Method and device for detecting verticality of conical upright post

A technology of detection device and detection method, which is applied in measurement device, surveying and navigation, measurement of inclination and other directions, can solve the problems of inaccurate measurement results and achieve the effect of improving applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

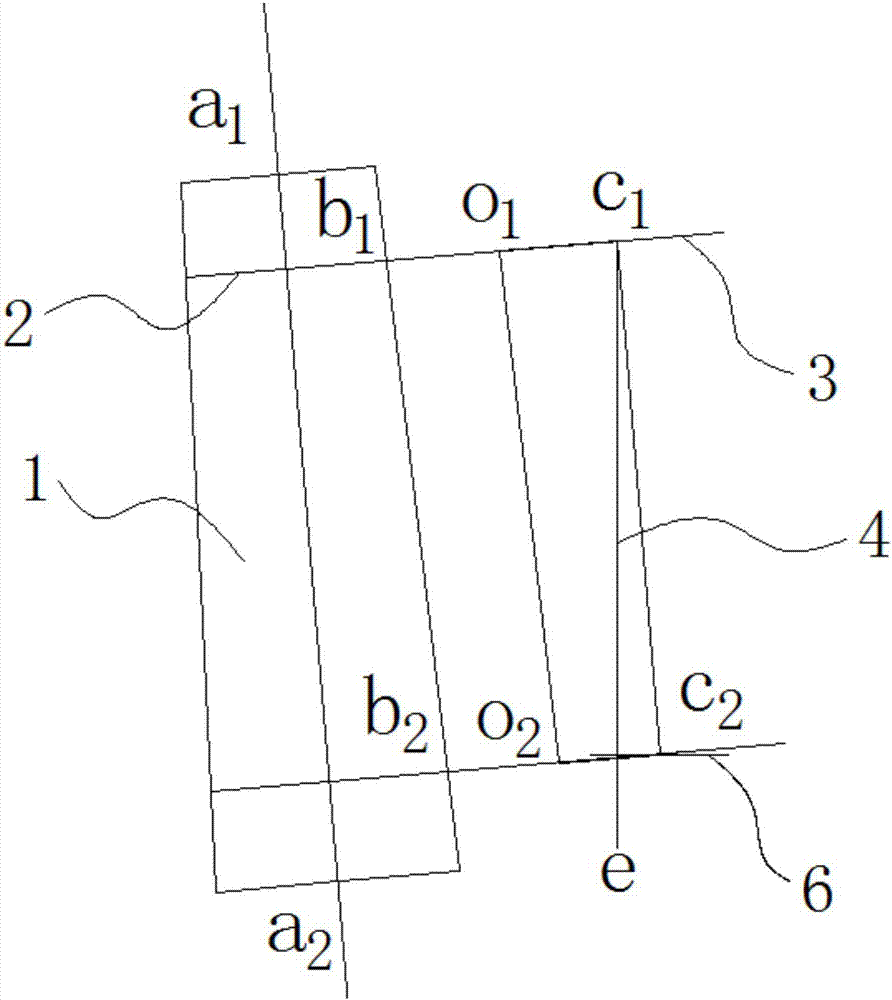

[0028] figure 1 with figure 2 A schematic diagram showing the principle of a method for detecting the verticality of a tapered column according to a preferred embodiment of the present invention, the method for detecting the verticality of a tapered column includes:

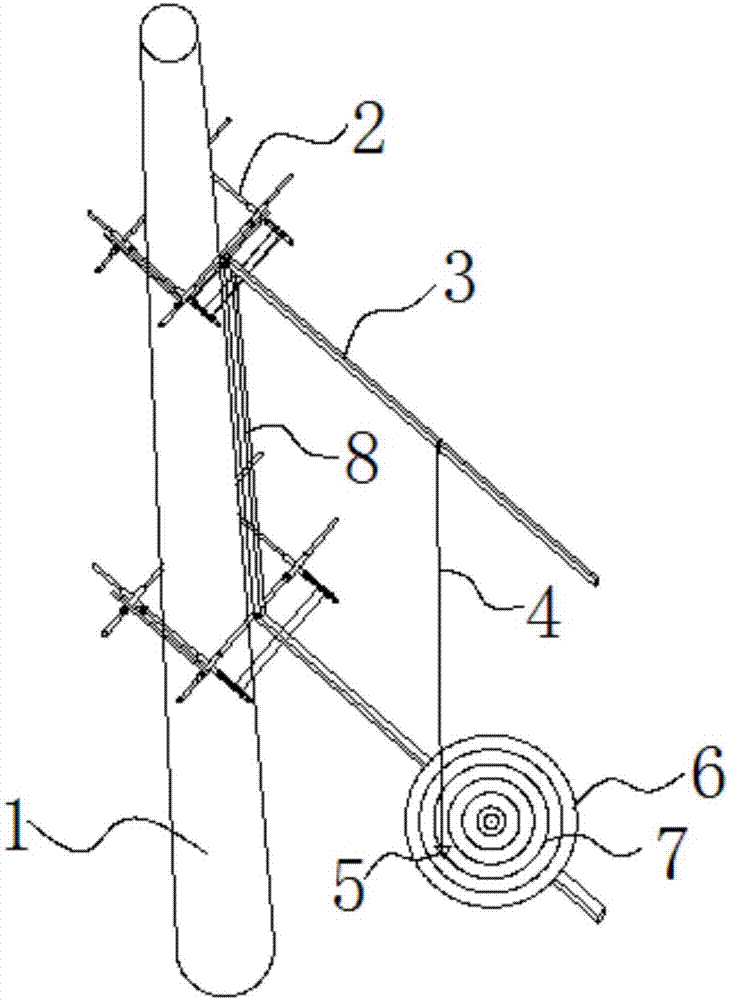

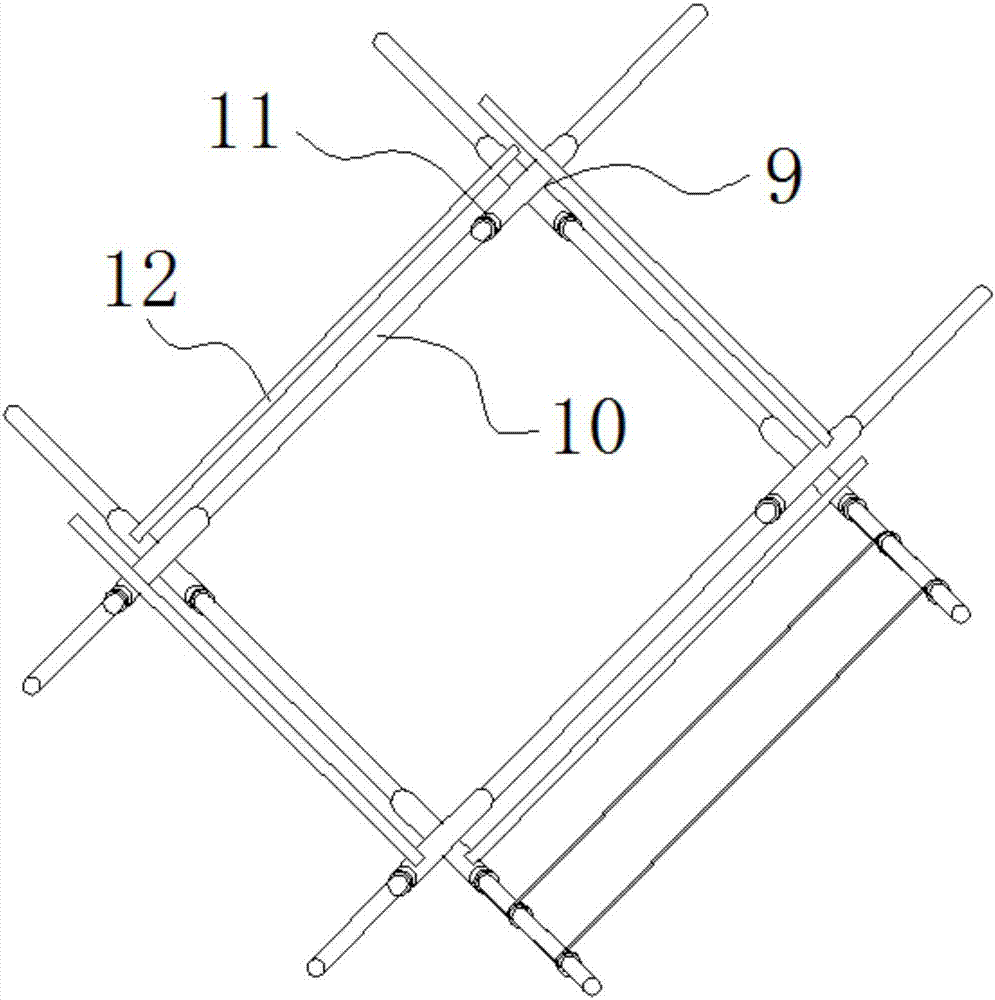

[0029] Step 1, two diameter measuring frames 2 in a square shape are fixedly installed on the tapered column 1 in a vertically distributed manner, and the side length of the lower diameter measuring frame 2 is greater than the side length of the upper diameter measuring frame 2, so that the lower The diameter measuring frame 2 is sleeved on the larger diameter position below the tapered column 1, and the upper diameter measuring frame 2 is sleeved on the smaller diameter position above the tapered column 1, and the two diameter measuring frames 2 are convenient. Can be separated by a certain distance up and down. When the two diameter measuring frames 2 are sleeved on the tapered column 1, the four sides of th...

Embodiment 2

[0035] Figure 1 to Figure 4 Shows a schematic structural view of a detection device for the verticality of a tapered column according to a preferred embodiment of the present invention, refer to figure 2 , the detection device of the verticality of the tapered column comprises two diameter measuring frames 2, two beams 3, a slide block, a dial 6 and a plumb line 4, each diameter measuring frame 2 is in a square shape; one of the diameter measuring The side length of the frame 2 is longer than the side length of the other diameter measuring frame 2. When the verticality of the tapered column 1 is detected, the two diameter measuring frames 2 are sleeved on the tapered column 1 in parallel up and down. The four sides are aligned one by one, and the midpoint of each side of each diameter measuring frame 2 is in contact with the surface of the tapered column 1, so that the diameter measuring frame 2 is perpendicular to the axis a of the tapered column 1 1 a 2 , and at this tim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com