A unitized energy-saving glass curtain wall

An energy-saving glass, unitized technology, applied in the direction of walls, buildings, building components, etc., can solve the problems of not being able to construct at the same time, limited stability and fire resistance, low installation efficiency, etc., to achieve simple installation, high degree of installation automation, The effect of improving installation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

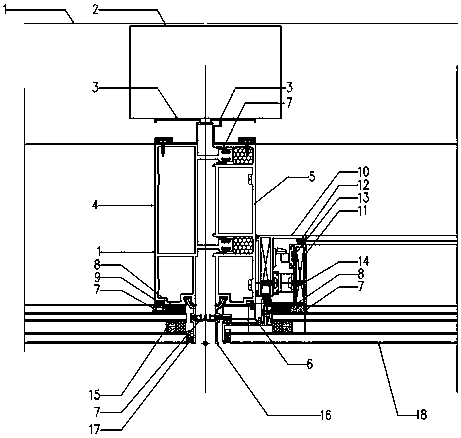

[0017] The invention provides a unitized energy-saving glass curtain wall, which takes the unit block as the unit and can be installed as a whole after being assembled in the factory. The installation is simple, the commissioning and maintenance are convenient, the shape of the profile can be customized, and the airtightness can be effectively completed with the sealing strip. Installation, the installation has a high degree of automation, which improves the installation efficiency, and can be constructed in parallel with civil engineering, which speeds up the work progress.

[0018] In order to better understand the above-mentioned technical solution, the above-mentioned technical solution will be described in detail below in conjunction with the accompanying drawings and specific implementation methods.

[0019] Such as figure 1 As shown, a unitized energy-saving glass curtain wall described in this embodiment includes an aluminum alloy window sill panel 1, an aluminum alloy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com