Excavation vertical frame sling cart

A technology for hoisting vehicles and erecting frames, which is applied in the direction of lifting frames, hoisting devices, cranes, etc., and can solve problems such as difficulties in precise coordination of machines, low installation efficiency, and potential safety hazards in construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

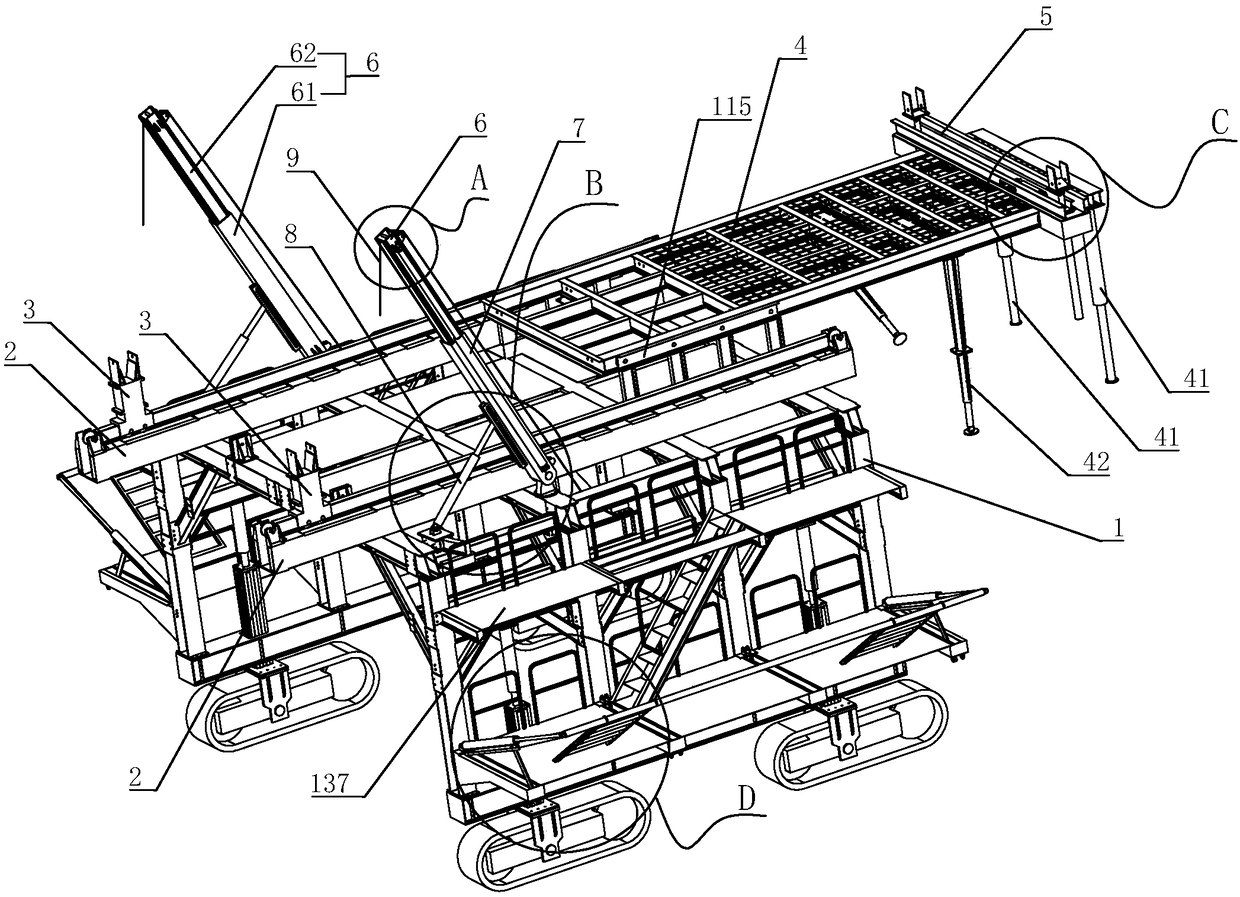

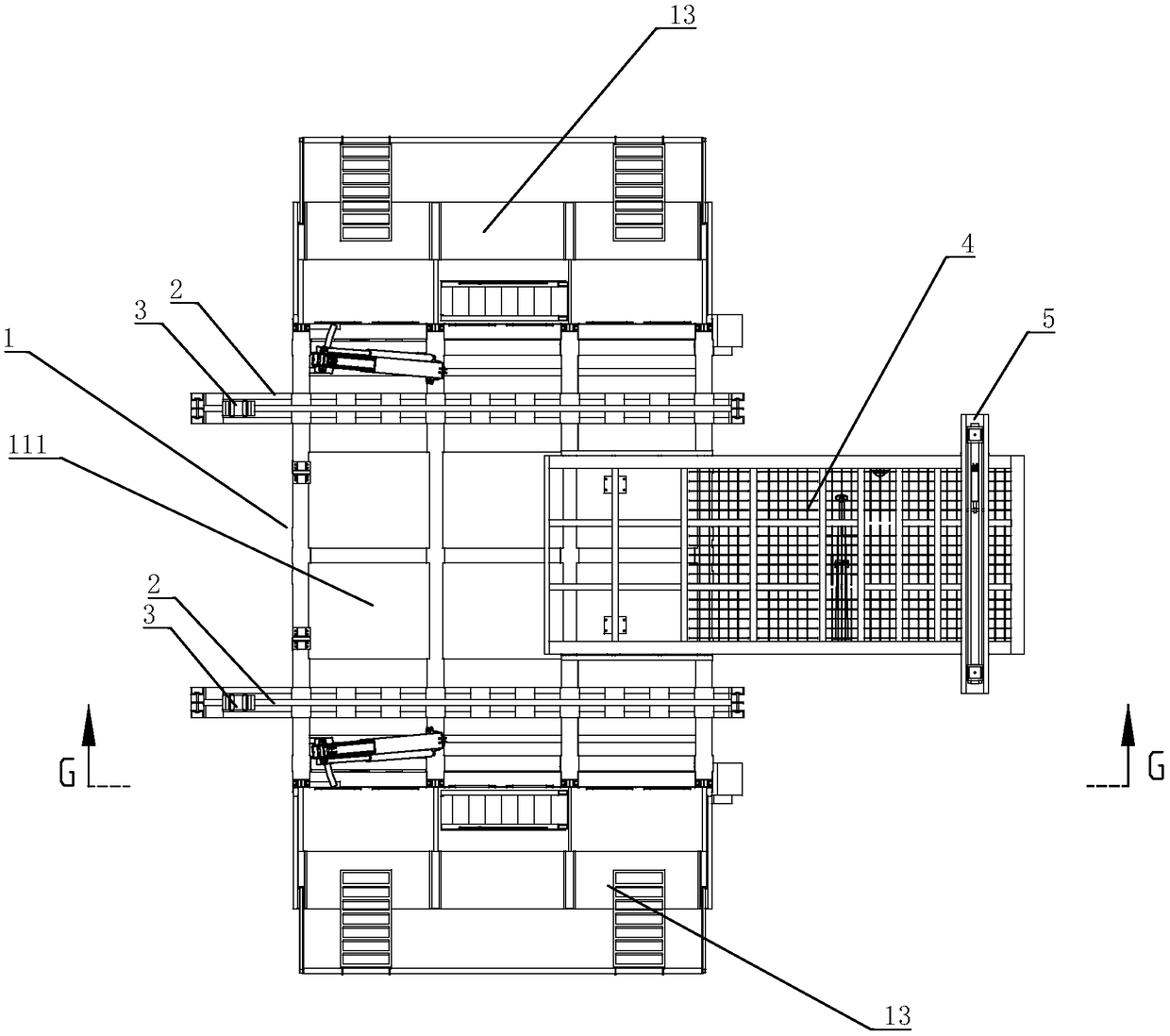

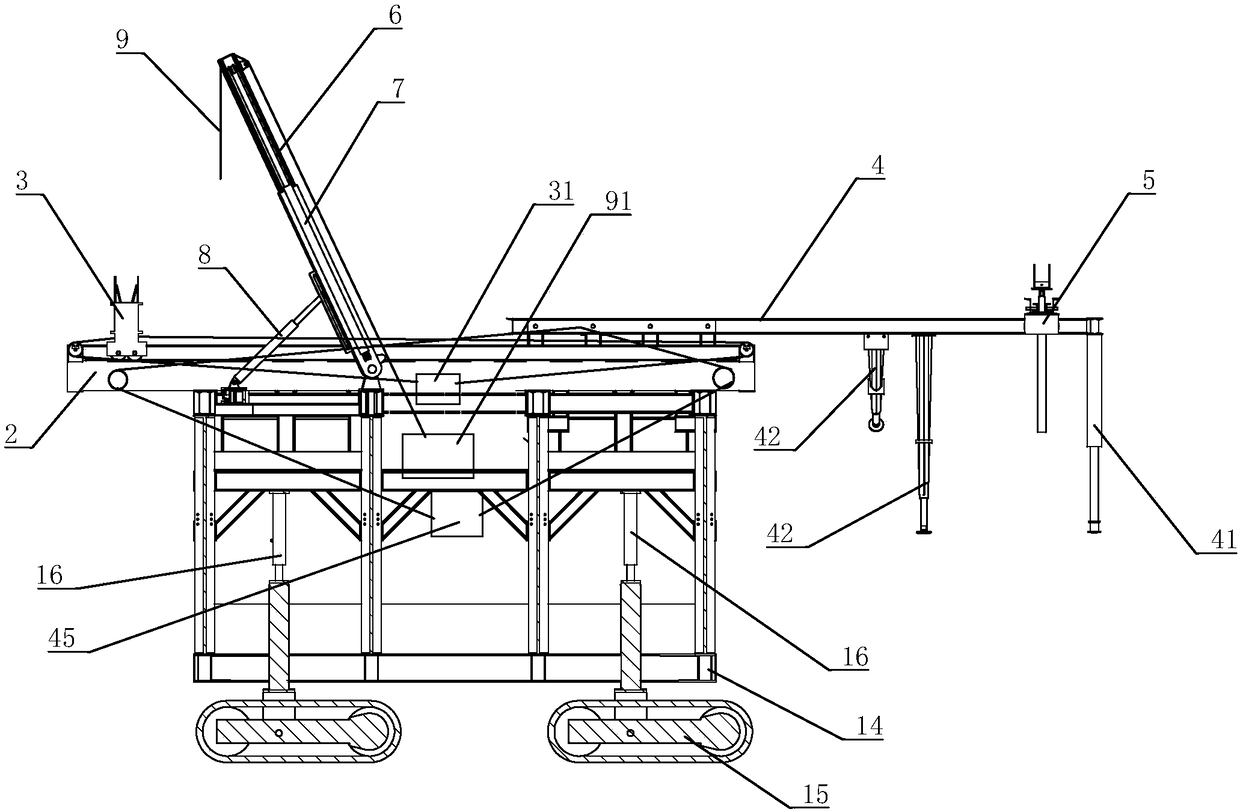

[0029] refer to Figure 1 to Figure 12 , a kind of excavation vertical frame hoisting vehicle of the present invention, comprises vehicle main body 1, guide rail 2, vertical frame carrying trolley 3, telescopic platform 4, jacking mechanism 5 and hoisting device.

[0030] The bottom of the vehicle main body 1 is provided with a rolling part 15, and the rolling part 15 is connected with a rolling driving mechanism for driving its rolling. In this embodiment, the rolling part 15 adopts a crawler belt structure, and the rolling driving mechanism is a motor, and the motor drives the crawler belt to roll to realize the forward or backward movement of the vehicle body 1. Of course, in other embodiments, the rolling part 15 can also be a roller-type structure. The track is only preferred in this embodiment, and is not specifically limited. The rolling mode ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com