Supporting treatment construction method for high and steep side slopes of tunnel portal bedding strong weathered rocks

A technology for high and steep slopes and construction methods, which is applied in excavation, infrastructure engineering, construction, etc., can solve the problems of large disturbance, difficult to reach, effectively prevent slope collapse, and the use of supporting methods is not effective, and achieves enhanced Overall stability, avoid direct contact, improve the effect of construction safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

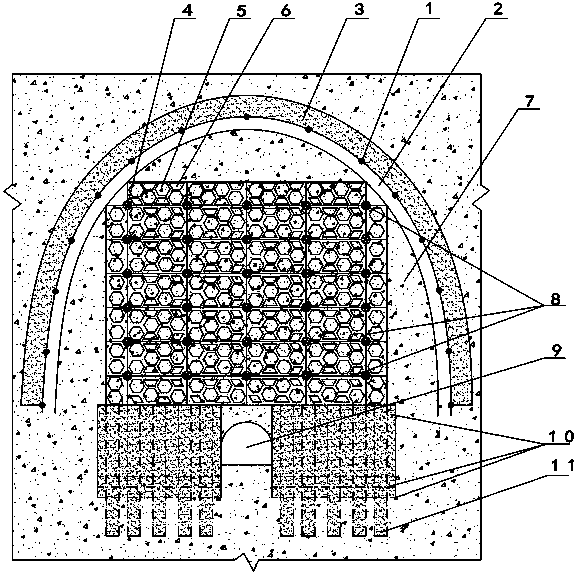

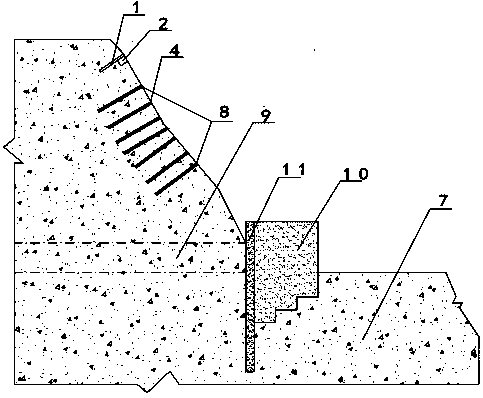

[0024] Example: The slope is a high and steep slope of 43m bedding strongly weathered rock formed after the excavation of a railway engineering mountain, and the railway tunnel construction site is located below the slope. Such as figure 1 and figure 2 As shown in Fig. 1, a support construction method for high and steep slopes of bedding strongly weathered rock at tunnel entrances. First, a plurality of hollow steel pipes distributed in approximately semicircular arcs are arranged along the design limits of the main slope. In addition, there are many holes on the hollow steel pipe, and concrete is injected into the hollow steel pipe. The concrete passes through the holes and forms cement and soil with the surrounding rock and soil, thereby forming a densely packed steel pipe pile 1, and the insertion depth of the steel pipe pile 1 is controlled to be 7m. , a 1m-deep U-shaped drainage groove 2 is arranged along the inner side of the densely packed steel pipe pile 1, forming a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com