Vertical bearing mounting device for motor rotor

A technology of motor rotor and bearing device, which is applied in the direction of electromechanical device, manufacture of motor generator, manufacture of stator/rotor body, etc. It can solve the problems of inconvenient automatic conveying of raw materials and low production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

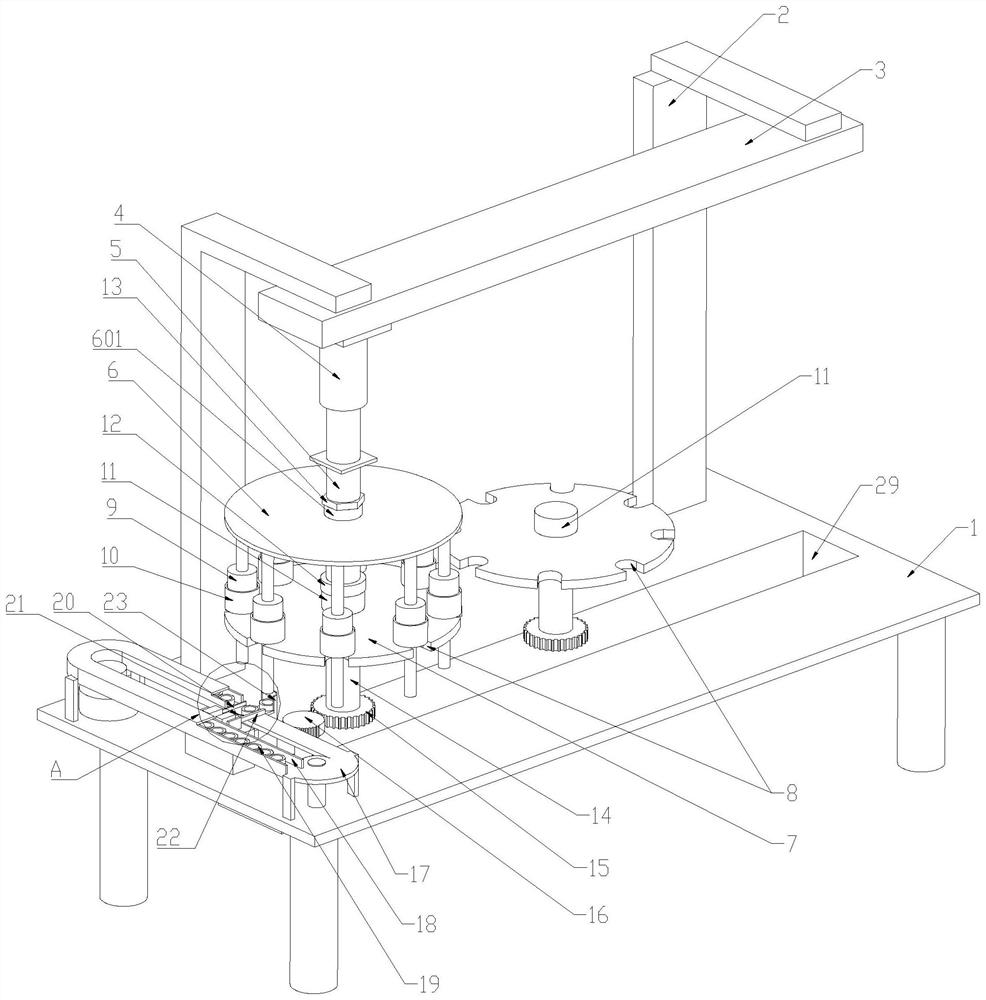

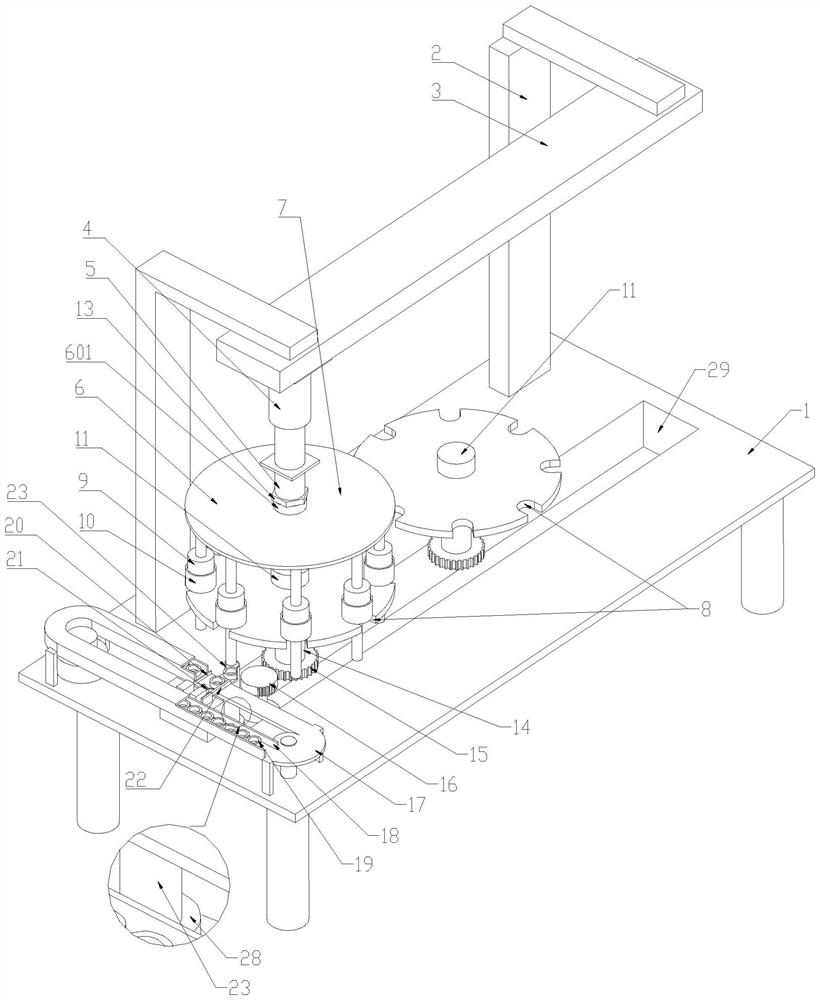

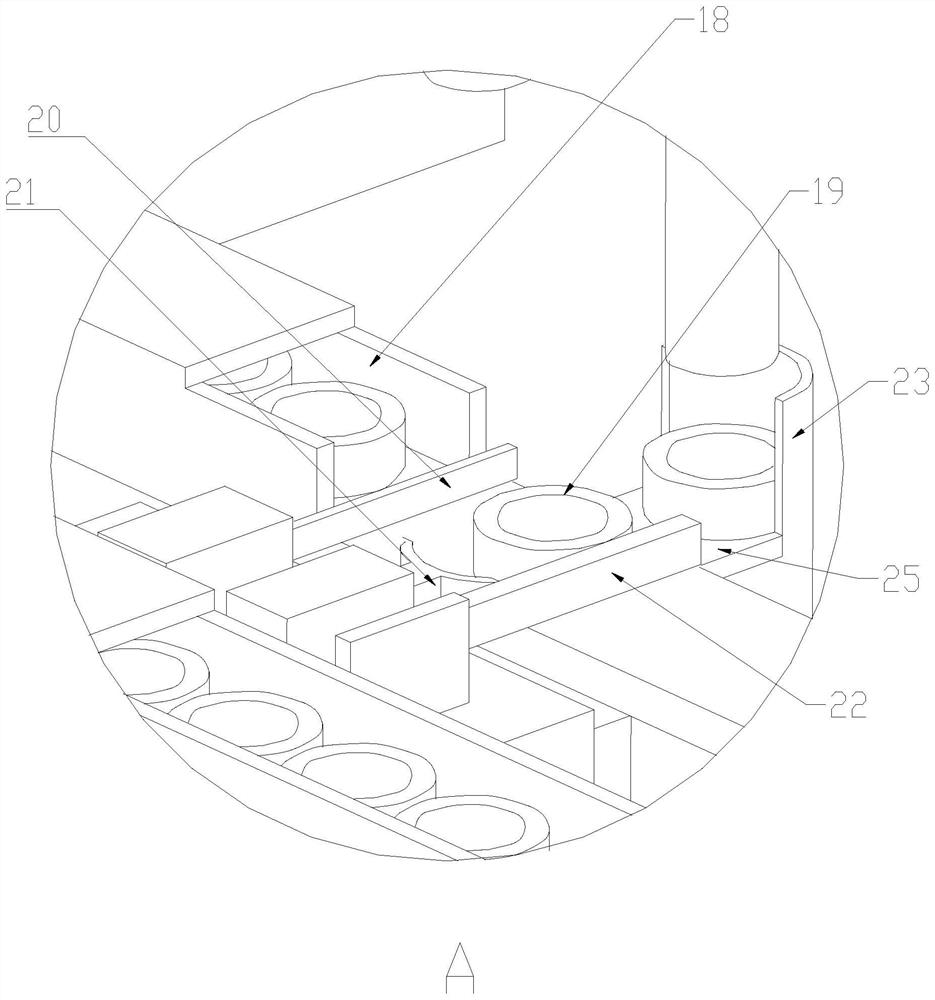

[0029] A kind of motor rotor vertical mounting bearing device of this embodiment, such as Figure 1-7 As shown, it includes a workbench 1, the inner side of the workbench 1 is fixedly connected with a column 2, the top of the column 2 is fixedly connected with a slide rail 3, and the bottom of the slide rail 3 is slidably connected with a cylinder I4. The bottom of the cylinder Ⅰ4 is connected with a connecting rod 5, through which a circular supporting plate 7 is suspended and connected, the middle of the top of the supporting plate 7 is connected with a rotating drum 11, and the bottom of the connecting rod 5 is fixedly connected with an electromagnet 12, through the electromagnetic Iron 12 absorbs and connects supporting plate 7. Supporting plate 7 is provided with multiple sets of placement grooves 8, and rotor 9 is vertically placed through placing grooves 8, and the middle of rotor 9 is connected with rotating shaft, and the bottom of supporting plate 7 is fixed with rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com