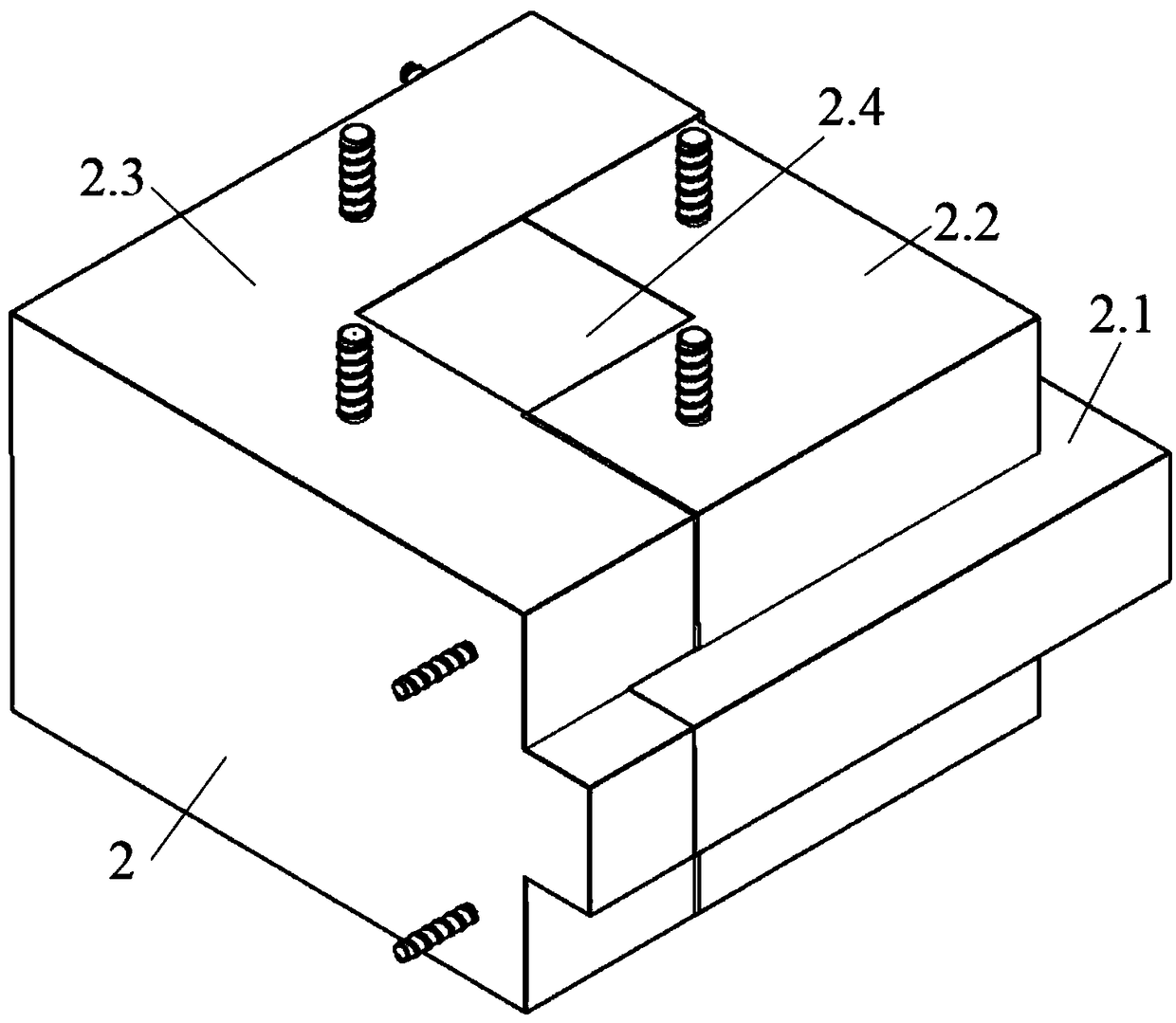

Assembly type power transmission line anchor rod static pressure miniature pile foundation and construction method thereof

ActiveCN108643219ASmall amount of workNo vibrationFoundation engineeringMaterial resourcesEngineering

The invention relates to an assembly type power transmission line anchor rod static pressure miniature pile foundation. The foundation comprises a first connecting main body and second connecting mainbodies, wherein the first connecting main body and the second connecting main bodies form a square bearing table, the first connecting main body is in a cross shape, and is formed by splicing the same four parts in a mutual embedding mode, the number of the second connecting main bodies is four, the four second connecting main bodies are distributed in a crossed grid of the first connecting mainbody and are spliced with the first connecting main body in a mutual embedding mode, each second connecting main body is in a concentric square shape and is formed by splicing two parts in a mutual embedding mode, and the two sides of each splicing joint between the side wall of the first connecting main body and the side wall of the corresponding second connecting main body are connected and fixed through a connecting steel plate, a pre-buried screw rod and a nut. All components of the assembly type power transmission line anchor rod static pressure miniature pile foundation with the design are prefabricated in factories and assembled on site, the construction is simple, convenient and fast, the influence on the environment is small, manpower and material resources are saved, and full-mechanical construction of the power transmission line foundation is realized.

Owner:HUAZHONG UNIV OF SCI & TECH +1

Quick lifting mechanism applied to bridge construction

InactiveCN111646362AImprove efficiency and stabilityReduce construction safety hazardsBase supporting structuresBraking devices for hoisting equipmentsElectric machineryWire rope

The invention discloses a quick lifting mechanism applied to bridge construction. The quick lifting mechanism comprises a movable rack, a motor crawler belt assembly and a hanging basket. The A trussis fixedly mounted on the top of the movable rack. The motor crawler belt assembly is fixedly mounted on the outer wall of the top of the movable rack. The outer wall of the end of the movable rack ishinged to the outer wall of the middle portion of a supporting frame. The upper half portion of the supporting frame is internally provided with sliding grooves. Wire ropes are wound on the outer walls of winding wheels and are attached to the outer walls of guide wheels. The hanging basket is fixed to the lower ends of the wire ropes. The edges of the ends of the movable rack are fixedly connected with locating tubes. The quick lifting mechanism applied to bridge construction facilitates position movement and change and positioning operation. The positioning and installation stability and efficiency of the mechanism are improved. Meanwhile, the quick lifting mechanism can be protected against falling in the using process. Potential construction safety hazards of the quick lifting mechanism during lifting motion are effectively reduced.

Owner:吕友飞

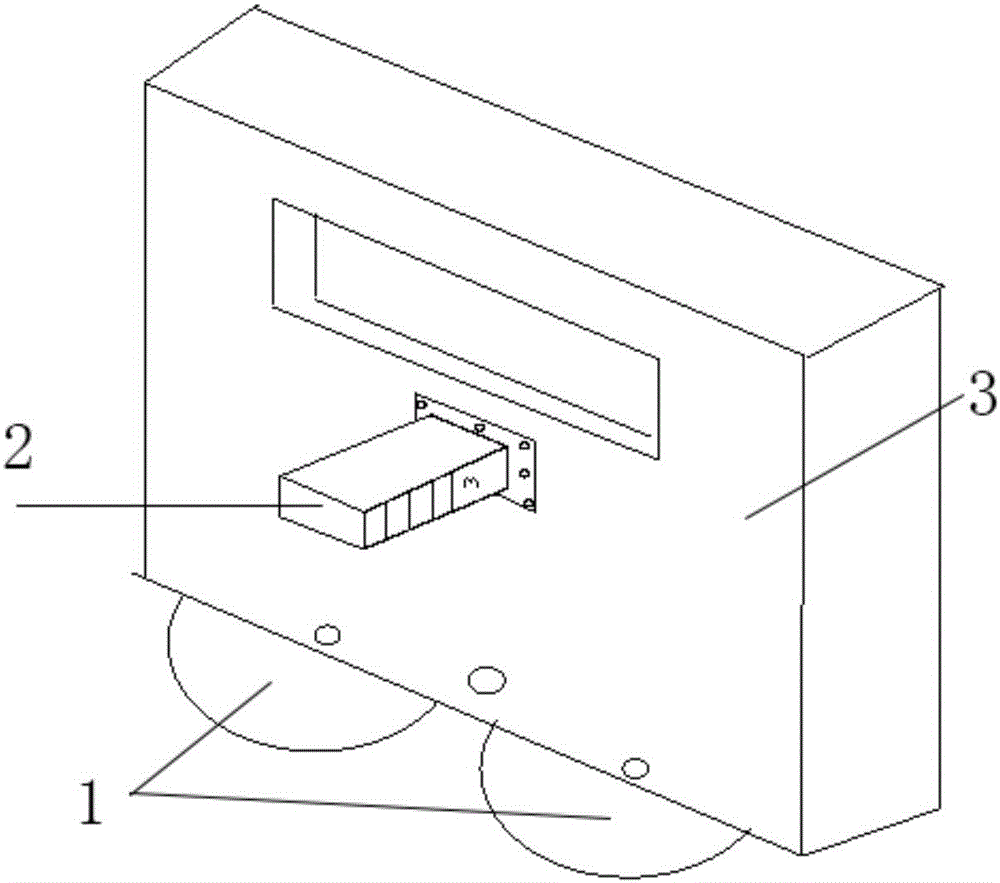

Device for measuring distance of conductor spacer

The invention provides a device for measuring the distance of a conductor spacer. The device comprises pulleys, a rotation speed meter, a box, a pull bar, a pulley support, a handle and a spring. The device has the advantages that 1) the rotation speed meter which can be used to read the installation distance; 2) the device is portable, safe and reliable and simple in operation; 3) hidden safety troubles in construction are reduced; and 4) construction time is reduced, and the construction efficiency is higher.

Owner:ANHUI ELECTRIC POWER TRANSMISSION & TRANSFORMATION ENG +2

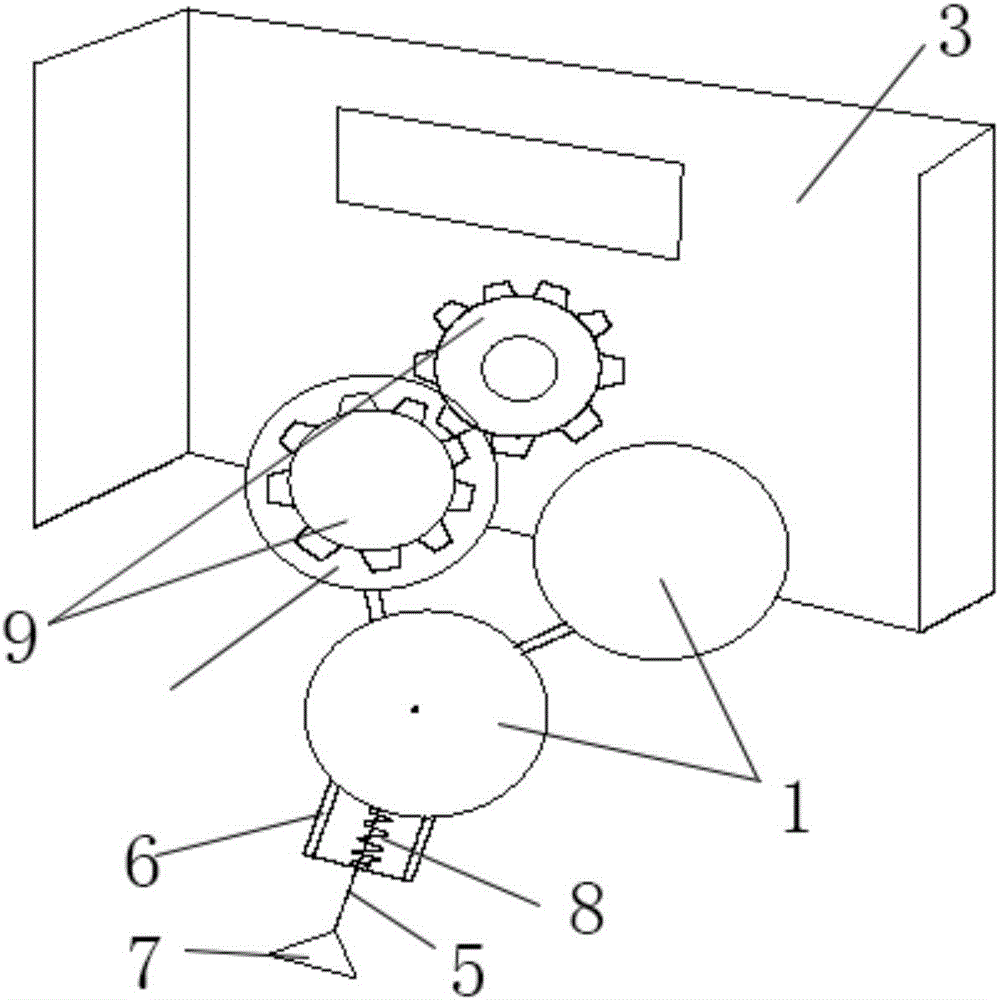

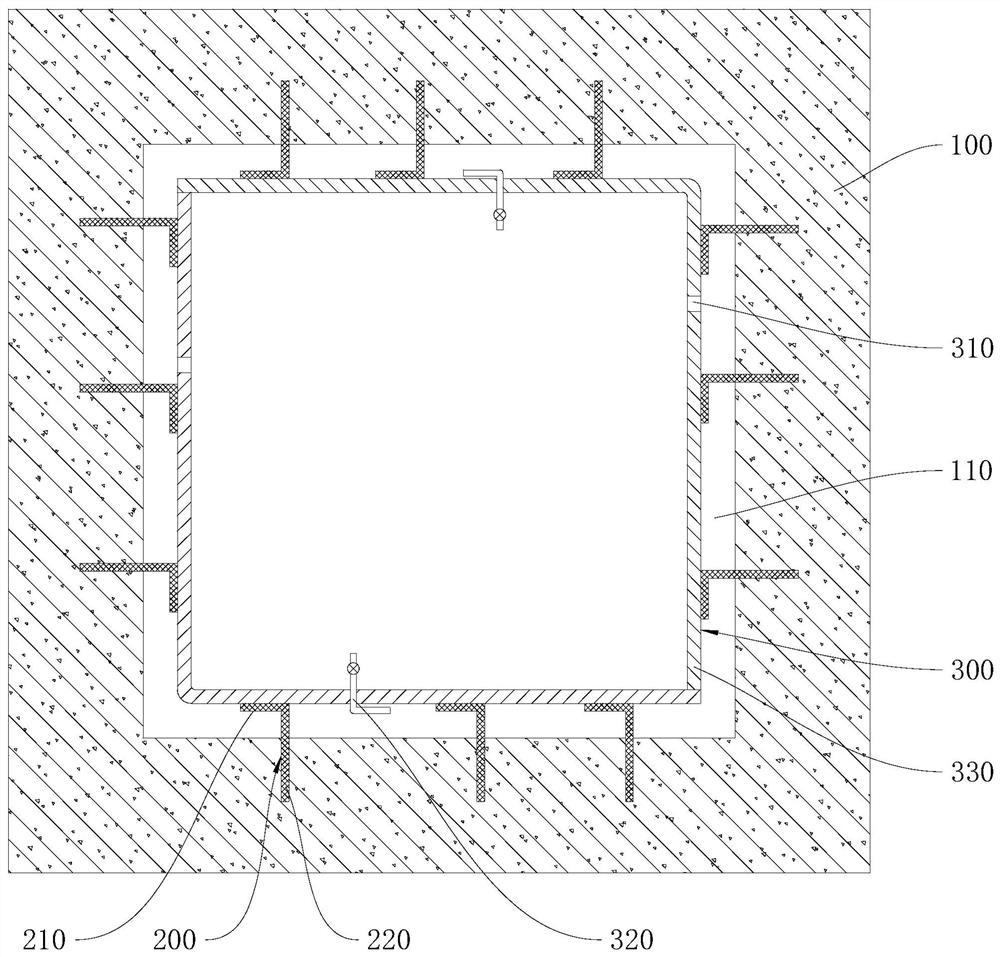

Automatic foundation pit support monitoring system

InactiveCN113482068AEasy to formulateReduce construction safety hazardsFoundation testingExcavationsArchitectural engineeringStructural engineering

The invention discloses an automatic foundation pit support monitoring system. The automatic foundation pit support monitoring system comprises an enclosure body, an anchor cable axial force monitoring device is arranged on the enclosure body and comprises an anchor cable arranged on the enclosure body in a penetrating mode and a tensioning mechanism used for providing tension for the anchor cable, one end of the anchor cable is poured into a slope body, a hole allowing the anchor cable to penetrate is formed in the enclosure body, and the tensioning mechanism is arranged at the end, away from the slope body, of the anchor cable and clamps the anchor cable. The anchor cable axial force monitoring device further comprises an anchor cable meter, the anchor cable meter and the anchor cable are concentrically arranged, an angle adjusting assembly is arranged on the enclosure body, a sleeve is arranged between the anchor cable meter and the tensioning mechanism, and the sleeve abuts against the anchor cable meter and the tensioning mechanism. Tensioning force is provided for the anchor cable through the tensioning mechanism, stress dissipation of the anchor cable meter is monitored, so that dissipation of prestress of the anchor cable is indirectly obtained, the prestress variable quantity of the slope body around the foundation pit is judged, workers can take and formulate necessary engineering measures in time, potential safety hazards of construction are reduced, and the construction safety is improved.

Owner:CRPCEC SHENZHEN ENG +1

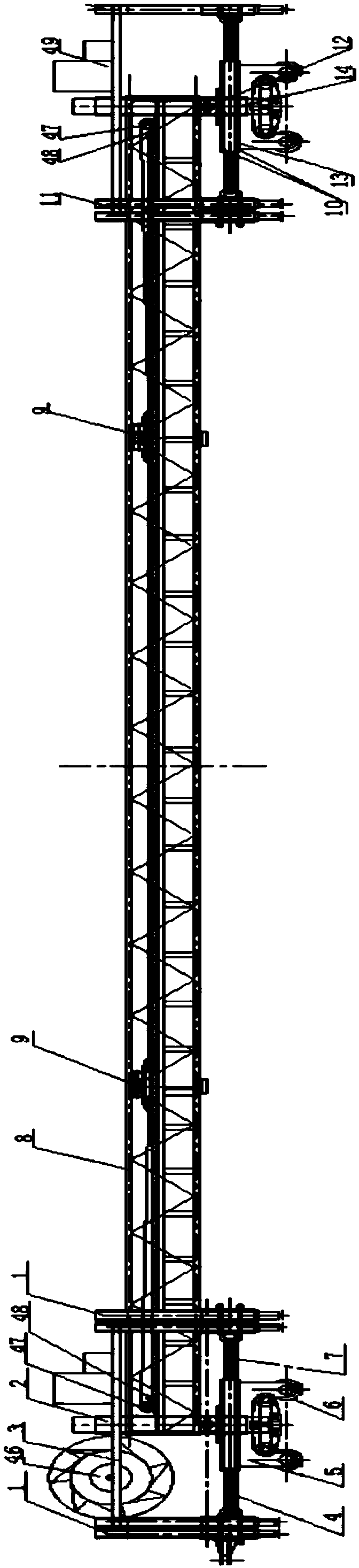

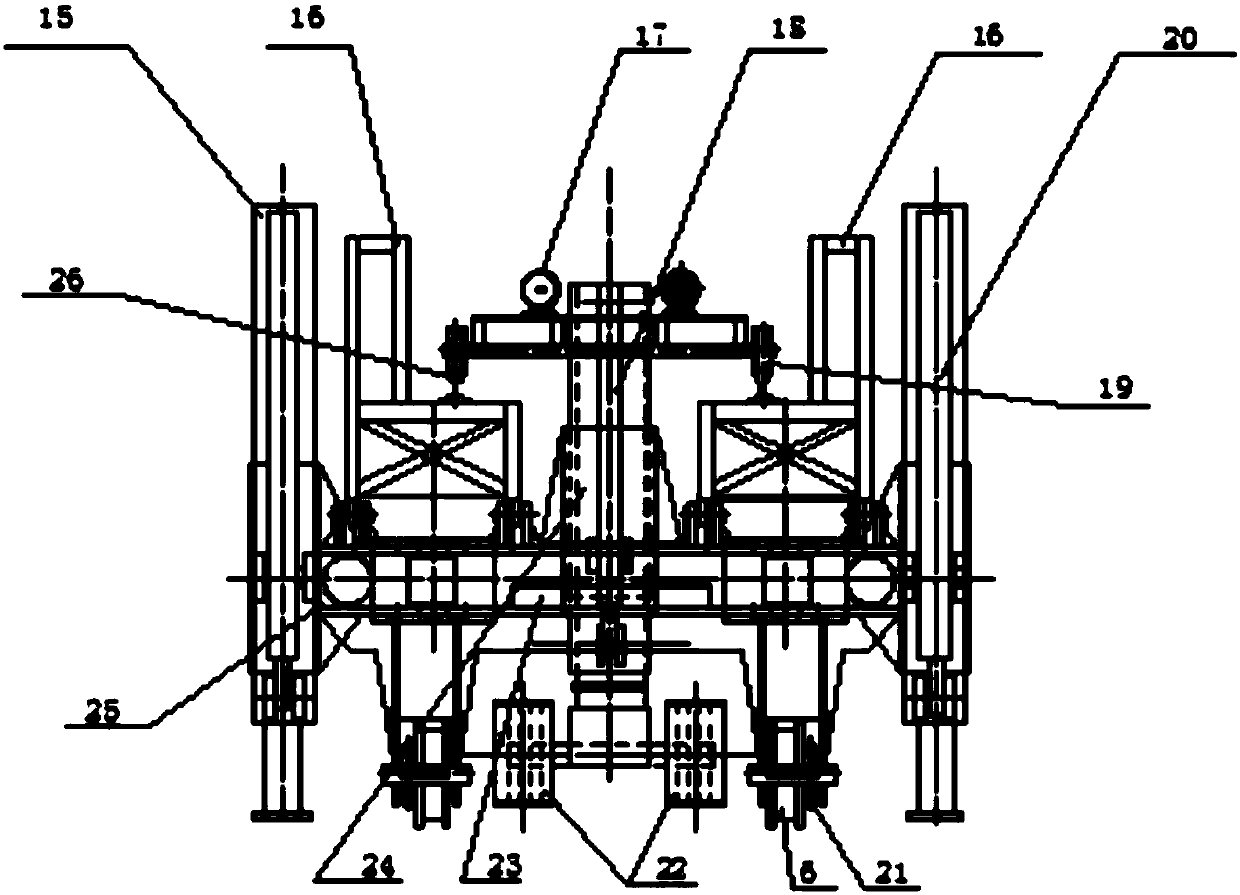

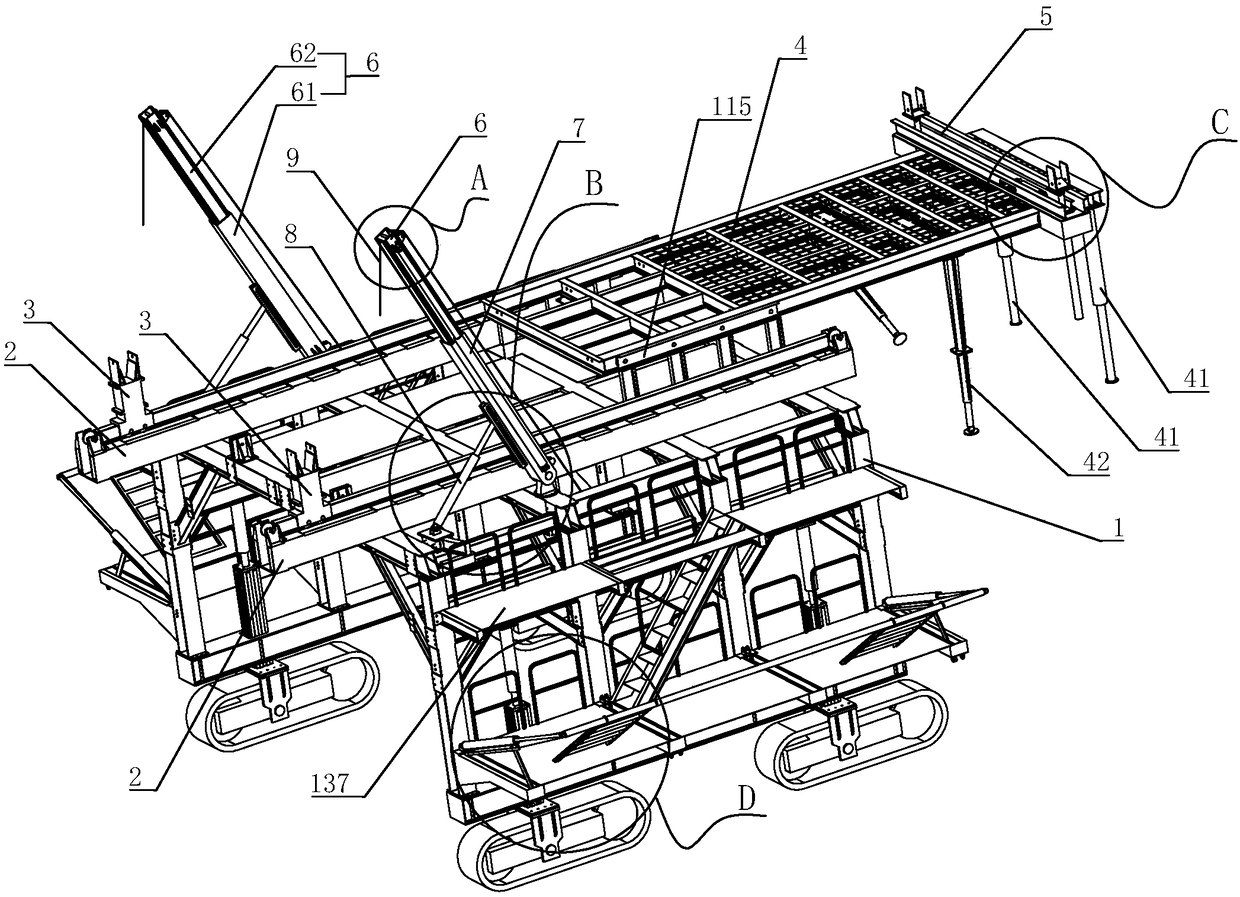

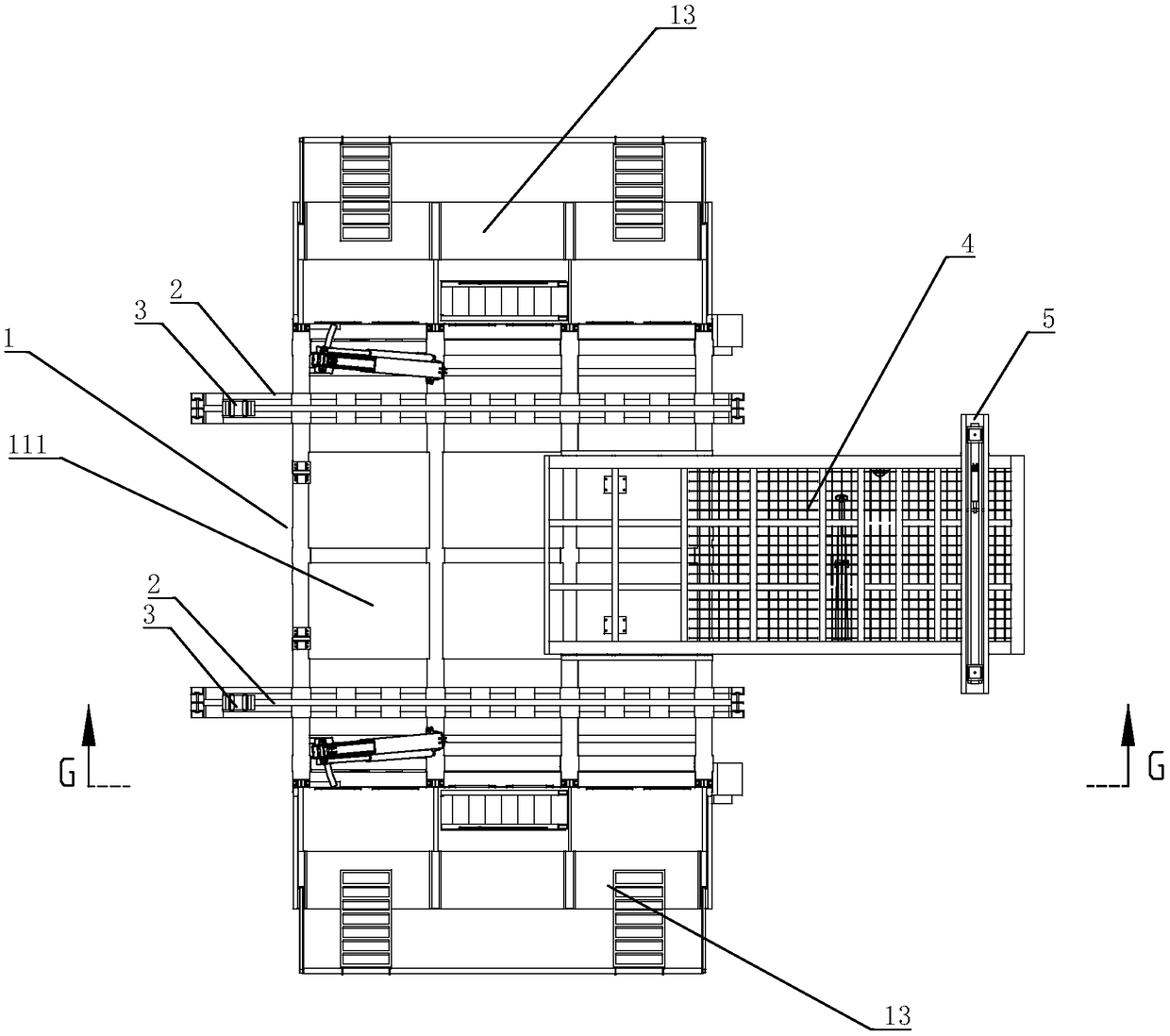

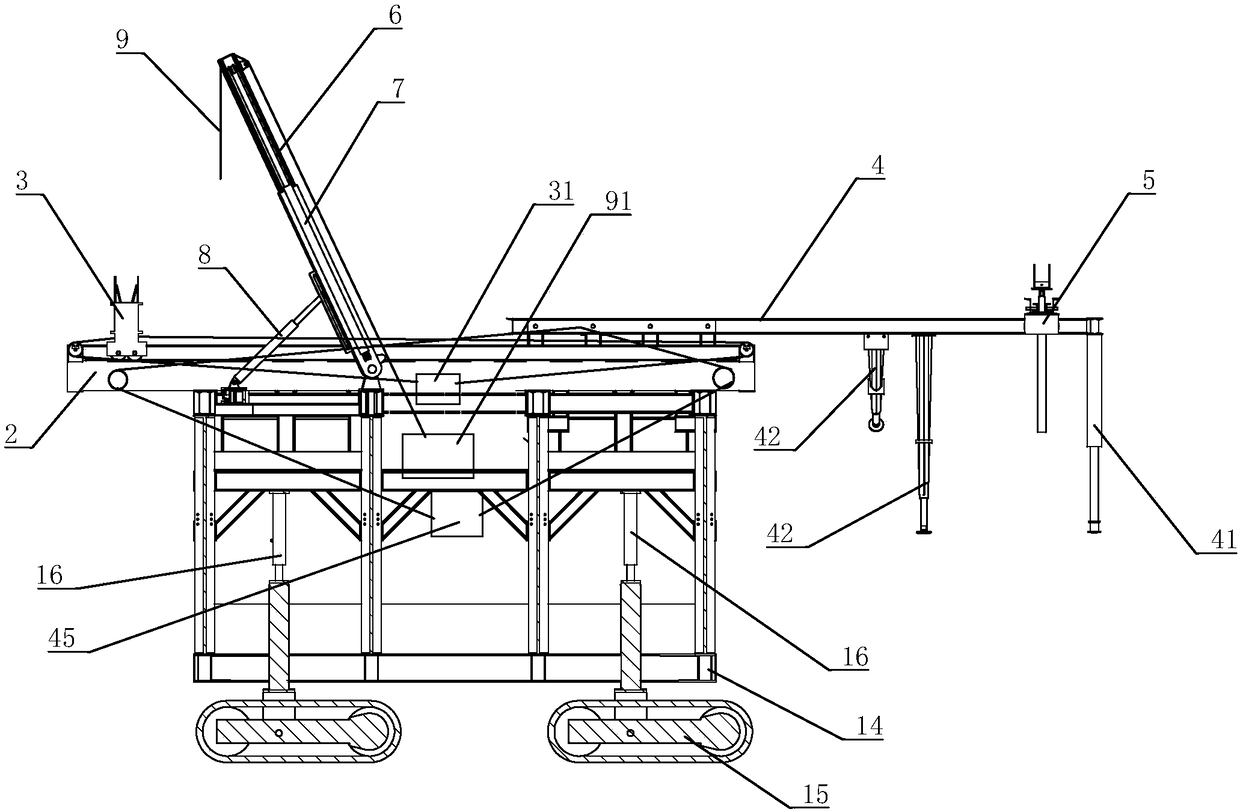

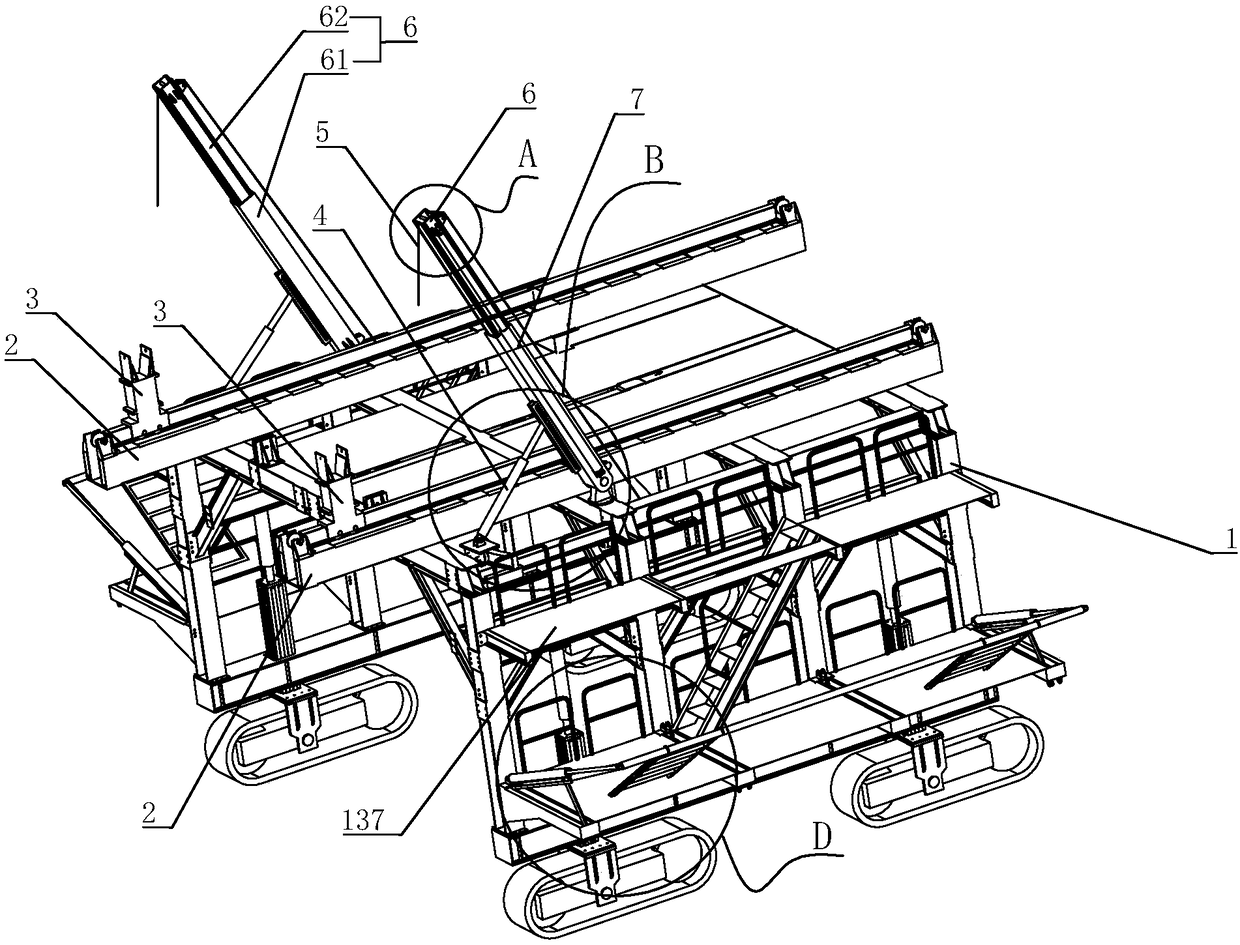

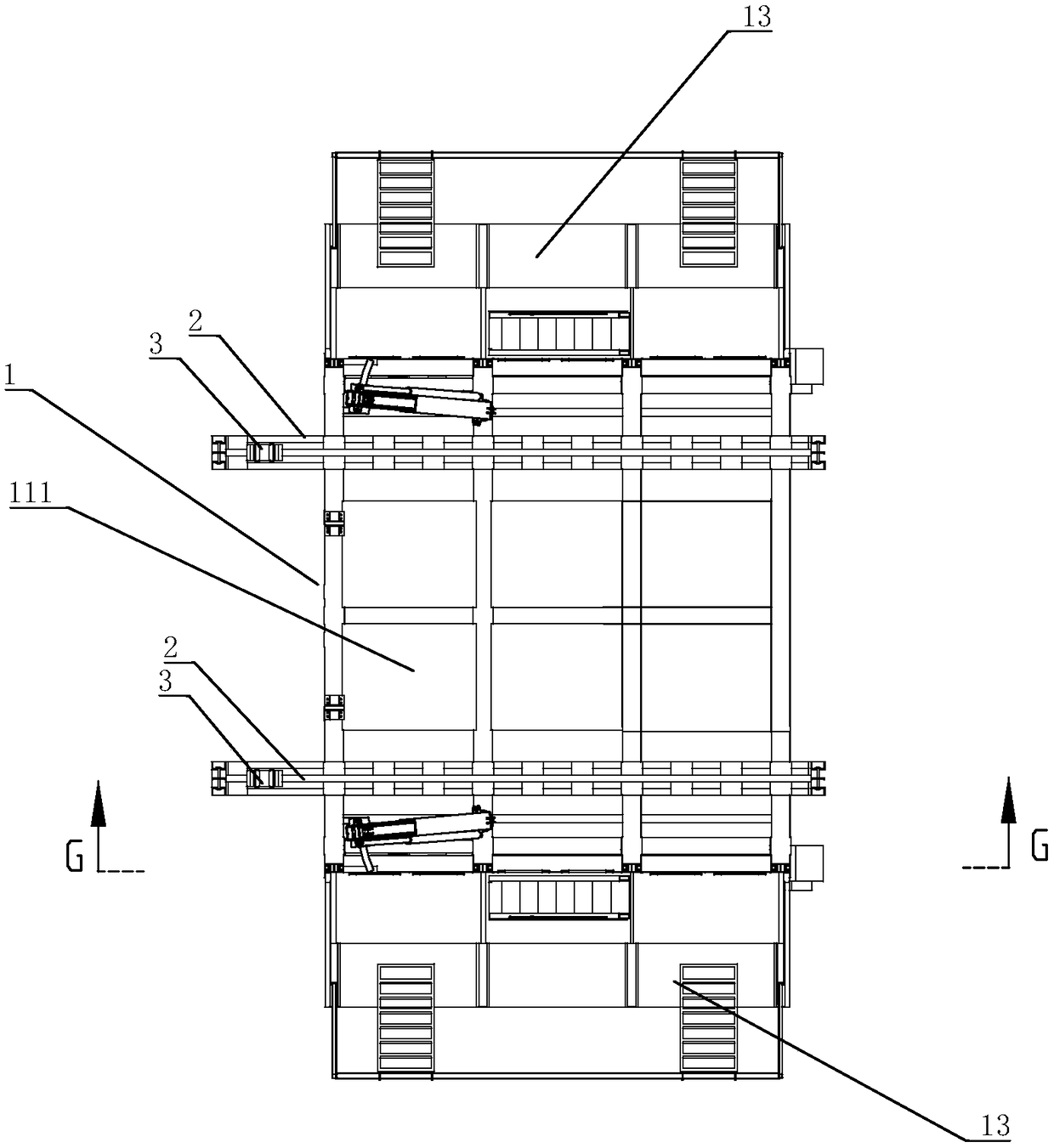

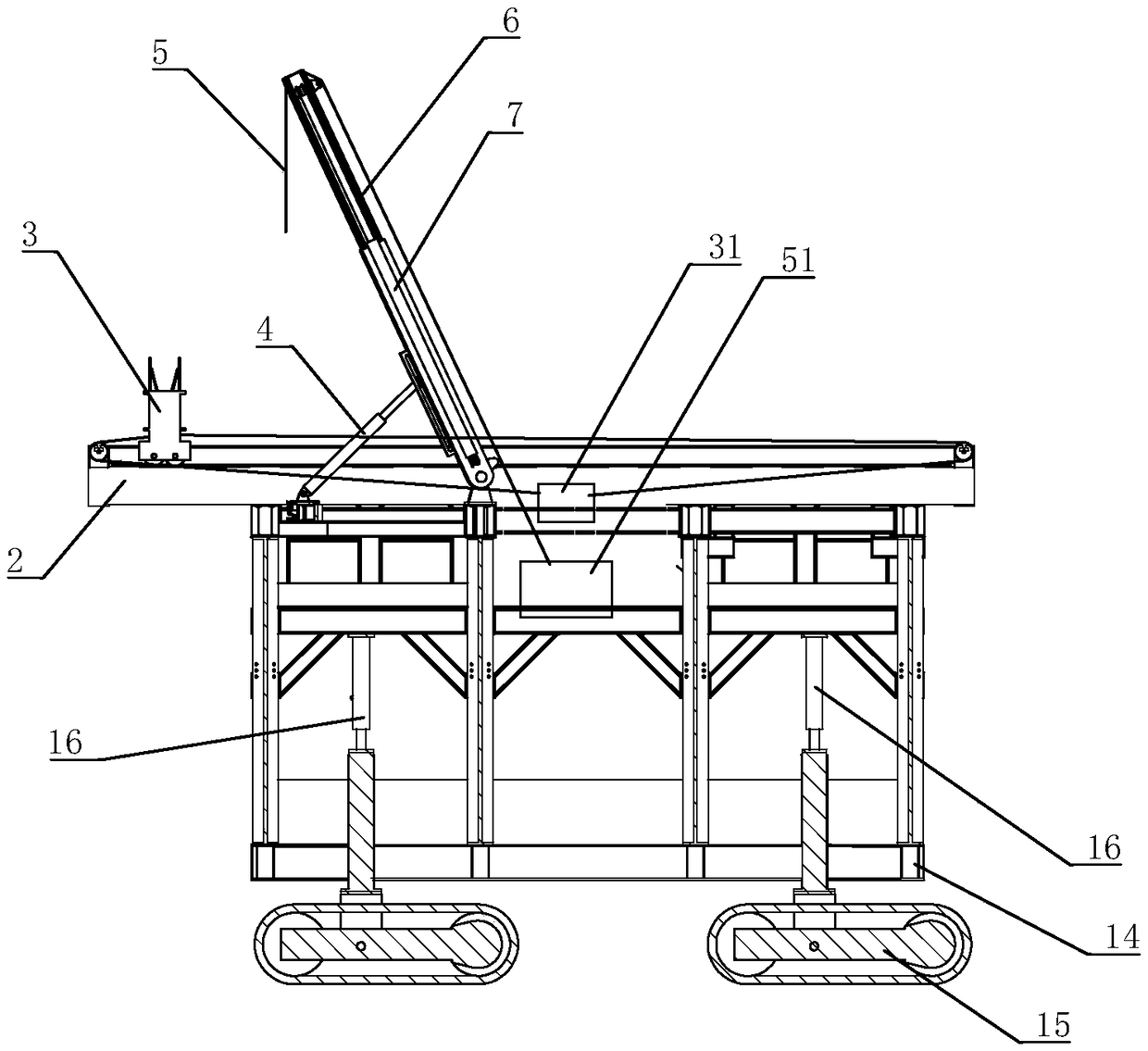

Excavation vertical frame sling cart

PendingCN108750967AHigh degree of installation automationImprove erection efficiencyLifting framesCranesEngineeringDesign integration

The invention discloses an excavation vertical frame sling cart which comprises a cart body, a guide rail, a vertical frame bearing trolley, a telescopic platform, a jacking mechanism and a hoisting device. The telescopic platform is installed at the upper end of the cart body in a telescopic mode and is connected with a first telescopic drive mechanism for driving the telescopic platform to be telescopic; the jacking mechanism is connected with the telescopic platform and used for jacking a vertical frame on the upper portion of the jacking mechanism; the hoisting device is used for hoistingand conveying the vertical frame to the vertical frame bearing trolley; the vertical frame bearing trolley is installed on the guide rail and can transversely and horizontally move and convey the vertical frame along the guide rail; the vertical frame bearing trolley is connected with a horizontal movement drive mechanism; and the horizontal movement drive mechanism can drive the vertical frame onthe vertical frame bearing trolley to transversely move and convey the vertical frame to the upper portion of the jacking mechanism in a retracting state. The excavation vertical frame sling cart ishigh in design integration degree, mounting automatic degree and vertical frame erecting efficiency, reduces manual operation and reduces potential safety hazards of construction.

Owner:湖南进军隧道智能装备有限公司

Excavation vertical frame lifting and placing vehicle

PendingCN108792959AHighly integrated designImprove erection efficiencyUnderground chambersTunnel liningMarine engineeringAutomation

The invention discloses an excavation vertical frame lifting and placing vehicle. The excavation vertical frame lifting and placing vehicle comprises a vehicle main body, guide rails, vertical frame bearing trolleys and lifting devices; a stretchable platform is installed at the upper end of the vehicle main body in a stretchable mode, and a jacking mechanism is connected to the stretchable platform; and the lifting devices are used for lifting a vertical frame and sending the lifting frame to the vertical frame bearing trolleys; the vertical frame bearing trolleys are installed on the guide rails and can transversely move so as to convey the vertical frame along the guide rails, the vertical frame bearing trolleys are connected with translation driving mechanisms, and the translation driving mechanisms can drive the vertical frame placed on the vertical frame bearing trolleys to transversely move and can convey the vertical frame to the position above the jacking mechanism in the retraction state. The excavation vertical frame lifting and placing vehicle has the advantages that the integration degree is high, the installation automation degree is high, the erection efficiency of the vertical frame is high, the manual operation is reduced, and the potential safety hazard of construction is reduced.

Owner:湖南进军隧道智能装备有限公司 +1

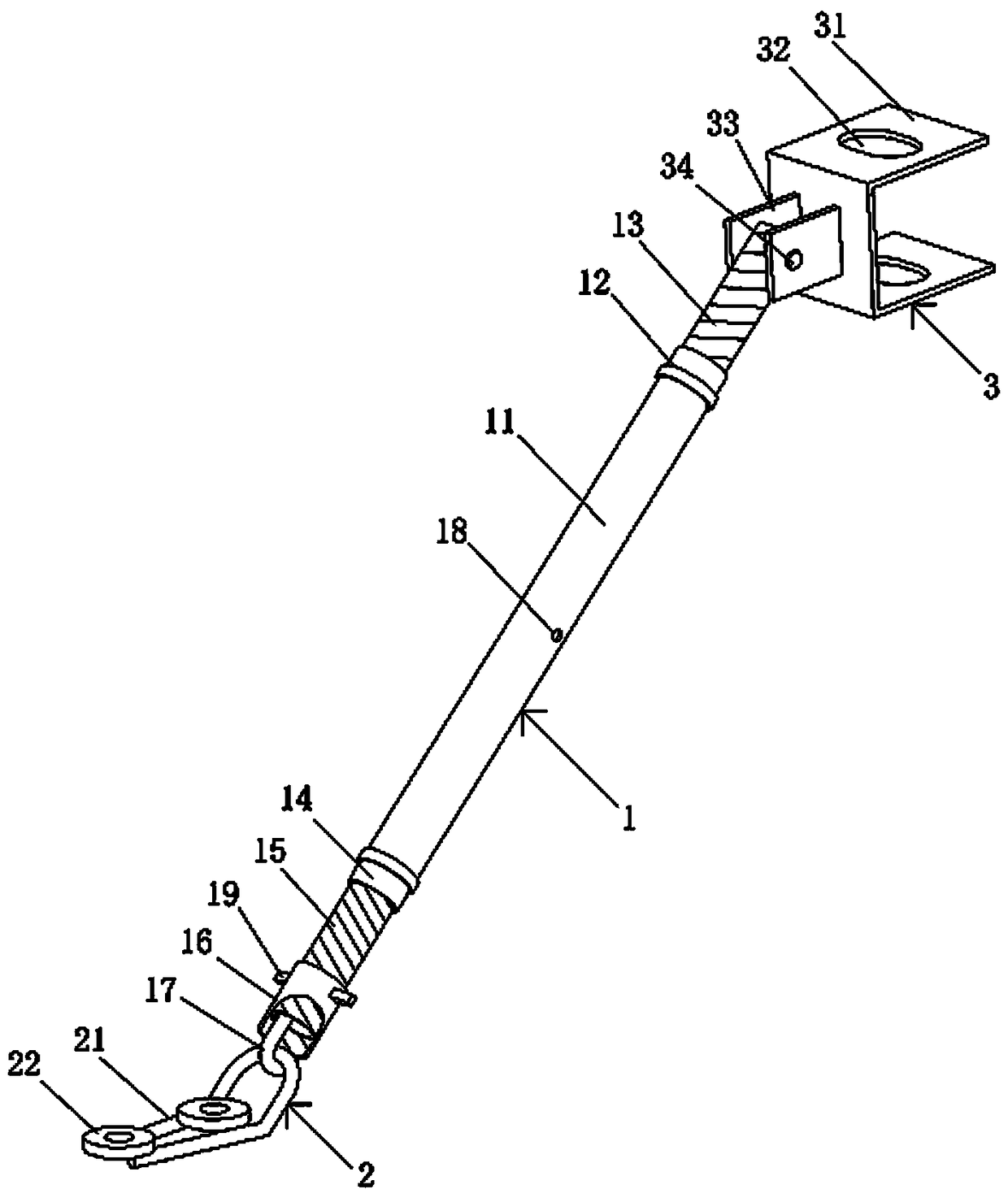

Diagonal bracing and pulling device used for supporting of cast-in-place concrete wall formwork

A diagonal bracing and pulling device used for supporting of a cast-in-place concrete wall formwork is composed of a diagonal bracing and pulling rod, a lower fixing piece and an upper connecting piece. The diagonal bracing and pulling rod is provided with a middle rod body, the upper end of the middle rod body is connected with an upper nut, and an upper lead screw is assembled on the upper nut and connected with the upper connecting piece in a hinged mode; and the lower end of the middle rod body is connected with a lower nut, a lower lead screw is assembled on the lower nut and provided with a pulling hook, and a fastening nut is assembled at the lower lead screw. The lower fixing piece is provided with a U-shaped connecting ring with the forward arc-shaped end, the front portion of theU-shaped connecting ring upwarps by 45 degrees, the pulling hook is hung at the arc-shaped end of the U-shaped connecting ring in a hooked mode, and anchor bolt gaskets are arranged on the rear portion of the U-shaped connecting ring; the upper connecting piece is provided with a transverse back arris connecting piece, through pin holes are formed in two wing plates of the transverse back arris connecting piece, and lug plates are arranged on the outer side of a web plate of the transverse back arris connecting piece; and the upper lead screw is connected with the upper connecting piece through a pin shaft in a hinged mode. The diagonal bracing pulling device is simple in structure and convenient to use, and the safe and reliable performance of supporting and connecting is good.

Owner:魏志光

Integrated construction method for main building body and indoor and outdoor decoration

PendingCN109083420AShort cycleImprove seismic performanceBuilding material handlingModular constructionBuilding construction

The invention discloses an integrated construction method for main building body and indoor and outdoor decoration, and belongs to the technical field of building decoration. The method comprises thefollowing steps that the foundation of a building is constructed, an embedded part is installed, and the foundation extends to a standard layer; according to the building purpose, a plurality of required integrated modules aee designed, and the integrated modules are machined according to a drawing in a factory; the factory conducts trial assembling, and then the construction base conducts splicedinstallment; after the integrated modules are calibrated, doors, windows and bottom plates are installed. According to the integrated construction method for main building body and indoor and outdoordecoration, modular construction and installment can be conducted on buildings, indoor and outdoor decoration and building construction can be conducted at the same time through a predesign, and morethan half of the construction period is shortened.

Owner:河南圣都装饰工程有限公司

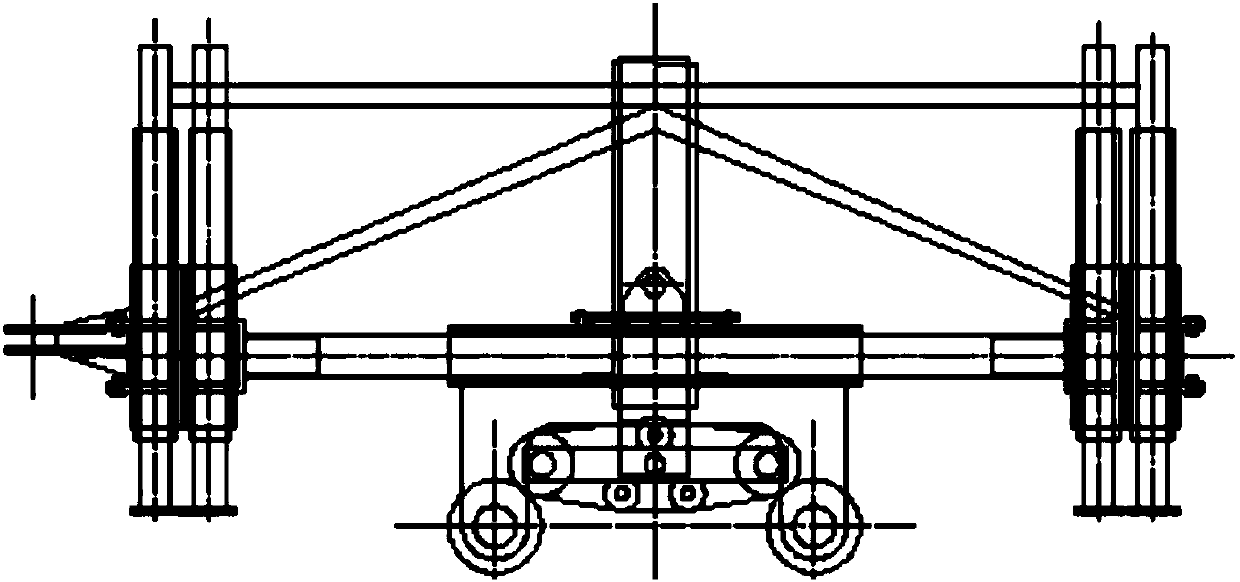

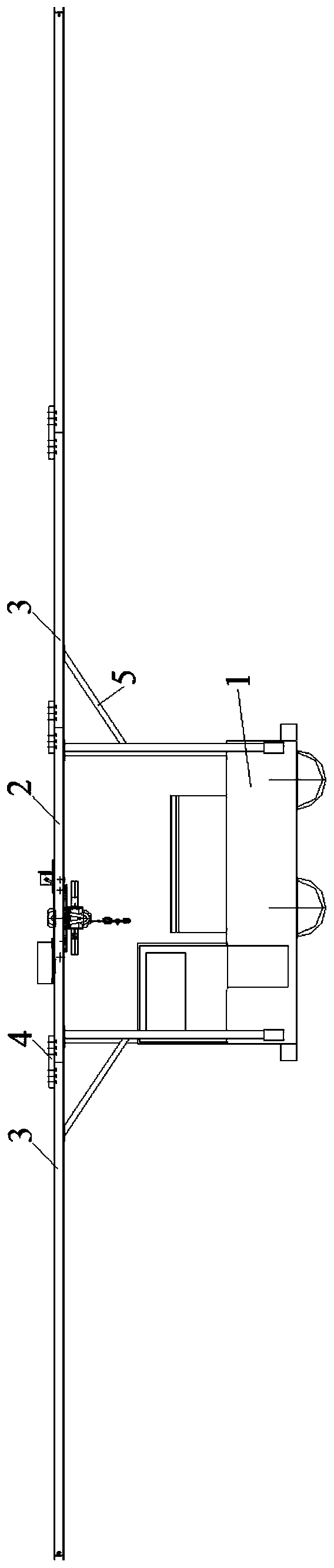

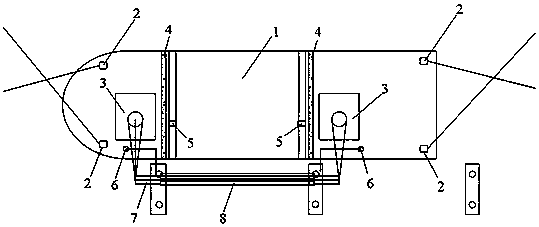

Track laying machine used for coal mine working, and track laying method thereof

InactiveCN110409233AReduce construction proceduresReduce construction safety hazardsRailway track constructionCoalLateral movement

The invention discloses a track laying machine used for a coal mine working. The track laying machine comprises a storage battery electric locomotive and a cross beam which is arranged above the storage battery electric locomotive and is fixed relative to the storage battery electric locomotive, wherein the cross beam is provided with a walking operating vehicle used for realizing hosting and track laying; the walking operating vehicle comprises a longitudinal walking unit which can carry out longitudinal movement relative to the cross beam, and a lateral walking unit which can carry out lateral movement relative to the longitudinal walking unit; and the lower side of the lateral walking unit is provided with a vertical hoisting unit used for carrying out loading and unloading as well as vertical movement. The invention also discloses a track laying method for the track laying machine used for the coal mine working. By use of the above track laying machine used for the coal mine working, through the walking operating vehicle, the mechanical track laying of the coal mine working can be realized, a phenomenon that track materials are manually carried for transportation or track materials are transported through a belt transportation machine is replaced, construction working procedures are reduced, construction input and construction cost are lowered, and construction potential safety hazards are reduced.

Owner:兖矿能源集团股份有限公司

Movable support based on development of underground space above subway and construction method thereof

InactiveCN110777848APlay a protective effectReduce construction safety hazardsArtificial islandsExcavationsSupporting systemPre stress

The invention relates to a movable support system arranged at the beam end of a supporting beam on a subway protective pile, a prestressed beam type underpinning structure and a foundation pit supporting structure based on development of an underground space above a subway and a construction method thereof. The movable support system comprises a plurality of underpinning piles and underpinning beams, wherein the underpinning piles and the underpinning beams are arranged in an abutting mode in sequence, and the underpinning beams are slidably connected with the underpinning piles. One side of each underpinning pile is provided with a pile body guard wall filled with concrete. A U-shaped waist beam arranged horizontally is embedded in each pile body guard wall. The end of each underpinning beam is arranged in an opening of the corresponding U-shaped waist beam. A gap is reserved between the end of each underpinning beam and a corresponding web plate. The construction method comprises thefollowing steps of S1, construction of the underpinning piles; S2, construction of movable supports; S3, construction of a floor transformational structure; S4, construction of the underpinning beams; S5, prestressed tensioning of a floor; and direct pouring of the underpinning beams into the basement floor. The movable support system and the construction method thereof have the effect that the underpinning beams have displacement as a result of prestressed tensioning and cannot forcibly drive the underpinning pile to have displacement.

Owner:广东省工程勘察院

Channel box defect repairing method

PendingCN112112248ASpeed upImprove connection strengthSewer pipelinesArchitectural engineeringCorrosion prevention

The invention provides a channel box defect repairing method, and belongs to the technical field of drainage channel boxes. The channel box defect repairing method comprises the steps that reinforcingribs are fixedly connected to the inner wall of a channel box; a steel plate box body is prefabricated, and a plurality of grouting holes are formed in the steel plate box body; the steel plate box body is installed in the channel box, and a repairing gap is formed between the outer side face of the steel plate box body and the channel box; the outer side face of the steel plate box body is fixedly connected with the reinforcing ribs; concrete grout is injected into the repairing gap through the grouting holes; the grouting holes are blocked; and the inner wall of the steel plate box body issubjected to anti-corrosion treatment. According to the channel box defect repairing method, in the abovementioned way, the steel plate box body is installed in the channel box, the reinforcing ribs are arranged between the channel box and the steel plate box body, concrete is poured to achieve repairing of the channel box and fixed connection between the channel box and the steel plate box body,grooving repairing does not need to be conducted on the ground, the channel box repairing progress is accelerated, and the construction potential safety hazards are reduced.

Owner:POWERCHINA WATER ENVIRONMENT GOVERANCE

Method for mounting prestressed T-shaped girder at sea by non-rotating synchronous hoisting of double cranes

ActiveCN110565527AAccurate and stable positioningReduce construction safety hazardsBridge erection/assemblyPre stressEngineering

The invention discloses a method for mounting a prestressed T-shaped girder at sea by non-rotating synchronous hoisting of double cranes. Firstly, two crawler cranes are fixed on a deck of a square barge, a non-rotating synchronous hoisting process is used to take and mount the T-shaped girder, and during the hoisting and mounting process, the mounting position of the T-shaped girder is controlledonly by raising and lowering crane jibs and by adjusting the hoisting distance, so that potential construction safety hazards can be effectively reduced; secondly, two elevating-type track translational vehicles and girder storage pedestals are arranged on the deck and used to complete the transport and storage of the T-shaped girder on the deck; and finally, a total of four windlasses are arranged respectively at the left front, front right, back left and back right parts of the square barge, and two winches are mounted at the positions, on one side of the square barge, corresponding to thetwo crawler cranes, so as to achieve the stability and accurate positioning of the square barge during the process of taking and mounting the T-shaped girder. By field practice, the method for mounting the prestressed T-shaped girder at sea by non-rotating synchronous hoisting of the double cranes is safe, achieves controllable quality, can effectively reduce the construction cost and improve theconstruction efficiency, and can be promoted for being used in similar projects.

Owner:CCCC FIRST HARBOR ENG +1

Construction method for reinforcing foundation of soft soil area

InactiveCN102162245AMeet the construction qualityEasy to operateBulkheads/pilesOperabilityBuilding construction

The invention discloses a construction method for reinforcing the foundation of a soft soil area. The construction method comprises the following steps of: preparing a construction facility; preparing a construction plant; measuring and lofting and the like. The construction method is a safe, economic and efficient construction method for reinforcing the foundation of the soft soil area. The method is high in on-site operability, and can be popularized easily; moreover, by the method, the construction safety and the construction quality of foundation reinforcement of a filling area beside an operation line of the soft soil area are guaranteed.

Owner:CHINA RAILWAY HI TECH IND CORP LTD +1

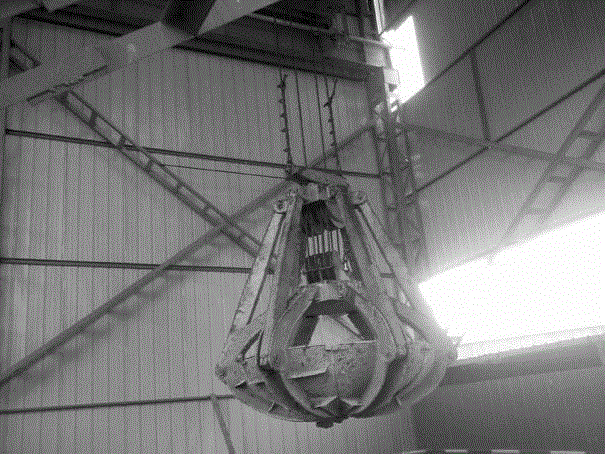

Design of hoisting slag hopper by utilizing shaft gantry

The invention discloses design of hoisting a slag hopper by utilizing a shaft gantry. According to the design, a slag hopper of the dimension (3m*2.5m*2m) is produced from a steel plate of more than 2 cm in thickness in a welding manner; double doors are arranged oppositely at the bottom of the slag hopper; two groups of fixed pulleys used for direction control are mounted on the side surfaces of hopper doors; steel wire ropes used for controlling the hopper doors are hung by travelling gantry crane secondary hooks; after the hopper doors are closed, both primary hooks and the secondary hooks are subjected to hoisting at the same time; after the slag hopper is lifted out of a drilled shaft and conveyed to a slag disposal pit, the hopper doors are opened by lowering the secondary hooks, so that slag is discharged to the slag disposal pit; and then, the hopper doors are closed by lifting the secondary hooks. The design provided by the invention is an improvement in the conventional slag hopper for drilled shaft slag removal, and has the advantages that the work efficiency of a drilled shaft gantry crane is improved during slag removal; the quantity of construction workers, the construction cost and the hidden danger in construction are reduced; and the construction progress is strongly guaranteed.

Owner:CHINA RAILWAY SHISIJU GROUP CORP

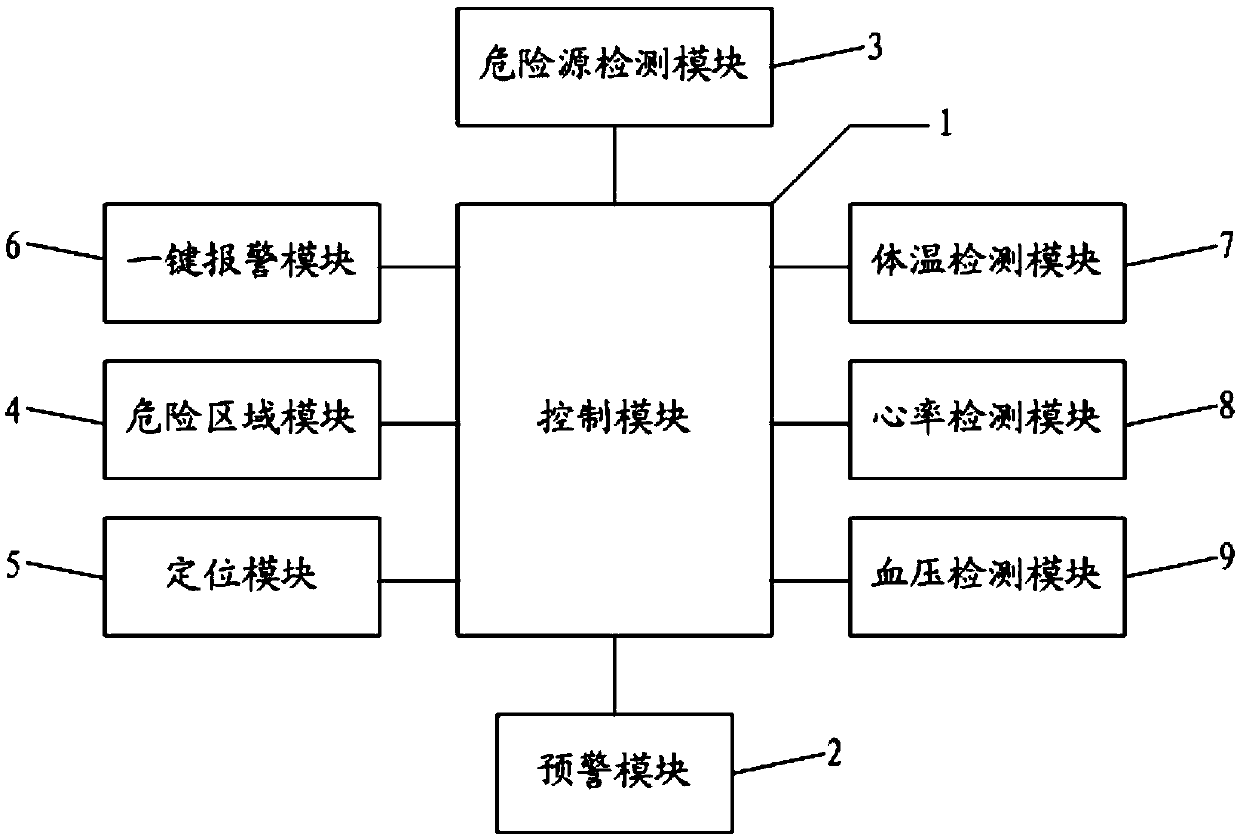

Wearable device applicable for construction site

InactiveCN109697828AEnsure safetyReduce construction safety hazardsEvaluation of blood vesselsSensorsArchitectural engineeringOccurrence probability

The invention relates to the technical field of construction safety, and discloses a wearable device applicable to the construction site. The wearable device comprises a danger source detection module, a control module and an early warning module, wherein the danger source detection module is used for detecting a starting signal in real time and sending the detected starting signal to the controlmodule; the starting signal is a signal sent by equipment in the construction site within a preset range when being started; the control module is used for sending an early warning signal to the earlywarning module when receiving the starting signal; and the early warning module is used for sending an alarm when receiving the early warning signal. The wearable device disclosed by the embodiment of the invention can give an alarm when a wearer gets close to the started equipment in the construction site so as to remind the wearer, thereby enabling the wearer to timely discover the danger source, guaranteeing the safety of the construction personnel, reducing the construction potential safety hazards in the construction site, and thus reducing the occurrence probability of accidents.

Owner:GUANGZHOU RAIL TRANSIT CONSTR SUPERVISION CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com