Patents

Literature

54results about How to "Precise verticality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

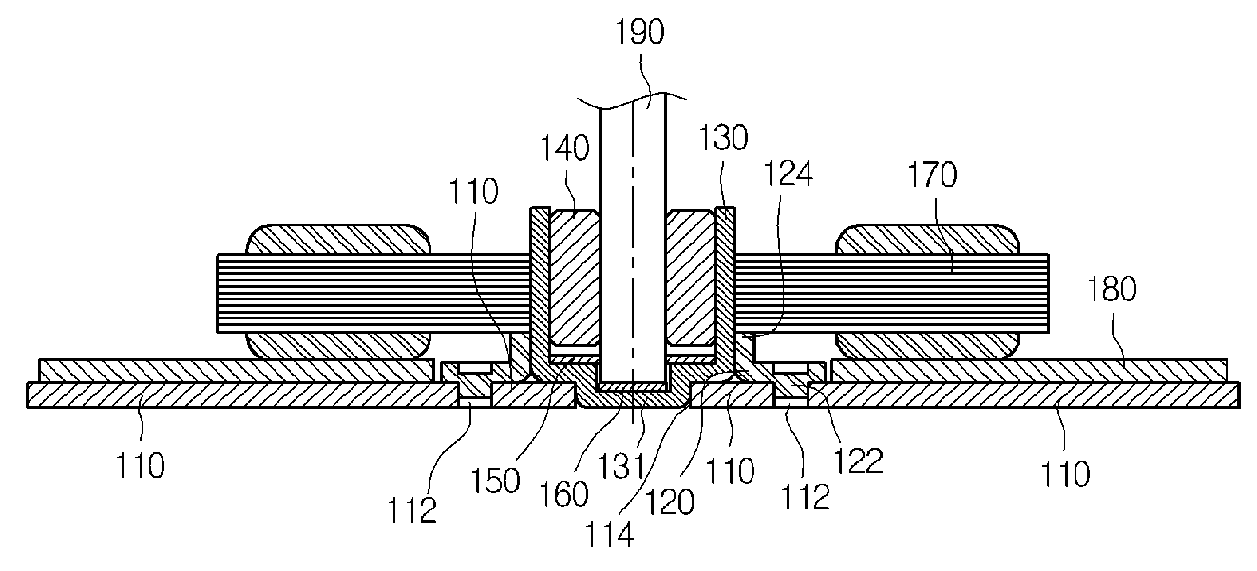

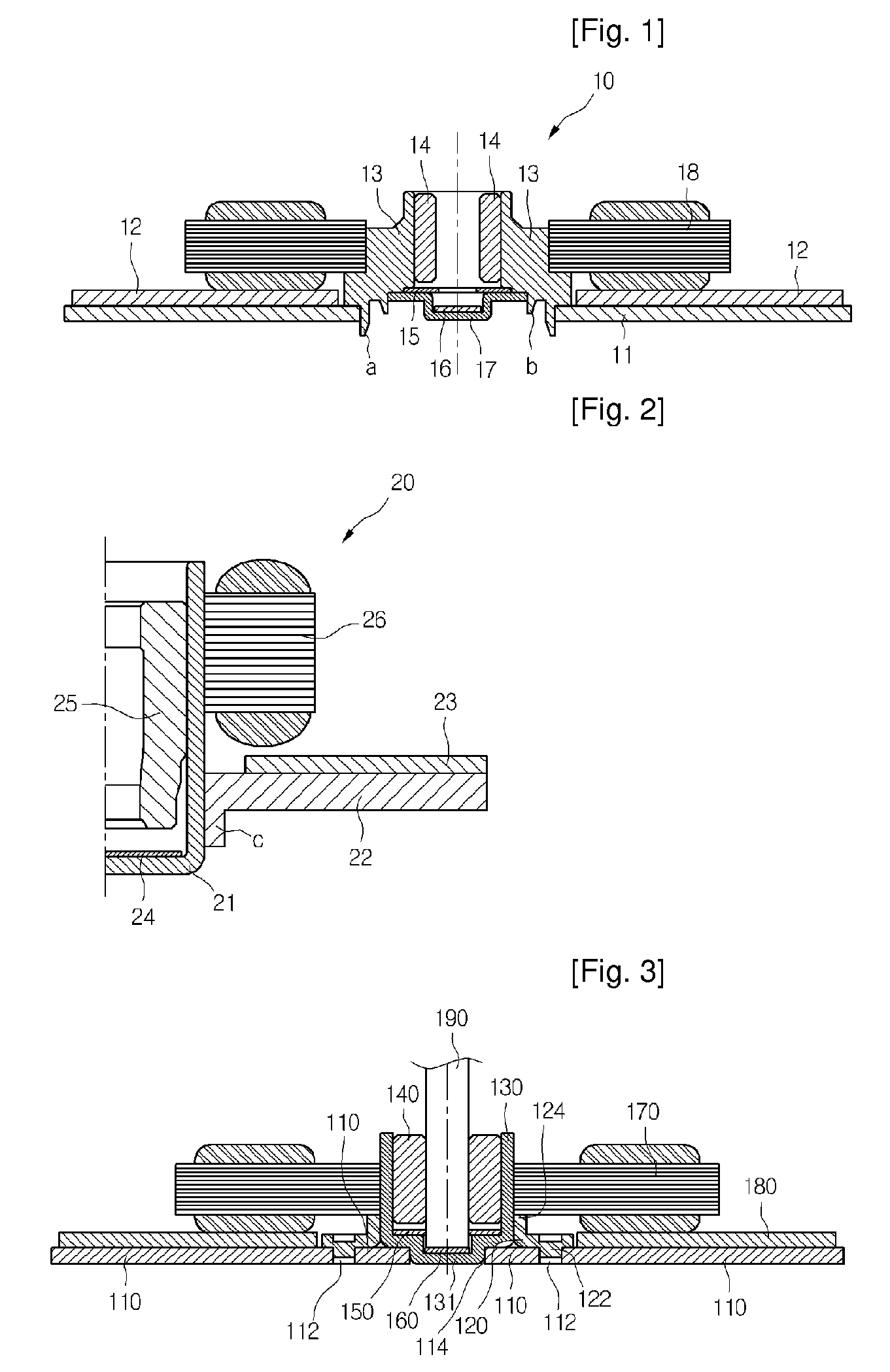

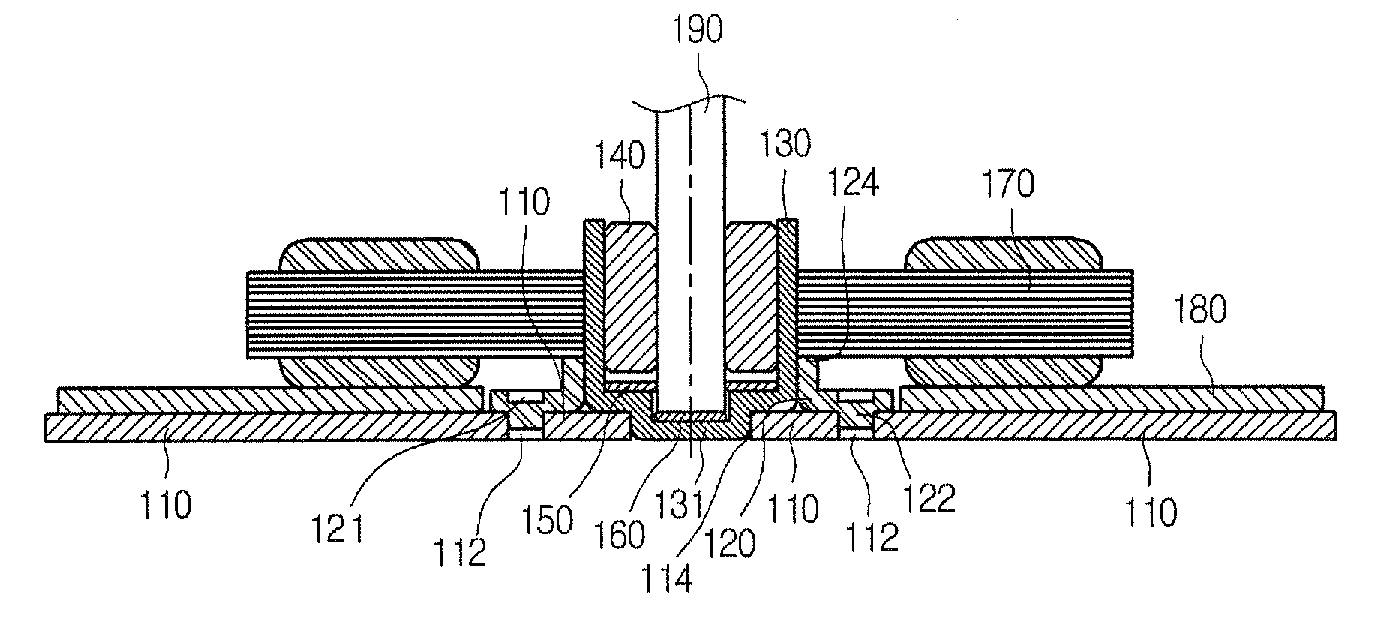

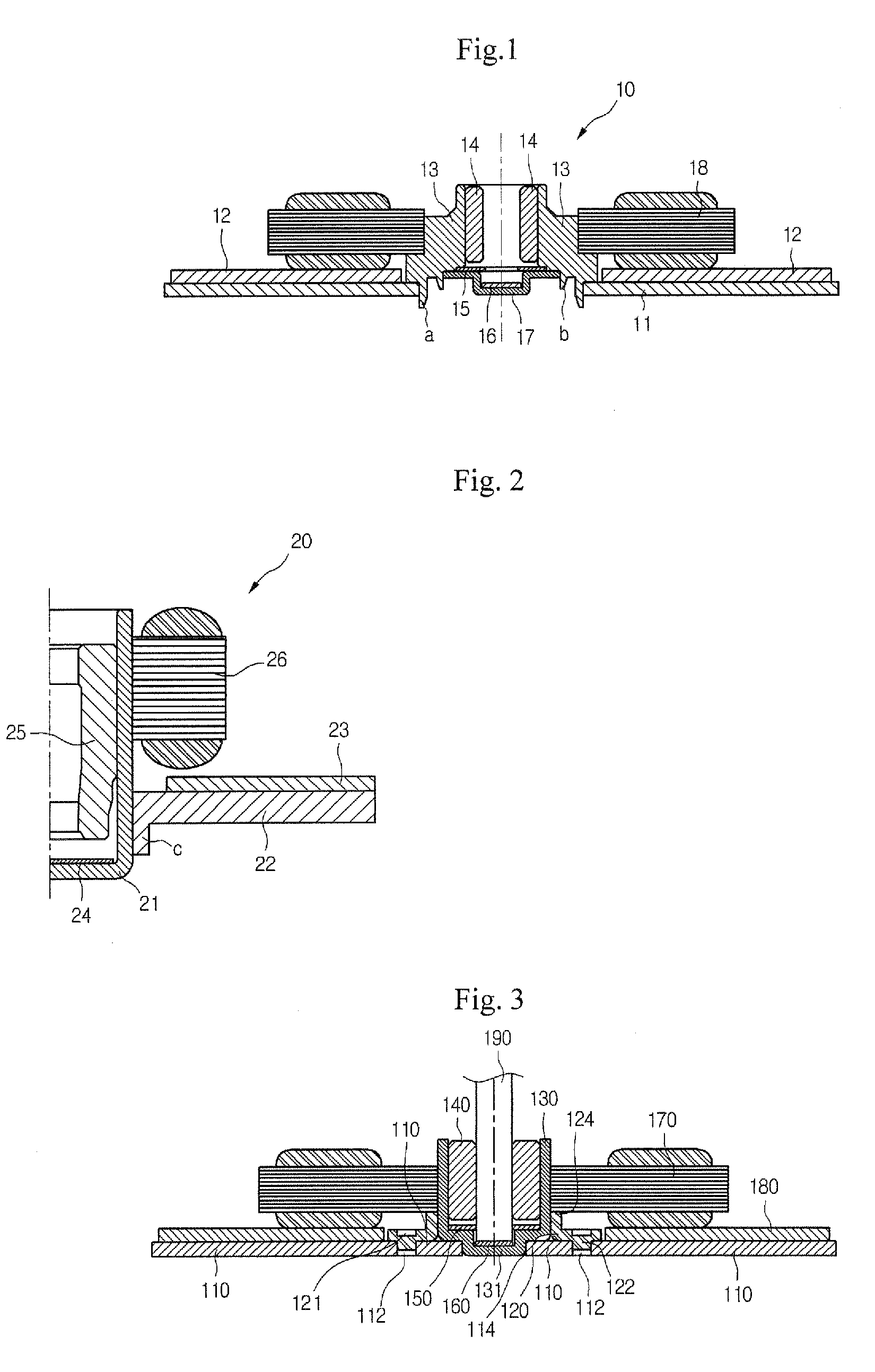

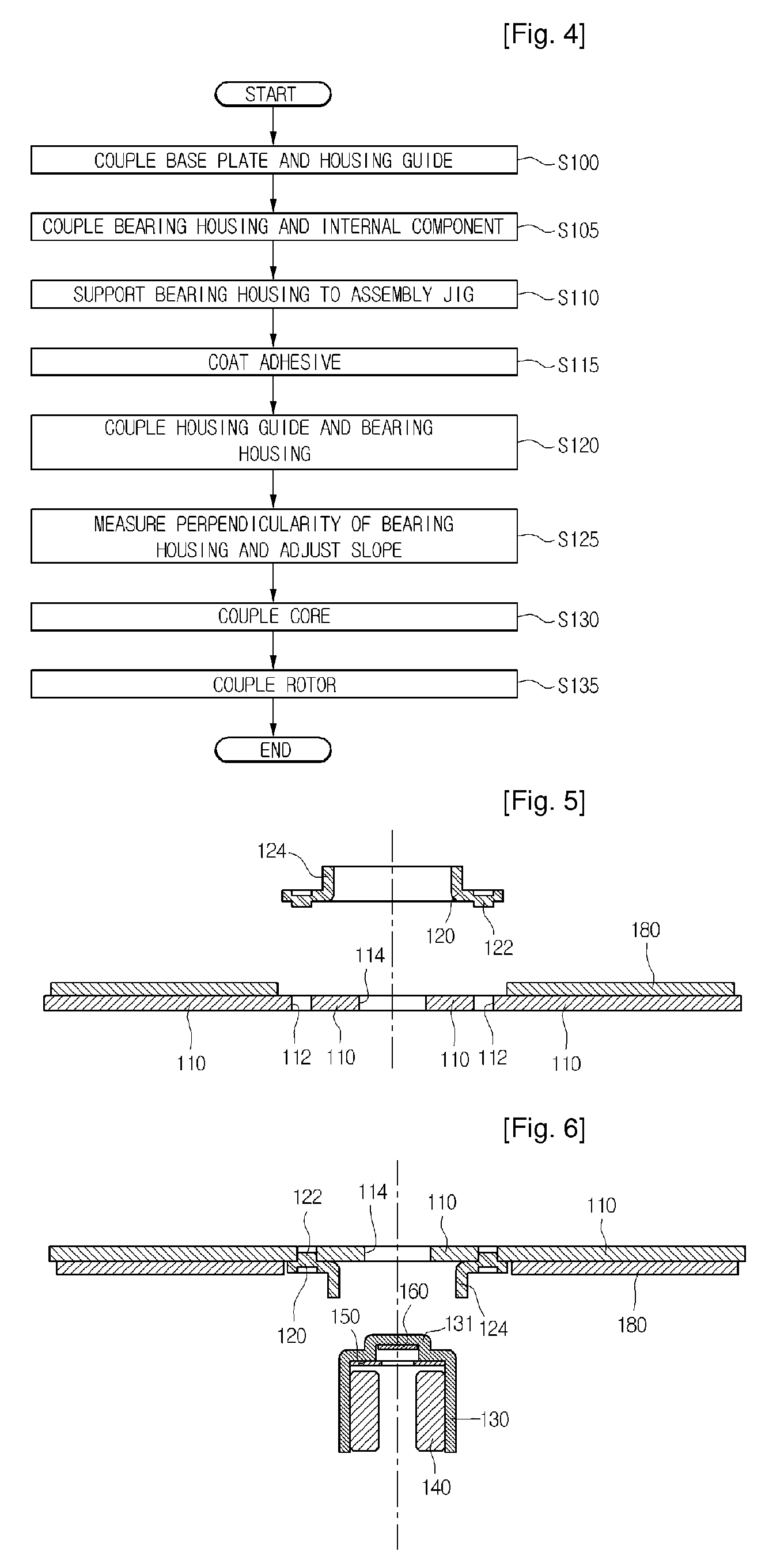

Spindle Motor and Fabricating Method Thereof

InactiveUS20080169709A1Avoid componentsAvoid defectsAssociation with control/drive circuitsWater closetsFixed bearingEngineering

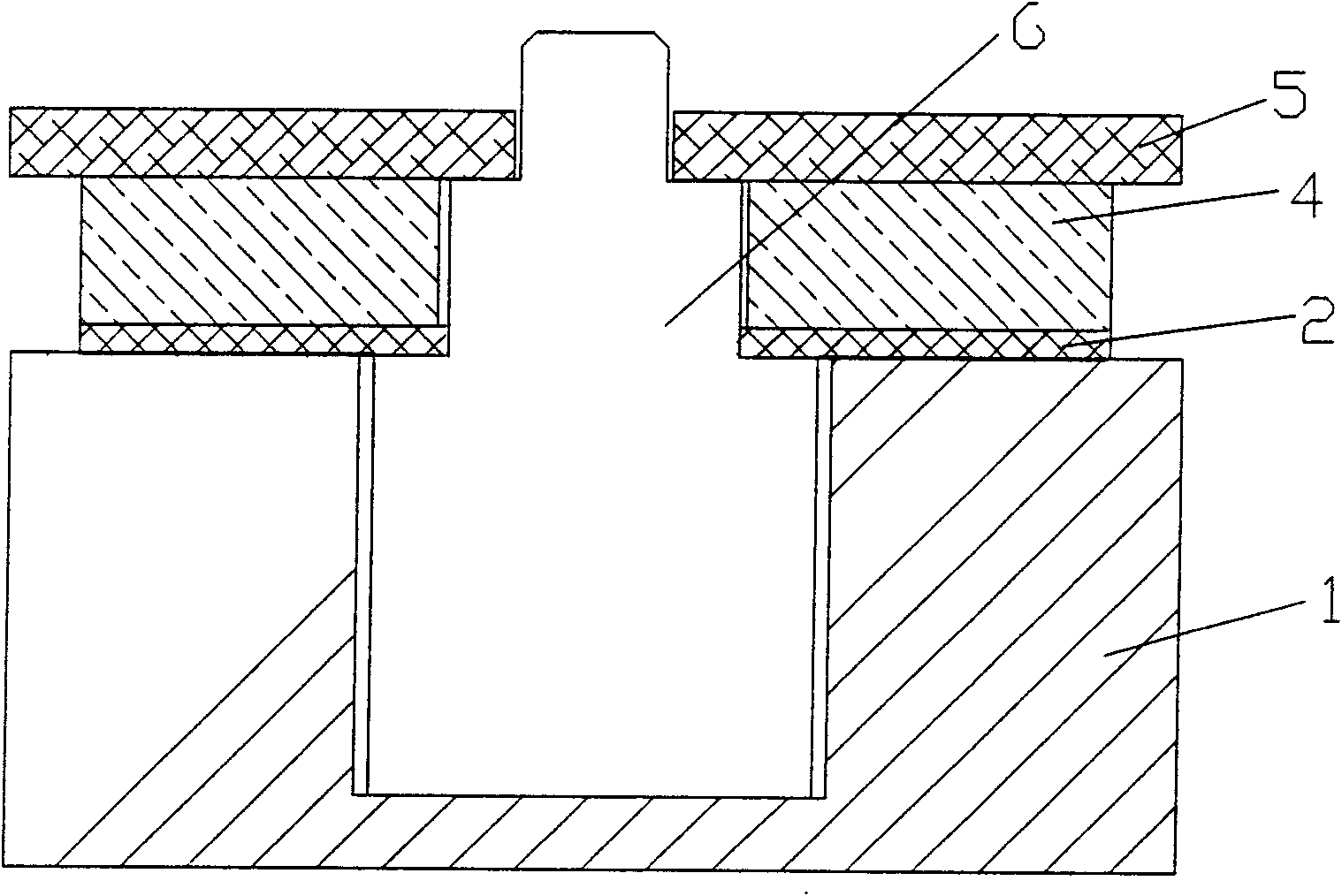

A spindle motor, obtaining more accurate shaft perpendicularity and more convenient assembling process, is disclosed, the spindle motor includes: a rotor; a bearing housing into which the rotor is inserted; a base plate fixing the bearing housing; a housing guide fixed to the base plate, the housing guide having at least one vertical portion guiding an outer surface of the bearing housing; a printed circuit board mounted on the base plate; and a stator coupled to an outer surface of the bearing housing and supplied with power from the printed circuit board.

Owner:HITACHI LG DATA STORAGE KOREA

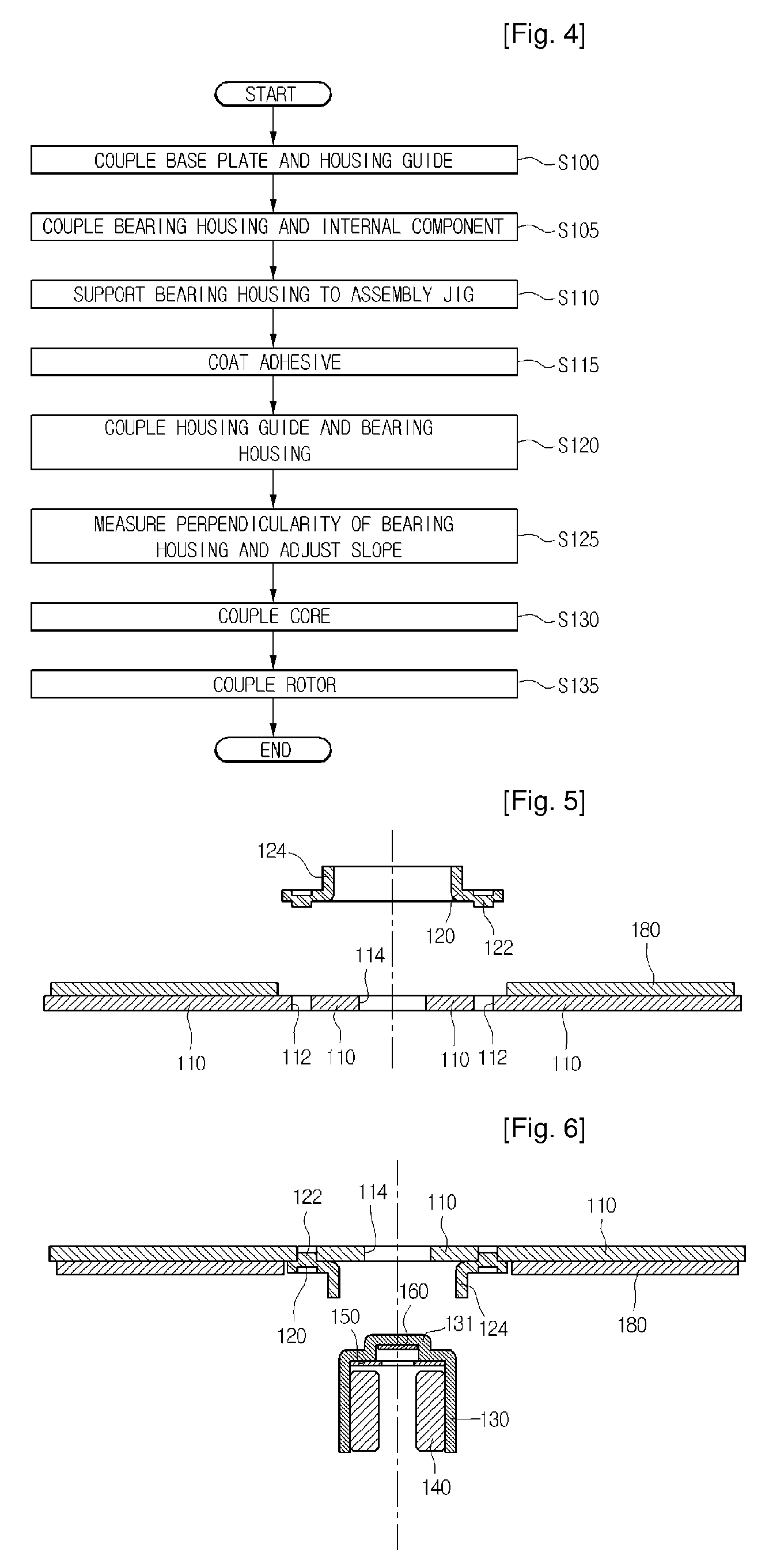

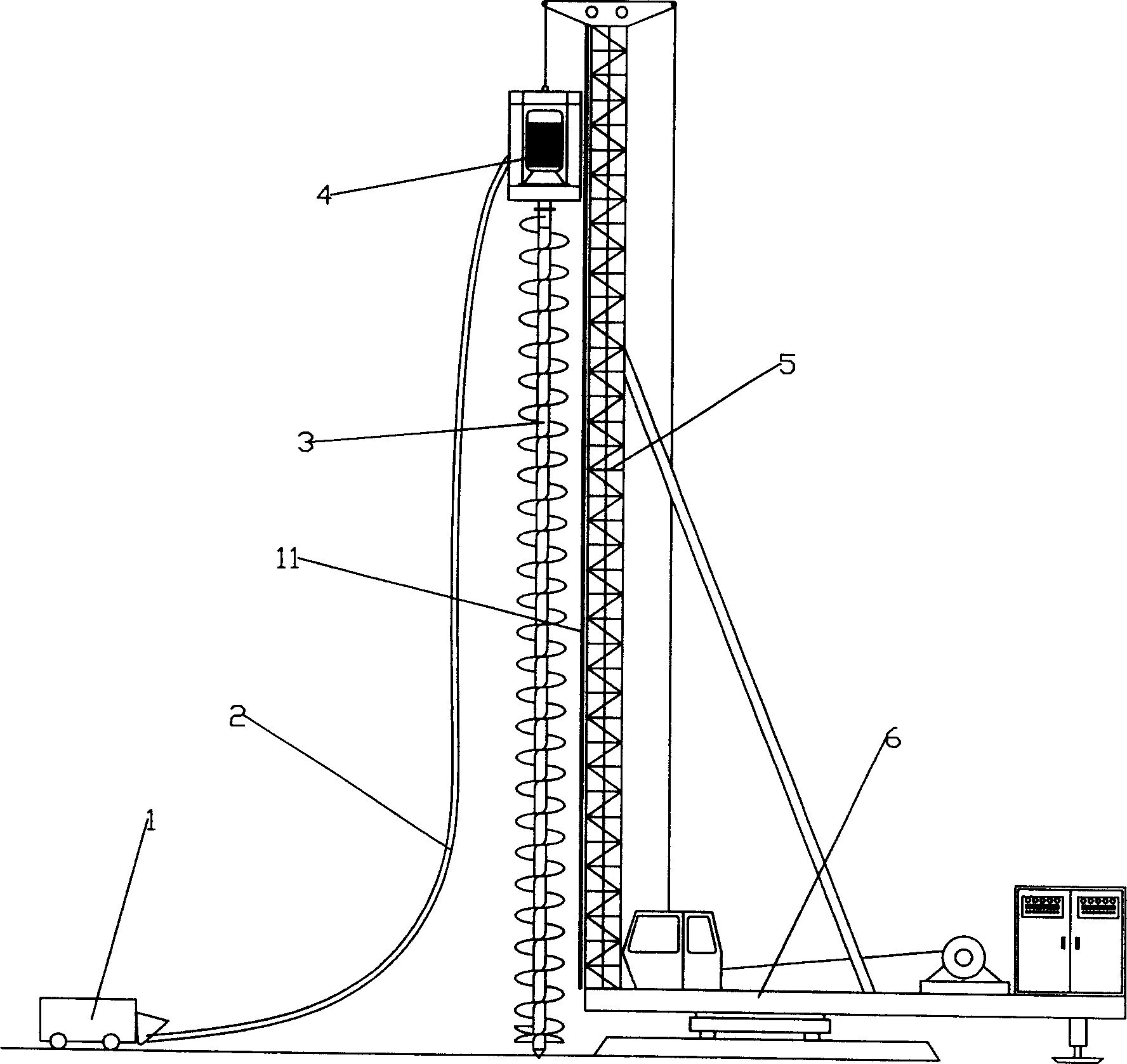

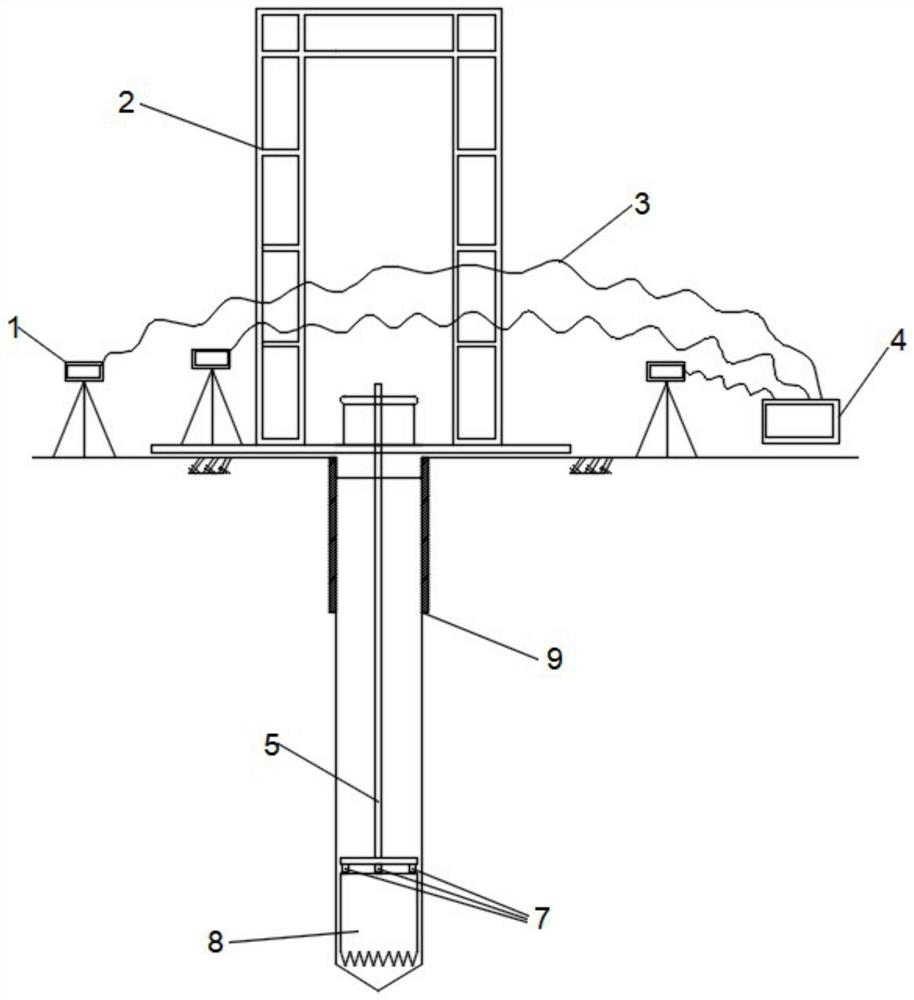

Construction machinery for long spiral press pouring concrete lock pin combination piles

The invention discloses a construction machine for long helical grouting concrete core-inserted composite piles. A long helical drilling and grouting pile mechanism and a static pressure pile mechanism are installed side by side on the walking chassis of a walking pile machine. The long helical auger The center points of the hole-pressing pile filling mechanism and the pile-pressing mechanism are all located on the same circle centered on the center point of the turntable of the traveling chassis of the pile machine. After the long spiral construction is completed, the static pile-pressing mechanism can be quickly aligned only by turning the turntable. The pile driver can independently complete the construction of the long spiral pressure grouting concrete core-inserted composite pile, and has the advantages of convenient construction, reliable quality and low construction cost.

Owner:雷玉华

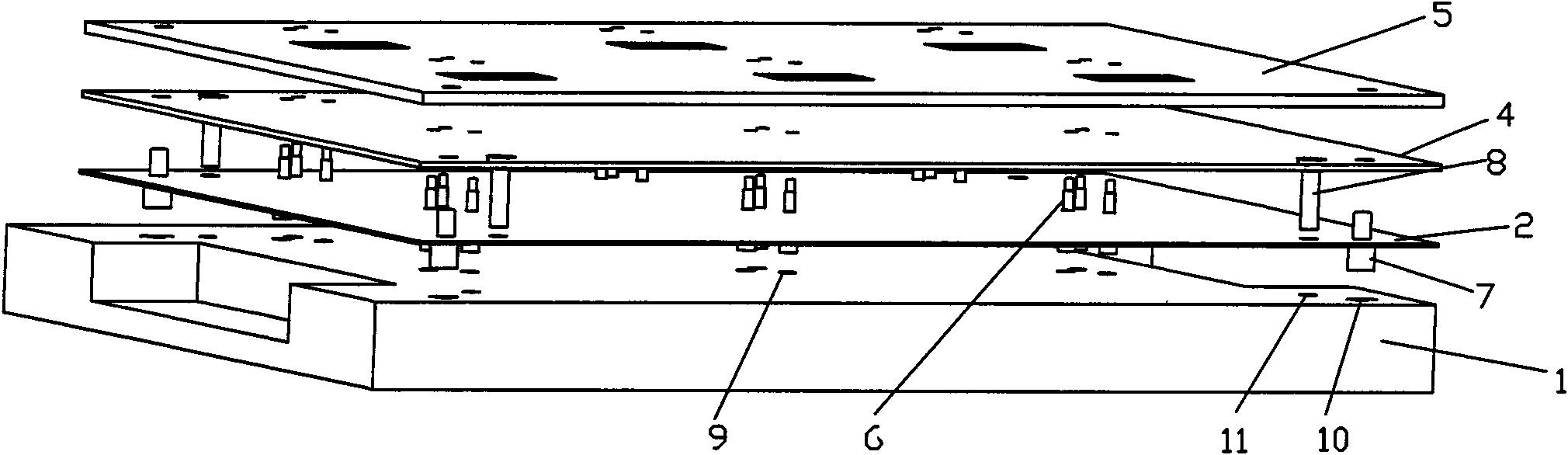

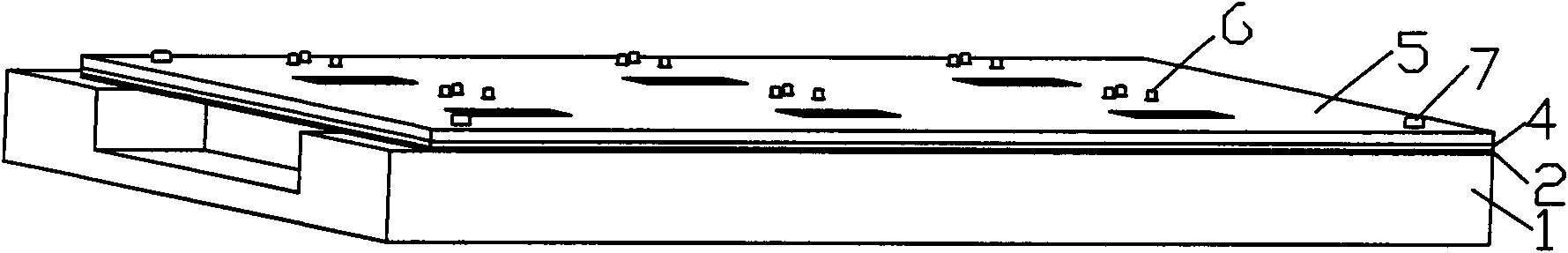

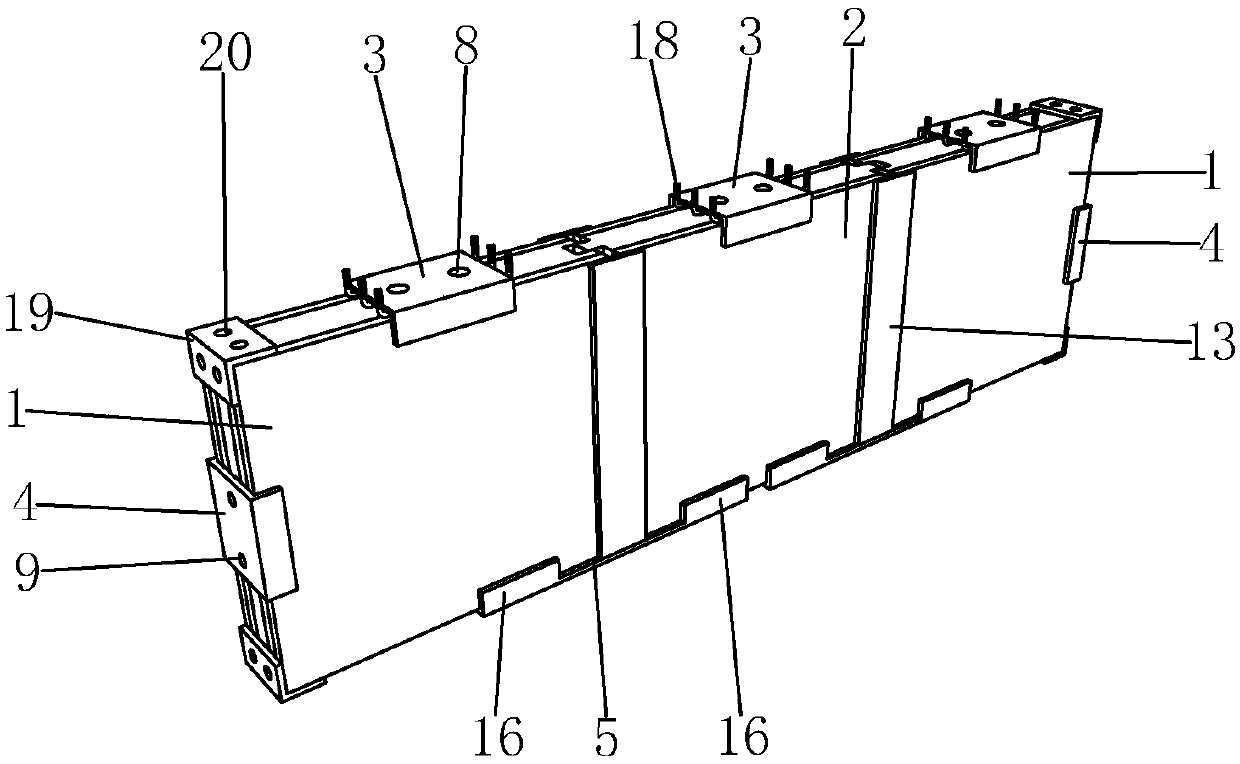

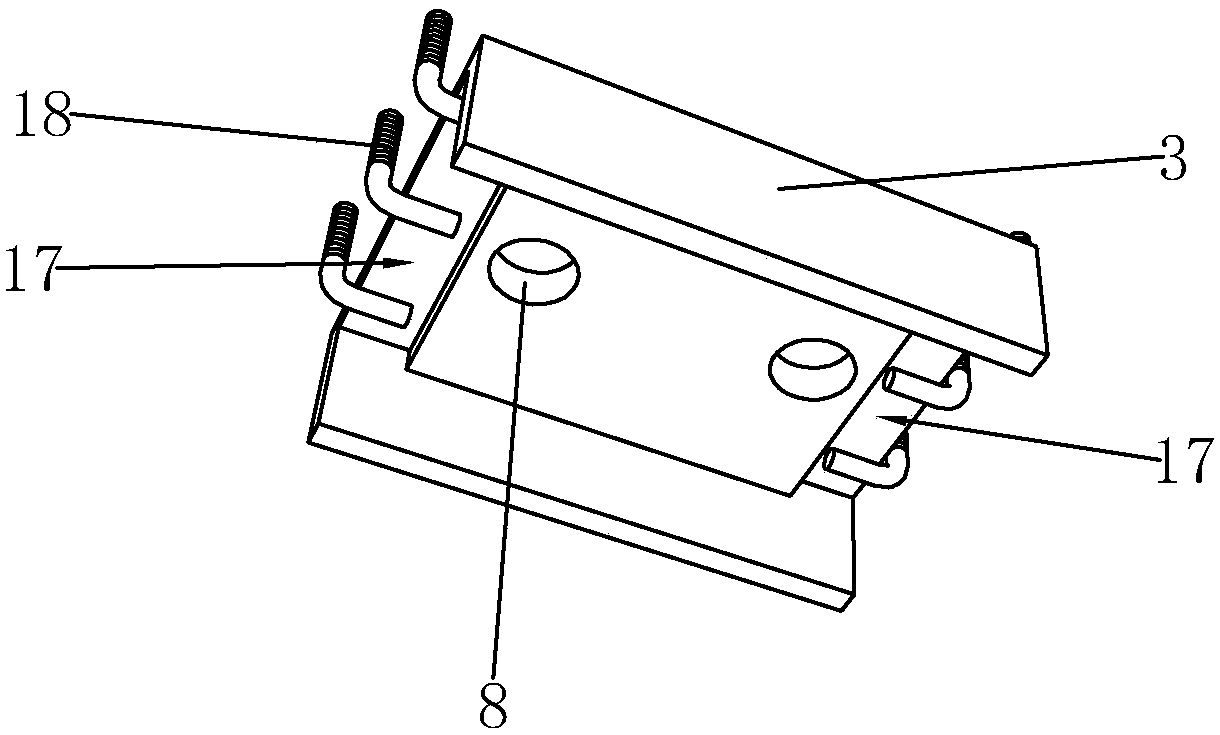

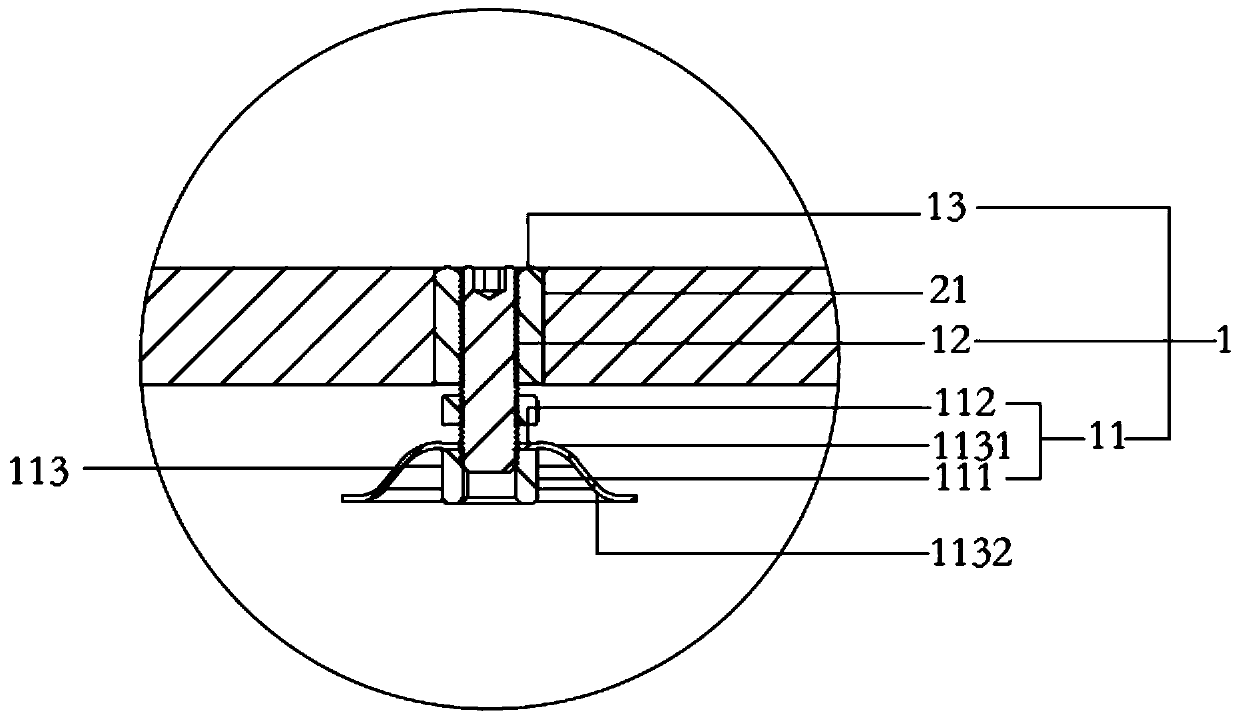

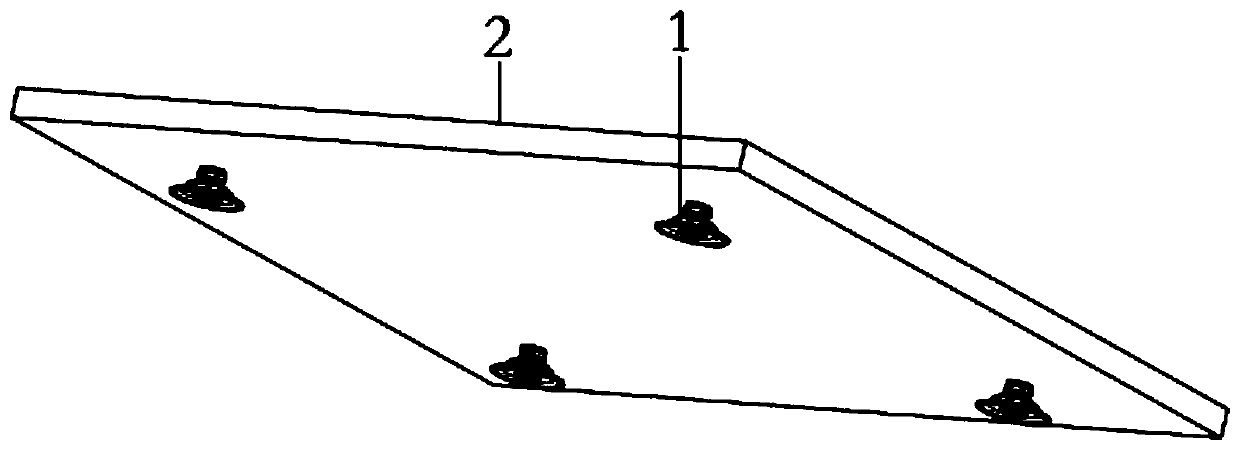

Positioning fixture for assembling flexible printing circuit (FPC)

InactiveCN101990362AAchieve tight fitHigh positioning accuracyPrinted circuit assemblingFlexible circuitsMechanical engineering

The invention belongs to the fixture field used in processing procedures of electronic products, and in particular relates to a positioning fixture for assembling a flexible printing circuit (FPC). The fixture comprises a layer of bottom plate, a layer of FPC carrier plate arranged on the bottom plate, a product positioning pin and a carrier plate positioning pin, wherein the product positioning pin and the carrier plate positioning pin vertically penetrate through the FPC carrier plate and are inserted into the bottom plate. The fixture is characterized in that a thin steel sheet is also arranged between the bottom plate and the FPC carrier plate and provided with holes so that the product positioning pin and the carrier plate positioning pin can pass through, the product positioning pin and the carrier plate positioning pin are tightly clamped by the thin steel sheet through the holes so that shaking is not generated, and the thin steel sheet is also provided with a layer of bonnet lock pressing plate used for pressing the thin steel sheet tightly. The fixture can reduce the possibility of deviation caused in the assembling process, is convenient for assembling, improves the assembling precision of the FPC and provides the accurate positioning for subsequent processing procedures of the FPC.

Owner:惠州市华阳数码特电子有限公司

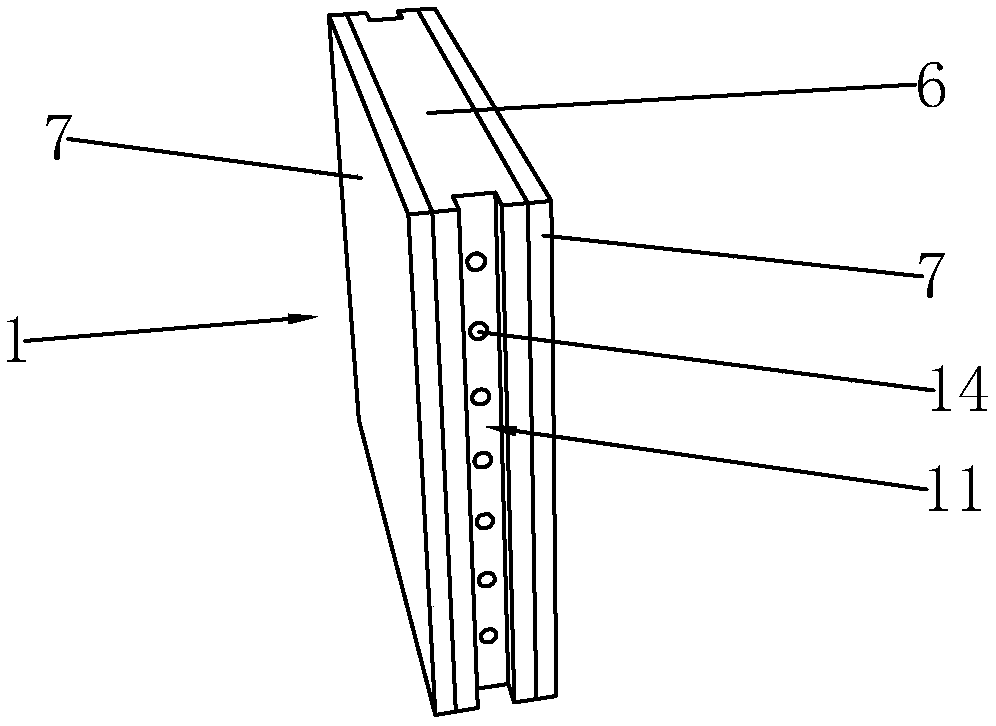

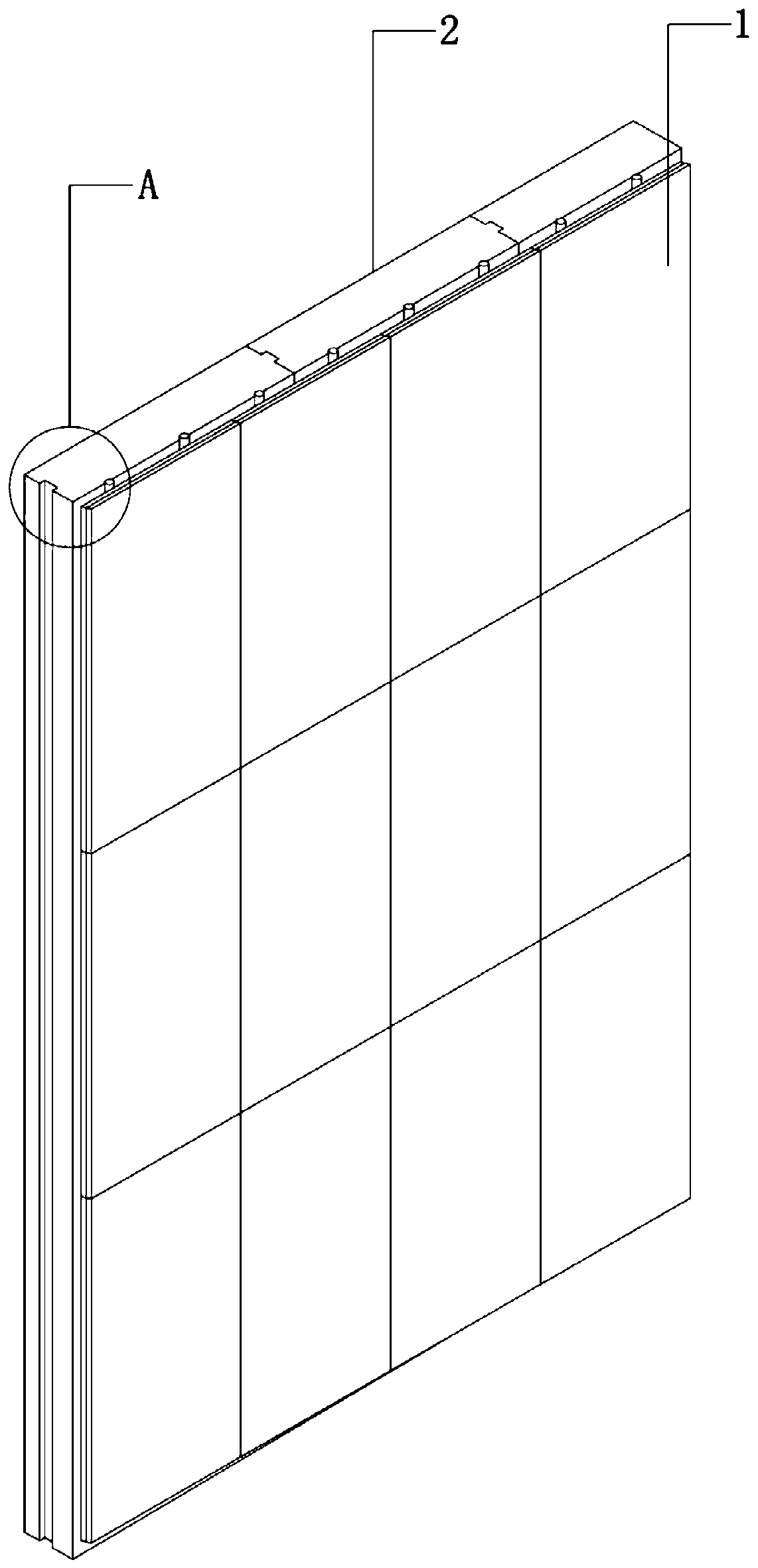

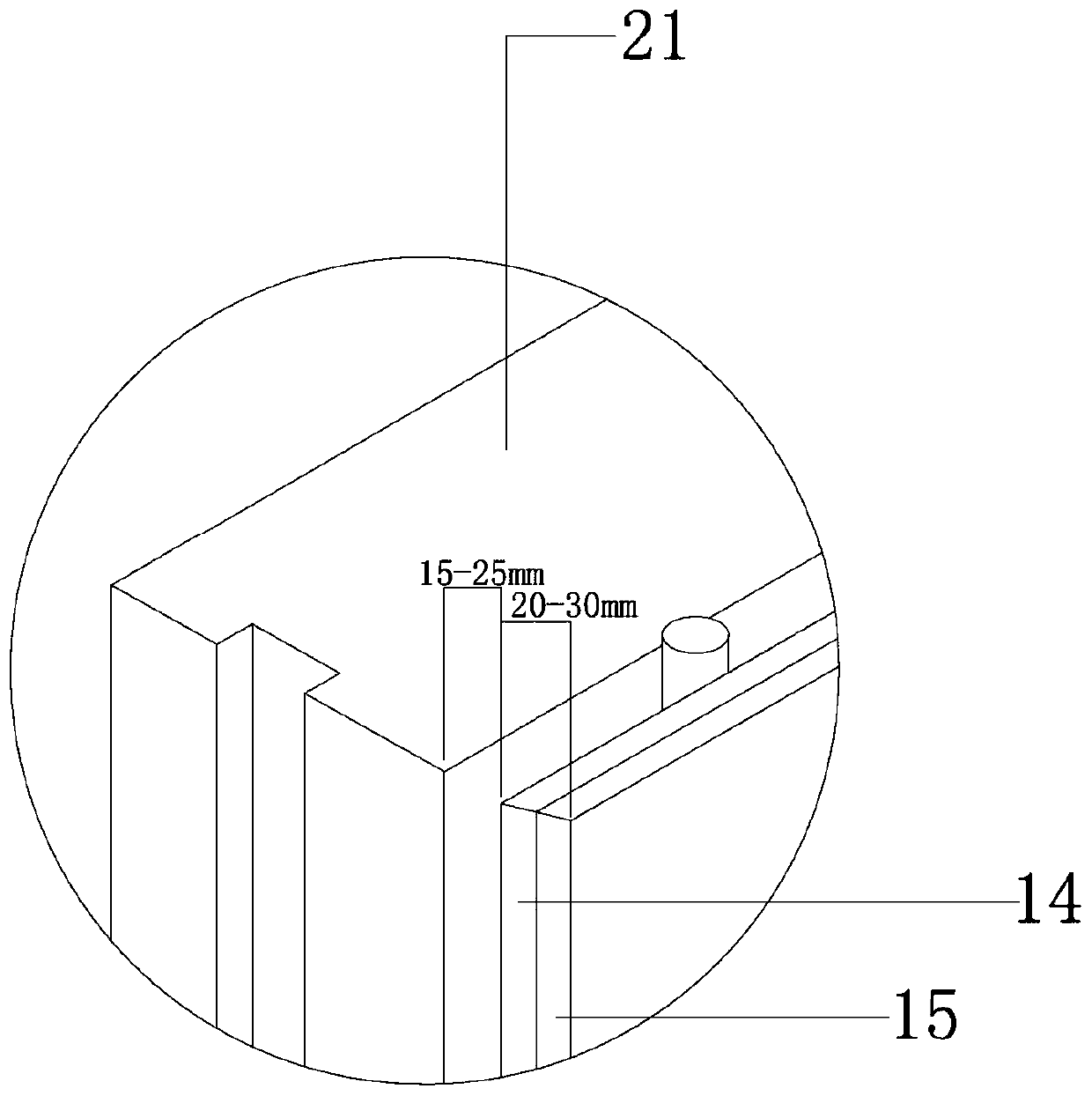

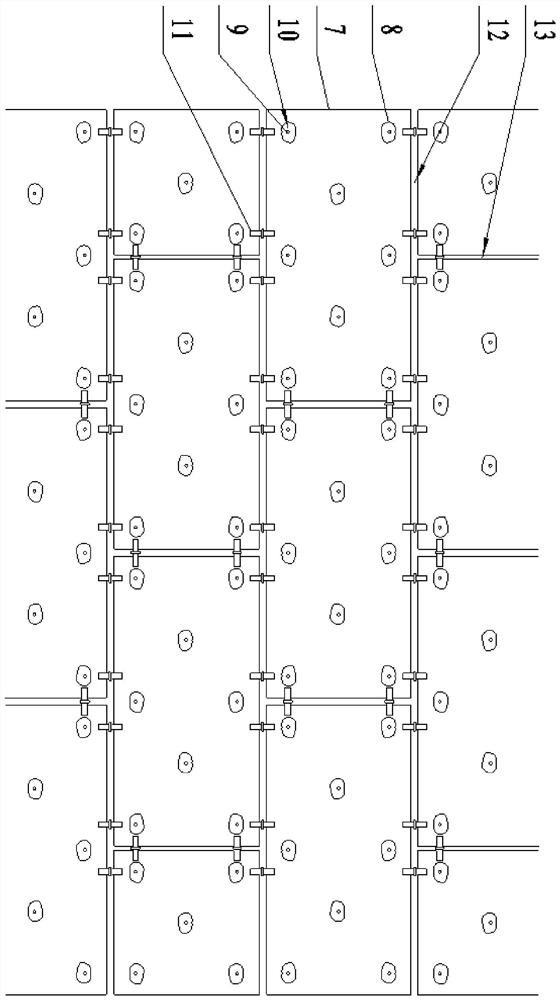

Light composite slat system and construction method thereof

ActiveCN107605071AImprove stabilityImprove flame retardant performanceWallsThermal insulationArchitectural engineering

The invention discloses a light composite slat system and a construction method thereof. The composite slat system includes first slats, second slats, U-shaped top clamping blocks, U-shaped side clamping blocks, and supporting bottom blocks; inner grooves are formed in two sides of the first slats; outer concave bars are arranged on two sides of the second slats; the outer concave bars are positioned in the inner grooves; the supporting bottom blocks connects the first slats and the second slats; and inner grooves are formed in two sides of the U-shaped top clamping blocks, and the inner grooves are connected to L-shaped bolts. The construction method includes the following steps: (a) construction preparation; (b) positioning plate installation; (c) installation of other slats; (d) wall column surface treatment; (e) gap filling; and (f) slat surface treatment. The light composite slat system is light in weight, is high in strength, can achieve a thermal insulation effect, is good in fire resistance, is fast to construct, and can solve the problem that the conventional outer wall construction methods are complex and cost lots time and effort; the construction method is simple, reasonable and orderly; the construction efficiency is high; and the used devices are few, and the cost is low.

Owner:ZHEJIANG KEDA NEW BUILDING MATERIALS

Construction method for integrally forming large cast-in-place thin-wall high pier through stiff skeleton reinforcement cage

The invention relates to a construction method for integrally forming a large cast-in-place thin-wall high pier through a stiff skeleton reinforcement cage. The construction method includes the main construction steps of (1) stiff skeleton erection, (2) locating frame installation, (3) locating frame and stiff skeleton butt joint, (4) reinforcing steel bar binding and forming, (5) lifting frame installation, (6) overall lifting and butt joint, (7) auxiliary facility disassembly, and (8) formwork construction. A structure related to the construction method has the beneficial effects that binding is convenient; the construction efficiency is high; a stiff skeleton can be partially disassembled and recycled; accurate localization of reinforcing steel bars is guaranteed and a double-layer locating frame is easy to disassemble; the reinforcing steel bars can be integrally formed and lifted for butt joint in a segmental manner; reinforcing steel bar binding time is shortened; the upper section and lower section concrete pouring period difference is reduced; and the economic and technological benefits are good.

Owner:SHANGHAI JIASHI (GROUP) CO LTD

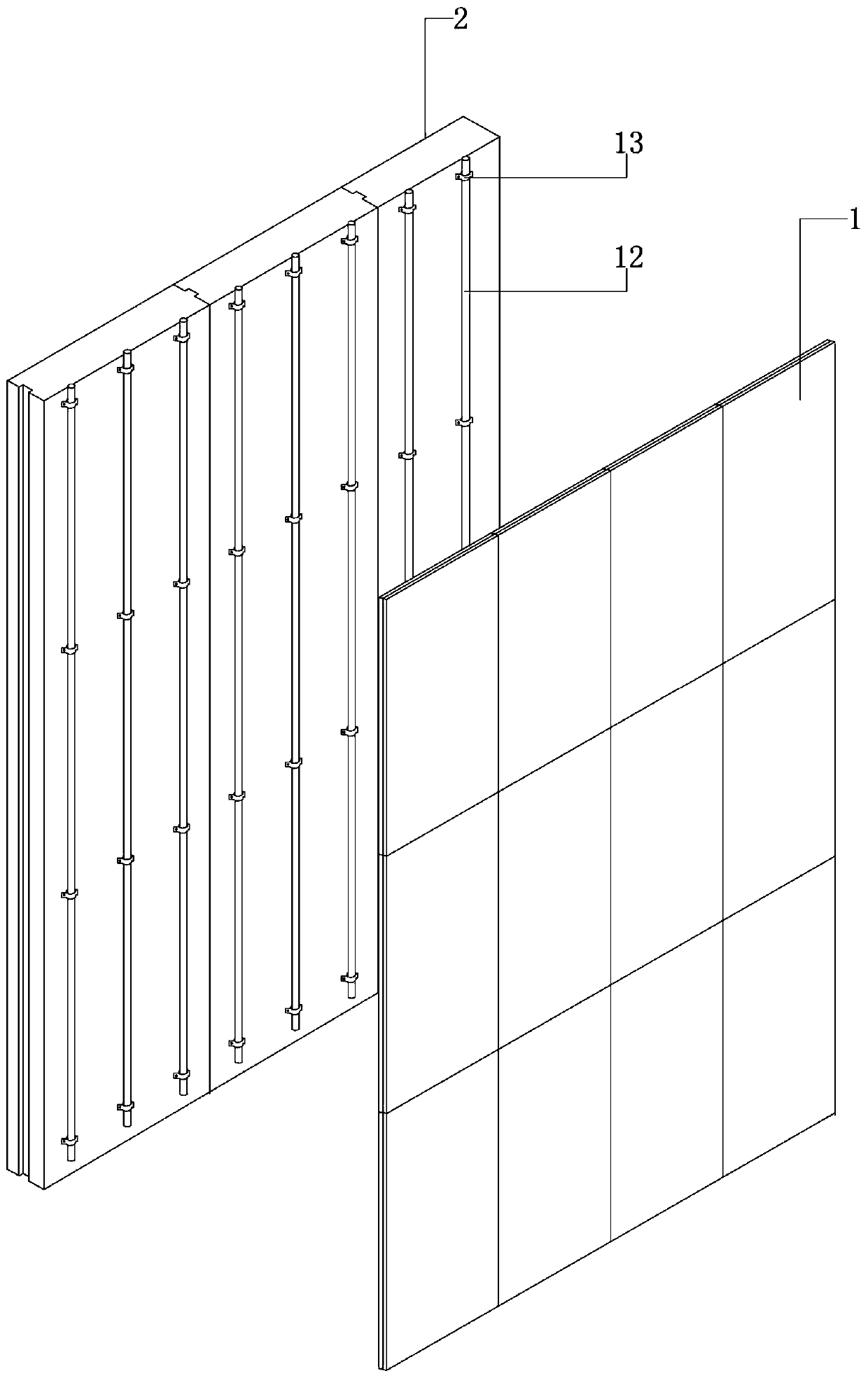

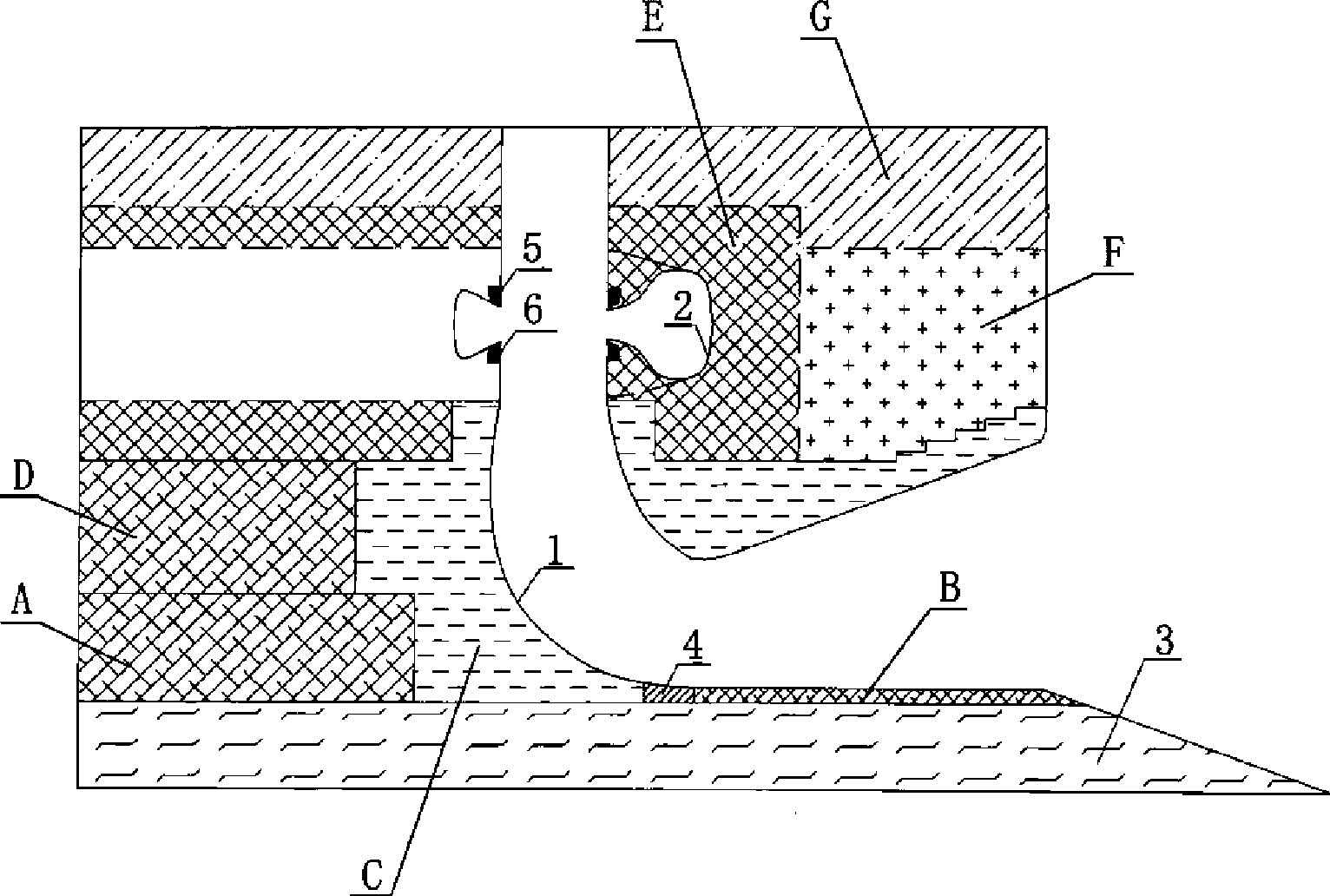

Fabricated ceramic tile concrete composite board wall surface mounting system and method

PendingCN110241993AAchieve high industrial integrationEffective installationCovering/liningsElectricitySurface mounting

The invention provides a fabricated ceramic tile concrete composite board wall surface mounting system, which includes a ceramic tile concrete composite board and a composite board connection mechanism. The back face of the ceramic tile concrete composite board is fixedly connected with a plurality of pipe clamps, the pipe clamps are arc-shaped opening pipe clamps, a cavity for laying water and electricity pipelines is left between the ceramic tile concrete composite board and a wall, the composite board connection mechanism includes a vertical metal pipe body and pipe codes, the ceramic tile concrete composite board is connected to the vertical metal pipe body through the pipe clamps, and the vertical metal pipe body is a round pipe; and the vertical metal pipe body is fixed to the wall by using the multiple pipe codes. The invention further provides a fabricated ceramic tile concrete composite board wall surface mounting method. According to the fabricated ceramic tile concrete composite board wall surface mounting system and method, compared with the prior art, industrial production of fabricated decoration products can be realized, quick and high-efficiency mounting on site by assemblers is achieved, the products are suitable for houses with the small inner space, during decoration engineering, a large amount of construction waste is reduced, maintenance is convenient, the products can be disassembled and reused for mounting, and the purpose of lowering the comprehensive construction cost is finally achieved.

Owner:GOLD MANTIS FINE DECORATION TECH SUZHOU CO LTD

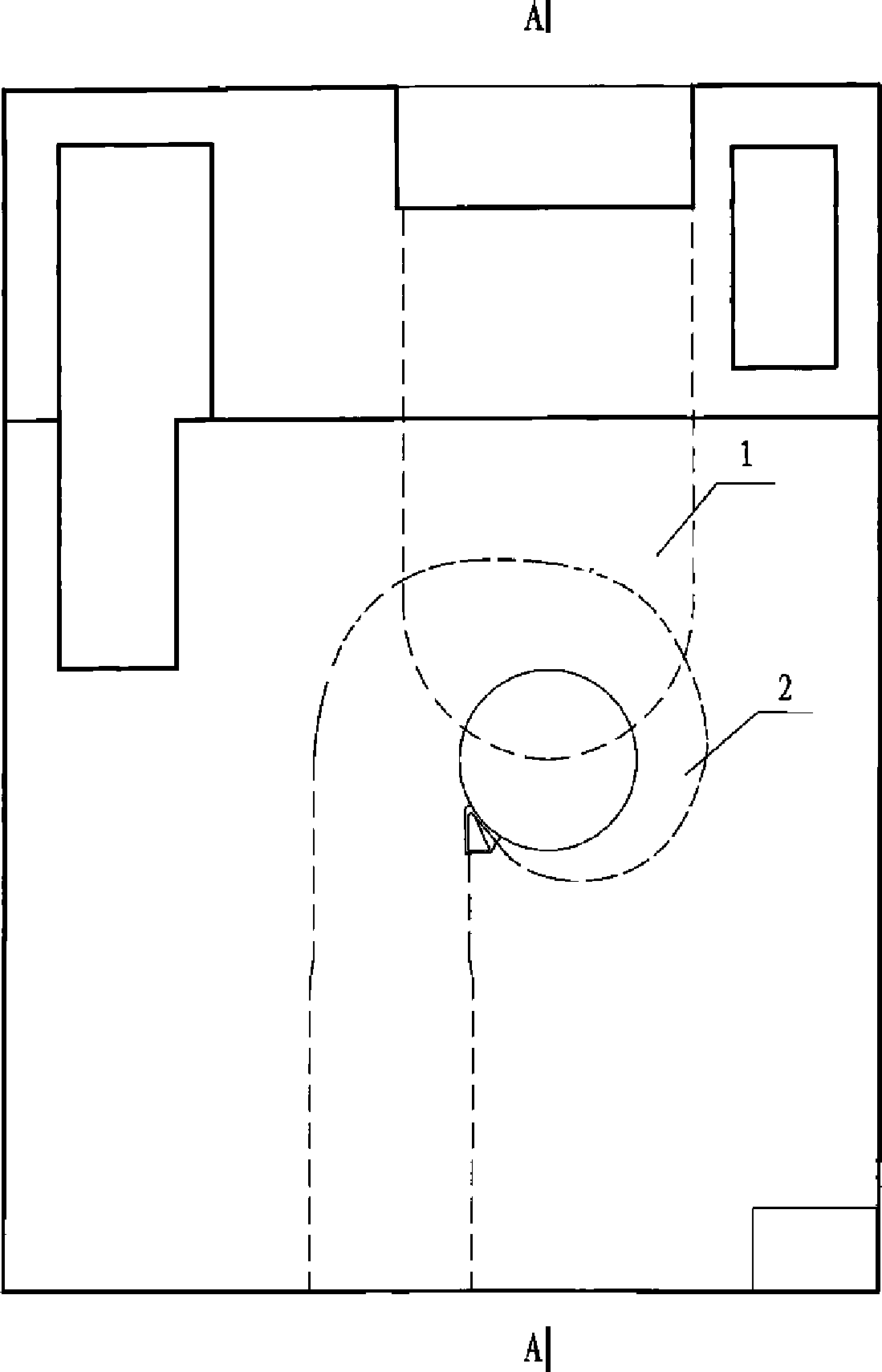

Construction method for large cast-in-situ steel reinforced concrete inlet channel and turbine housing

InactiveCN101476308AReduced likelihood of cracksConstruction quality is easy to guaranteeArtificial water canalsFoundation engineeringInlet channelReinforced concrete

The invention relates to a large-scale cast-in-situ reinforced concrete water inlet duct and scroll case construction method, the construction sequence is: bottom board of the water inlet duct, far end lower part outside the turning of the water inlet duct, far end upper part outside the turning of the water inlet duct, outer circumference of the turning of the water inlet duct, far end outside the scroll case, near end outside the scroll case, top outside the scroll case and the second pouring construction. The construction method has clear levels, reduces the concrete pouring amount at the key parts of the water inlet duct: the outer circumference of the turning of the water inlet duct and the near end outside the scroll case, by partitioning construction; ensures the concrete forming quality of the water inlet duct and the scroll case; and avoids large volume concrete cracks.

Owner:CHINA CONSTR SECOND ENG BUREAU LTD +1

Supporting structure for an Anti-noise barrier wherein foundations and lifting post are realized in a single element and relative assembly method

InactiveUS20130180799A1Simple structureLow production costCeilingsNoise reduction constructionSingle phaseNoise barrier

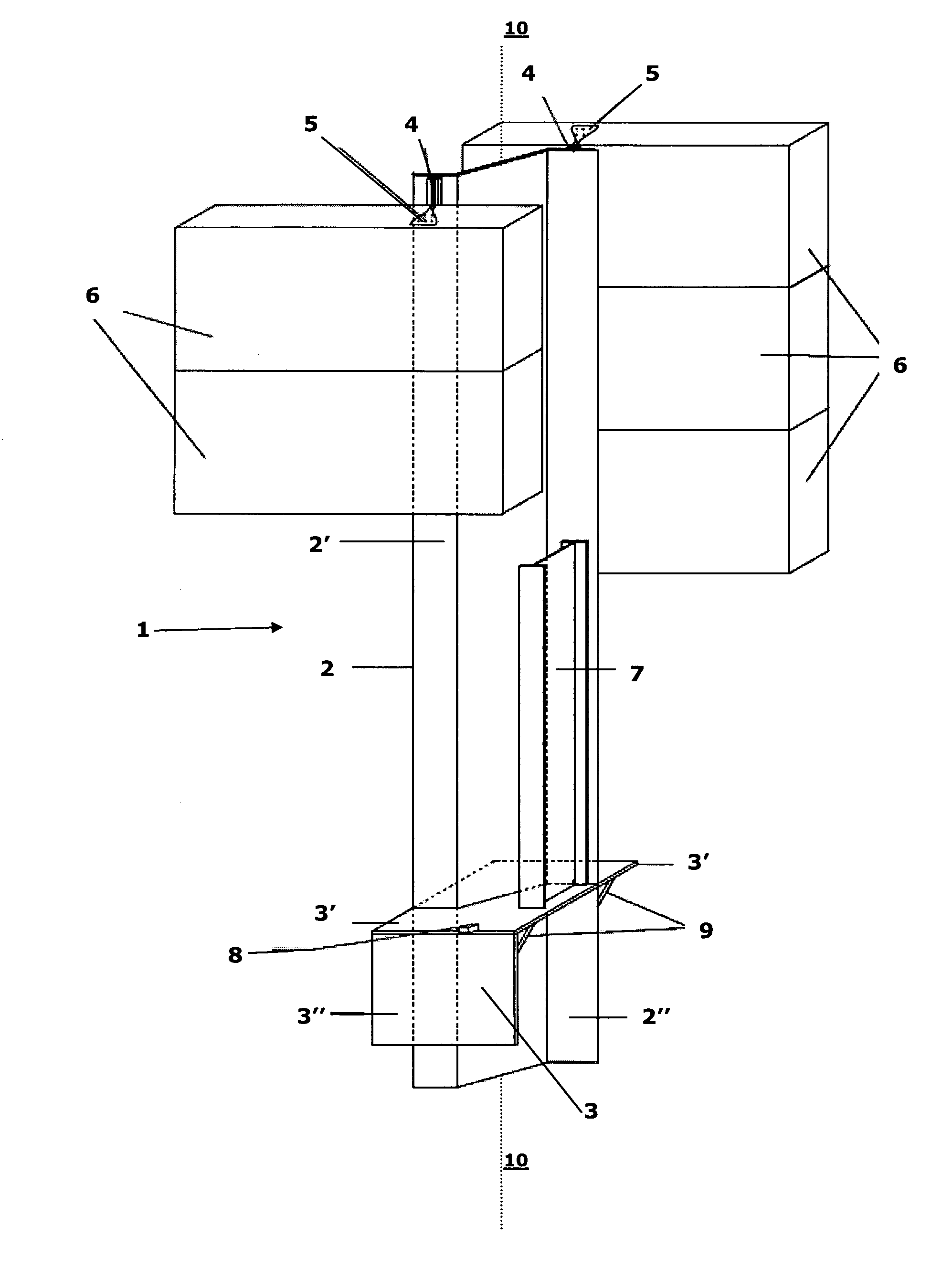

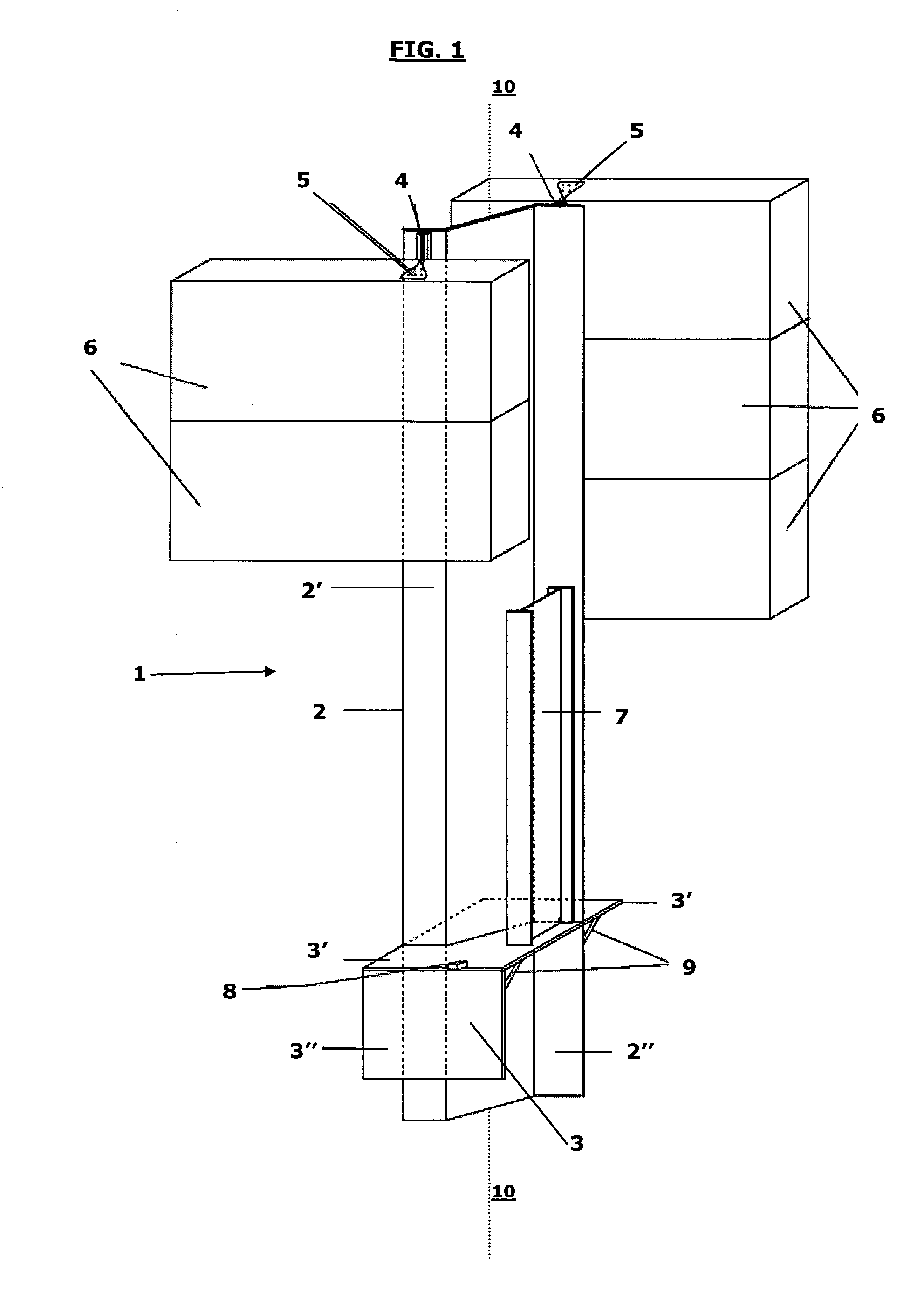

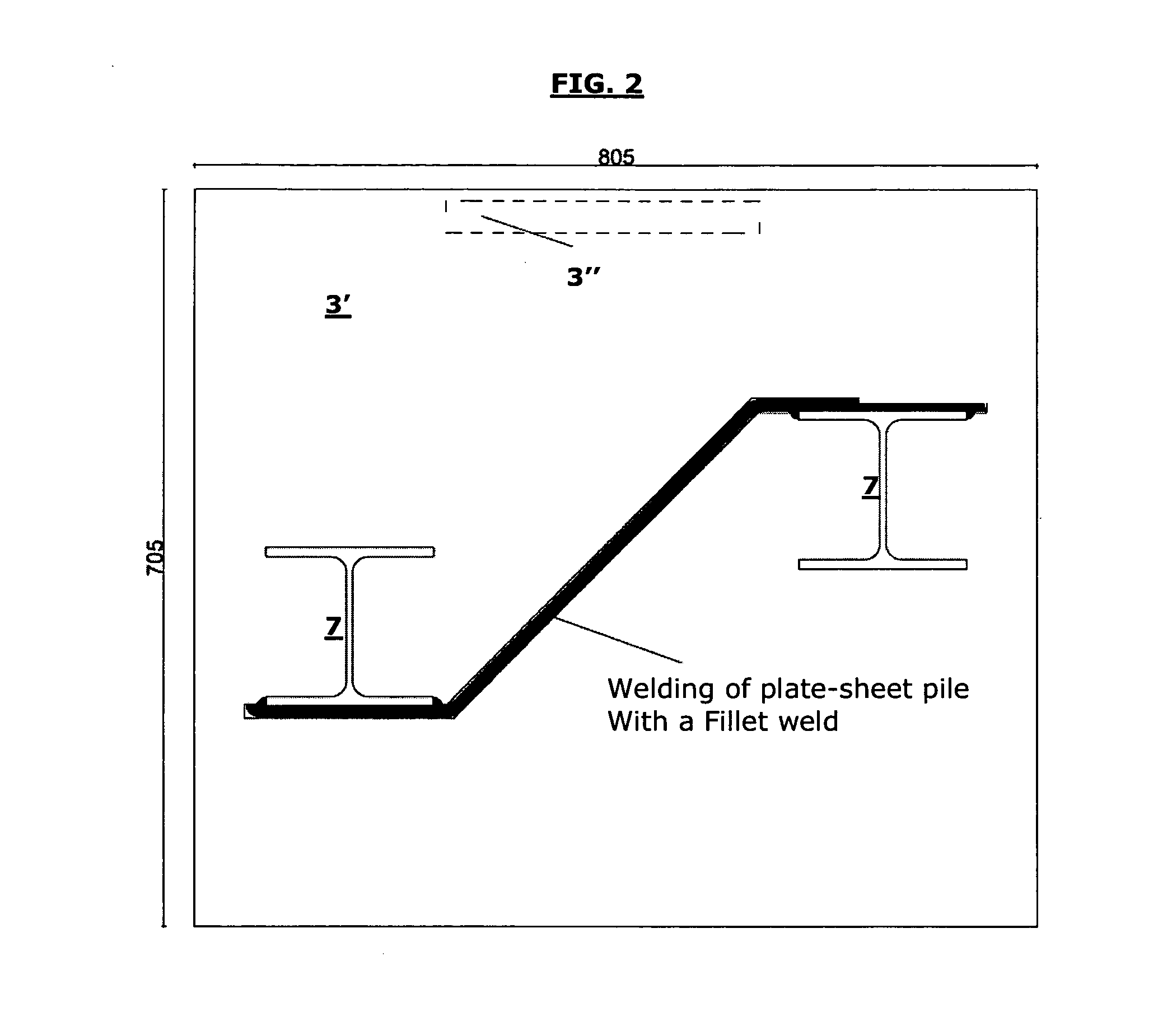

A supporting structure for an anti-noise barrier and relative assembly method are disclosed. The foundation and the structural post of the barrier are a single continuous piece in the shape of a sheet pile. The sheet pile has a first part and a second part of such a length that, in use, the second part is insertable on the ground to realize the foundation, while, contextually, the first part emerges from the ground upwards. The first part of the sheet pile, besides, is provided with connection means through which to be able to connect the sound-absorbent panels, and with a plate on which to lean the panels themselves in such a way that the arrangement on the ground of the foundation and of the structural post is realizable in a single phase to then proceed with the second phase of application of the panels.

Owner:URBANTECH

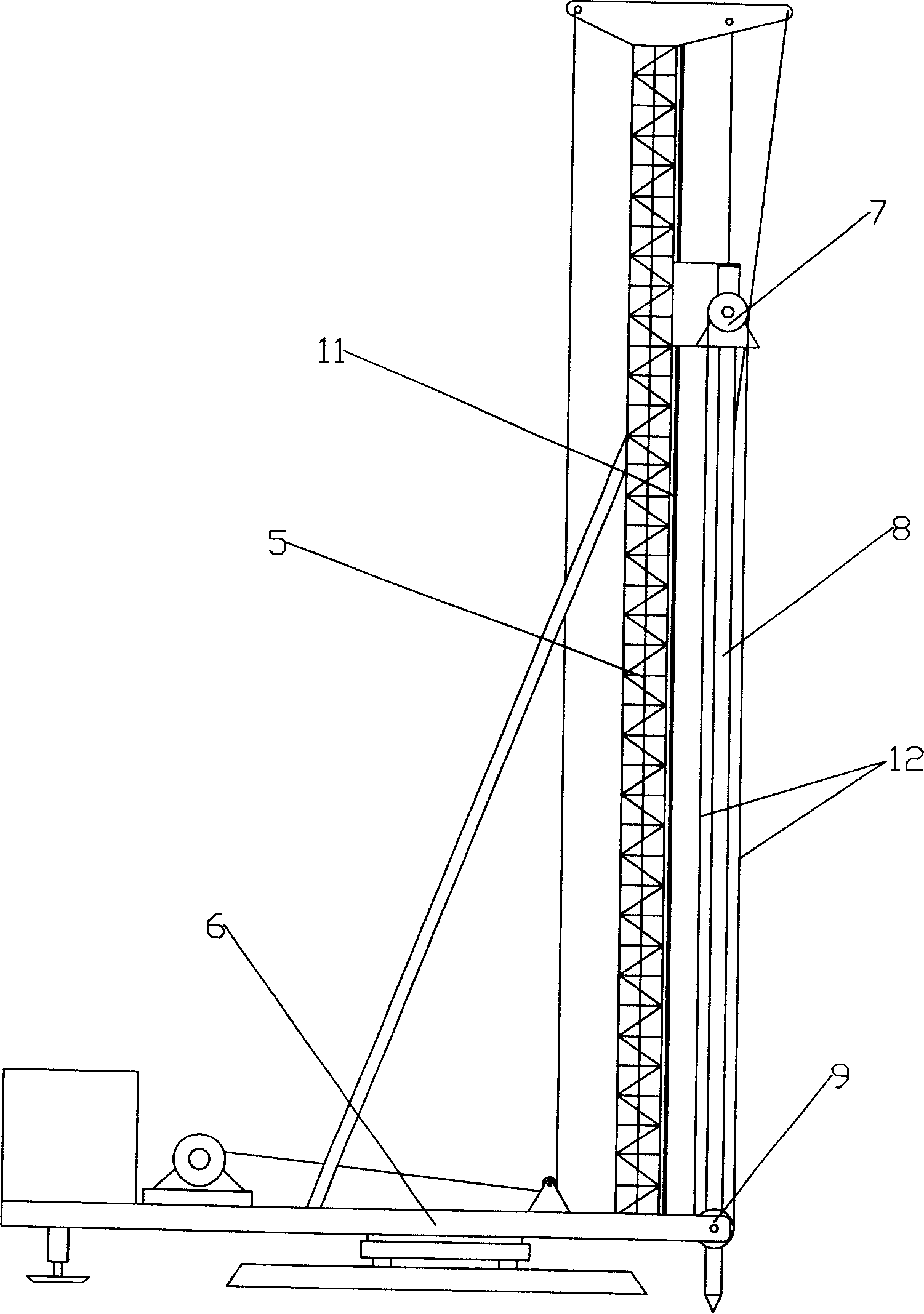

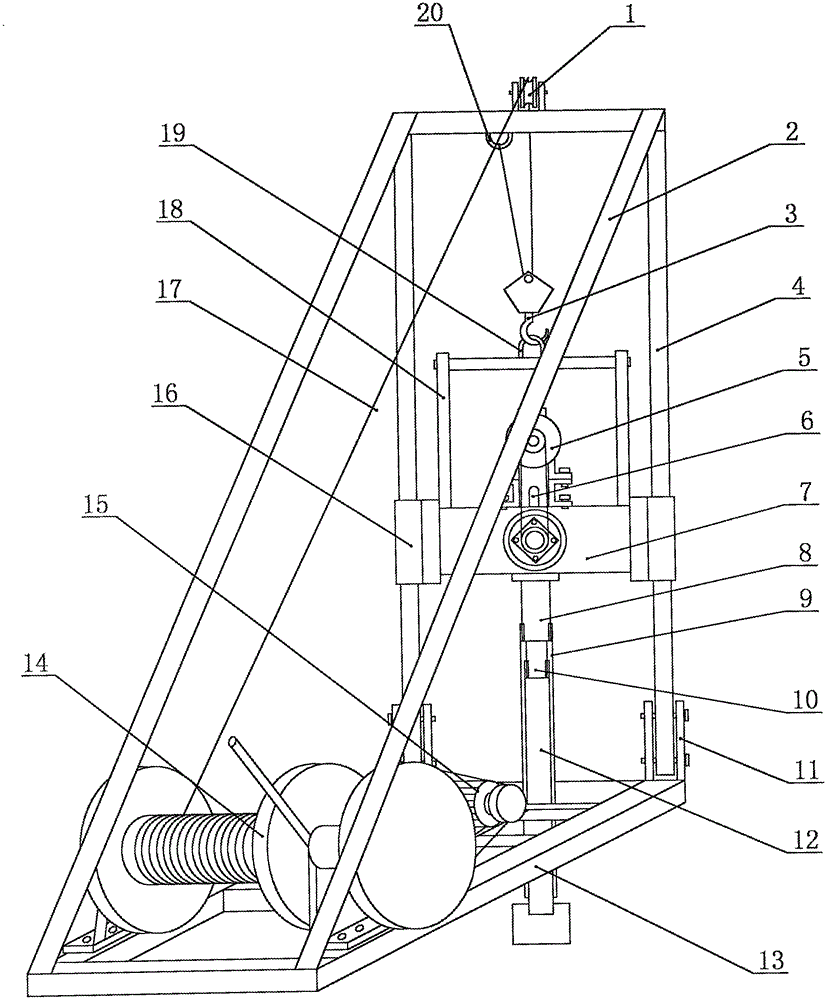

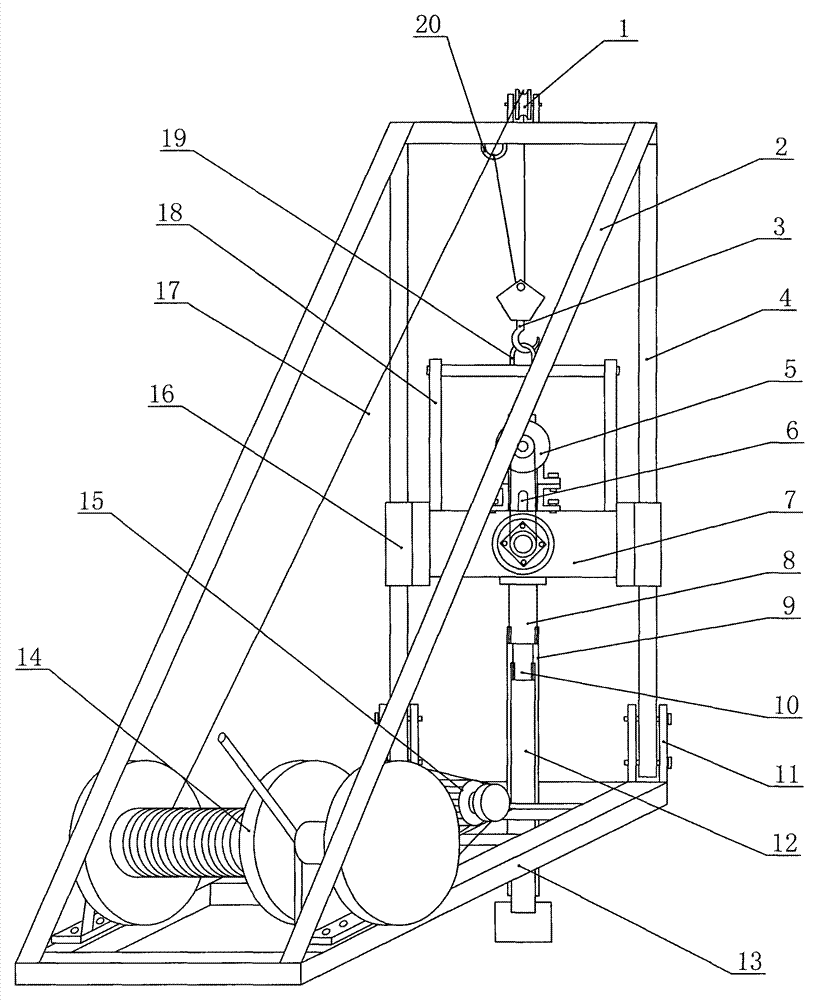

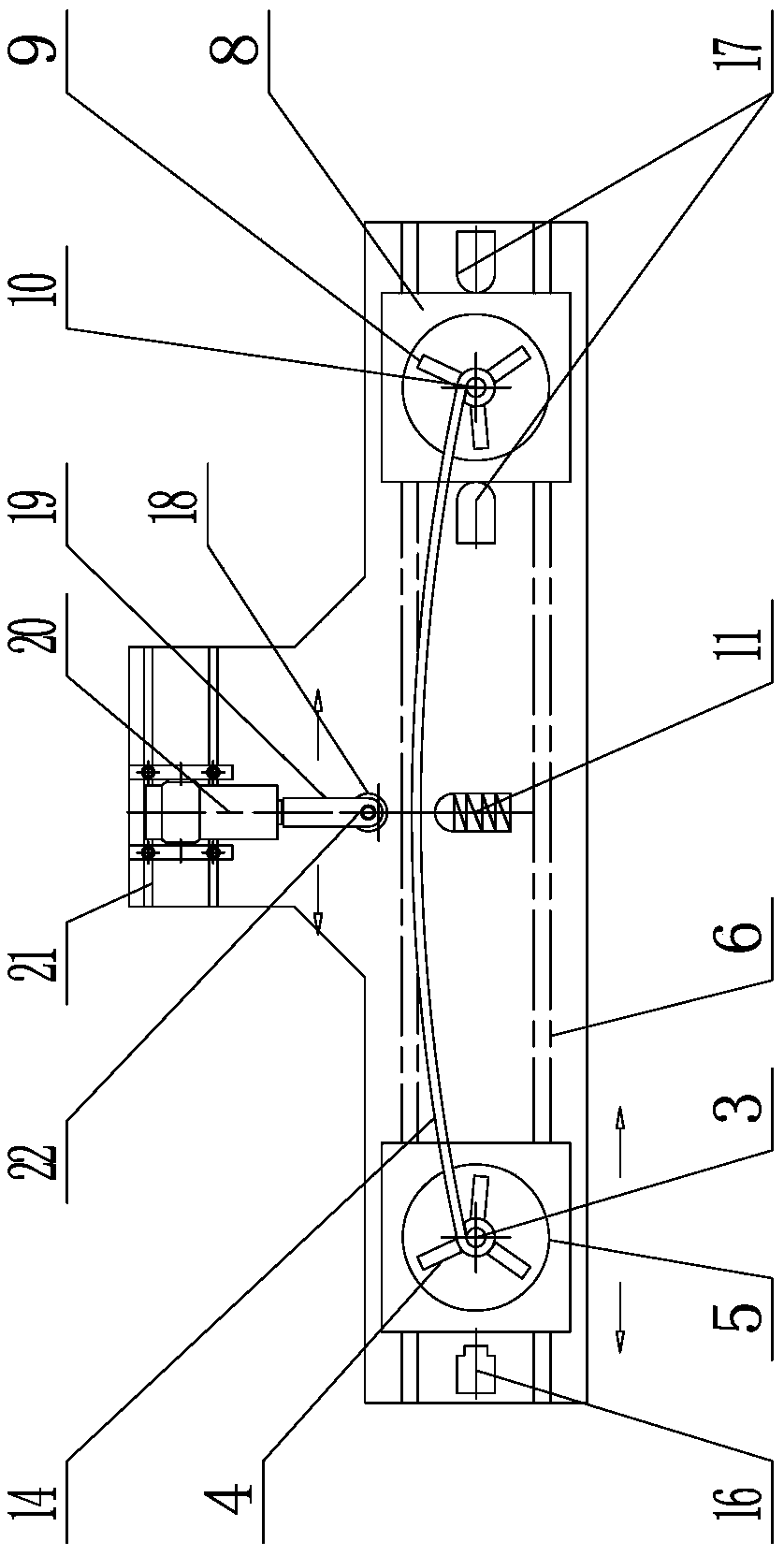

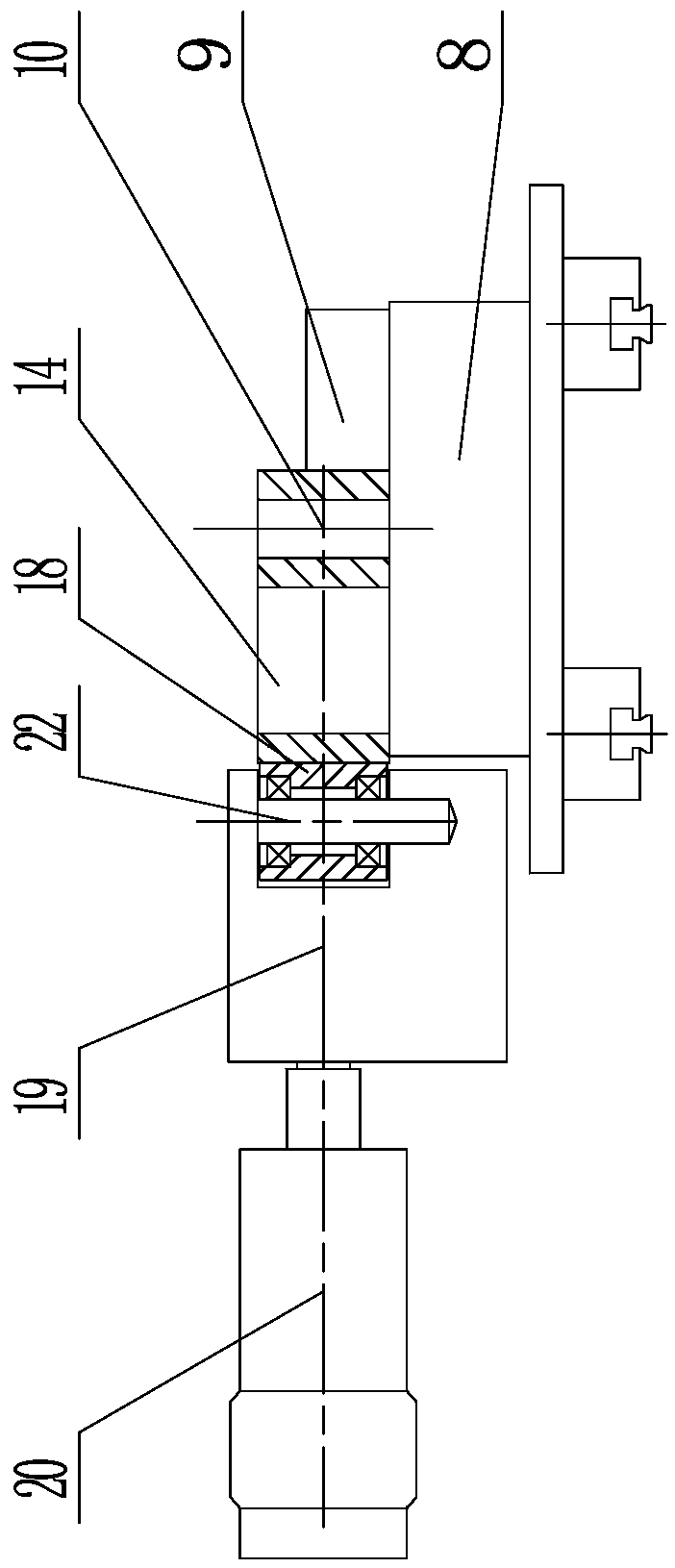

Double-rod well drilling machine

InactiveCN105275389APrecise verticalitySolve the landslide problemDrilling rodsConstructionsWell drillingDrilling machines

The invention discloses a double-rod well drilling machine. The double-rod well drilling machine comprises a rack, a traction device arranged on the rack, a power head movably installed on the rack, drilling rods fixedly installed at the bottom of the power head, wherein the power head comprises a drilling machine head, movable sleeves fixed at two sides of the drilling machine head, a motor fixed at the top of the drilling machine head, a hanging frame, a grouting pipe and drilling rod seats fixed at the bottom of the drilling machine head. The double-rod well drilling machine is characterized in that the drilling rod seats include an outer drilling rod seat and an inner drilling rod seat fixed inside the outer drilling rod seat; the drilling rods include an outer drilling rod and an inner drilling rod arranged in the outer drilling rod; the outer diameter of the inner drilling rod is smaller than the inner diameter of the outer drilling rod; the inner drilling rod is in threaded connection with the inner drilling rod seat; and the outer drilling rod is in threaded connection with the outer drilling rod seat. The double-rod well drilling machine of the invention has the advantages of stability, reliability, easiness in assembly and disassembly and multi-purposed performance. With the double-rod well drilling machine adopted, the problem of landslide can be effectively solved, and safety production can be ensured.

Owner:辛爱香

Spindle motor and fabricating method thereof

InactiveUS7830054B2Avoid componentsAvoid defectsAssociation with control/drive circuitsWater closetsFixed bearingPrinted circuit board

Owner:HITACHI LG DATA STORAGE KOREA

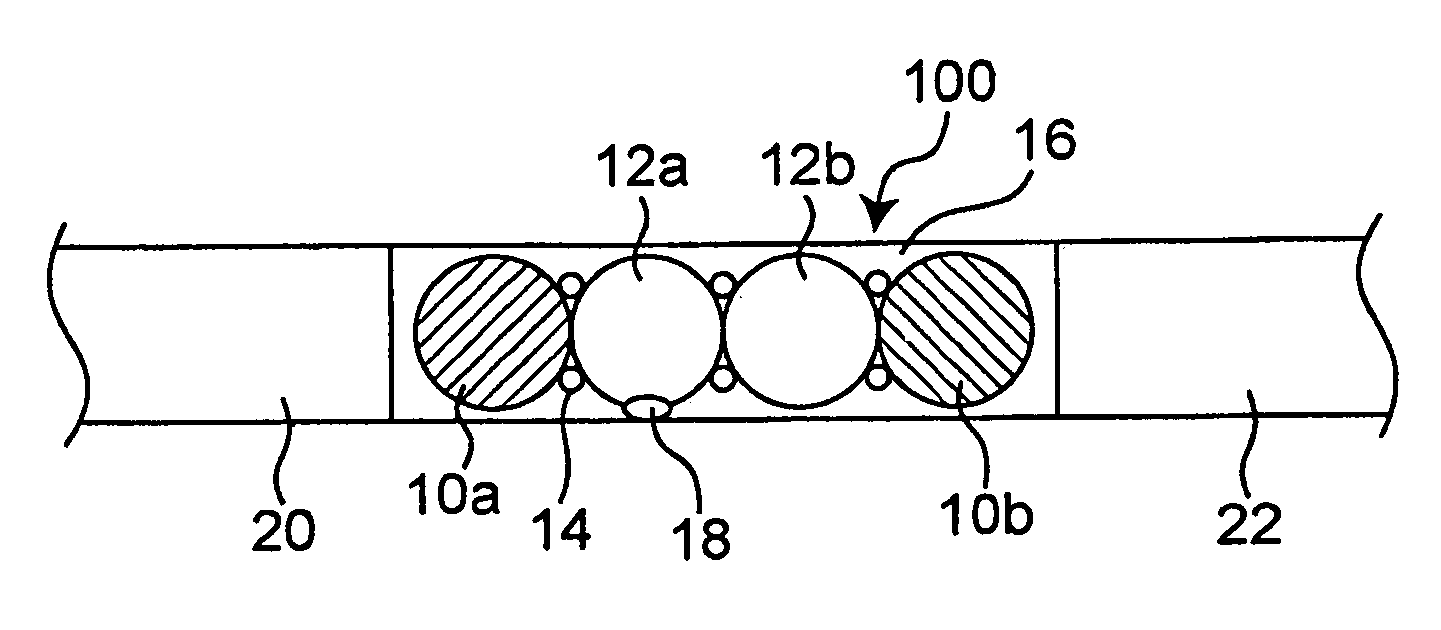

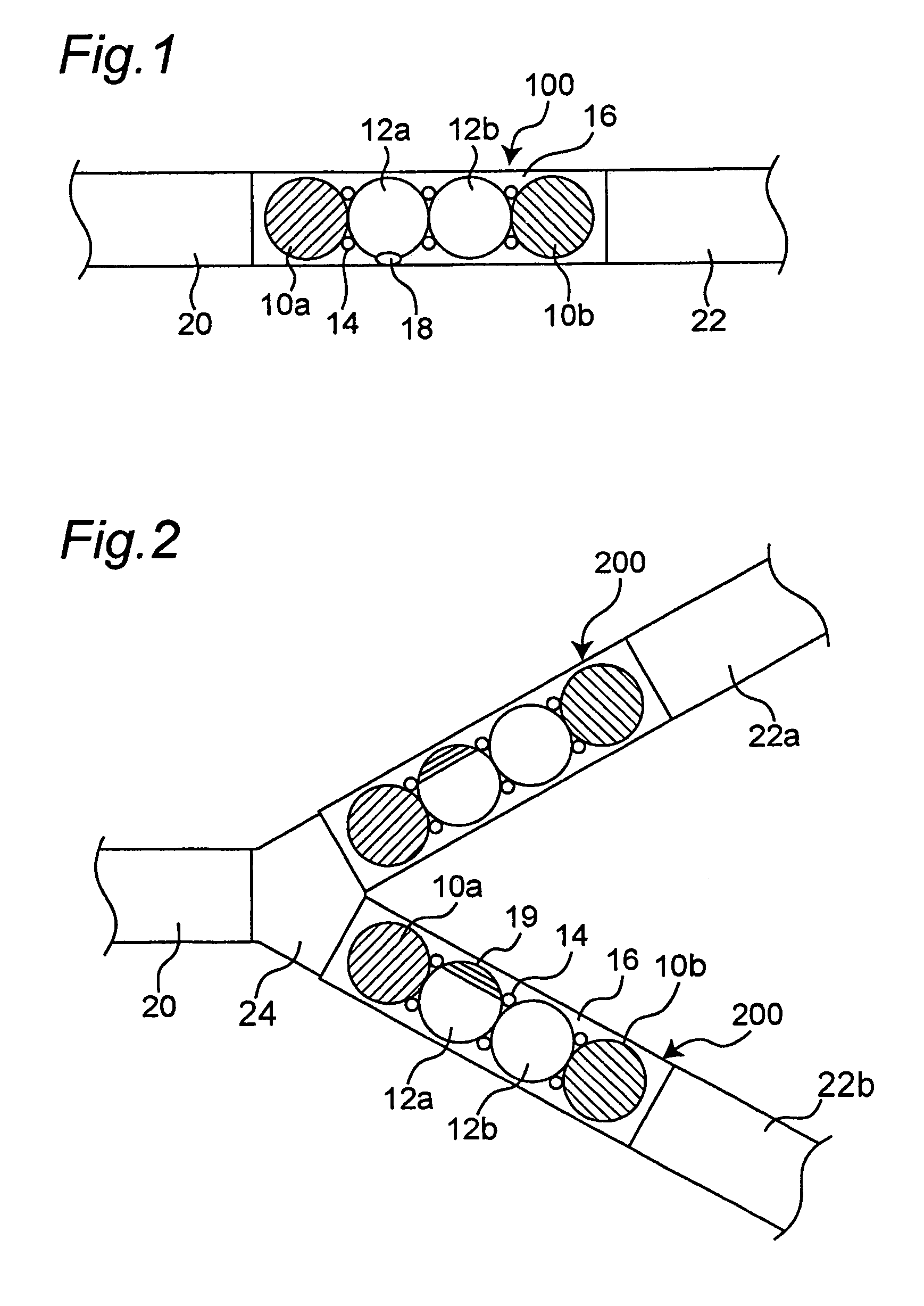

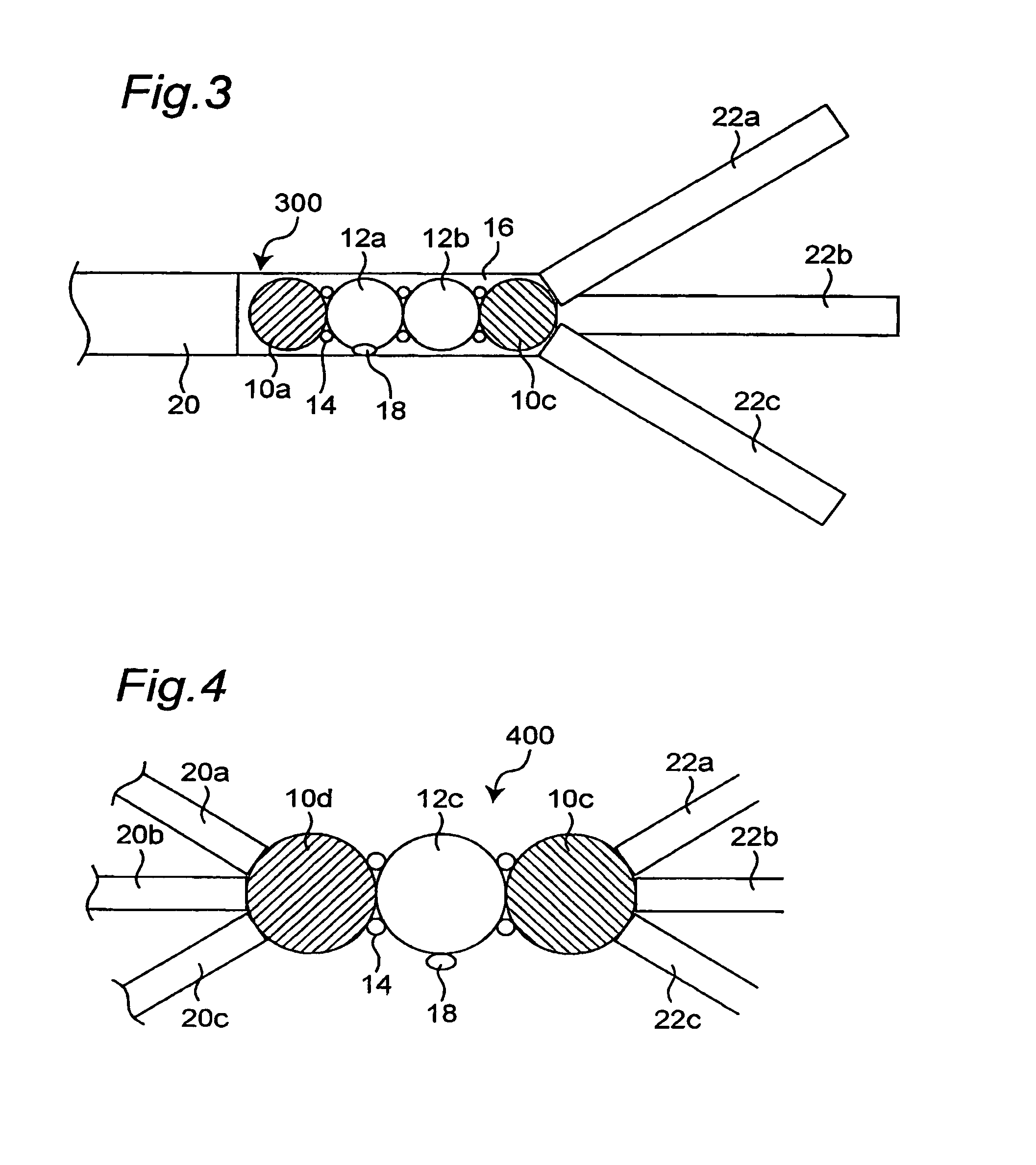

Mount assembly, optical transmission line and photoelectric circuit board

InactiveUS7136543B2Reduce speedPrecise verticalityCladded optical fibreSemiconductor/solid-state device detailsElectrical connectionEngineering

A mount assembly which amplifies a light signal from an optical transmission line and transmits the light signal to another optical transmission line and does not require a highly precise perpendicularity at a connection portion between the optical transmission line and the mount assembly. The mount assembly (100) is obtained by connecting a photo-electro conversion device (10a), spherical semiconductor devices (12a) and (12b) and an electro-photo conversion device (10b) through electrical-connection portions (14) so that a light received by the photo-electro conversion device (10a) is amplified by the spherical semiconductor devices (12a) and (12b) and then emitted from the electro-photo conversion device (10b).

Owner:PANASONIC CORP

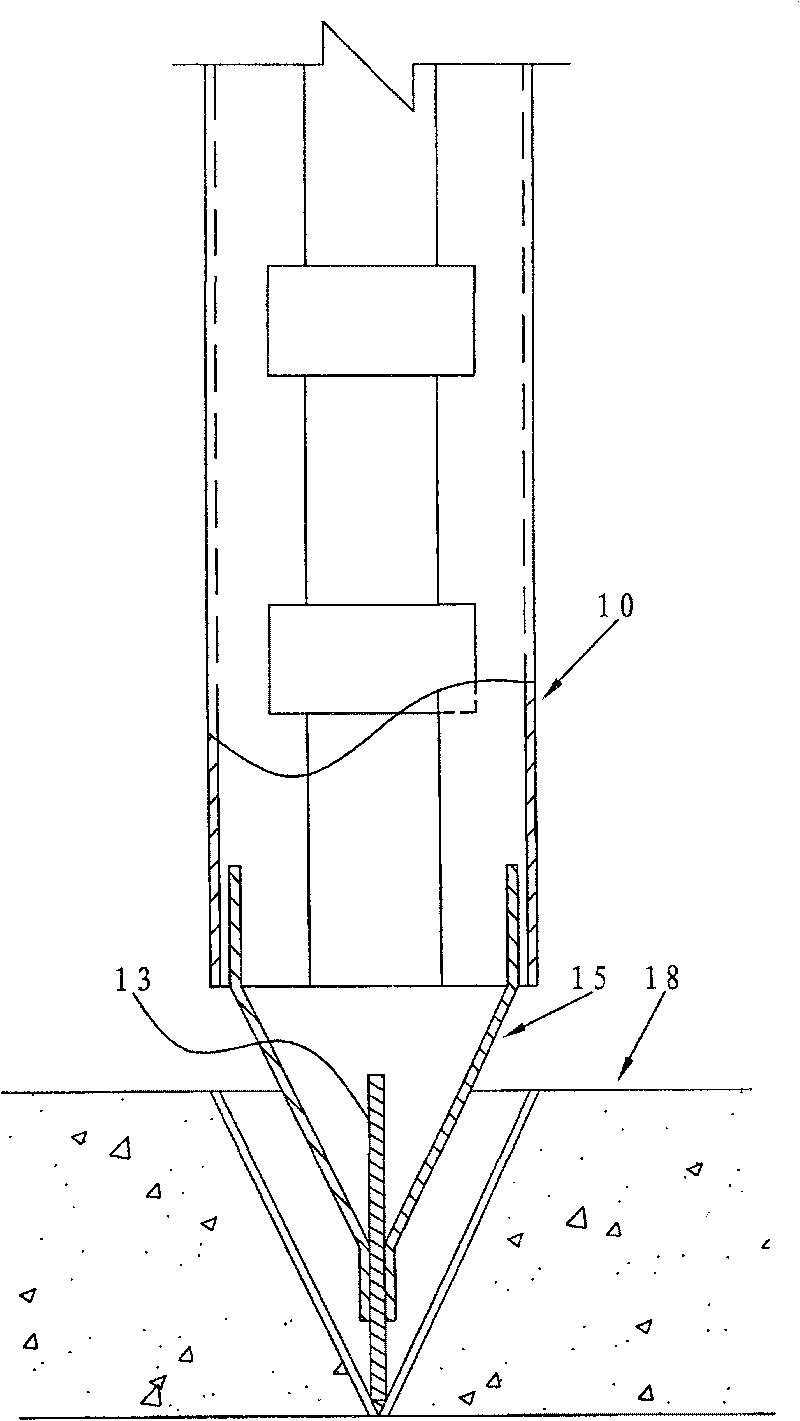

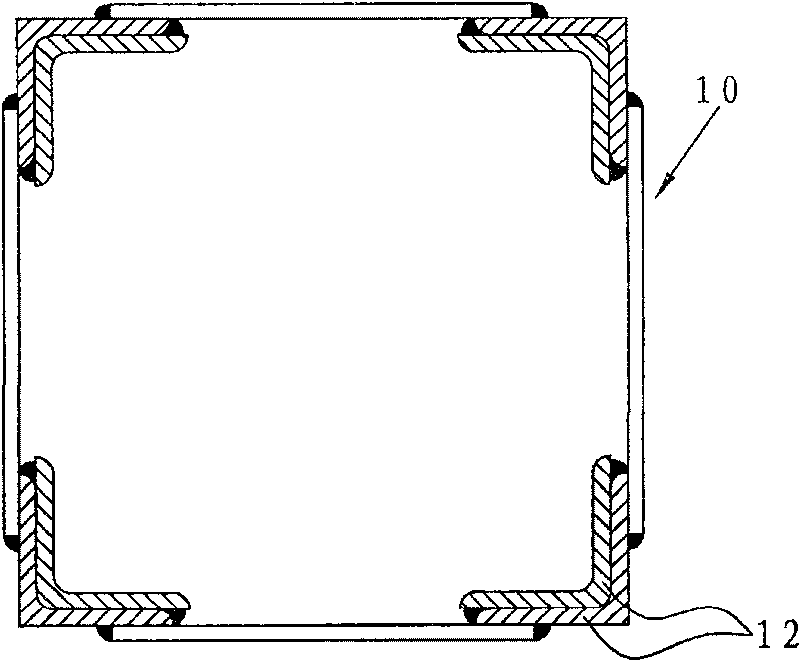

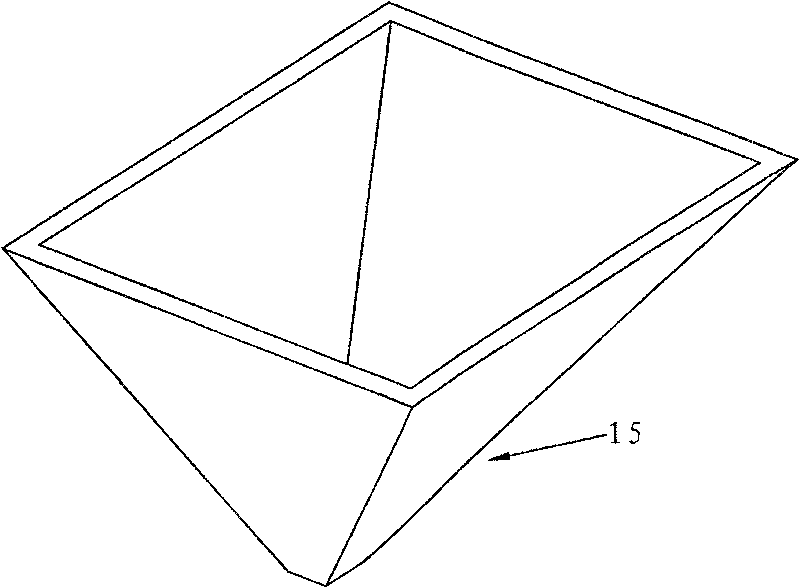

Double-drill-pipe well sinker

InactiveCN104265182APrecise verticalitySolve the landslide problemConstructionsDerricks/mastsHookingDrilling machines

The invention discloses a double-drill-pipe well sinker which comprises a rack, a traction device arranged on the rack, a power head movably arranged on the rack and drill pipes fixedly arranged at the bottom of the power head. The power head comprises a drilling machine head, movable sleeves fixed to the two sides of the drilling machine head, a motor, a hooking frame, a grout pipe and drill pipe seats fixed to the bottom of the drilling machine head, and the motor, the hooking frame and the grout pipe are fixed to the top of the drilling machine head. The double-drill-pipe well sinker is characterized in that the drill pipe seats comprise an outer drill pipe seat and an inner drill pipe seat arranged in the outer drill pipe seat, the drill pipes comprise an outer drill pipe and an inner drill pipe arranged in the outer drill pipe, and the outer diameter of the inner drill pipe is smaller than the inner diameter of the outer drill pipe; the inner drill pie is in threaded connection with the inner drill pipe seat, and the outer drill pipe is in threaded connection with the outer drill pipe seat. The double-drill-pipe well sinker is stable and reliable and convenient to dismount and mount, achieves multiple purposes, and can effectively solve collapse problems and guarantee production safety.

Owner:于维嘉

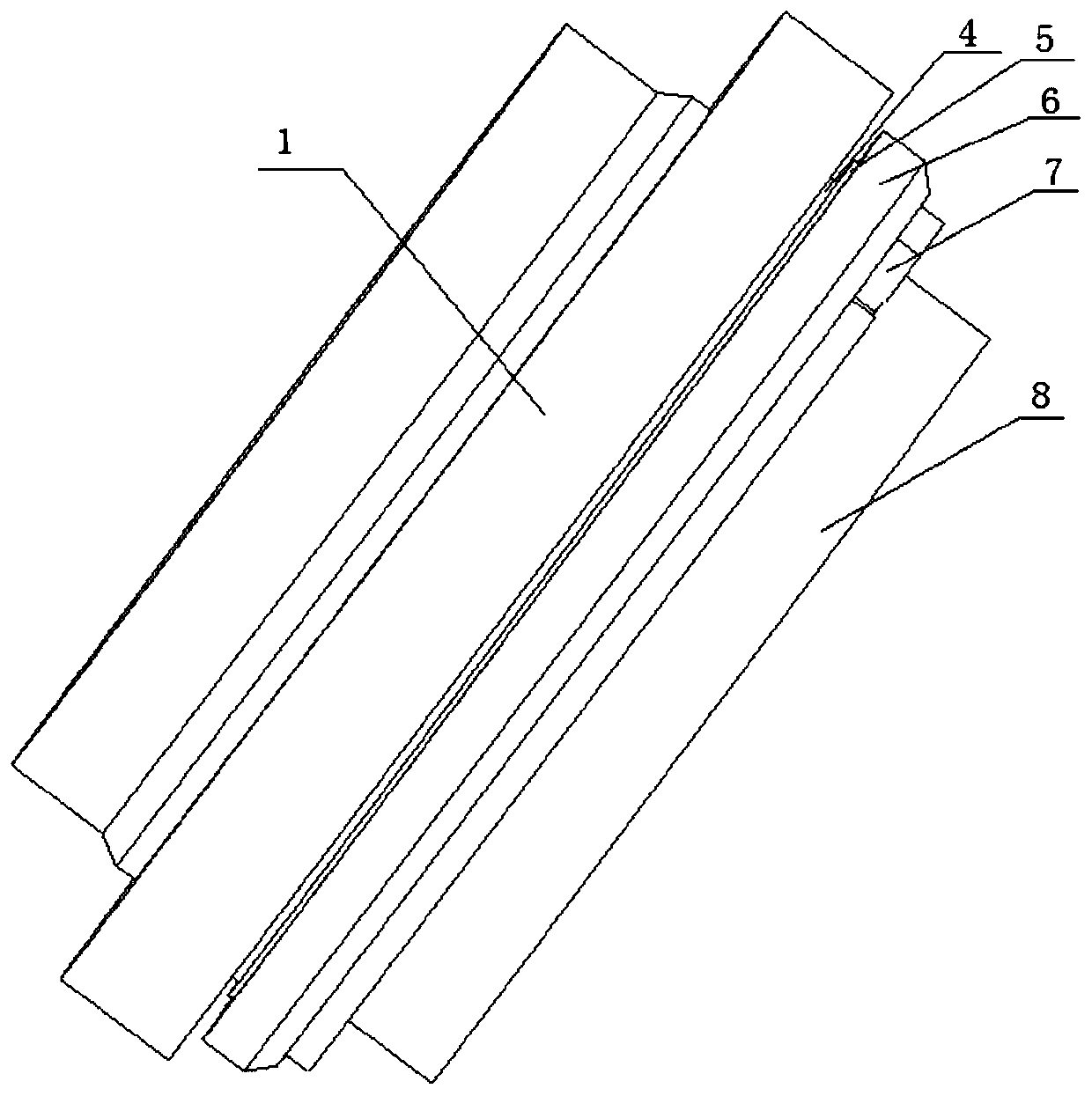

Steel-structure external wall dry hanging integrated board and installation method

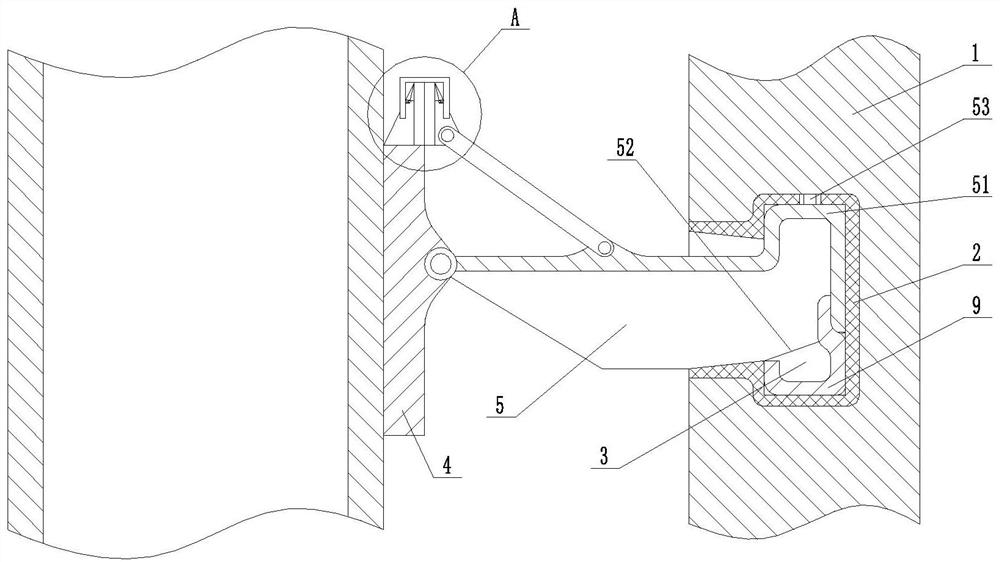

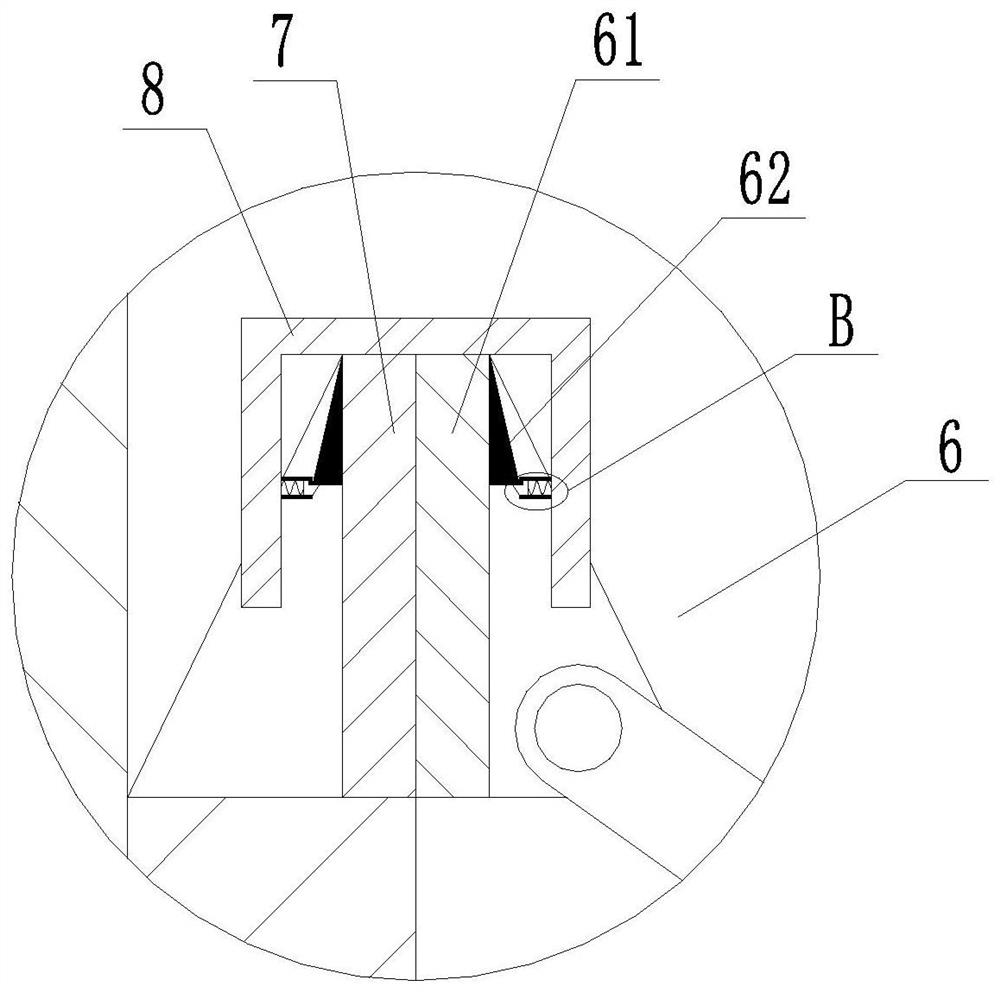

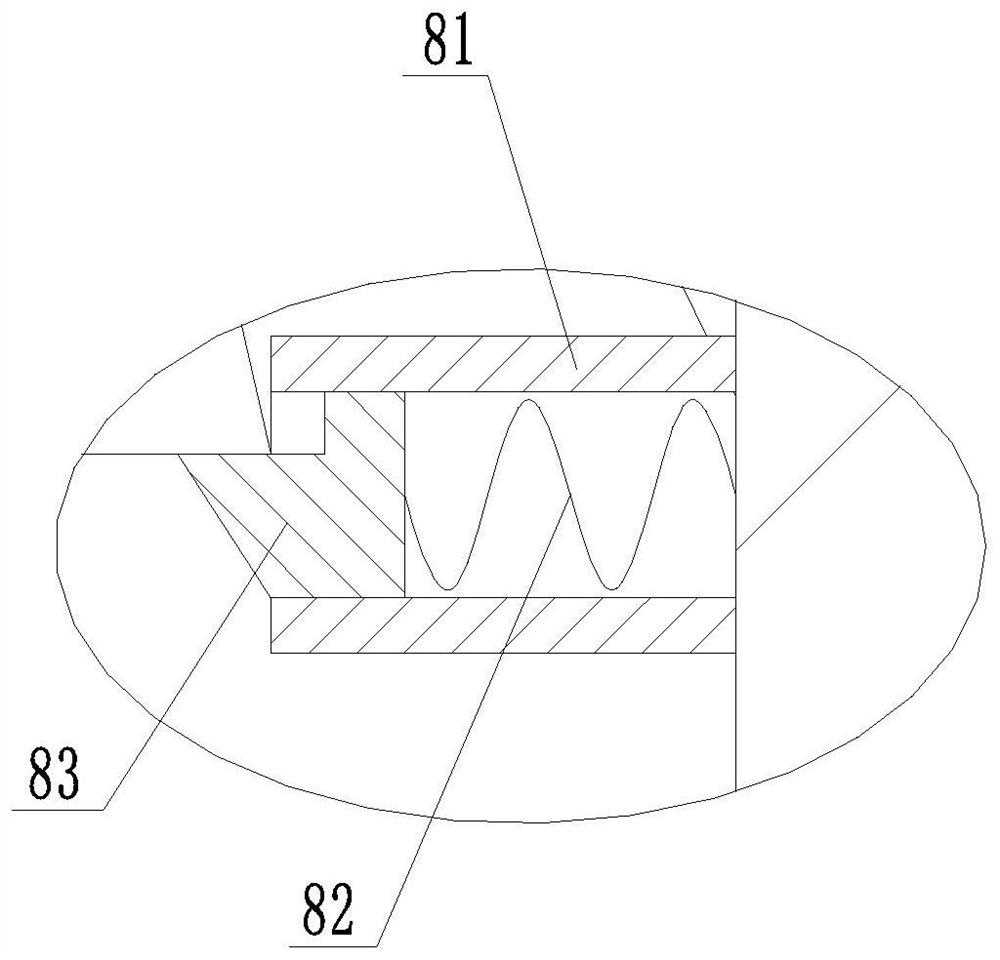

ActiveCN111927025AReduce assembly and disassembly stepsImprove construction efficiencyCovering/liningsWallsBoard structureExternal cladding

The invention discloses a steel-structure external wall dry hanging integrated board and an installation method, and belongs to the technical field of steel-structure external wall board hanging construction. The steel-structure external wall dry hanging integrated board comprises a prefabricated external wall hanging board and a connecting assembly matched with the prefabricated external wall hanging board, and a prefabricated beam is embedded in the prefabricated external wall hanging board. A base in the connecting assembly is fixedly installed on a steel-structure external wall column so that a connecting piece can rotate relative to the base. The angle of the connecting piece is adjusted through an angle adjustment structure so that the connecting piece can enter an installation groove through a guide part and be connected with the installation groove in a matched manner through a protrusion part, and meanwhile, a fixing effect can be achieved without damaging the external wall hanging board structure. Through a mode of fixedly installing the prefabricated external wall hanging board through matching between the connecting piece and the installation groove after rotation, thesteps of installing and detaching the prefabricated external wall hanging board can be greatly reduced, the construction efficiency can be improved, and meanwhile the phenomenon that a large number ofinstallation pieces are exposed and prone to rusting and corrosion in the prior art can be avoided.

Owner:CHINA MCC17 GRP

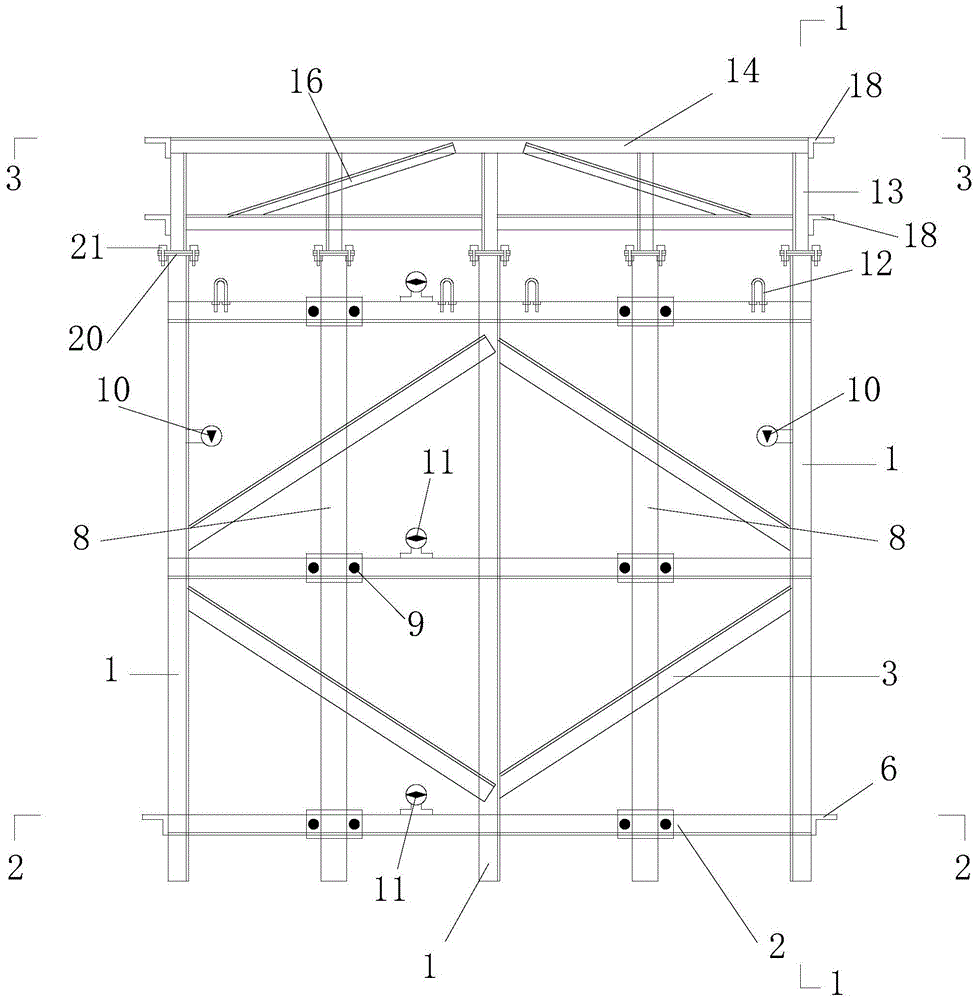

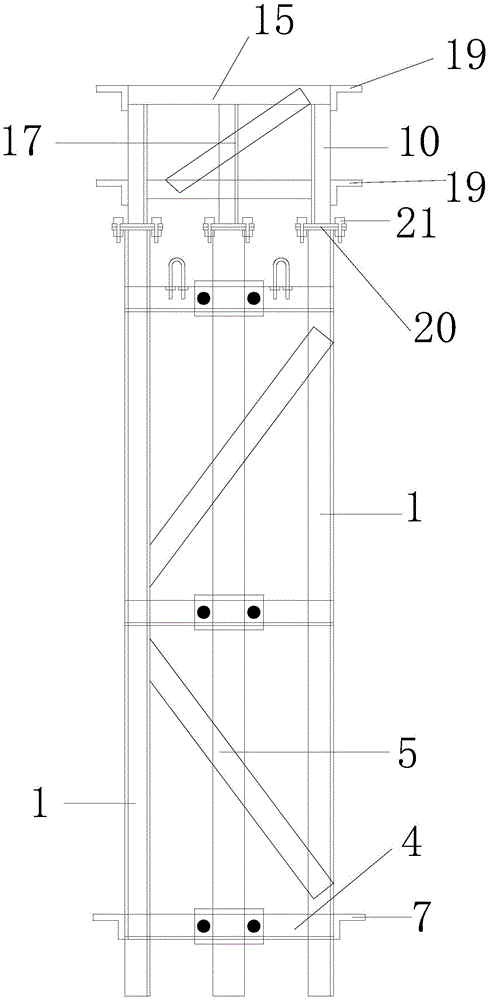

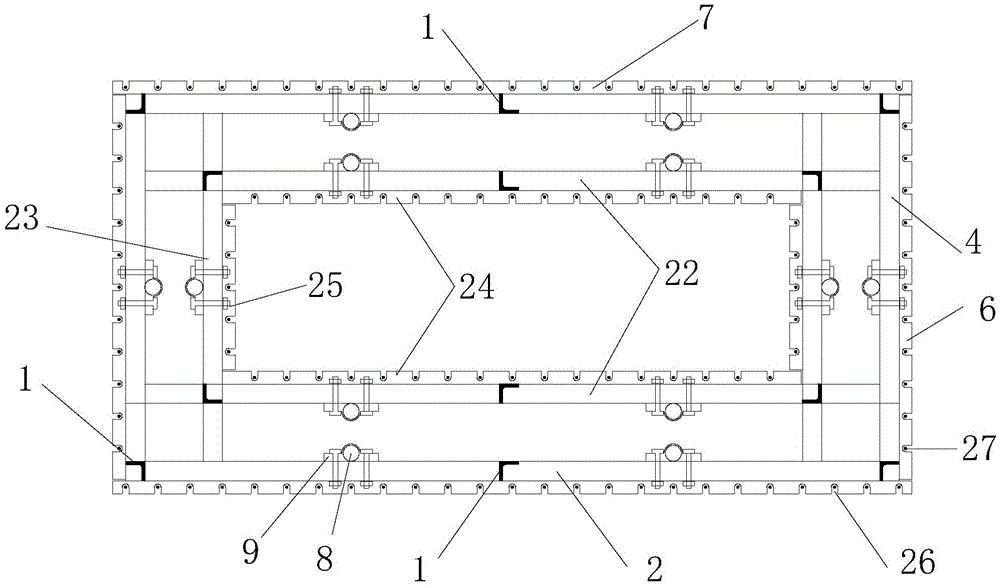

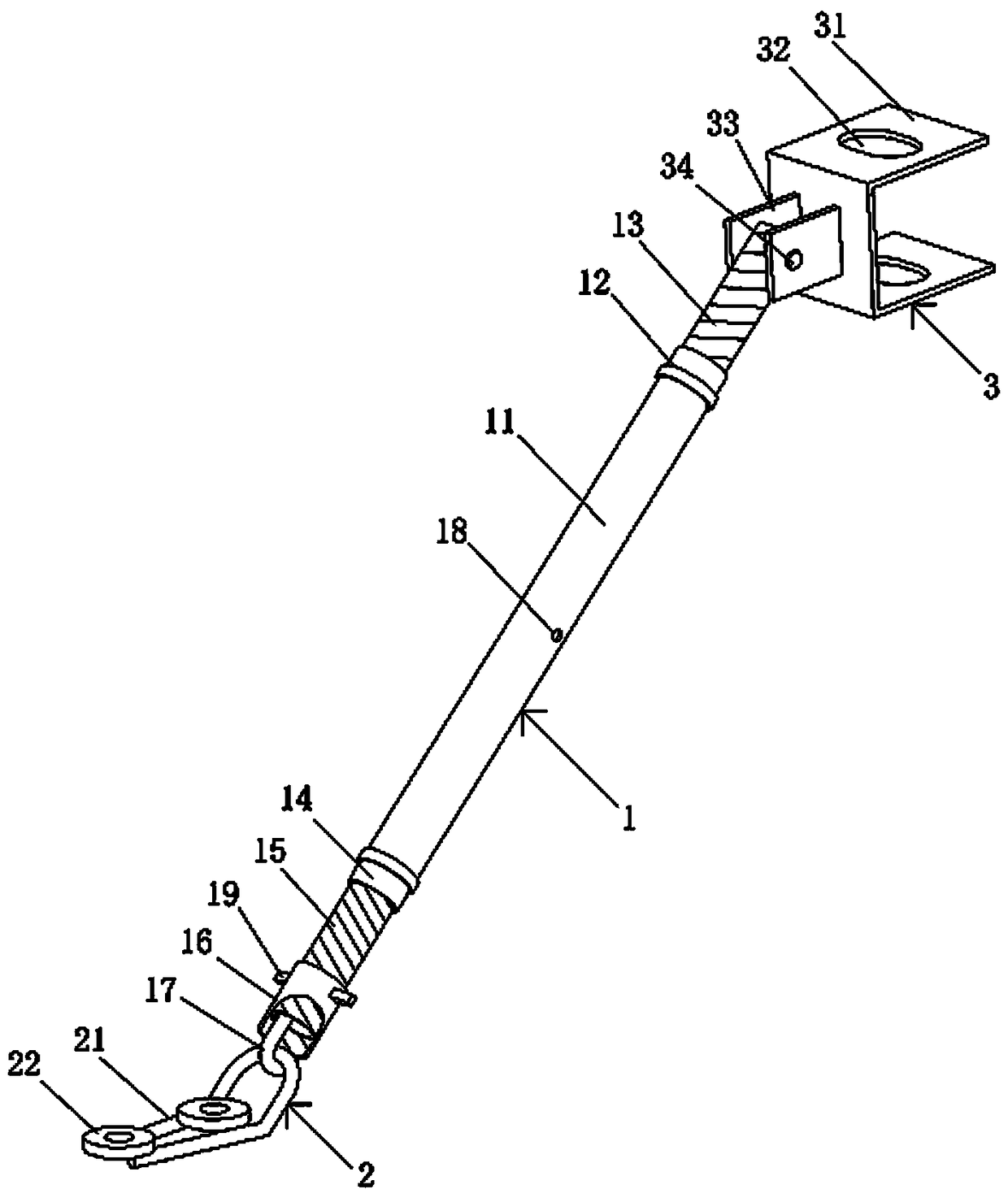

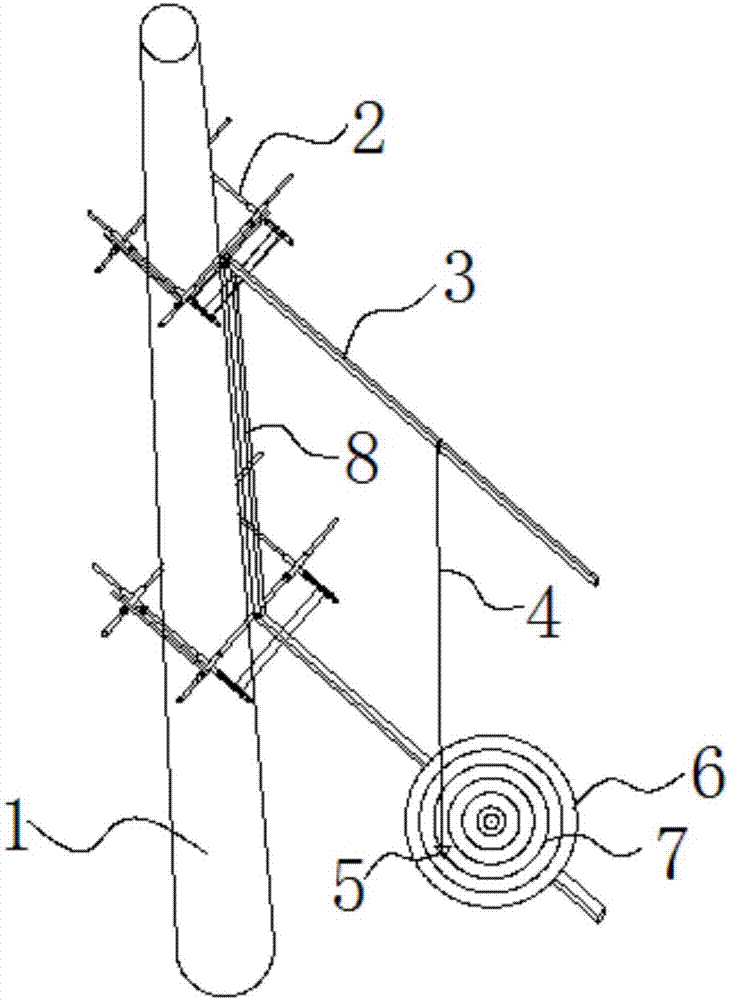

Diagonal bracing and pulling device used for supporting of cast-in-place concrete wall formwork

A diagonal bracing and pulling device used for supporting of a cast-in-place concrete wall formwork is composed of a diagonal bracing and pulling rod, a lower fixing piece and an upper connecting piece. The diagonal bracing and pulling rod is provided with a middle rod body, the upper end of the middle rod body is connected with an upper nut, and an upper lead screw is assembled on the upper nut and connected with the upper connecting piece in a hinged mode; and the lower end of the middle rod body is connected with a lower nut, a lower lead screw is assembled on the lower nut and provided with a pulling hook, and a fastening nut is assembled at the lower lead screw. The lower fixing piece is provided with a U-shaped connecting ring with the forward arc-shaped end, the front portion of theU-shaped connecting ring upwarps by 45 degrees, the pulling hook is hung at the arc-shaped end of the U-shaped connecting ring in a hooked mode, and anchor bolt gaskets are arranged on the rear portion of the U-shaped connecting ring; the upper connecting piece is provided with a transverse back arris connecting piece, through pin holes are formed in two wing plates of the transverse back arris connecting piece, and lug plates are arranged on the outer side of a web plate of the transverse back arris connecting piece; and the upper lead screw is connected with the upper connecting piece through a pin shaft in a hinged mode. The diagonal bracing pulling device is simple in structure and convenient to use, and the safe and reliable performance of supporting and connecting is good.

Owner:魏志光

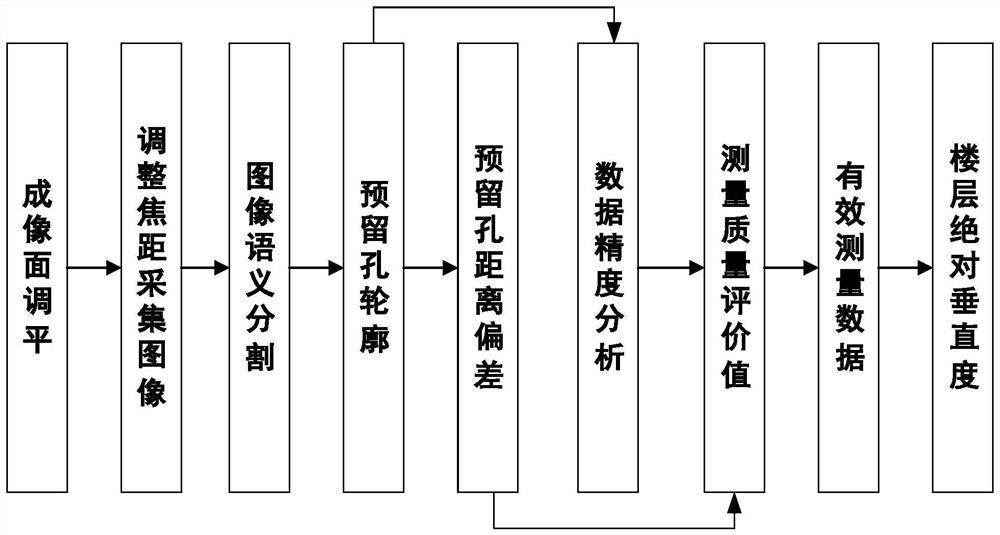

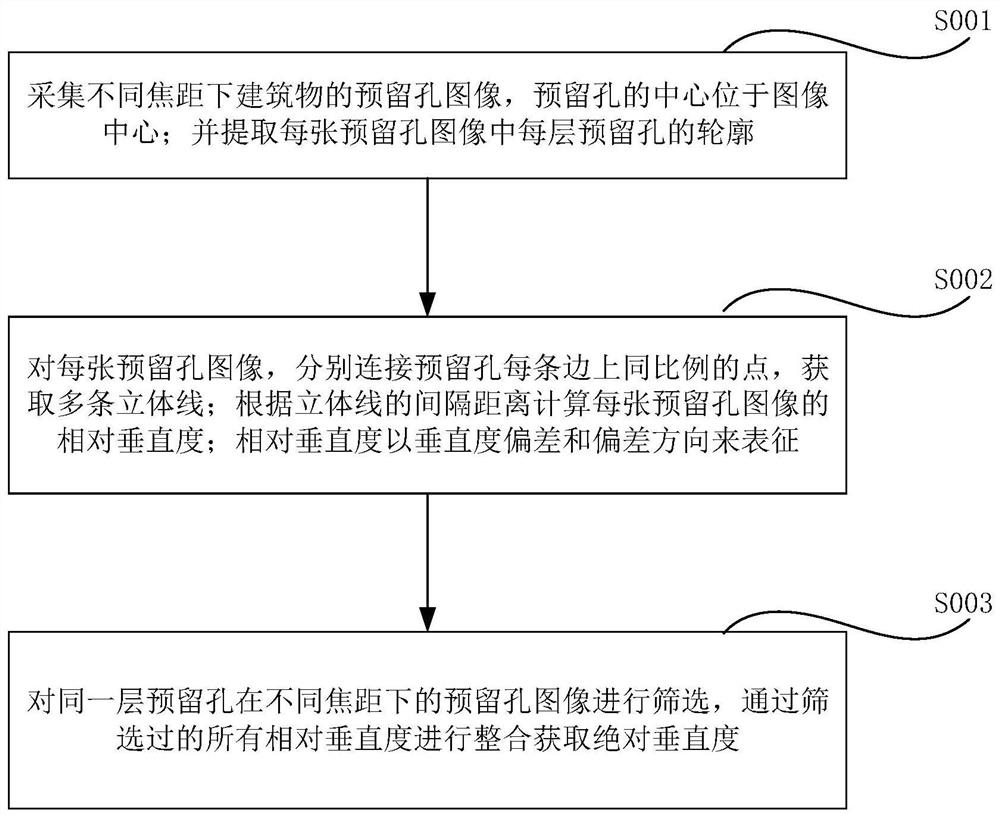

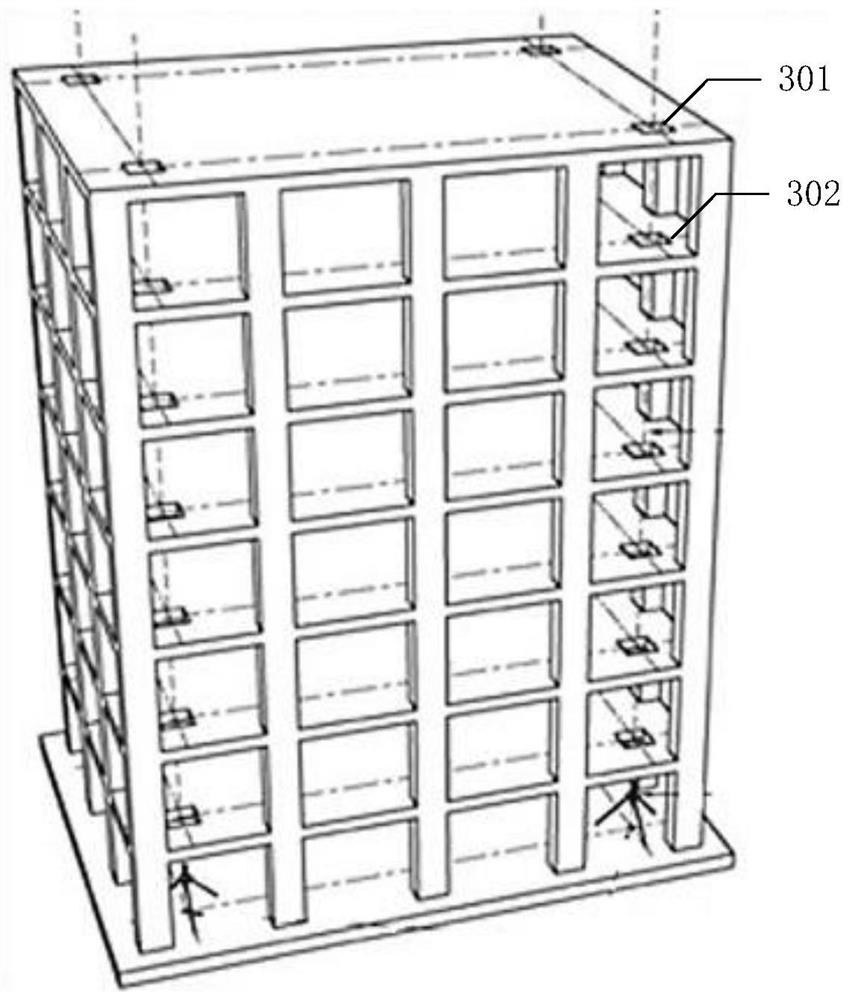

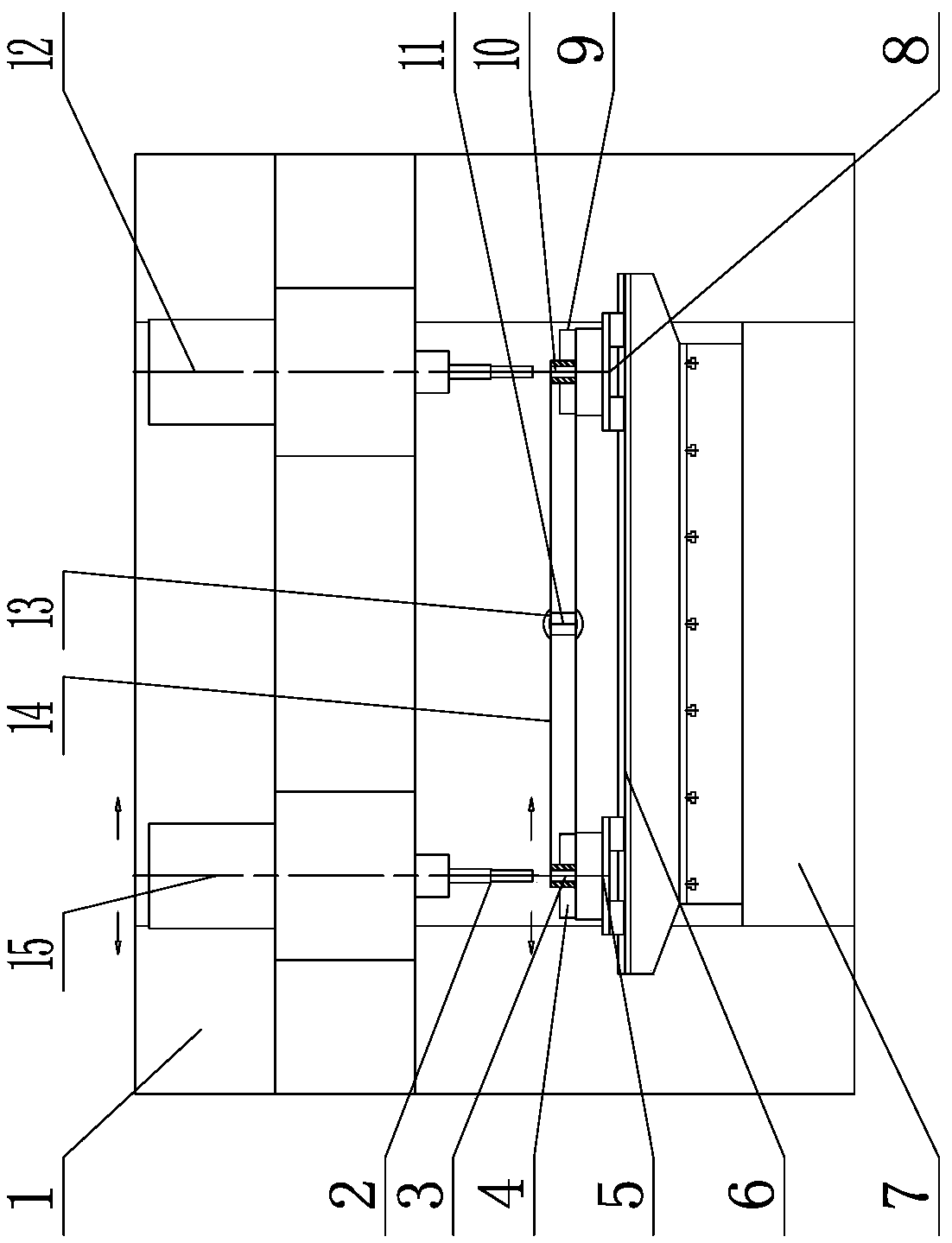

Method for measuring and controlling perpendicularity of super high-rise building

ActiveCN113514036AHigh degree of automationFast measurementPicture interpretationIncline measurementEngineeringMechanical engineering

The invention relates to the technical field of artificial intelligence, and in particular relates to a method for measuring and controlling the perpendicularity of a super high-rise building. The method comprises the steps of collecting preformed hole images of the building under different focal lengths, wherein the centers of preformed holes are located in the centers of the images; extracting the contour of each layer of preformed hole in each preformed hole image; for each preformed hole image, respectively connecting points with the same proportion on each side of the preformed hole to obtain a plurality of three-dimensional lines; calculating the relative perpendicularity of each preformed hole image according to the spacing distance of the three-dimensional lines; representing the relative perpendicularity by perpendicularity deviation and deviation direction; and for the preformed hole images of the preformed holes in the same layer under different focal lengths, screening the preformed hole images according to the reliability of the relative perpendicularity to obtain effective data, and integrating all screened relative perpendicularity to obtain absolute perpendicularity. According to the embodiment of the invention, the perpendicularity of the super high-rise building can be accurately obtained, the operation is simple and convenient, and the accuracy is high.

Owner:CHINA CONSTR FIFTH ENG DIV CORP LTD

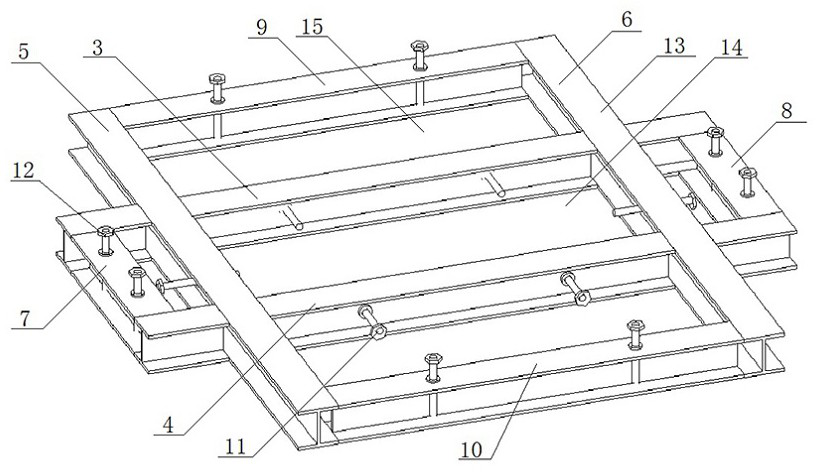

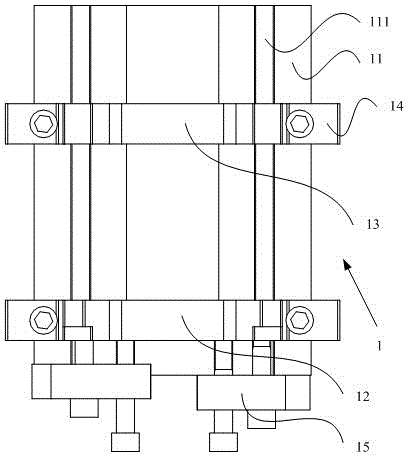

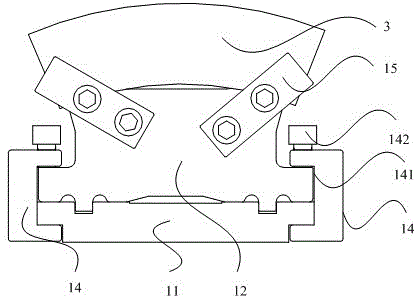

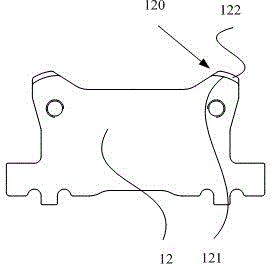

Leaf spring numerical control boring device and special clamp

InactiveCN108723844AIncrease productivityReduce manufacturing costWork clamping meansPositioning apparatusNumerical controlEngineering

The invention relates to a leaf spring numerical control boring device and a special clamp, and belongs to the technical field of leaf spring machining and assembling production equipment and technology. The leaf spring numerical control boring device and the special clamp are characterized in that the special clamp comprises a clamp installation frame body, a spring eye clamping device and an archeight control device, wherein a front sliding rail and a rear sliding rail are arranged on the clamp installation frame body, the spring eye clamping device comprises a fixed clamping end and a movable clamping end, the fixed clamping end is fixedly installed at the right end of the front sliding rail, and the movable clamping end is installed at the left end of the front sliding rail and can move along the front sliding rail; and hydraulic three-jaw chucks are installed on the fixed clamping end and the movable clamping end respectively, and the hydraulic three-jaw chucks can clamp the outer peripheral wall of the spring eye. According to the leaf spring numerical control boring device and the special clamp, clamping-fixing and boring-milling operations can be carried out on the springeyes with different specifications, the production efficiency is effectively improved, and the production cost is reduced.

Owner:SHANDONG LEOPARD AUTOMOTIVE HLDG

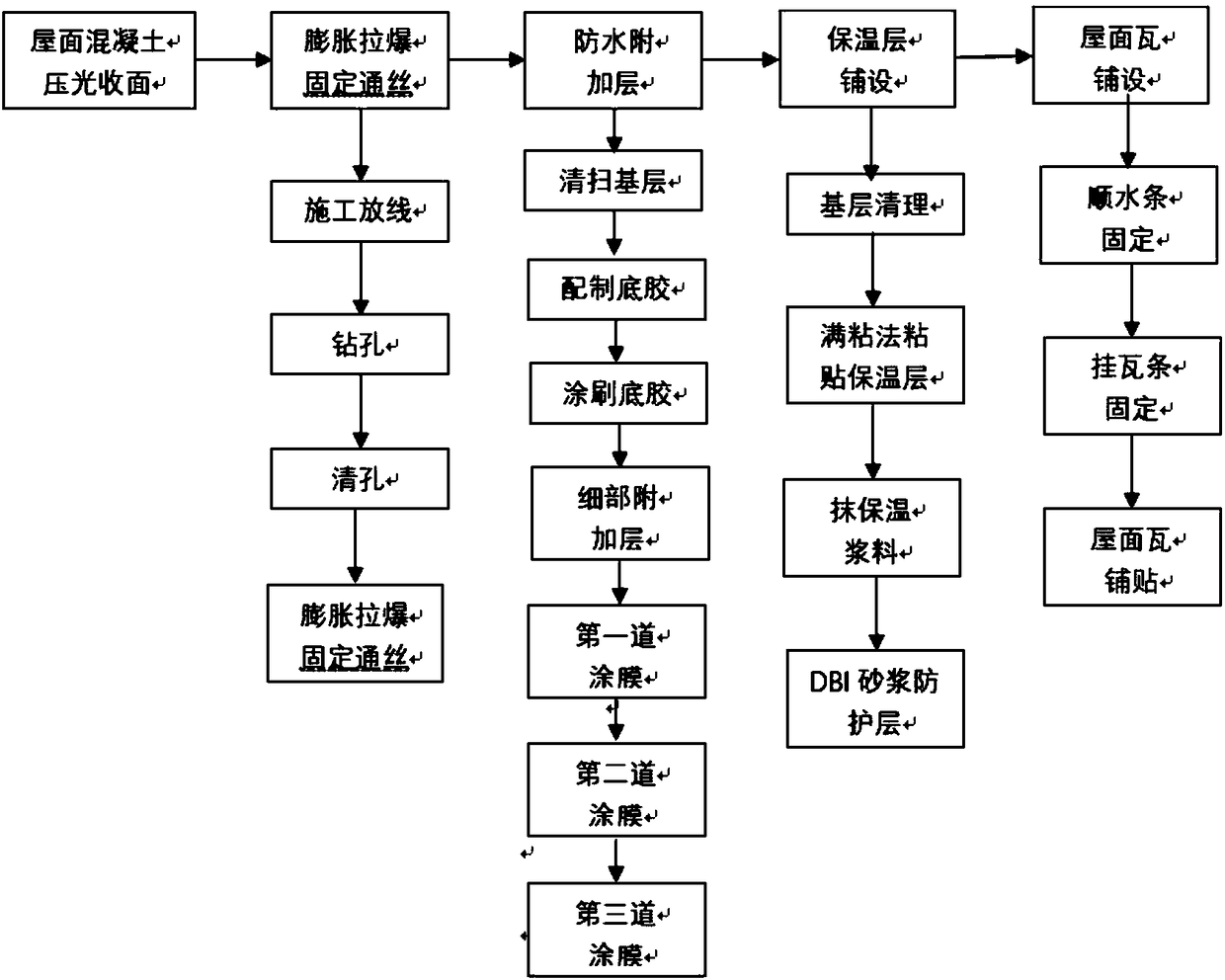

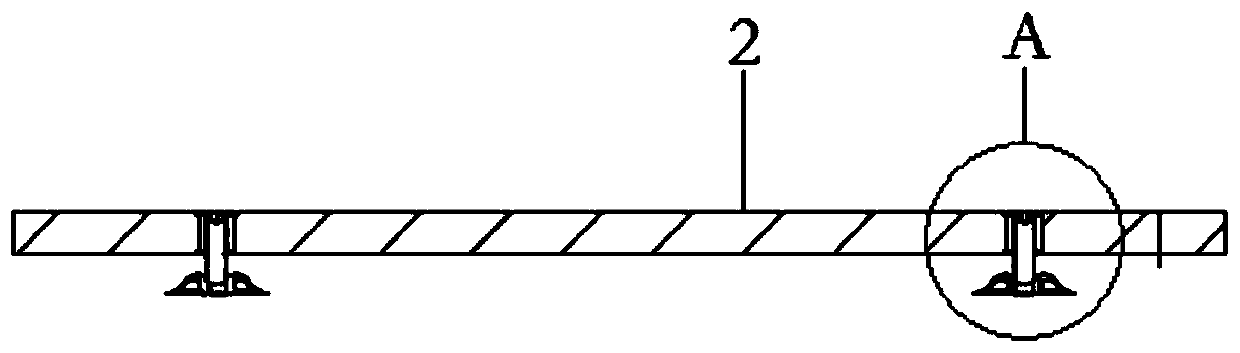

Pitched roof construction technology

InactiveCN108487556AEasy to pourAccurate installation spacingBuild-up roofsRoof covering insulationsRoof tileThermal insulation

The invention discloses a pitched roof construction technology which comprises the following steps that (a), press polishing and surface finishing are carried out on roof concrete, and setting-out iscarried out to mount full-thread expansion bolts; (b), a waterproof additional layer is made and three coating films are smeared; (c), a thermal insulation plate is pasted, and a thermal insulation slurry layer and a DBI mortar protective layer are painted; (d), counter battens are fixed to the full-thread expansion bolts through double nuts, and roof battens are fixed to the counter battens; and(e), roofing tiles are laid. The pitched roof construction technology has the advantages that 1, pouring and surface finishing of the pitched roof concrete are easier; 2, the full-thread bolts are combined with the waterproof layer more tightly, mounting space and perpendicularity of the full-thread bolts are more accurate, and stress is more uniform; and 3, the counter battens are mounted to thefull-thread expansion bolts through the double nuts, welding on the upper portion of the roof thermal insulation layer is avoided, and mounting joints are not liable to be rusted; flatness of the counter battens can be flexibly adjusted by adjusting the double nuts, construction is more flexible, and construction quality is higher.

Owner:北京城建十六建筑工程有限责任公司

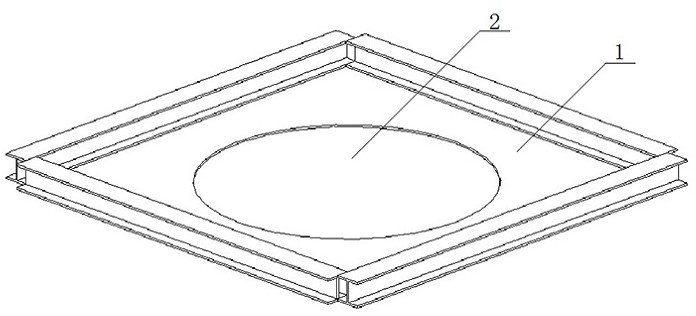

Fabricated concrete overhead ground mounting structure and mounting method

PendingCN110607891AAchieve high industrial integrationEffective installationFalse floorsEngineeringStructural engineering

Owner:GOLD MANTIS FINE DECORATION TECH SUZHOU CO LTD

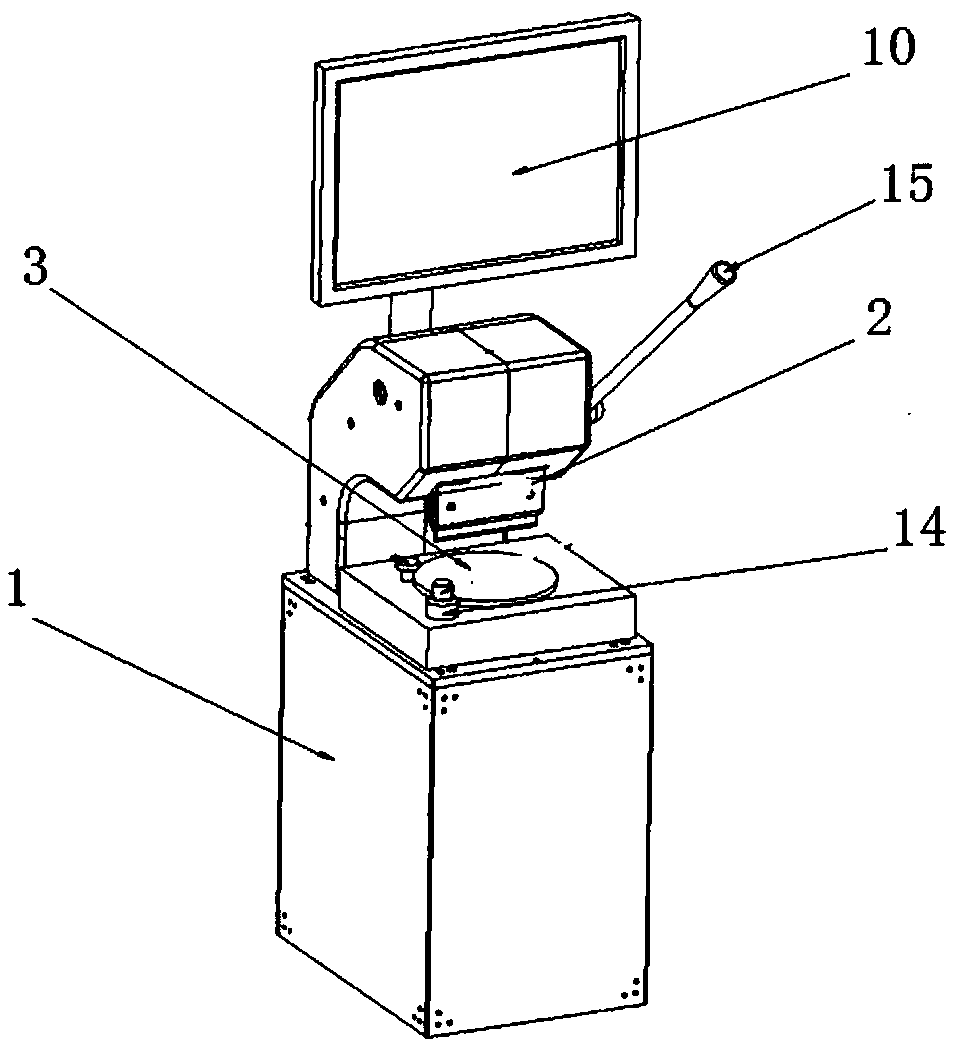

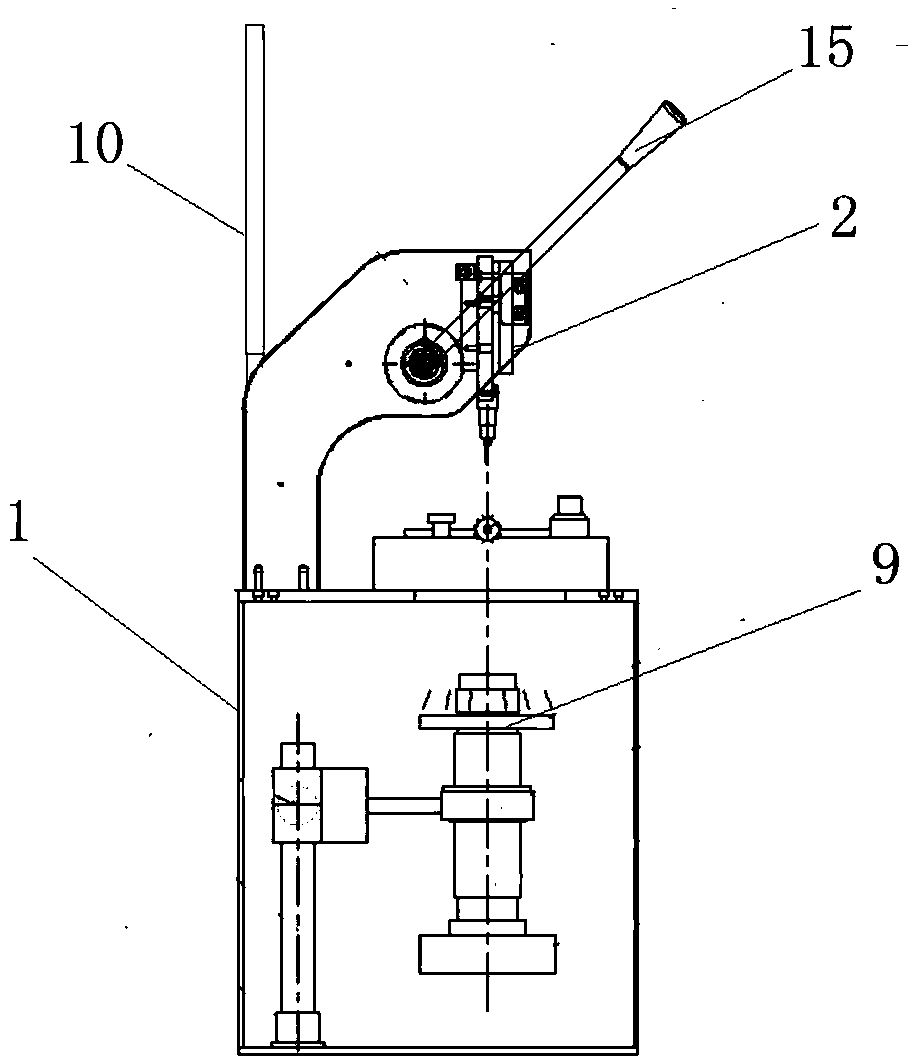

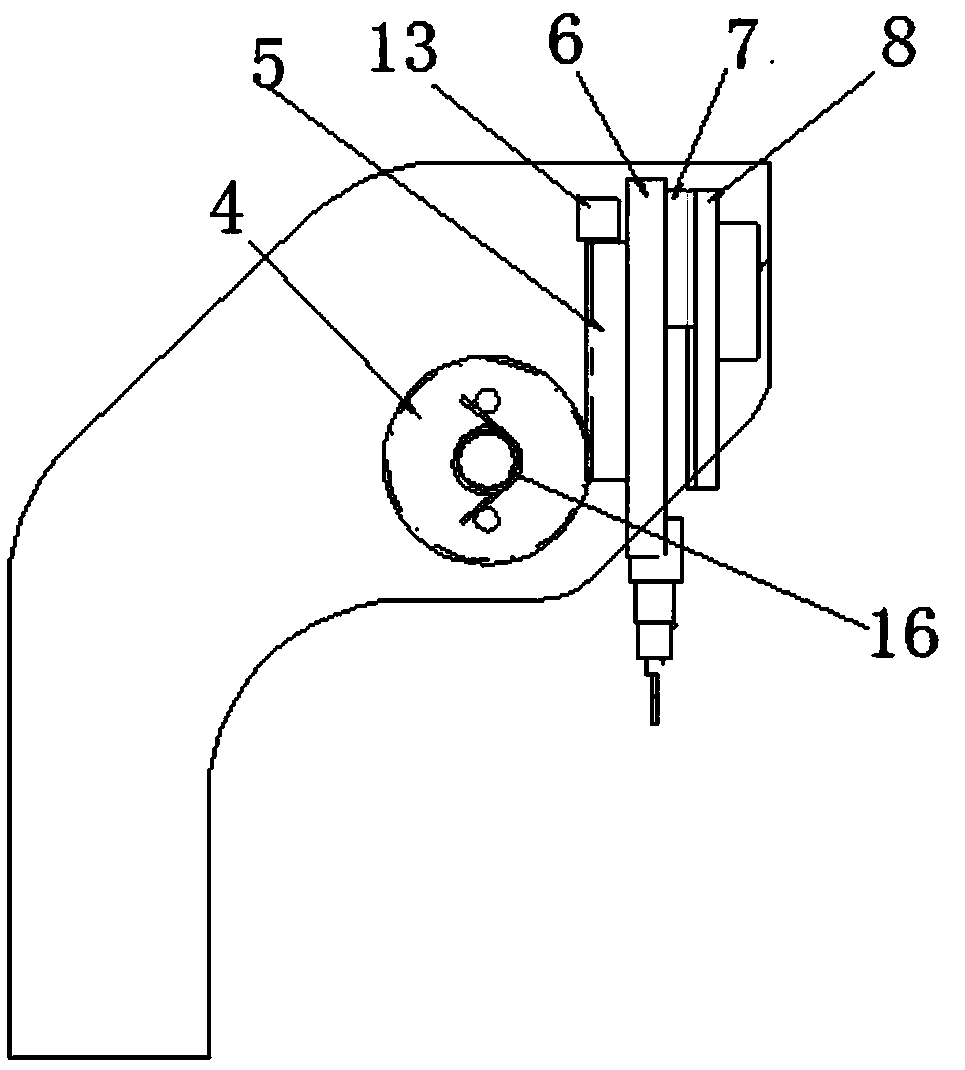

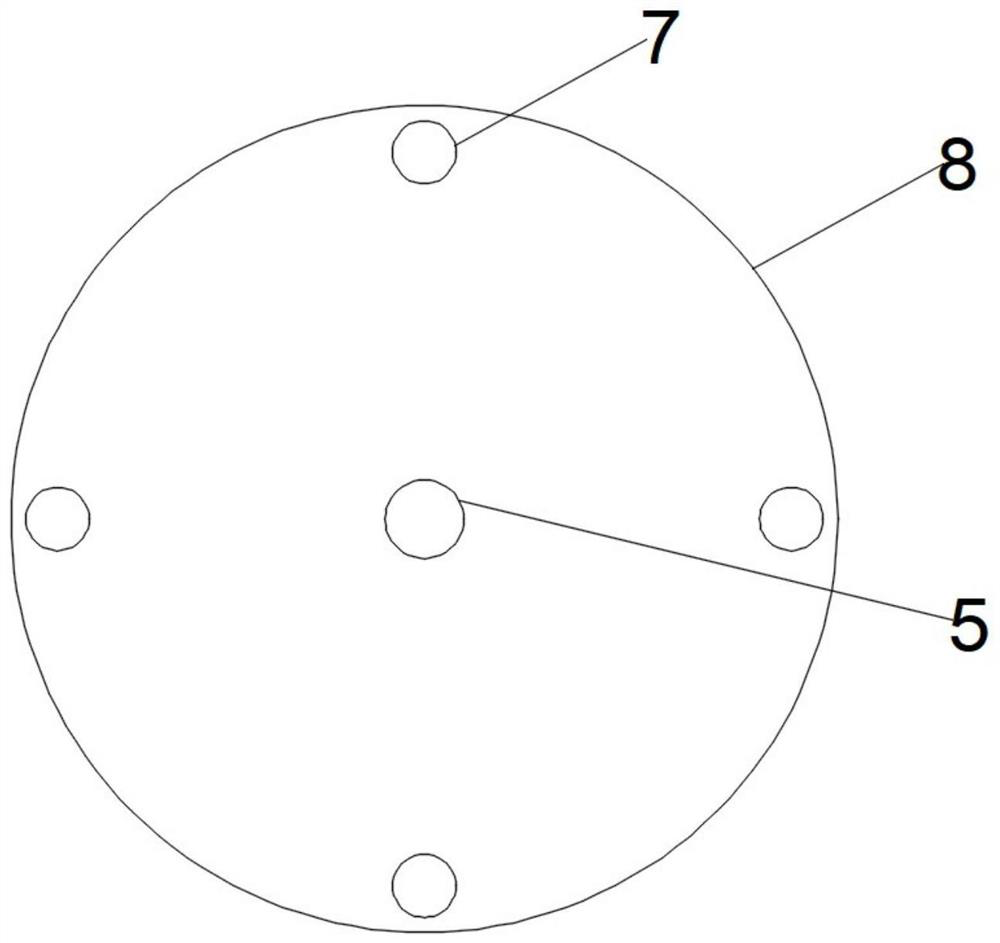

Micro-fluidic chip cutting and perforating device

PendingCN109676686APrecise verticalityPrecise positioningMetal working apparatusMicrofluidic chipCamera lens

The invention provides a micro-fluidic chip cutting and perforating device which comprises a main body, wherein the main body comprises an objective table, and a cutting device and an imaging device that are arranged on the objective table; a tray is arranged on the objective table; the cutting device comprises a housing; the housing is internally provided with a gear shaft, a rack engaged with the gear shaft, a drilling and cutting component fixed on the rack, a slide block fixed on the drilling and cutting component, and a slide rail corresponding to the slide block; the imaging device comprises an image acquisition lens over against the tray, and a display host machine; the display host machine is used for displaying image information acquired by the image acquisition lens; and the image acquisition lens comprises a microscope lens and a camera lens. With the adoption of a precise gear pair mechanical transmission and coaxial imaging system, the perforating device that is high in verticality and accurate in positioning can be manufactured easily, quickly and precisely.

Owner:安徽中鼎玉铉新材料科技有限公司

Off-line assembling device for foundation bolts and adjustment method thereof

PendingCN110629782AStable positionPrecise verticalityFoundation engineeringBuilding material handlingEngineeringRebar

The invention provides an off-line assembling device for foundation bolts. The off-line assembling device comprises a fixing part, a positioning part and an adjustable part. The positioning part is inlaid in the fixing part and is located above the adjustable part. A plurality of sets of first through holes are formed in the positioning part. The foundation bolts penetrate through the first through holes and are vertically arranged. The positioning part is perpendicular to the fixing part and parallel to the adjustable part. The adjustable part is perpendicular to the longitudinal axis of thefixing part, is detachably connected with the fixing part, and horizontally penetrates through the fixing part and the adjustable part in sequence. The invention further provides an adjustment methodof the off-line assembling device for the foundation bolts. The off-line assembling device is simple in structure, off-line assembly of the bolts is achieved before installation, and all the foundation bolts are tied through steel bars after being fixed and installed, so that re-working is avoided, labor investment and steel bar waste are reduced, and the deviation caused by impacts of cement to the foundation bolts in the pouring process is minimized.

Owner:MCC TIANGONG GROUP

Lattice pillar component and mounting method thereof

The invention discloses lattice column components used in pile and an installation method. The components comprise a lattice column, a top localizer, and a bottom localizer; the lattice column is a combined column which is formed by connecting profiled bar batten plates; the bottom localizer is in a shape of flat cup, which comprises a cup body, a flat-shaped base which is connected with the cup body, and a guide section which is connected with one side of the cup body away from the base; the lower end of the lattice column is matched with the cup body, and the base is supported by a profiledbar. The bottom localizer is arranged at a condensate concrete core, thereby the position of the bottom localizer can be adjusted conveniently and accurately; the guide section can make the lattice column drop into the matching cup, so which can reduce disturbance and position accurately; the profiled bar is an angle iron which is rolled by thick steel plate, which is less a related joint vacant position than the double-welding angle iron in the same thickness, thereby which has no welding deformation and can ensure the stiffness of the angle iron; the groined top localizer can be independently assembled with sub-components, which can be adjusted flexibly, so that the verticality of the lattice column and the accuracy of the top positioning can be ensured.

Owner:GUANGZHOU CONSTR ENG +1

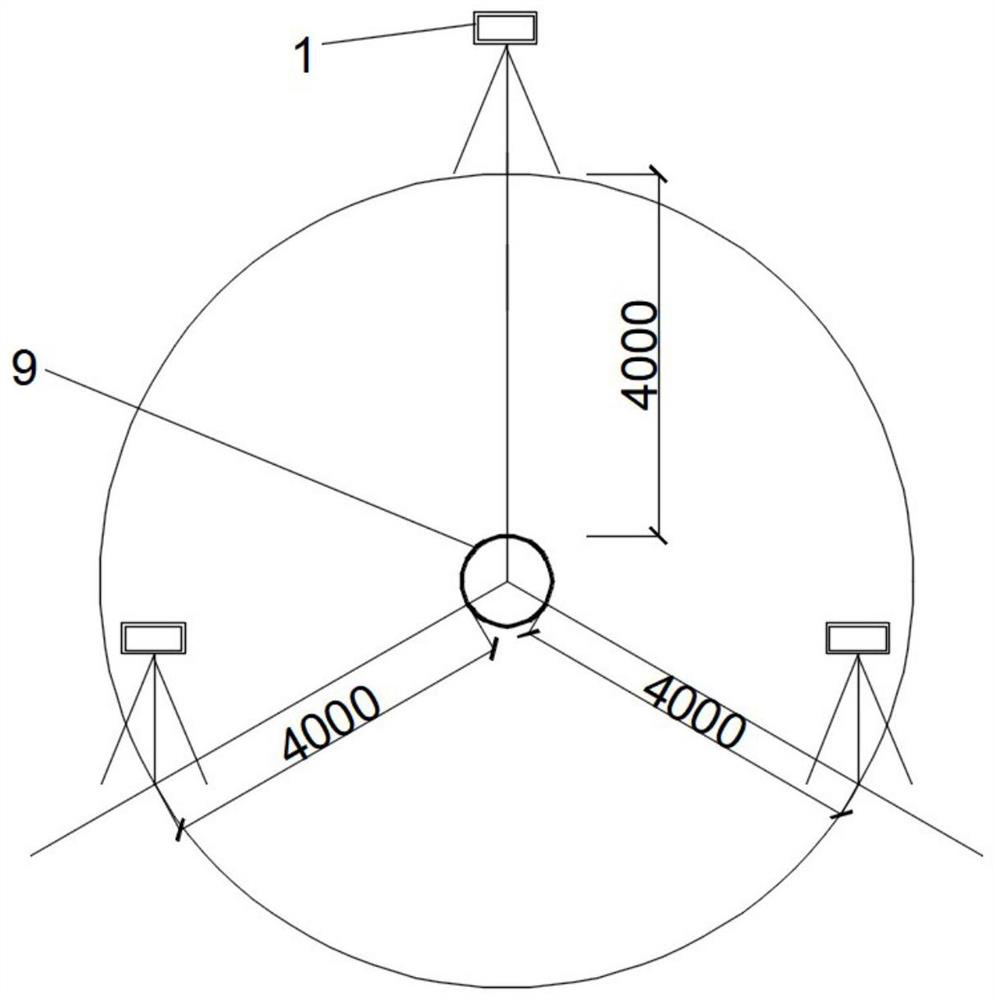

Drilling verticality monitoring and deviation rectifying method along with drilling process

PendingCN111997526AVerticality real-time monitoringThere will be no crooked drillingSurveyDirectional drillingMarine engineeringMonitoring system

The invention provides a drilling verticality monitoring and deviation rectifying method along with a drilling process, and relates to the field of auxiliary devices and methods for drilling cast-in-place pile construction. The drilling verticality monitoring and deviation rectifying method along with the drilling process comprises the following steps that S1, a drilling machine is in place, and after the drilling position is confirmed, the drilling machine is moved to a construction position; and S2, a verticality monitoring system and a drill bit deviation rectifying system are installed, firstly, a verticality inductor is placed in a drill bit of the drilling machine and fixed, three positioning emission receivers are arranged on the ground around a hole to be drilled, the three positioning emission receivers are connected with a computer terminal through cables, and the drill bit is provided with a hydraulic deviation rectifying device. According to the method, the verticality of the inner wall of the drilled hole can be monitored in real time, the drilling direction of the drill bit can be adjusted in real time according to the monitoring data, automatic deviation rectifying is realized, and the hole forming quality and the construction efficiency are guaranteed.

Owner:BEIJING MUNICIPAL CONSTR

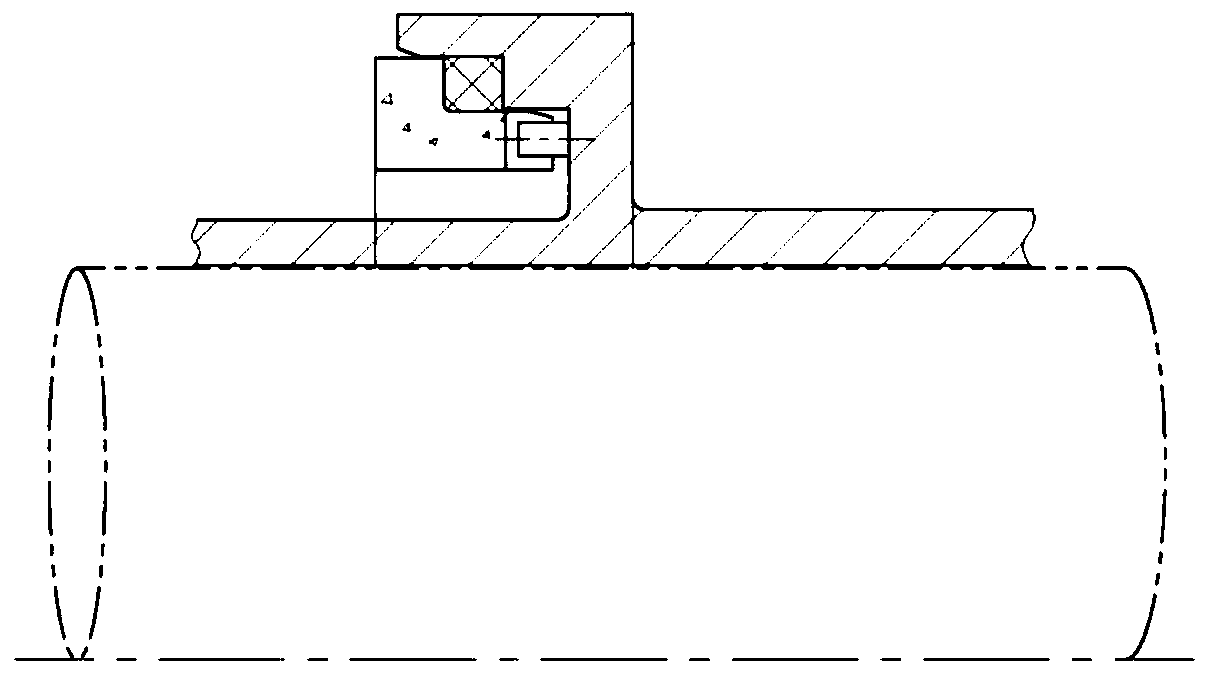

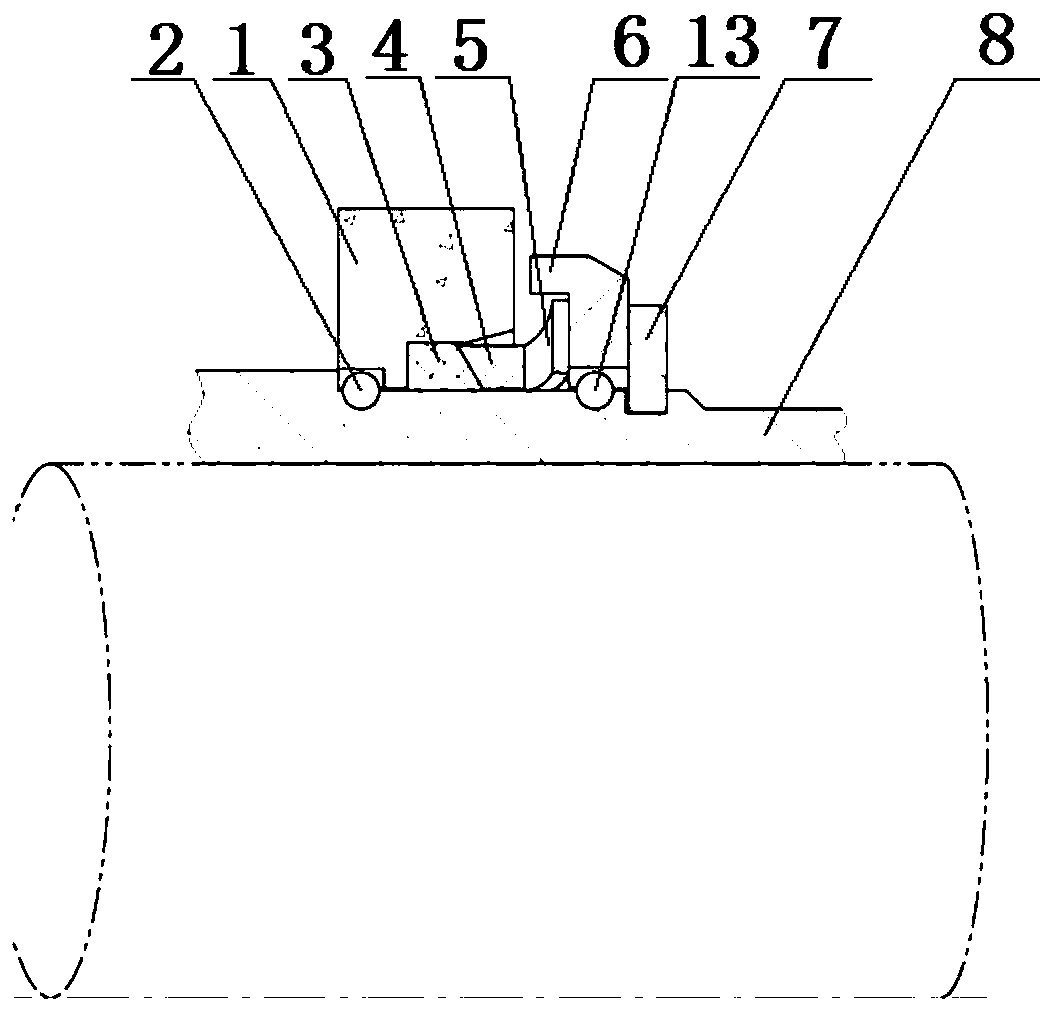

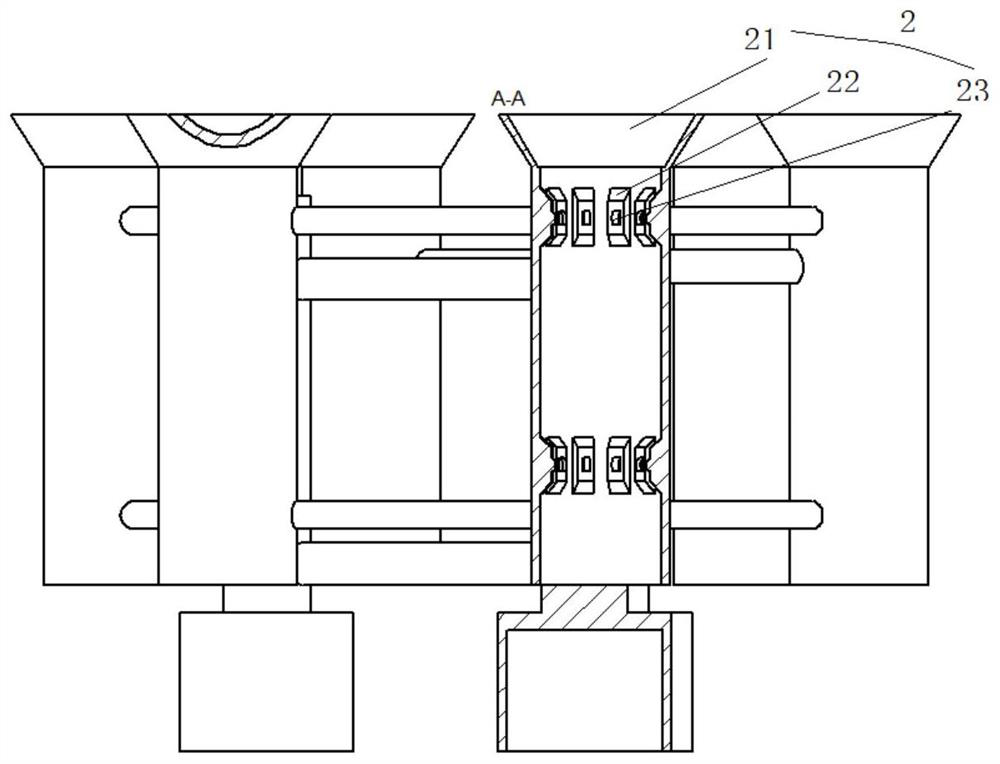

Movable ring assembly sealing device

PendingCN110107692AAxial dimension shortSave axial installation spaceEngine sealsEngineeringMechanical engineering

The invention discloses a movable ring assembly sealing device. The movable ring assembly sealing device is composed of a movable ring assembly and a shaft sleeve. The movable ring assembly is composed of a movable ring, a first steel ball, a sealing gasket, a pressing ring, a wave spring, a wave spring seat, a shaft retainer ring and a second steel ball. A shaft sleeve step is arranged at one endof the shaft sleeve. A first steel ball socket is arranged on the right side of the shaft sleeve step, a spring clamping groove is formed in the other end of the shaft sleeve, and a second steel ballsocket is arranged on the left side of the spring clamping groove. The first steel ball is arranged in the first steel ball socket. The movable ring abuts against the shaft sleeve step. The sealing gasket is pressed into an inner hole of the movable ring and pressed by the pressing ring. The wave spring abuts against the pressing ring. The second steel ball is arranged in the second steel ball socket. The wave spring seat abuts against the wave spring. The shaft retainer ring is clamped in the spring clamping groove and is integrated with the spring clamping groove. The movable ring sealing assembly is small in axial size and convenient to install, the flatness and perpendicularity of the end face of the movable ring are high, and the load around the end face is uniform.

Owner:XIAN YONGHUA GROUP

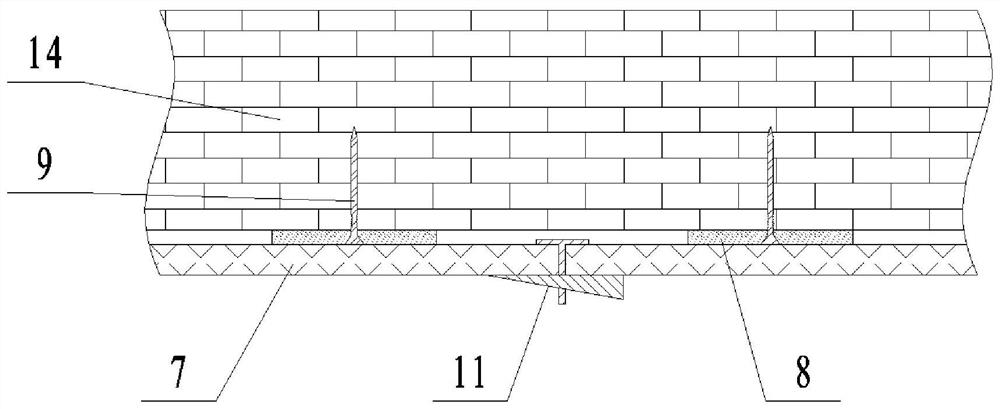

Construction method for dry sticking of large wall bricks for interior decoration

The invention relates to a construction method for dry sticking of large wall bricks for interior decoration, and belongs to the technical field of interior decoration. The construction method for drysticking of the large wall bricks for interior decoration comprises the steps of carrying out construction preparation; arranging and positioning the wall bricks; installing anchoring nails; dry sticking the wall bricks; and carrying out levelling, wall brick seam beautifying and inspection and acceptance between the surfaces of the adjacent wall bricks. Dry sticking points are arranged on sticking positions of the wall bricks of a wall, an anchoring nail is arranged on each dry sticking point part, the installation position of each anchoring nail is consistent to the position of each dry sticking point, and dry sticking adhesives are coated on the peripheries of the anchoring nails, so that the wall, the anchoring nails, the dry sticking adhesives and the wall bricks are integrated intoa whole; the anchoring nails are arranged on the surface of a base layer of the wall, and the anchoring nails are consistent to the positions of the dry sticking points applied with the dry sticking adhesives, so that the wall bricks, the dry sticking adhesives and the anchoring nails are integrated into a whole, the defects of empty bulge and falling off of the wall bricks due to slight shrinkagebetween the base layer of the wall and the dry adhesives are made up, the anchoring nails and the base layer of the wall are firmly connected, and the dry sticking adhesives can be ensured to be firmly connected with wall base layers made of different materials.

Owner:NANTONG SIJIAN CONSTR GRP

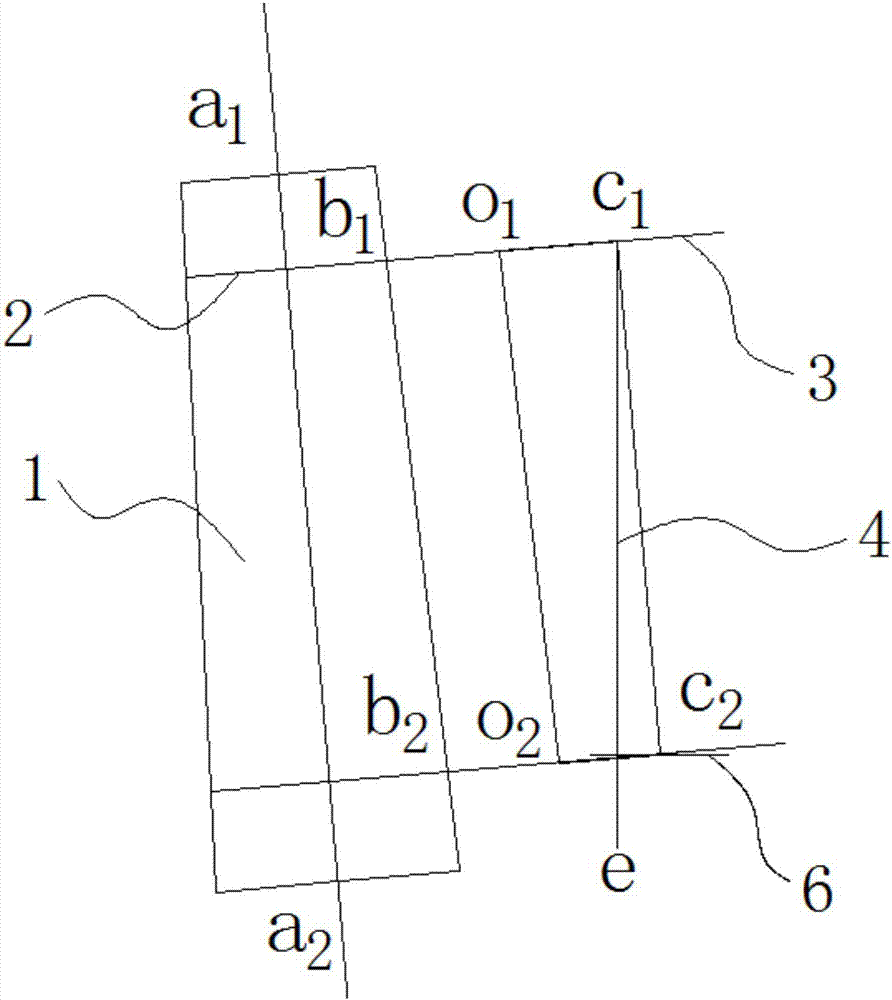

Method and device for detecting verticality of conical upright post

ActiveCN107014355AImprove applicabilityPrecise verticalityPlumb lines for surveyingIncline measurementEngineering

The invention discloses a method for detecting verticality of a conical upright post. The method disclosed by the invention comprises the following steps: firstly sheathing two diameter measuring frames on the conical upright post, wherein a middle point of each side of each diameter measuring frame is contacted with the surface of the conical upright post; the sides at one side of the two diameter measuring frames are respectively connected with one end of one cross beam; secondly, marking an o1 point on an upper cross beam and an o2 point on a lower cross beam, wherein distances between the cross beams corresponding to the o1 and o2 and end parts connected with the diameter measuring frames are equal; thirdly, fixing a plumb line at one c1 point on the upper cross beam, hanging one sharp cone at the lower end of the plumb line; horizontally mounting a dial provided with circular scale lines on the lower cross beam with the circle center aligned to one c2 point, wherein the ratio of the distance between c1 and o1 to the distance between c2 and o2 is equal to the ratio of the side length of the diameter measuring frame arranged below to the side length of the diameter measuring frame arranged above; and fourthly, obtaining the verticality of the conical upright post by virtue of the circular scale line pointed by the sharp cone and the distance between the two diameter measuring frames. The method disclosed by the invention has the advantage that the verticality of the conical upright post can be accurately obtained by carrying out measurement once.

Owner:GUANGXI TRANSPORTATION SCI & TECH GRP CO LTD +1

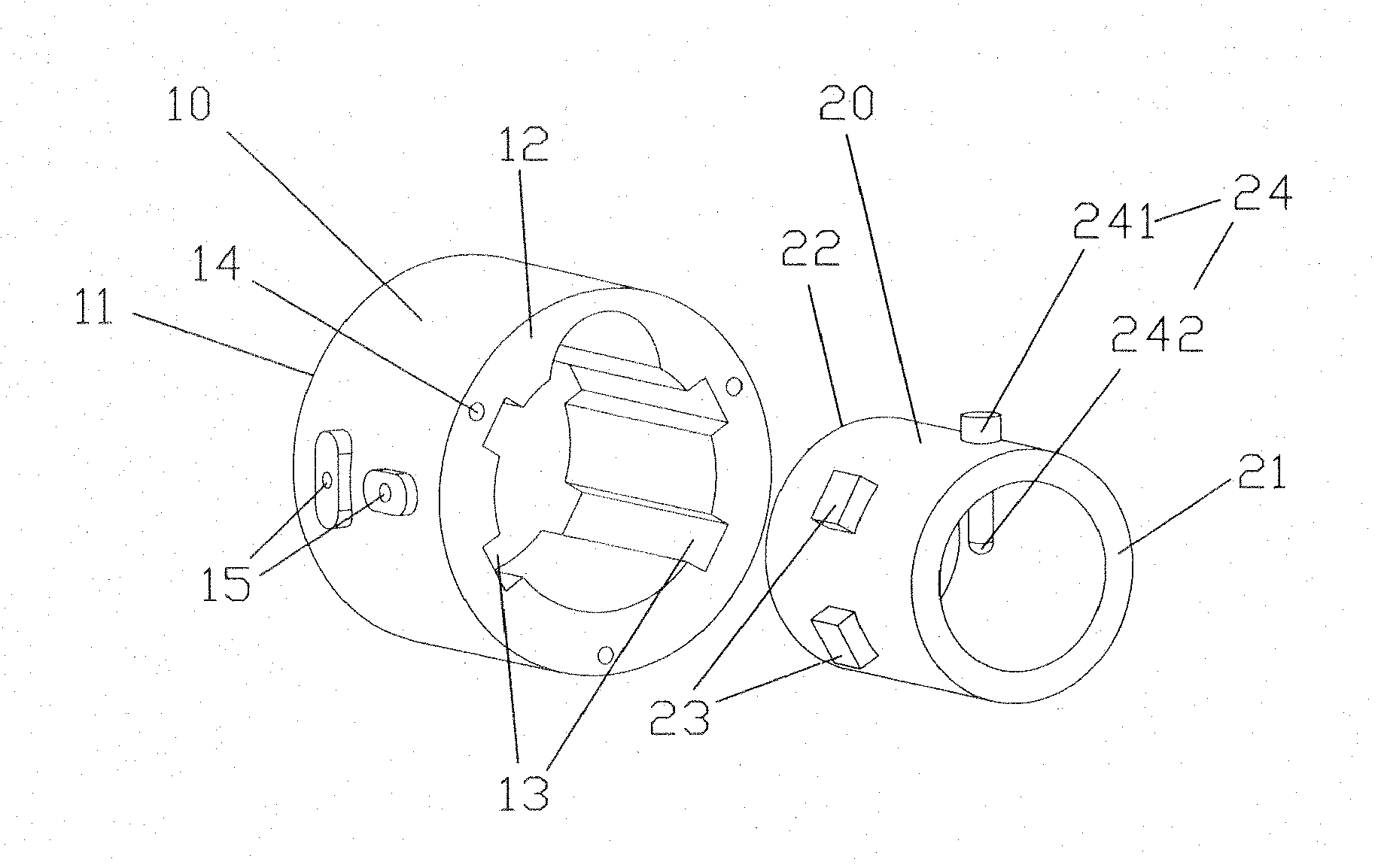

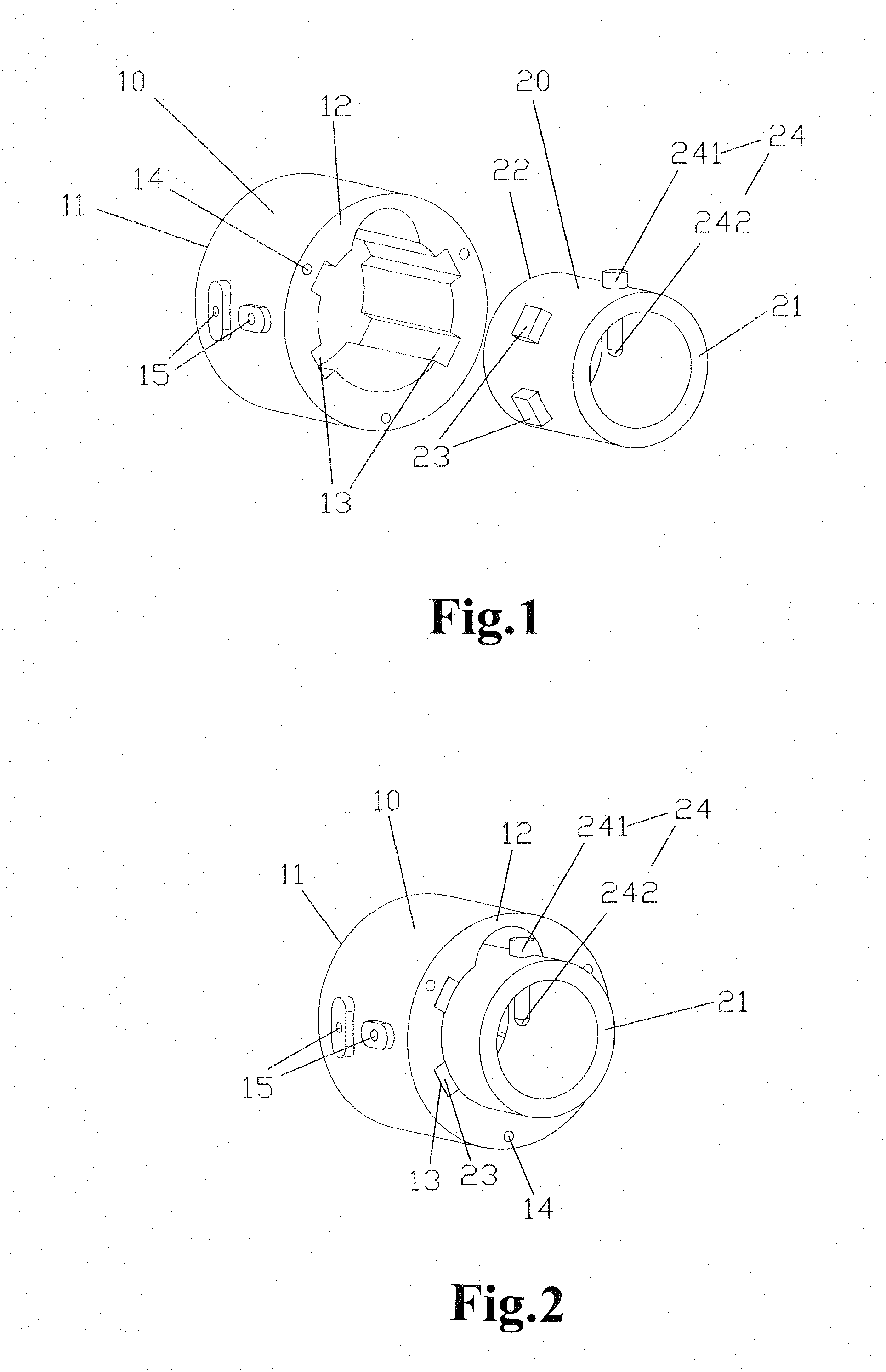

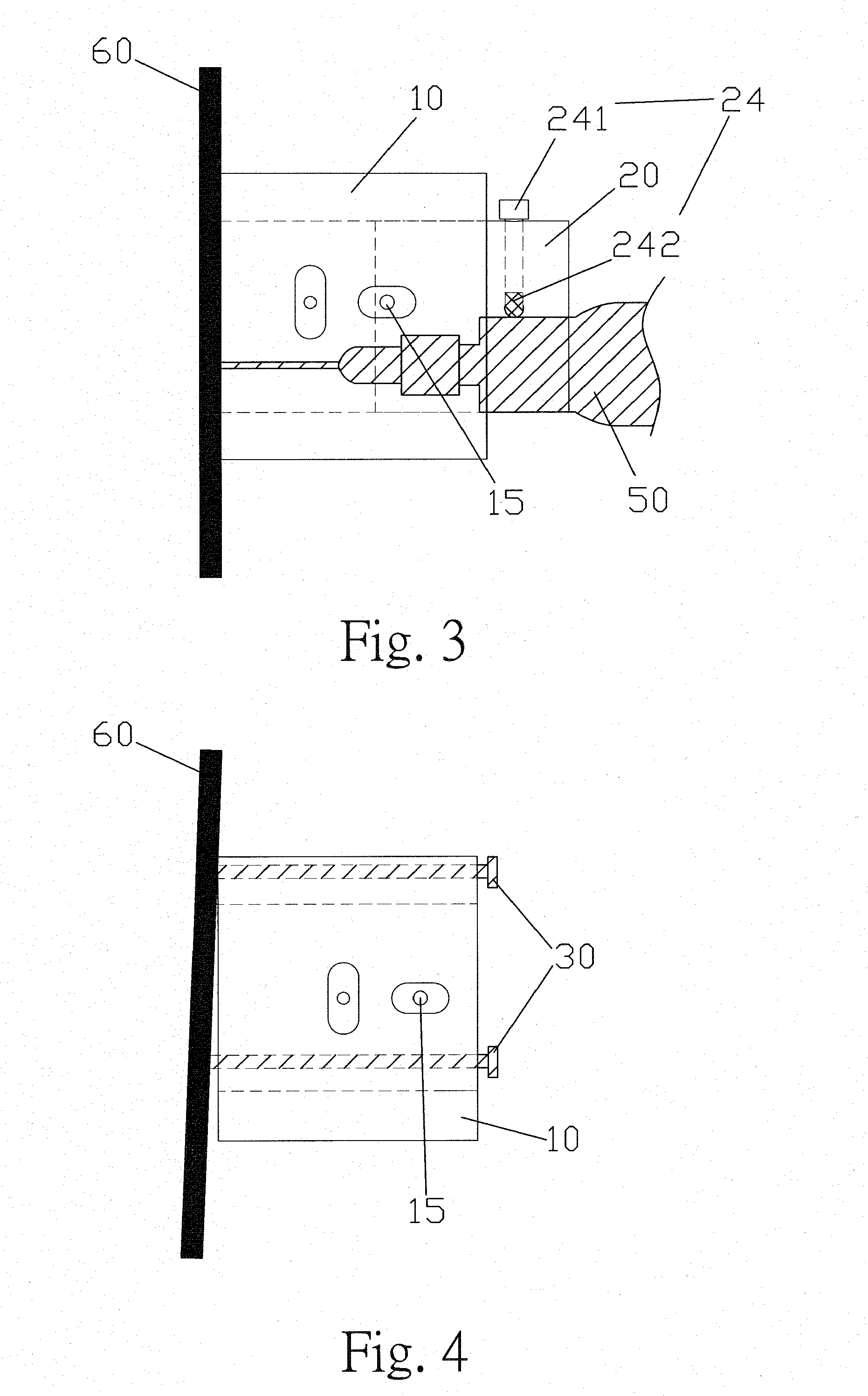

Driller retaining device able to be positioned with well horizontality and verticality

InactiveUS20140345950A1Precise horizontalityPrecise verticalityDrilling/boring measurement devicesDrilling rodsEngineeringMechanical engineering

A driller retaining device able to be positioned with well horizontality and verticality includes a hollow outer sleeve having two end, one is a working end and the other being an assembly end; an inner wall of the assembly end being formed with a plurality of axial sliding tracks; an inner hollow cylinder arranged within the sleeve; two ends of the inner hollow cylinder being an machine end and an assembly end; an outer wall of the inner hollow cylinder having at least one sliding block which is arranged corresponding to the axial sliding groove. In in assembly, the inner hollow cylinder is combined to the driller; then the assembly end of the inner hollow cylinder is assembled to the assembly end of the outer sleeve; and at the same time, the sliding block of the inner hollow cylinder is assembled into the axial sliding groove of the outer sleeve.

Owner:HU KU HSI

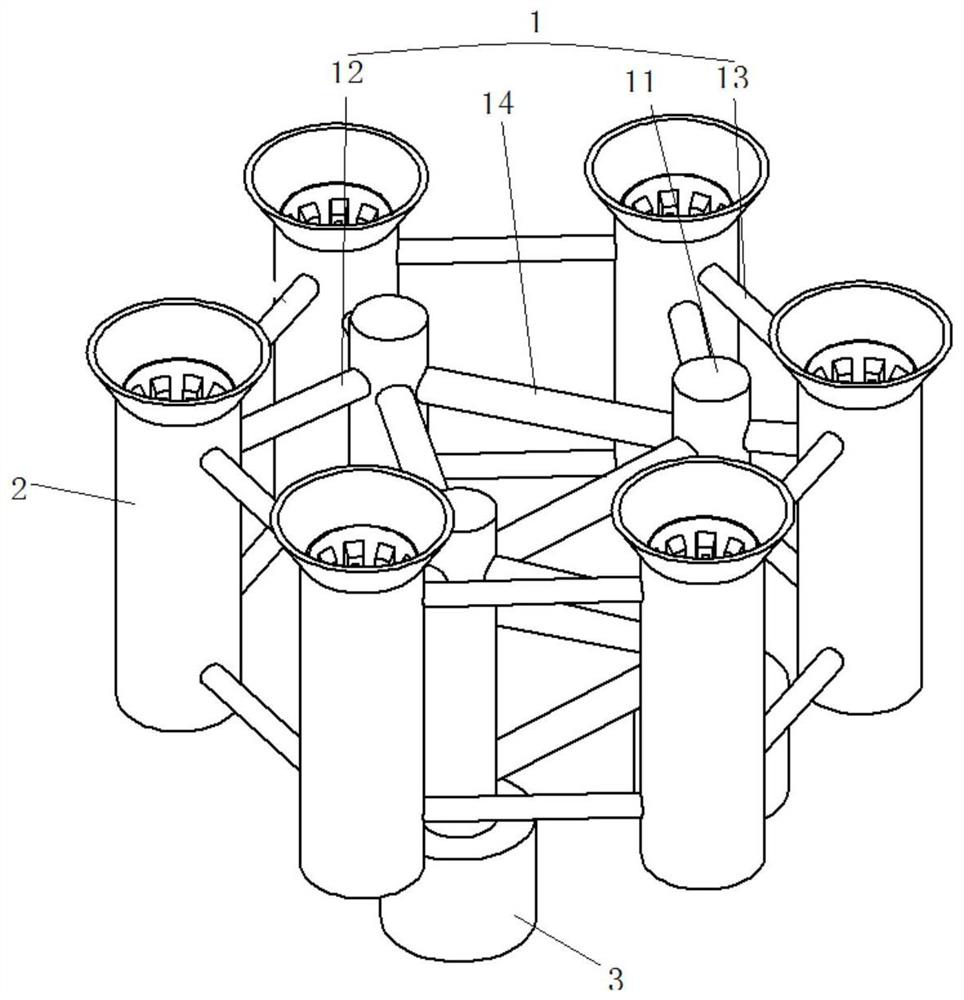

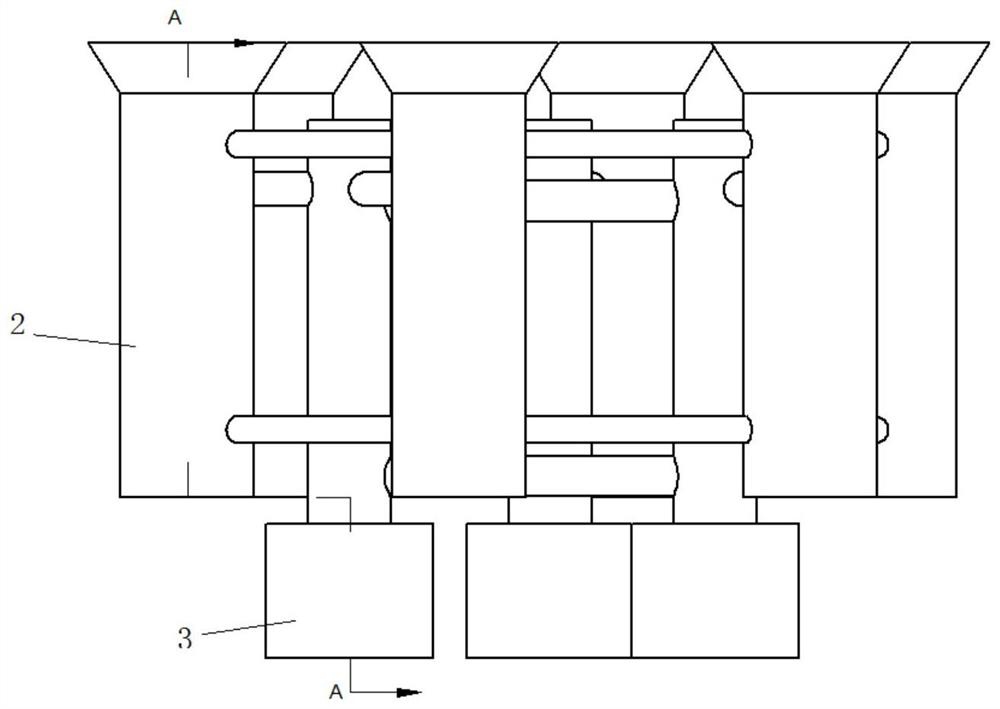

Pile holding frame, and high-rise pile cap foundation installation system suitable for very shallow water areas

PendingCN111794234ARealize pile sinking to realize positioning functionEasy to buildWind motor assemblyWind motor supports/mountsPile capArchitectural engineering

The invention relates to the technical field of wind power generation equipment, and specifically relates to a pile holding frame, and a high-rise pile cap foundation installation system suitable forvery shallow water areas. The pile holding frame comprises a base body, and several guide cylinders and negative pressure cylinders respectively arranged on the base body, wherein the negative pressure cylinders are located under the guide cylinders and arranged in a staggered form with the guide cylinders. In use, the pile holding frame provided by the invention is integrally fixed through the negative pressure cylinders, after the negative pressure cylinders fix the pile holding frame well, the guide cylinders can be used for installing steel piles and so on, thus, a positioning function forpile sinking in the high-rise pile cap foundation can be realized, and construction of the high-rise pile cap foundation is facilitated.

Owner:HUADIAN HEAVY IND CO LTD

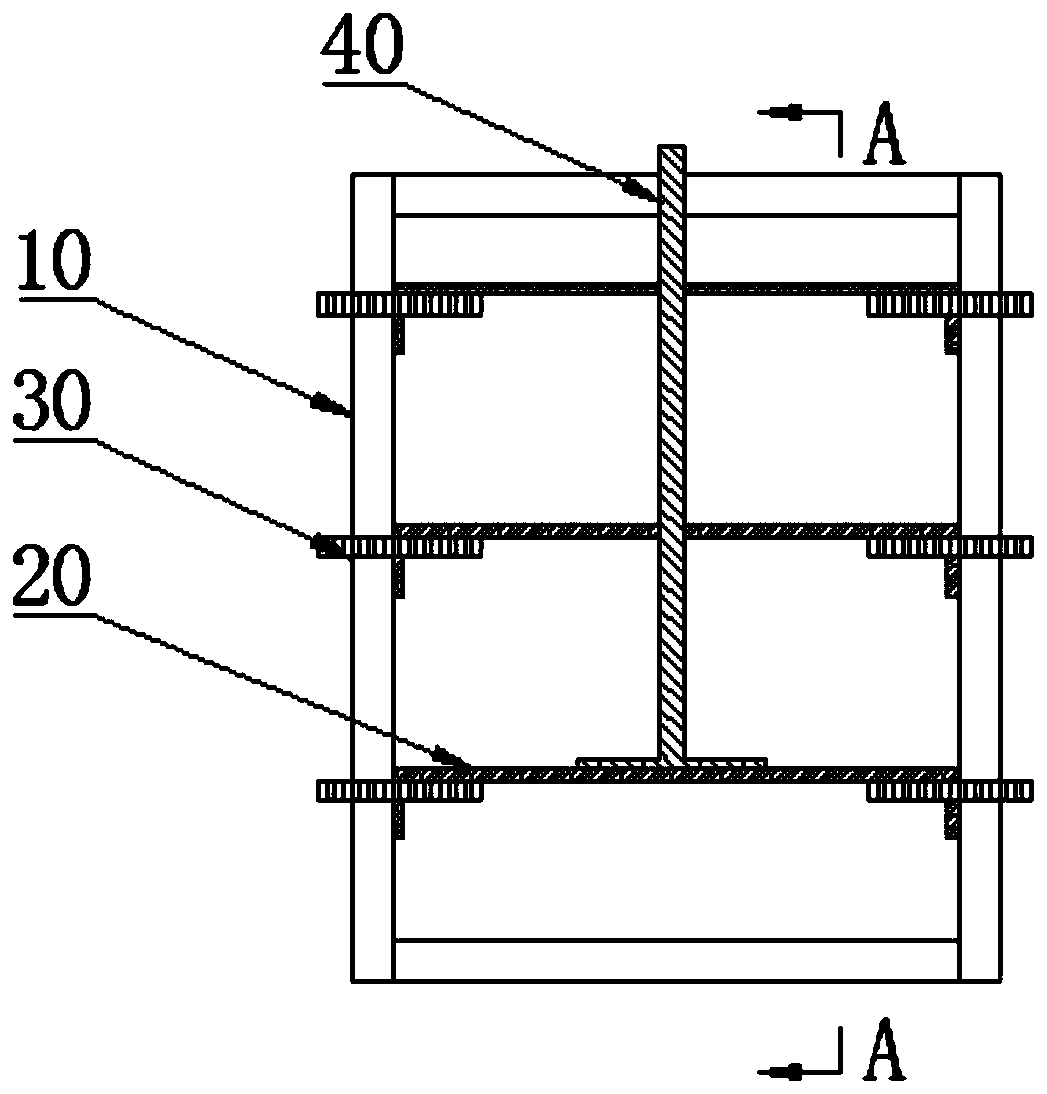

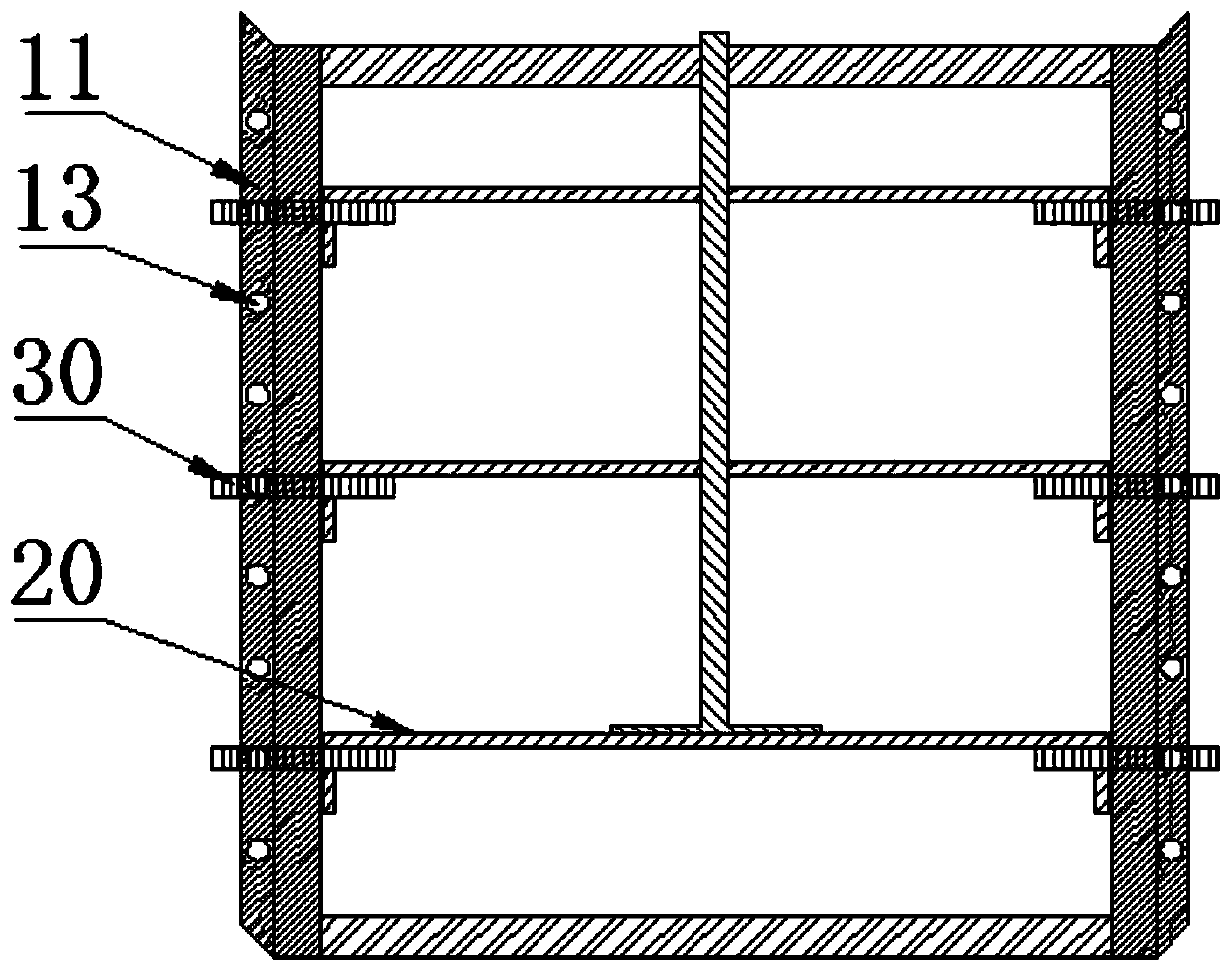

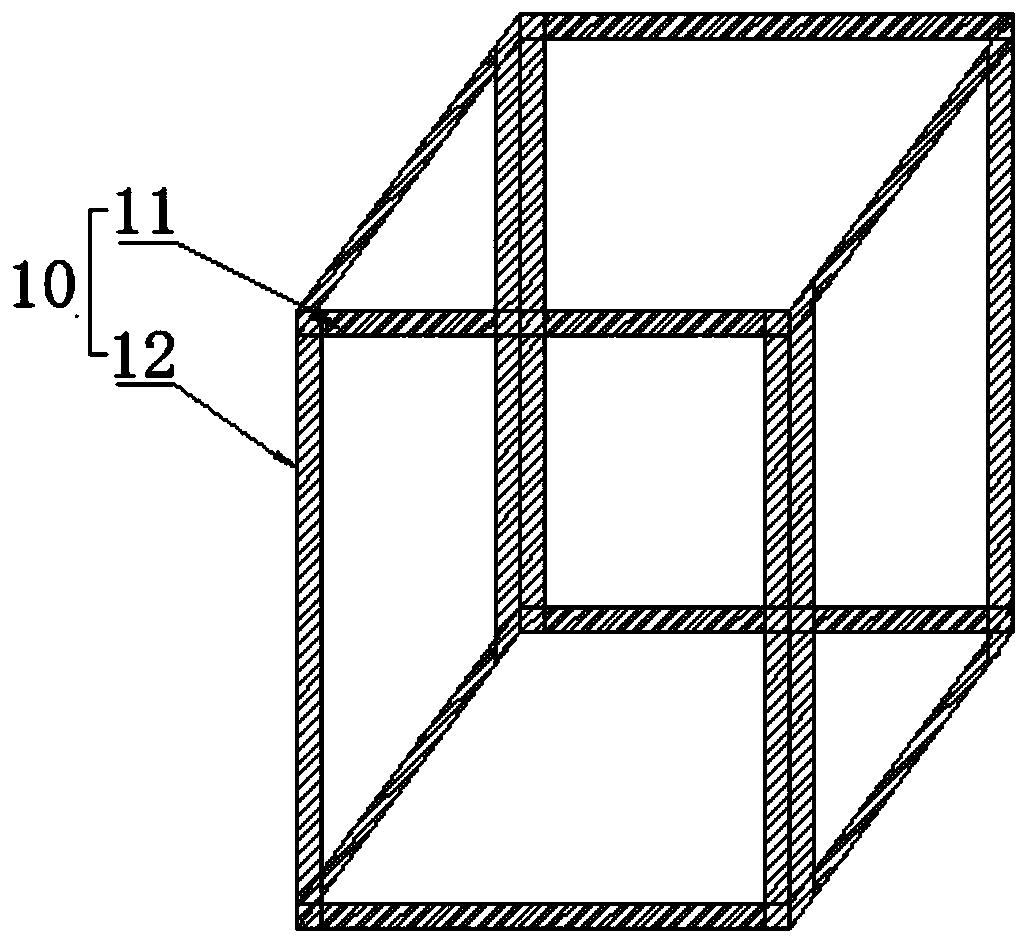

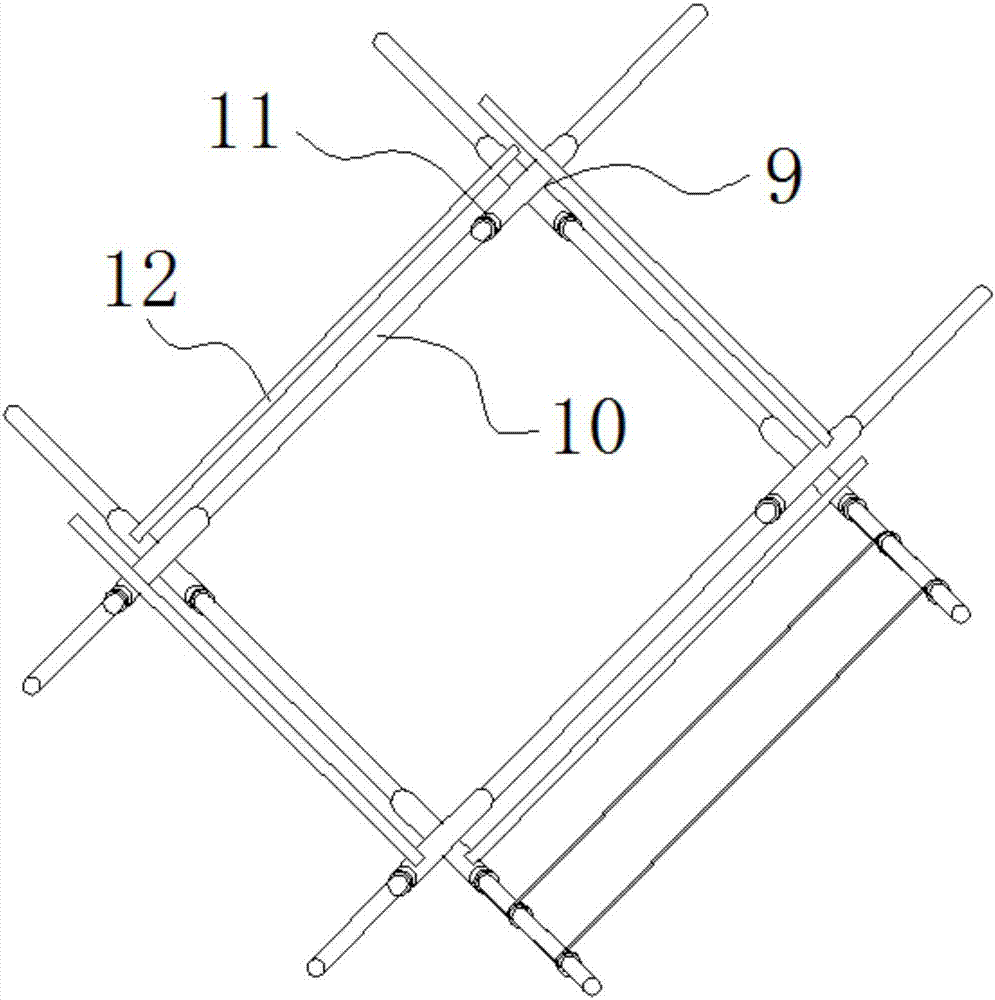

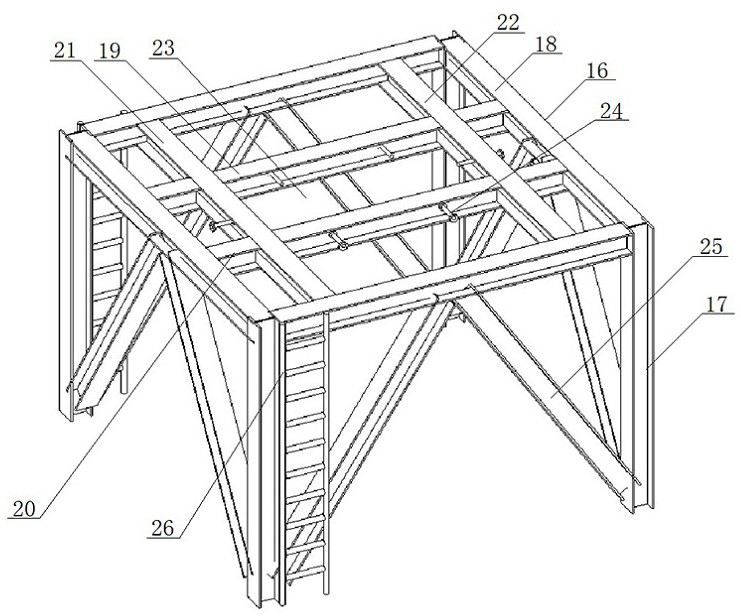

Perpendicularity adjusting device for one-pile two-column construction and using method

PendingCN112761186AVerticality adjustmentPrecise verticalityArtificial islandsUnderwater structuresMechanical engineeringSteel tube

The invention relates to a perpendicularity adjusting device for one-pile two-column construction and a using method. The perpendicularity adjusting device comprises a base, a perpendicularity adjusting disc and a perpendicularity adjusting frame, wherein the base is used for being fixed to a pile hole opening and is rectangular, an avoiding hole corresponding to a pile hole is formed in the center of the base, the perpendicularity adjusting disc is placed on the base, the perpendicularity adjusting disc is number sign-shaped and comprises a first adjusting frame and positioning frames, double steel pipe columns can penetrate through the first adjusting frame, the positioning frames are fixed to the side edges of the first adjusting frame, first adjusting bolts for adjusting the perpendicularity of the double steel pipe columns are arranged on the first adjusting frame, second adjusting bolts for adjusting the flatness of the perpendicularity adjusting disc are arranged on the positioning frames, the first adjusting frame is arranged corresponding to the avoiding hole, the perpendicularity adjusting frame comprises supporting legs fixed to the base and an adjusting frame fixed to the upper portions of the supporting legs, the adjusting frame comprises a second adjusting frame vertically corresponding to the first adjusting frame, and a third adjusting bolt used for adjusting the perpendicularity of the double-steel-pipe column is arranged on the second adjusting frame. According to the perpendicularity adjusting device, the perpendicularity adjusting precision of the double-steel-pipe column is ensured.

Owner:CHINA CONSTR SEVENTH ENG DIVISION CORP LTD +1

Roundness control tool for stripe ring

ActiveCN105290821AImprove machining accuracyImprove processing efficiencyMilling equipment detailsPositioning apparatusEngineeringNotching

The invention discloses a roundness control tool for a stripe ring. The roundness control tool comprises an end face milling tool and a vertical face milling tool. The end face milling tool comprises a base, a fixing plate and a supporting plate. A sliding groove is formed in the base. The supporting plate is connected to the sliding groove in a sliding manner. The fixing plate is fixed to the base. Notches are formed in the two ends of the upper portion of the fixing plate respectively. First circular arc benchmark faces are formed by the bottom faces of the notches, and end face benchmark faces are formed by the side faces of the notches. Second circular arc benchmark faces are formed at the two ends of the upper portion of the supporting plate respectively. The fixing plate and the supporting plate are parallel. The notches are formed in the plane, back to the supporting plate, of the fixing plate. The vertical milling tool comprises a splicing plate and a plurality of joint plates. The surface of the splicing plate is provided with protruding circular ring guide rails, and arc guide grooves are formed in the joint plates. The joint plates are connected to the splicing plate in a sliding manner, and the circular ring guide rails are located in the arc guide grooves. The end face milling tool and the vertical face milling tool are used for installing and fixing stripe blocks to be machined for milling, and the machining precision of the stripe ring is improved.

Owner:软控联合科技有限公司

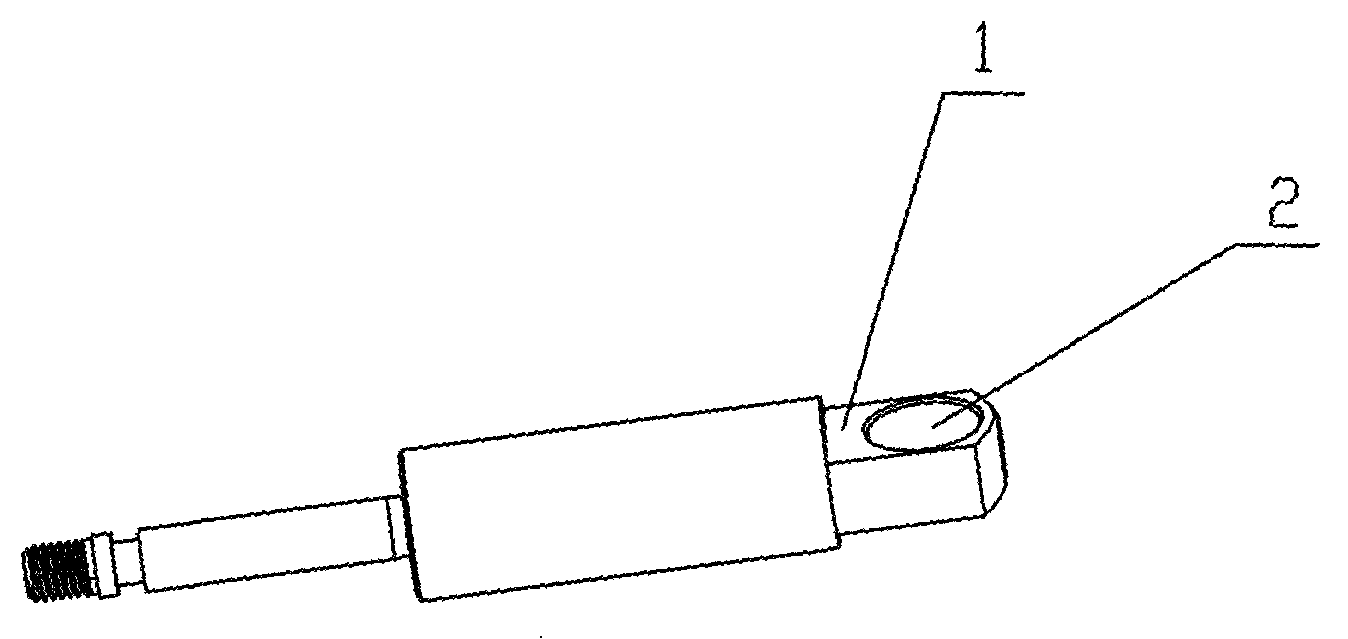

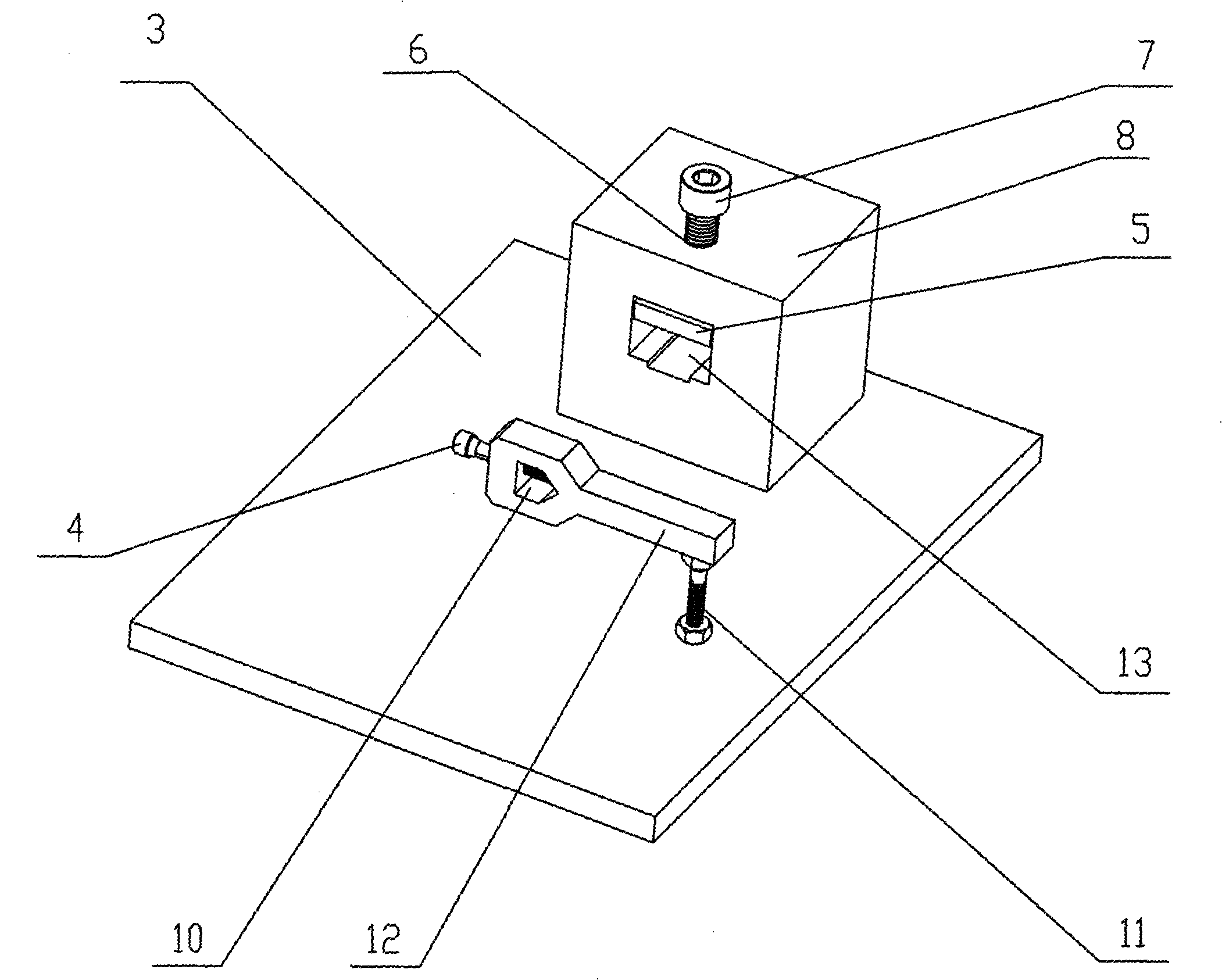

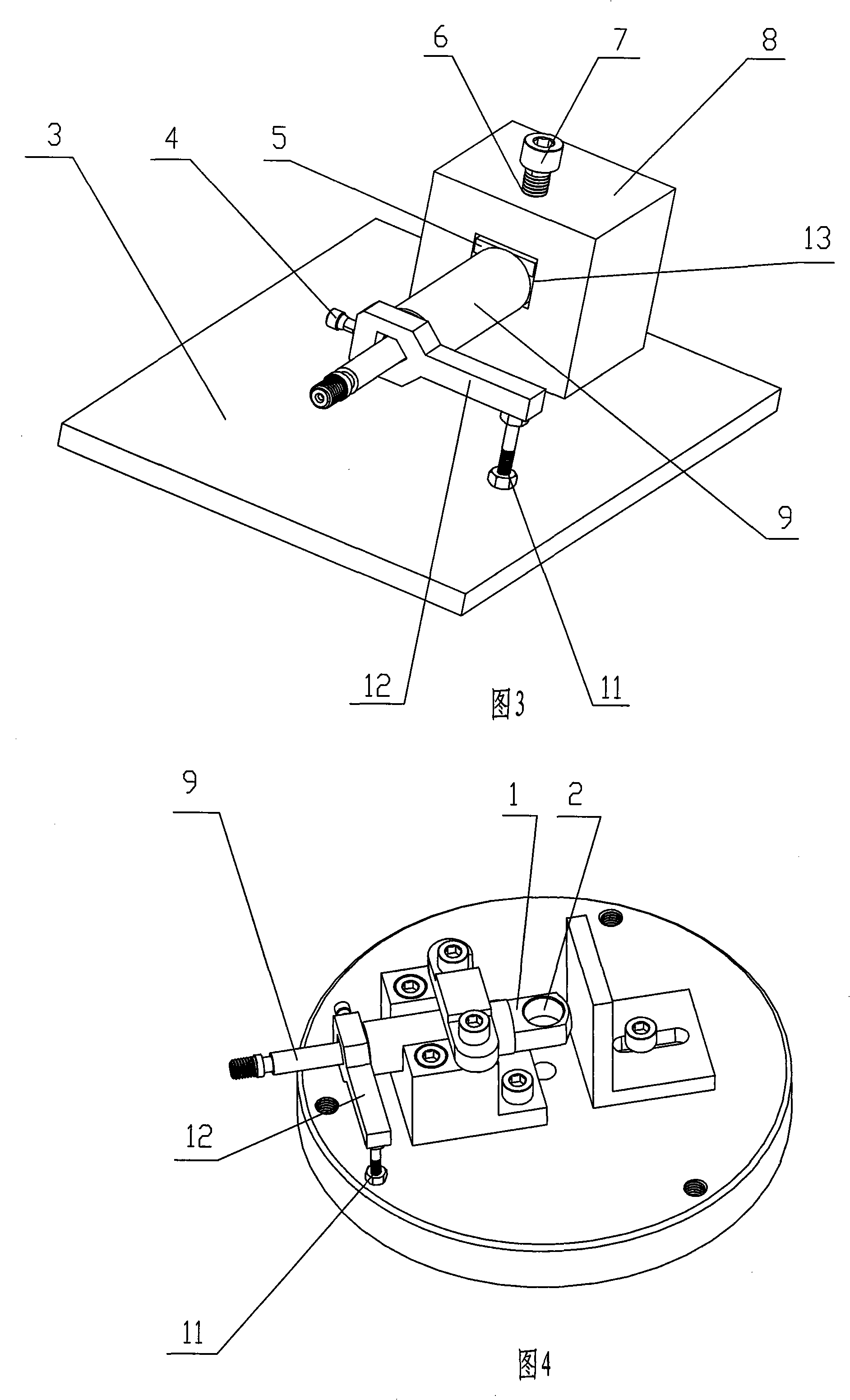

Plunger piston borehole positioning apparatus

InactiveCN101474753BPrecise verticalityPositioning apparatusMetal-working holdersEngineeringMechanical engineering

The present invention discloses a plunger piston boring positioning device which comprises an angular positioning block (12) installed with a through hole (10) and a verticality positioning block (8) connected with the base board (3). The left end of angular positioning block (12) is connected with a positioning screw I(4). The base of right end of angular positioning block (12) is connected witha supporting screw II(2) which is detachably connected with the base board (3). One side of verticality positioning block (8) relatively to the angle positioning block (12) is installed with a concave hole (13) which is used for placing the boring end of plunger piston (9) and has a base surface and a top surface that are equally horizontal surfaces. A cushion block (5) which has a base surface parallel with the base surface and top surface of concave hole (13) is provided in the concave hole (13). The top part of verticality positioning block (8) is provided with a threaded hole (6) communicated with the concave hole (13). A screw III(7) is connected with the threaded hole (6). The base part of screw III(7) is connected with the cushion block (5). The plunger piston boring positioning device of the invention can guarantee the accurate verticality between the boring axis of processed plunger piston and the top surface and the bottom surface of boring.

Owner:NINGBO XIANGRUI MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com