Diagonal bracing and pulling device used for supporting of cast-in-place concrete wall formwork

A concrete wall and formwork support technology, which is applied to the preparation of building components on site, pillars, buildings, etc., can solve the problem of poor stability and reliability of the connection between the upper connector and the horizontal back corrugated, and can not guarantee the support strength and Stability, cumbersome adjustment of the length of the diagonal tie rods, etc., to achieve the effects of reducing construction safety hazards, convenient connection and operation, and good support strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The specific embodiment of the present invention will be described with reference to the accompanying drawings.

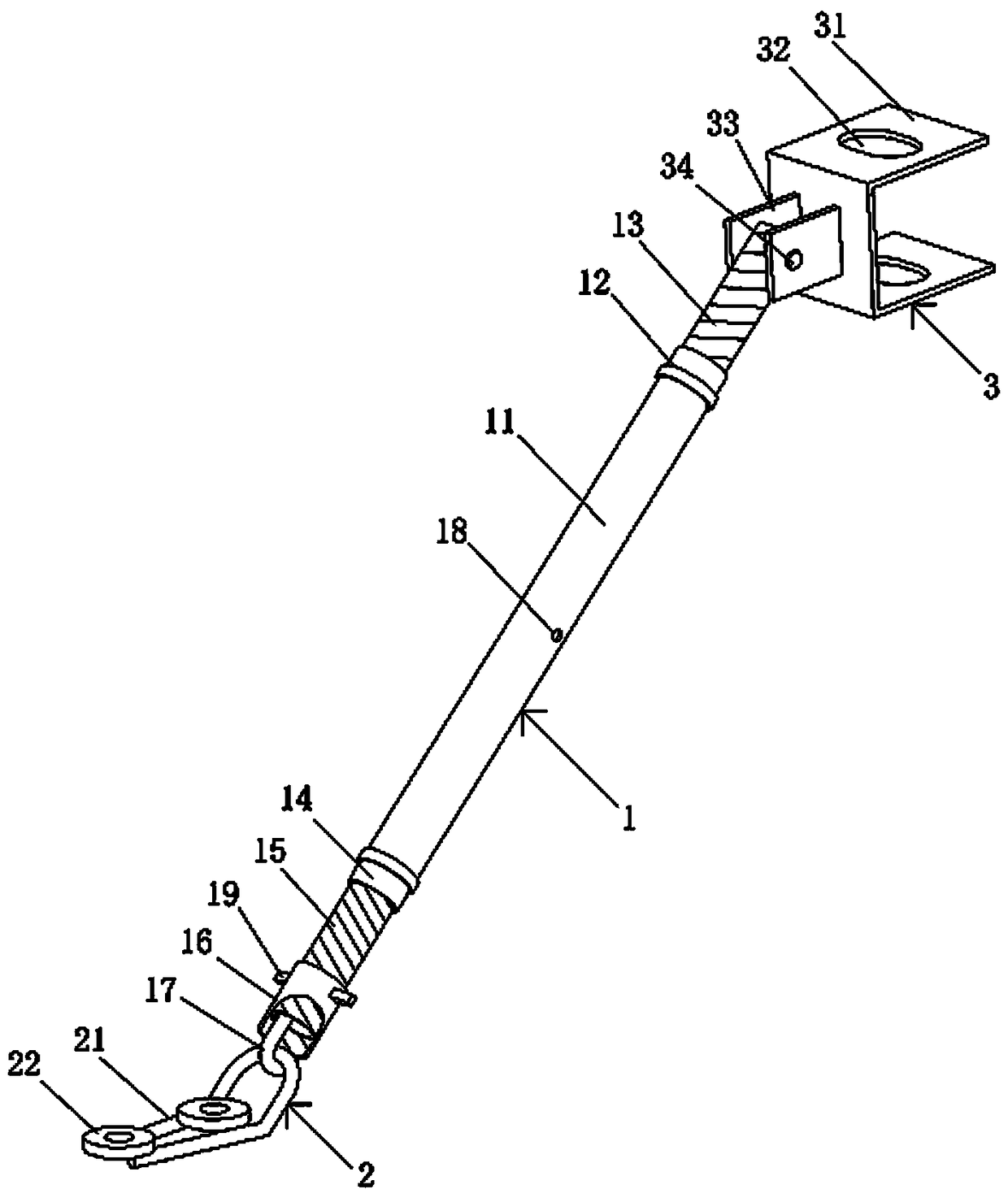

[0012] Such as figure 1 , the diagonal bracing device used for the support of cast-in-place concrete wall formwork, consists of a diagonal brace rod 1 with adjustable length, a lower fixing part 2 connected to the lower end of the diagonal brace rod 1 and a brace connected to the upper end of the diagonal brace rod 1 The upper connection part 3 is formed. The diagonal bracing rod 1 has a middle rod body 11, and the middle rod body 11 is a hollow circular rod. The upper end of the middle rod body 11 is coaxially connected with an upper nut 12 , the upper nut 12 is assembled with an upper lead screw 13 , and the upper end of the upper lead screw 13 is hingedly connected with the upper connecting piece 3 . The lower end of the middle rod body 11 is coaxially connected with a lower nut 14 , the lower nut 14 is assembled with a lower lead screw 15 , and the low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com