Concrete slant component upper supporting system and construction method for same

A support system and concrete technology, which is applied to the preparation of building components on site, pillars, building structures, etc. Uniform, improve connection strength, improve the effect of overall stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

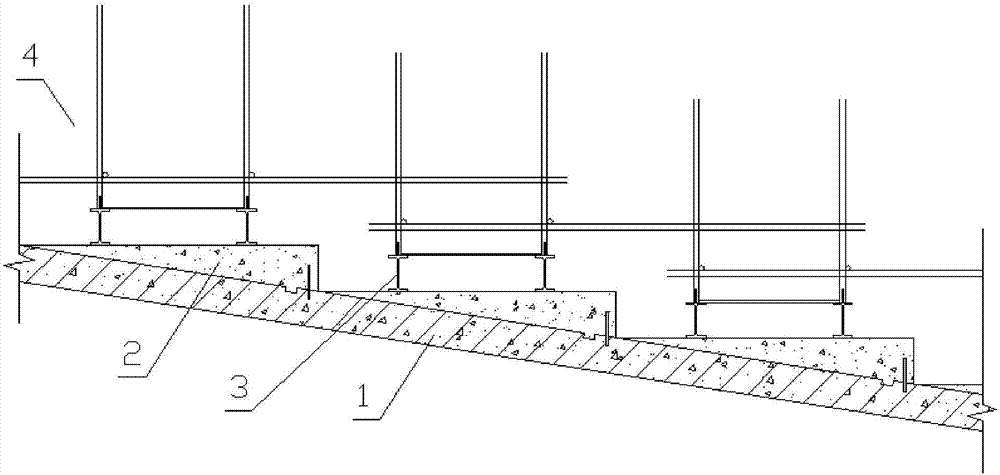

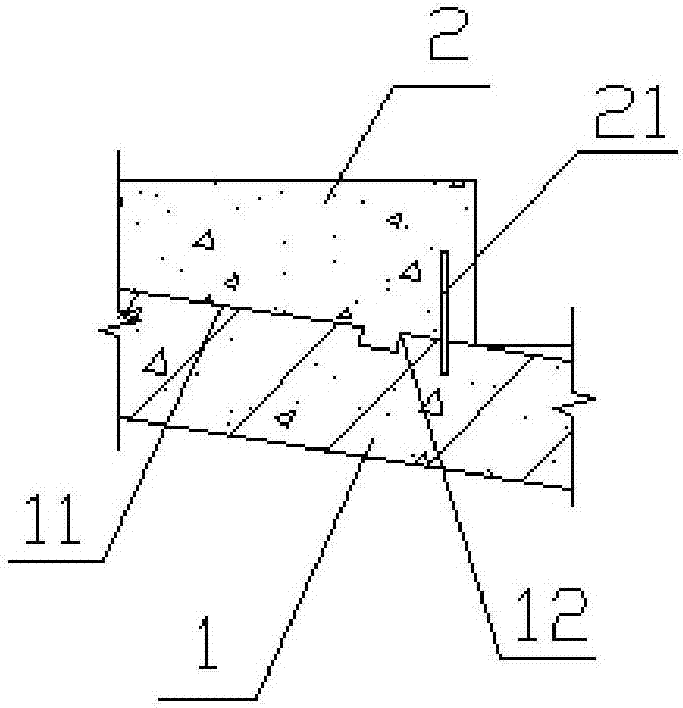

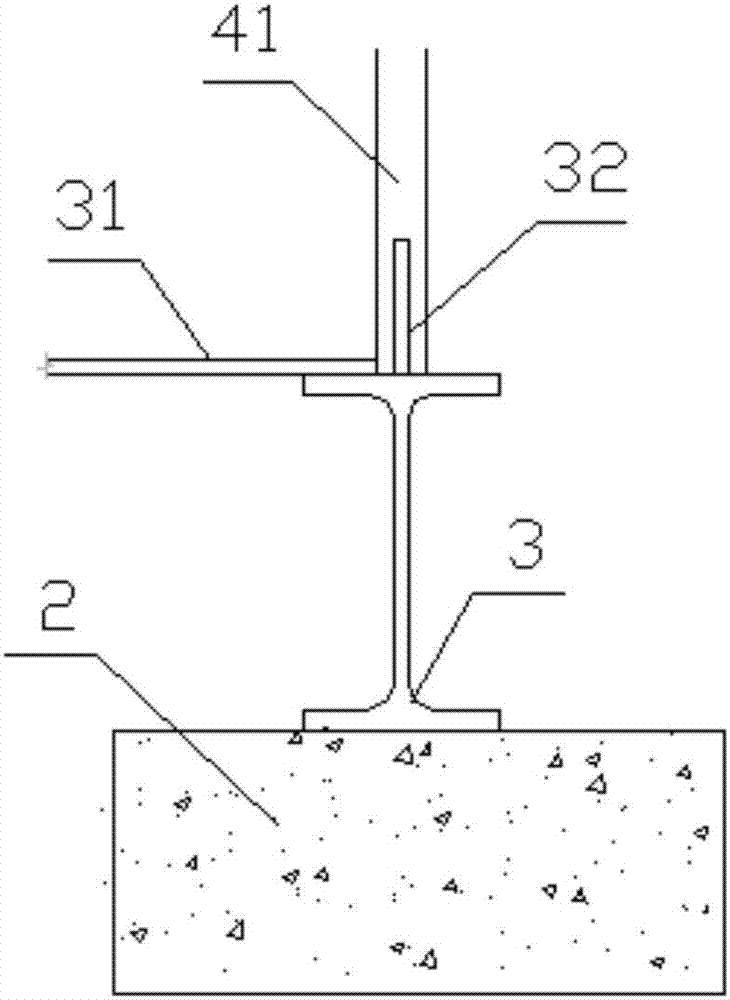

[0025] Example 1, such as Figure 1 to Figure 3 As shown, an upper support system of a concrete inclined member is built on the completed reinforced concrete inclined member 1, which includes several levels of concrete steps 2 arranged along the slope of the reinforced concrete inclined member. A full-length I-beam 3 is placed on the concrete steps 2, and a support frame 4 is set up above the I-beam, and the support pole of the support frame is supported on the I-beam.

[0026] Wherein, the slope of the reinforced concrete inclined member 1 is provided with a chiseled surface 11 combined with the concrete steps 2, and further, the slope of the reinforced concrete inclined member is provided with an anti-slip surface integrated with the concrete steps. The shear pressure groove 12 and the concrete steps 2 are poured with vertical inserts 21 inserted into the inclined members of reinforced concrete. The above technical measures improve the connection strength of the contact sur...

Embodiment 2

[0038] Example 2, such as Figure 4 As shown, the difference from Embodiment 1 is that a threaded sleeve is pre-embedded at the position corresponding to the concrete step on the slope of the reinforced concrete inclined member, and a screw rod 22 is screwed in the threaded sleeve, and the screw rod is fixed with a concrete step by a nut. Pouring the integrated stiffener plate 23. In order to further enhance the joint force to the concrete steps 2, the stiffener plate 23 can be provided with stiffeners vertically. Therefore, the connection strength of the contact surface is further improved, and the overall stability of the support frame is improved

[0039] In addition, the concrete steps are pre-embedded with positioning sleeves corresponding to the positions of the I-beams, and the I-beams are provided with positioning ribs inserted into the positioning sleeves to achieve rapid positioning of the I-beams and ensure the stability of the I-beams.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com