Plunger piston borehole positioning apparatus

A technology of positioning device and plunger, which is applied in the direction of positioning device, clamping, support, etc., can solve the problems of inability to achieve accuracy and affect the working state of the plunger, and achieve the effect of precise verticality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

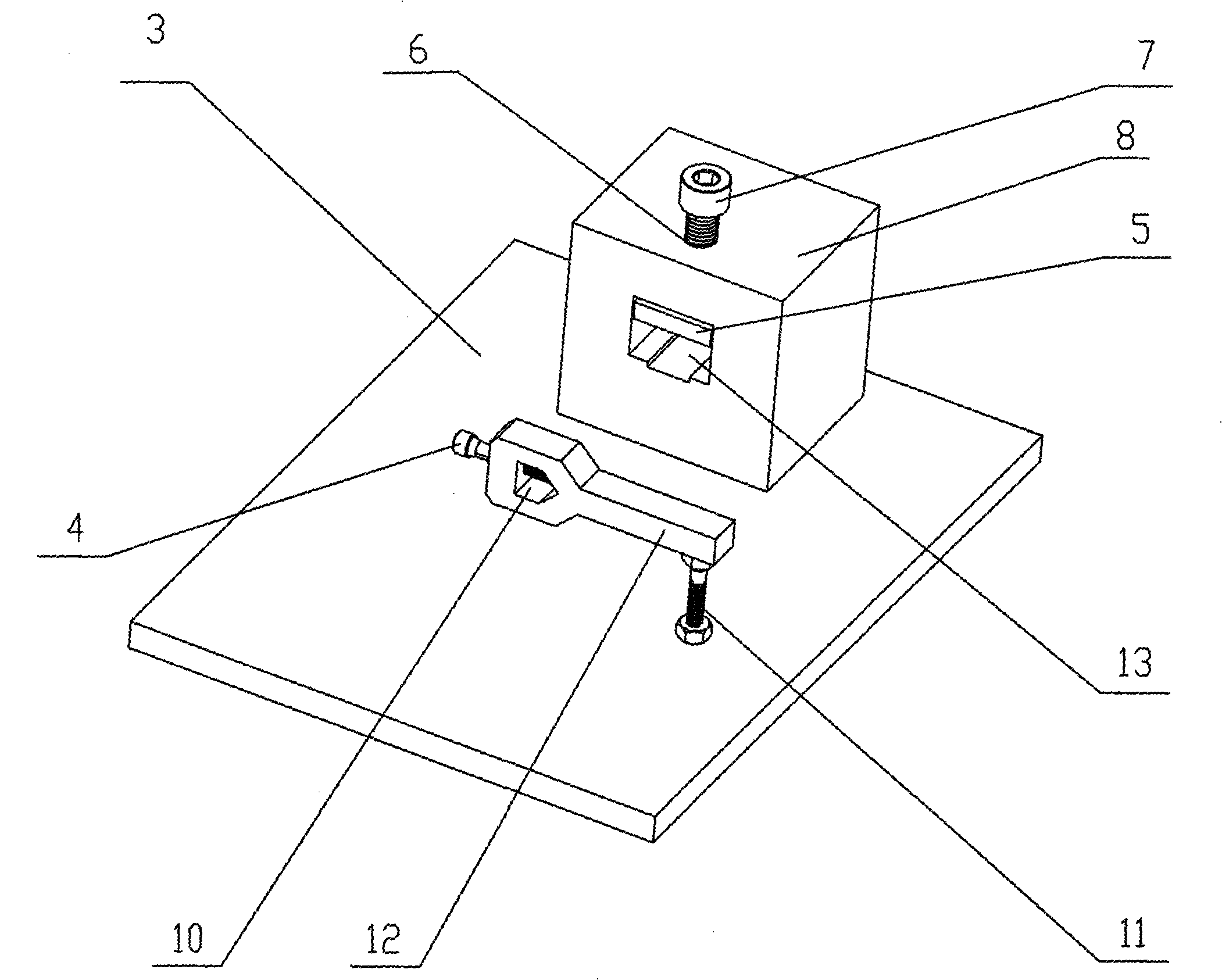

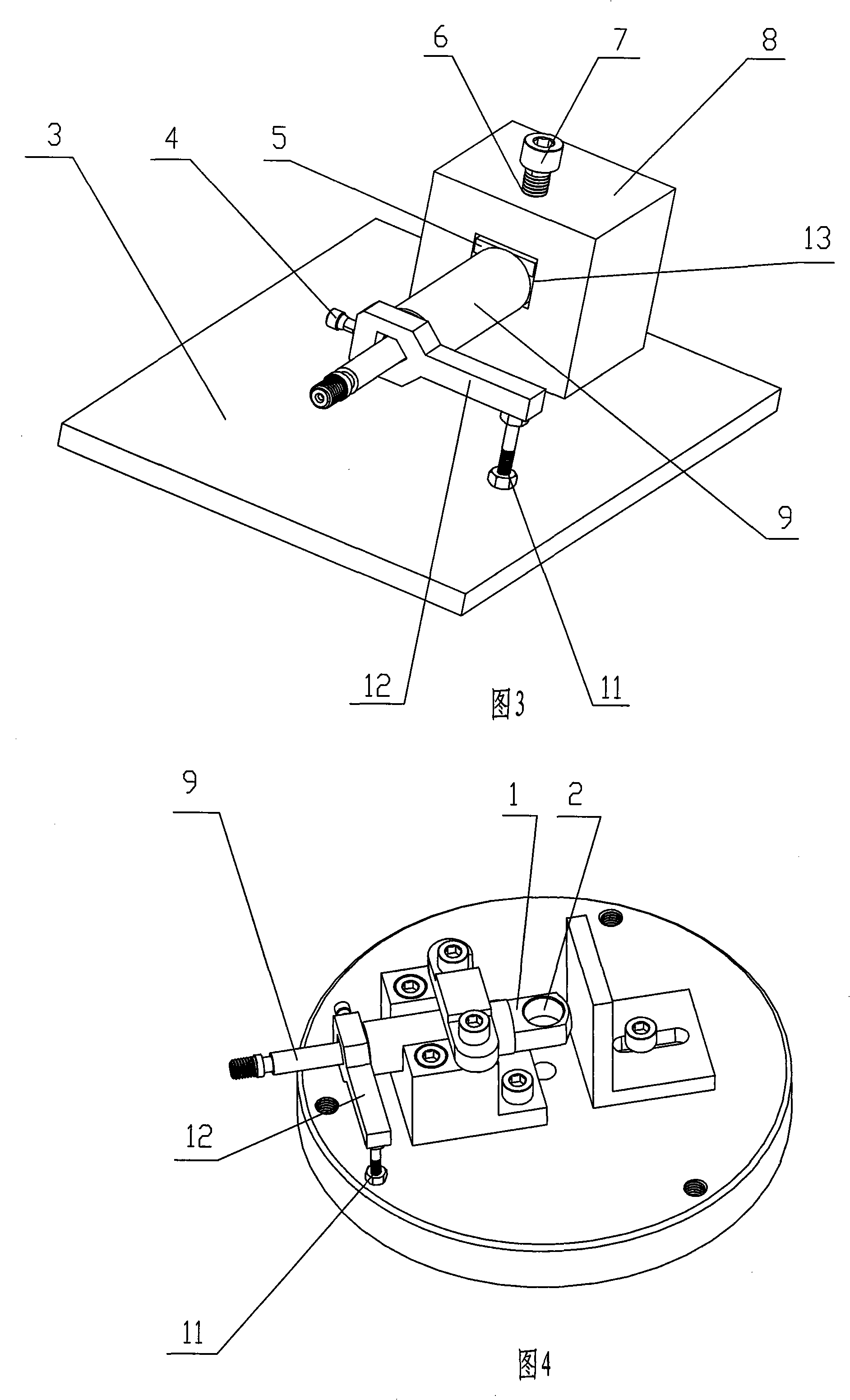

[0011] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

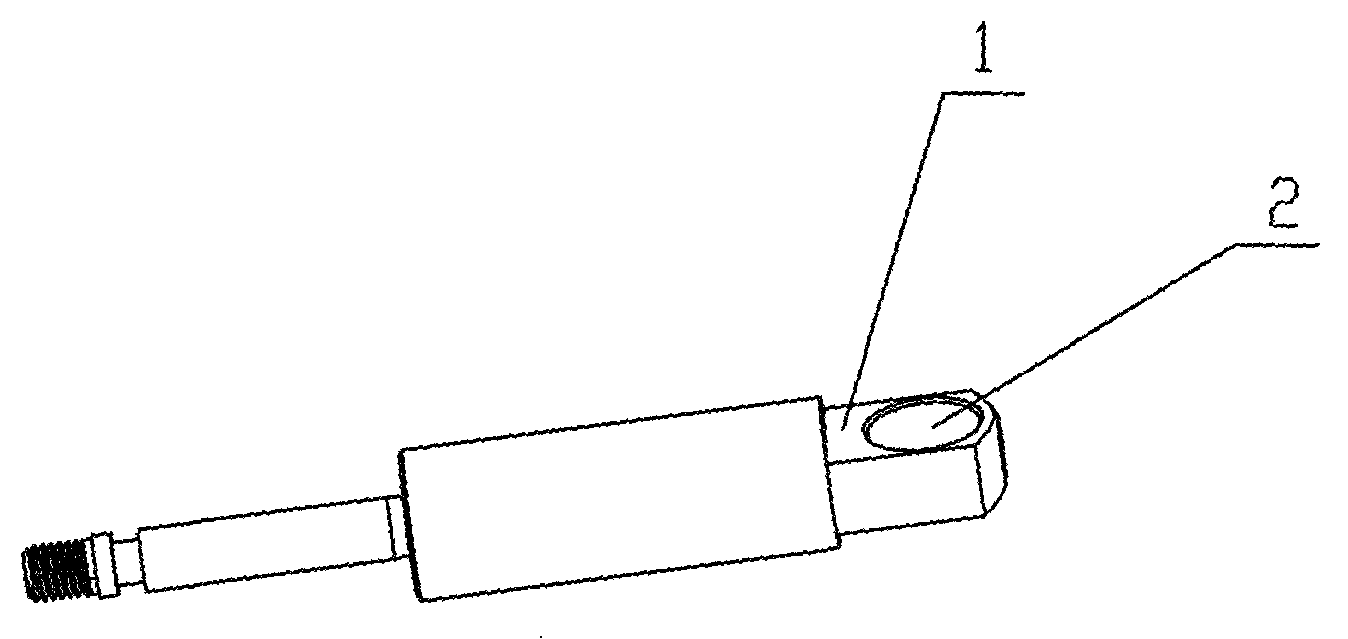

[0012] Such as figure 2 As shown in Fig. 3, in this specific embodiment, the plunger bore positioning device of the present invention includes an angular positioning block 12, a bottom plate 3 and a verticality positioning block 8 connected to the bottom plate 3; on the angular positioning block 12 There is a through hole 10 that allows the plunger rod to pass through; the left end of the angular positioning block 12 is connected with a set screw I4 that can fix the plunger 9 in the through hole 10; the right end of the angular positioning block 12 The bottom is connected with a support screw II11; the base plate 3 is provided with a threaded hole (not shown in the figure), and the bottom of the support screw II11 is screwed in the threaded hole to realize a detachable connection with the base plate 3; the vertical Degree positioning block 8 is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com