Fabricated support and intelligent hydraulic jacking type mounting method thereof

An installation method and an assembly-type technology are applied in the field of assembly-type support and its intelligent hydraulic jack-up installation, which can solve the problems of large deformation and loss of support rods, large amount of high-altitude operations, and high safety risks, and reduce construction costs and operations. The effect of less personnel and high construction safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The support structure and installation method of the present invention will be described in detail below with reference to the accompanying drawings. The terms "horizontal" and "longitudinal" used in the following description are relative terms. When a horizontal direction is set to be horizontal, the horizontal direction perpendicular to it is the vertical. Therefore, the "horizontal" and "longitudinal" are not Specific restrictions on the structure of the bracket or the installation sequence.

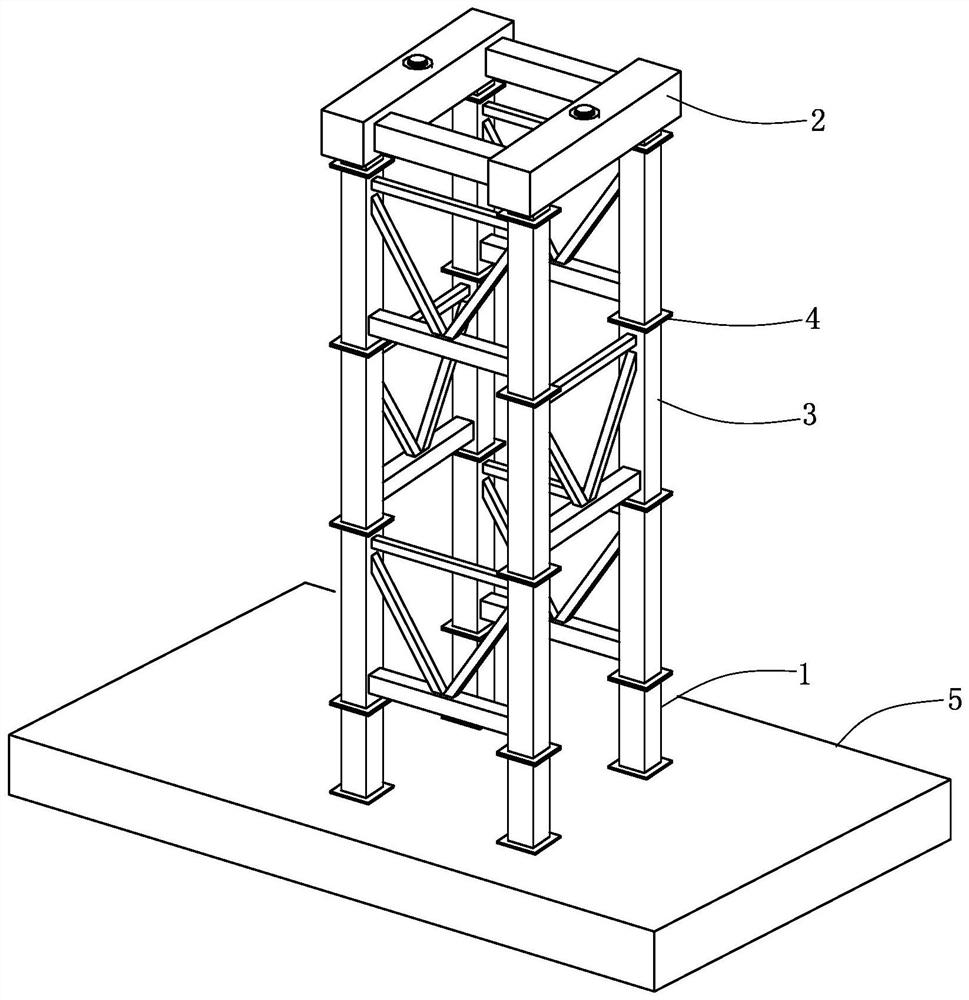

[0054] like figure 1 As shown, the assembled bracket provided by the present invention includes 4 bracket foundation columns 1, a cap beam 2 and a plurality of bracket segments;

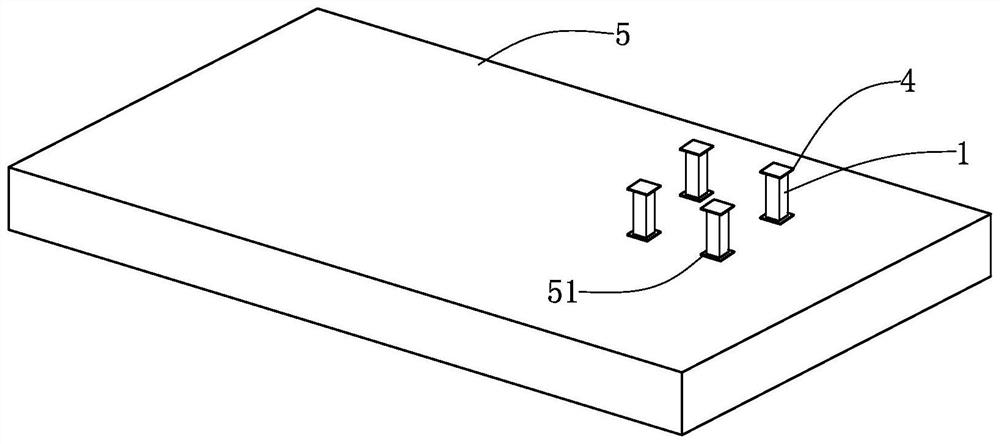

[0055] like figure 2 As shown, the lower ends of the four support foundation columns 1 are respectively fixed on the concrete foundation 5, and the upper ends are respectively provided with flanges 4;

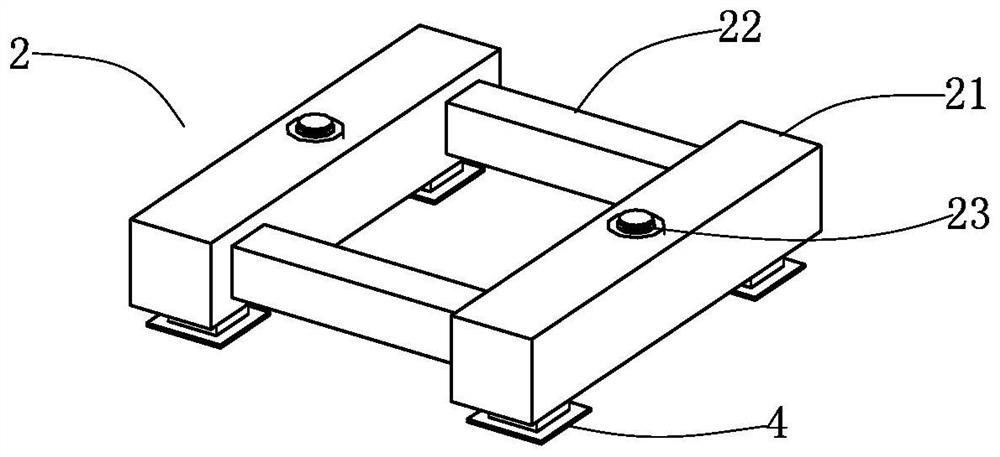

[0056] like image 3As shown, the hat beam 2 includes two beams 21, and flanges 4 are provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com