Mini step excavation method suitable for IV-V level of surrounding rocks of large-section tunnel

A technology of step excavation and large cross-section, which is applied in tunnels, tunnel linings, earthwork drilling and mining, etc., to achieve the effects of reducing loads, preventing landslides, and reducing the scope

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

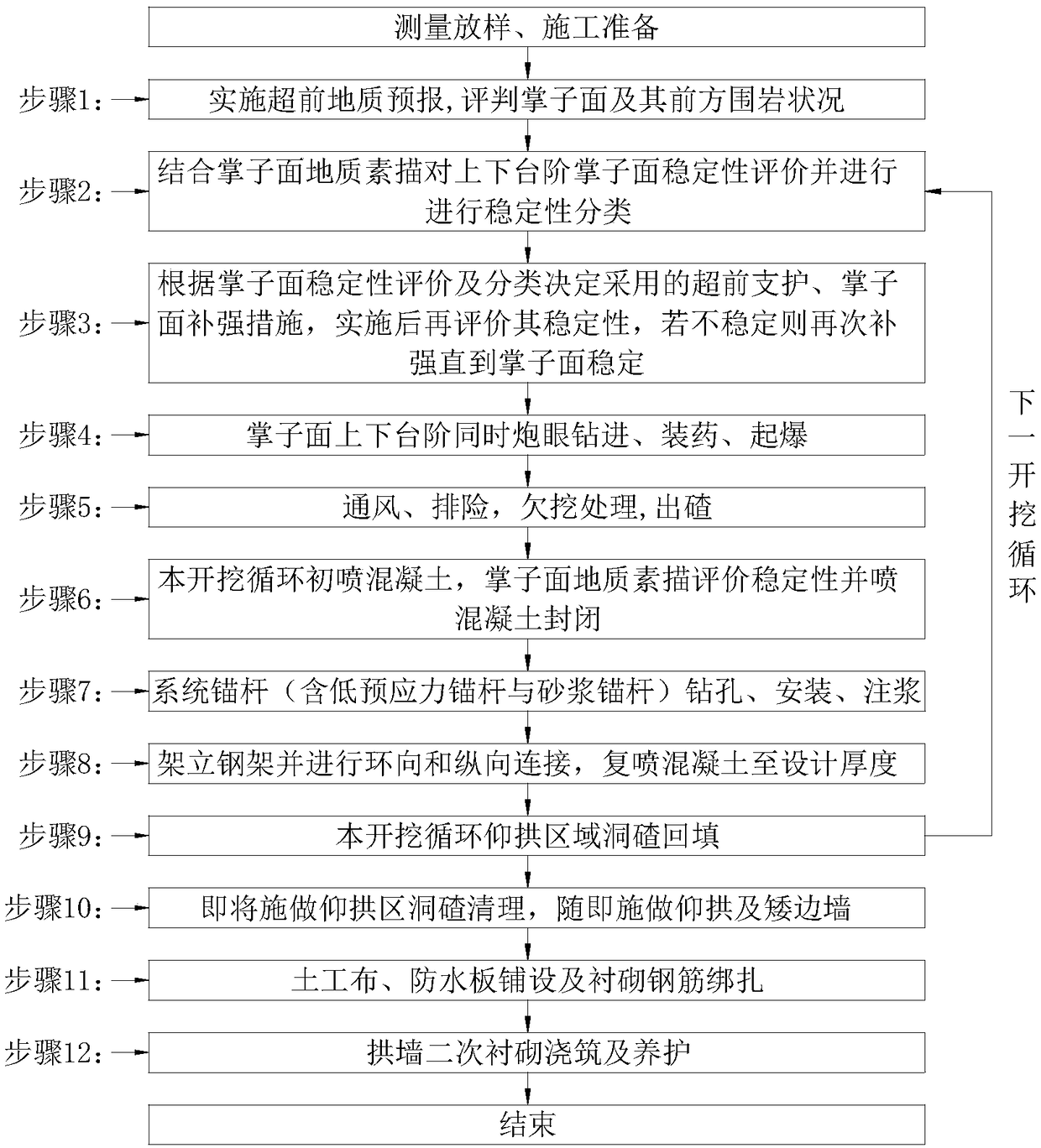

[0061] Such as figure 1 As shown, a kind of micro-step excavation method suitable for large-section tunnel IV-V grade surrounding rock described in the present invention comprises the following steps:

[0062] Step 1, set the cross-sectional area to 150m 2 The face of a large-section high-speed railway tunnel is divided into upper and lower steps, of which the height of the upper step is 6m and the height of the lower step is 7m. The geological sketch method, geophysical prospecting method, advanced drilling method or MWD geological drilling cloud image prediction of rock drilling rigs are used One or more types for advanced geological prediction;

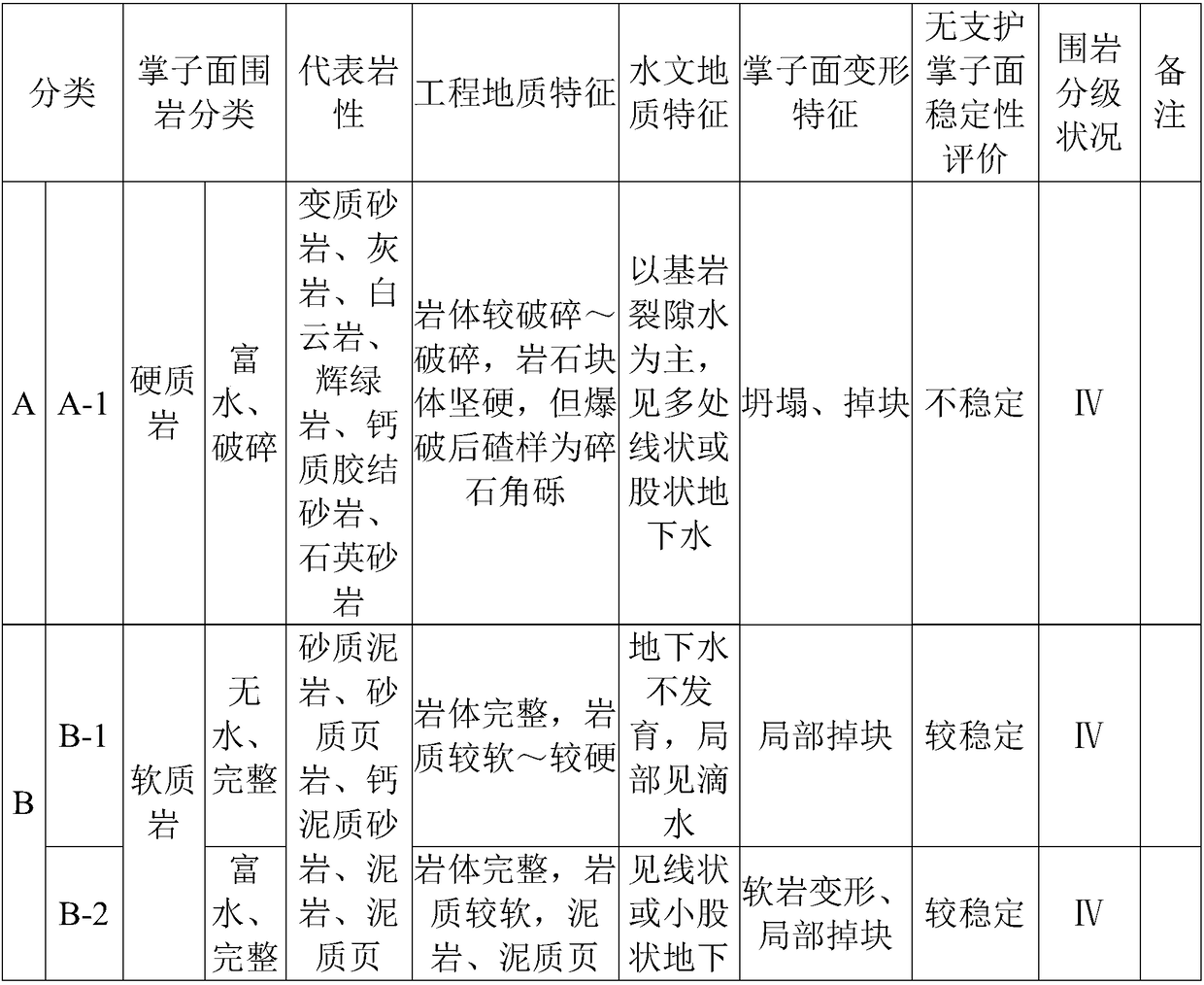

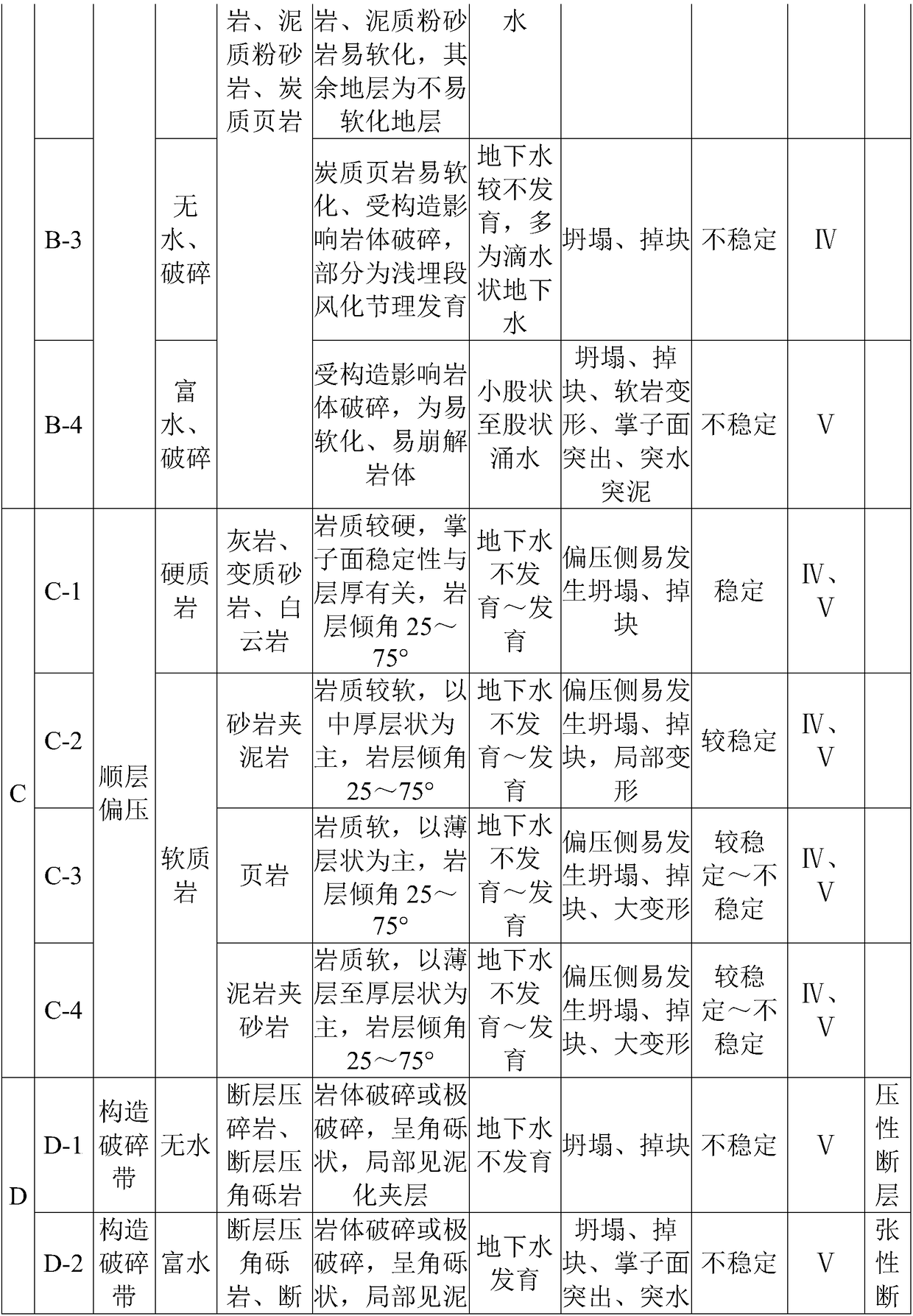

[0063] Step 2. According to the results of the advanced geological prediction, the tunnel face within the entire cross-section is water-rich and broken hard rock. The tunnel face collapses and blocks fall off. The surrounding rock is classified as Grade IV. The stability evaluation is unstable, that is, category A-1;

[0064] St...

Embodiment 2

[0077] A micro-step excavation method suitable for large-section tunnel IV-V surrounding rock, the difference from Example 1 is that after the first step:

[0078] Step 2. According to the results of the advanced geological prediction, the tunnel face within the entire cross-section is anhydrous and complete soft rock, the tunnel face is partially broken, the surrounding rock is classified as grade IV, and the tunnel face is stable without support. The evaluation is relatively stable, that is, category B-1;

[0079] Step 3: According to the evaluation and classification results of the stability of the tunnel face, use a φ42 small conduit with a length greater than 5m for advance support, and partially seal the face with shotcrete, and re-evaluate the stability of the face. Continue to implement this step until the face of the palm is stable;

[0080] Step 4: After the face of the tunnel in Step 3 is stabilized, use a rock drilling jumbo to drill and charge the blasthole within ...

Embodiment 3

[0083] A micro-step excavation method suitable for large-section tunnel IV-V surrounding rock, the difference from Example 1 is that after the first step:

[0084] Step 2. According to the results of the advanced geological prediction, the tunnel face within the entire tunnel section is water-rich and complete soft rock. The soft rock on the tunnel face is deformed and local blocks are lost. The surrounding rock is classified as Grade IV. The stability evaluation of the subsurface is relatively stable, which is B-2 category;

[0085] Step 3: According to the evaluation and classification results of the stability of the tunnel face, use a φ42 small conduit with a length greater than 5m for advanced support, partially seal the tunnel face with shotcrete and locally install fiber anchors, and evaluate the tunnel again If the stability of the face is not met, continue to implement this step until the face of the face is stable;

[0086] Step 4: After the face of the tunnel in Ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com