Installation technology of inner separation wall body

An installation process and wall technology, applied in the direction of walls, building materials, building components, etc., can solve the problems of inconvenient operation, labor and time-consuming, inconvenient to ensure the verticality and flatness of the board, and achieve easy installation, Easy to operate, guarantee the effect of flatness and verticality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described below in conjunction with accompanying drawing description and specific embodiment:

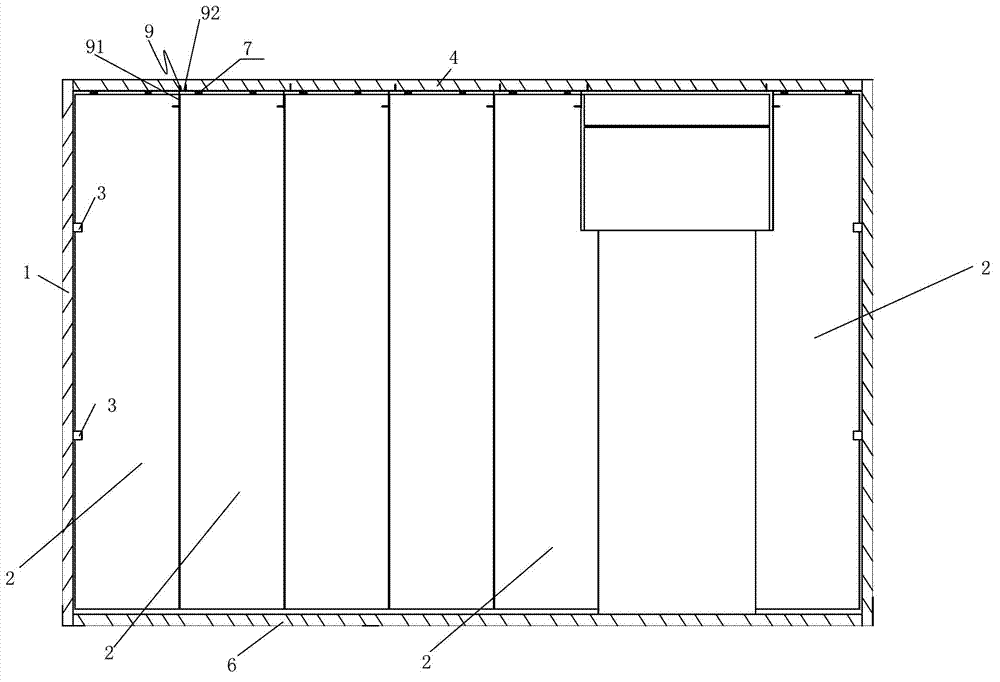

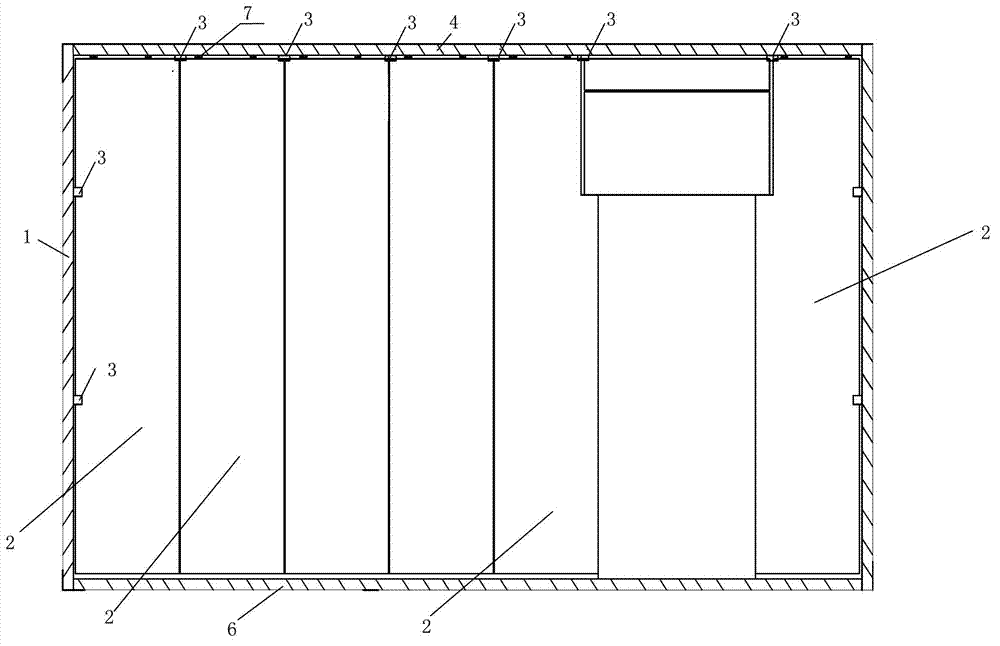

[0046] Such as Figures 1 to 13 Shown, the present invention is a kind of installation process of inner partition wall body, and it comprises the following steps:

[0047] A. Positioning and setting out: release the wall line on the construction site to position the inner partition wall to be installed. The wall line includes the ground line and the antenna line;

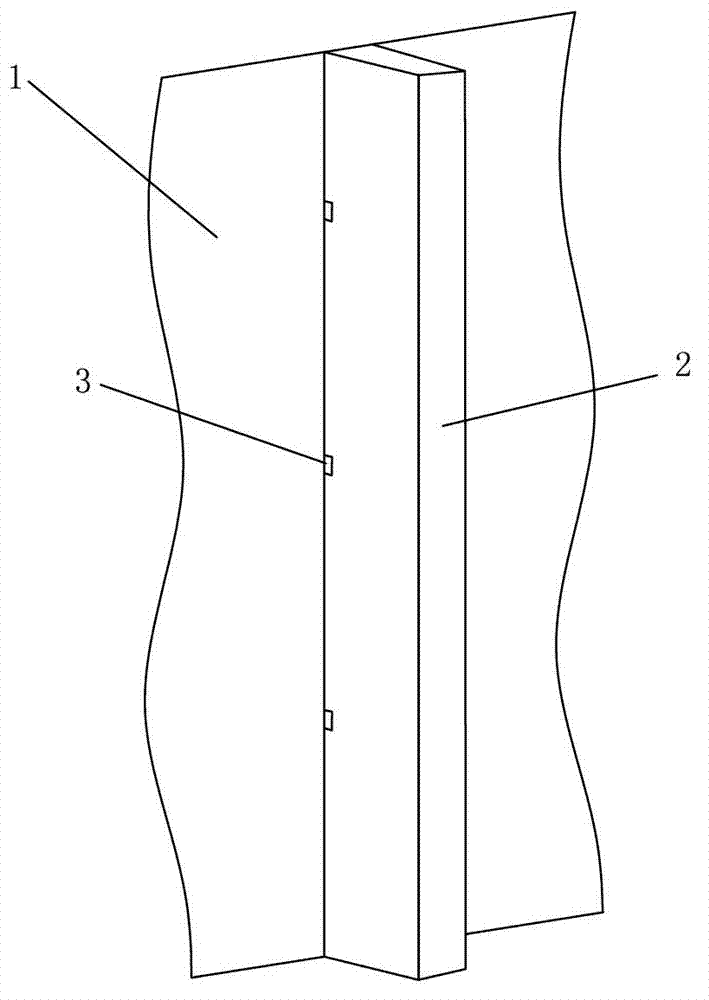

[0048] B. Install the U-shaped positioning clip 3: the U-shaped positioning clip 3 includes a connecting piece 31,

[0049] The first card 32 and the second card 33 perpendicular to it are respectively connected to both sides of the connecting piece 31, and the inner surface of the connecting piece 31 is formed between the first card 32 and the second card 33 for placing the wallboard 2. The mounting groove 34, the width of the mounting groove 34 is equivalent to the thicknes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com