Pile holding frame, and high-rise pile cap foundation installation system suitable for very shallow water areas

A technology of pile frame and base body is applied in the field of high pile cap foundation installation system, which can solve the problems of high cost and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

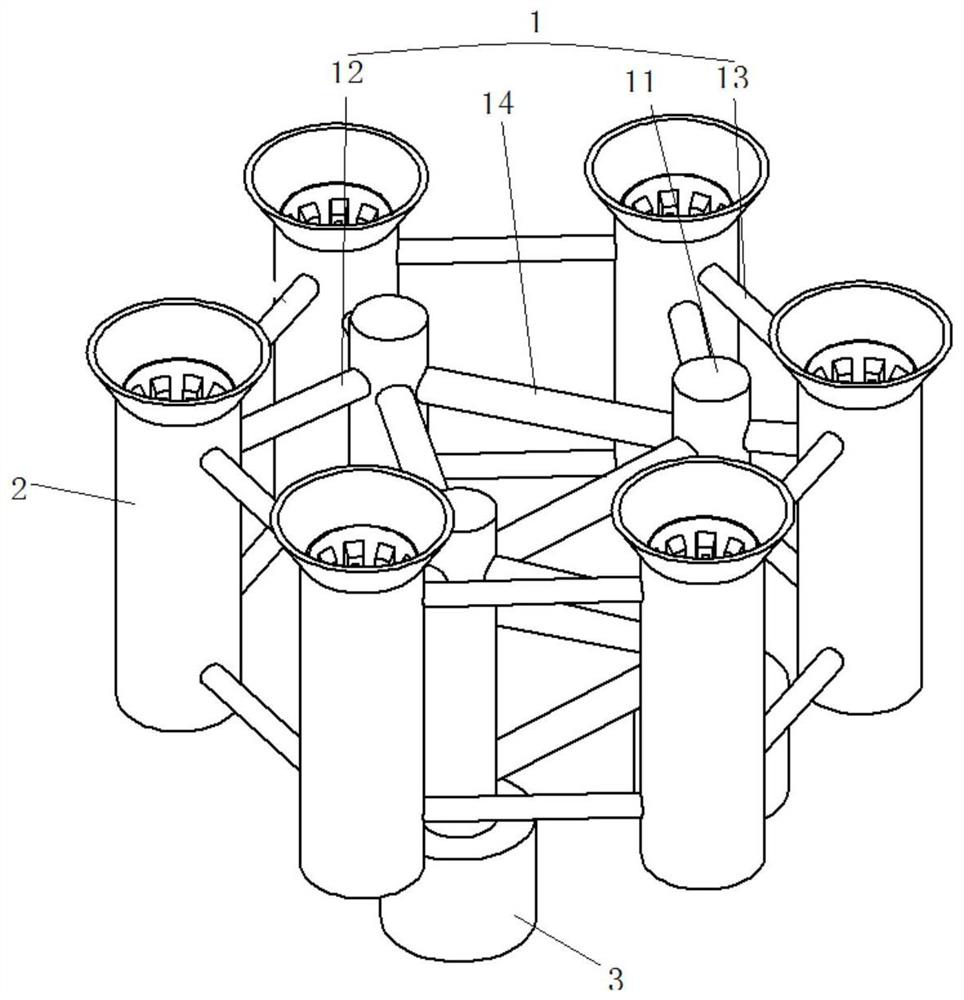

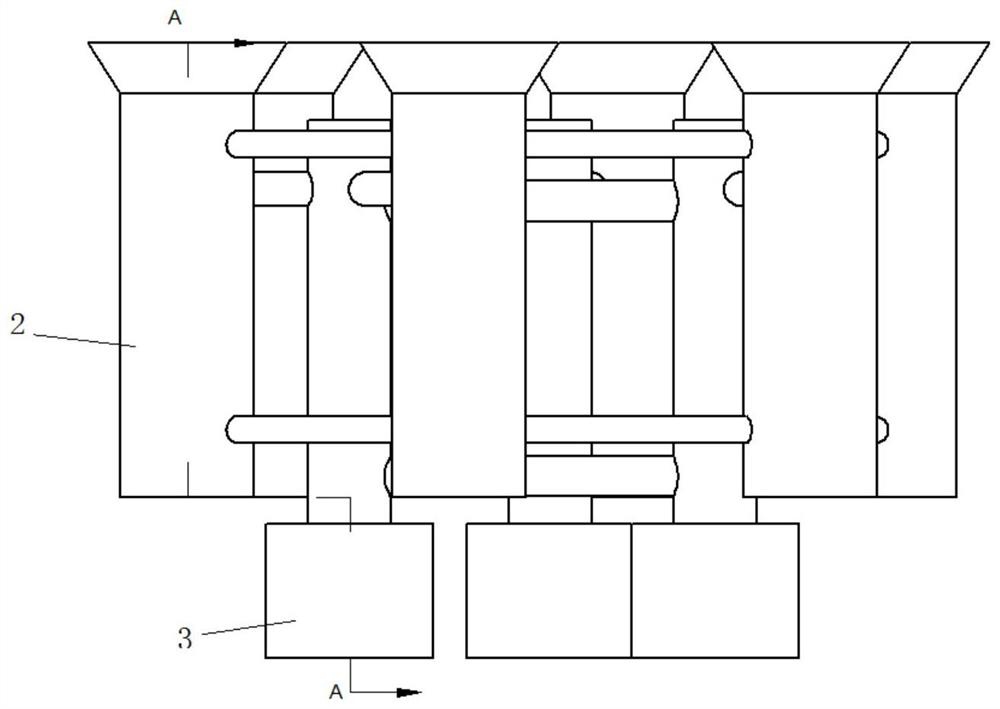

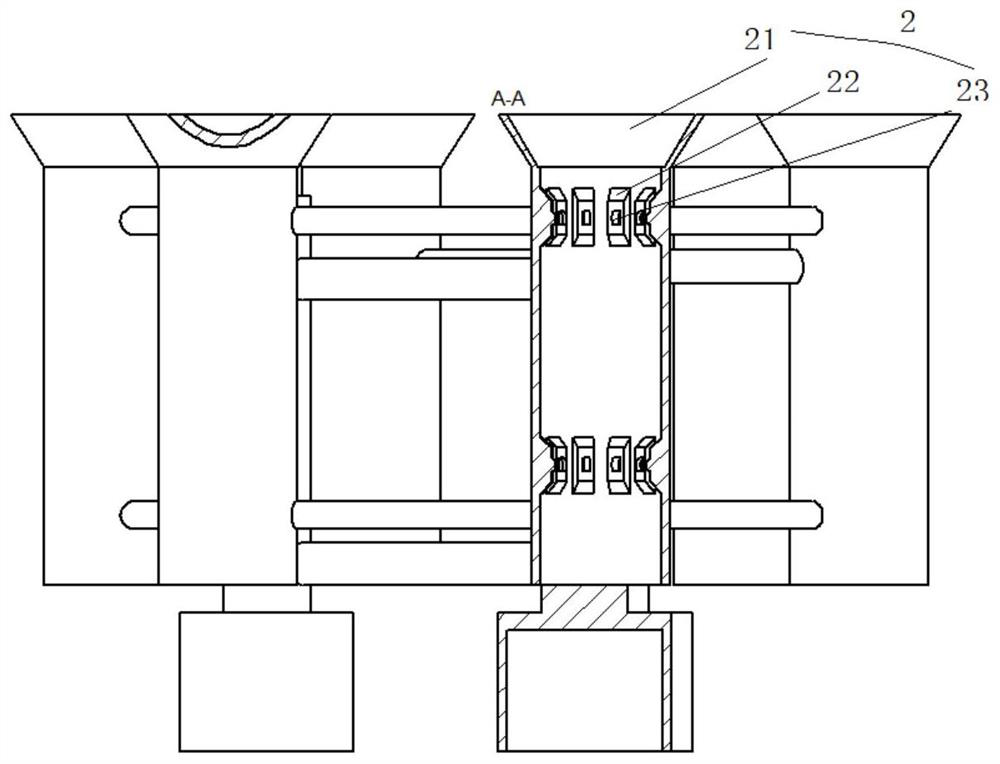

[0037] Such as Figure 1 to Figure 4 As shown, a pile holding frame provided for this embodiment includes: a base body 1; and several guide cylinders 2 and negative pressure cylinders 3 respectively arranged on the base body 1; wherein the negative pressure cylinder 3 is located below the guide cylinder 2, and It is set in a misplaced position with the guide cylinder 2. The pile-holding frame in this embodiment utilizes the negative pressure cylinder 3 to fix the pile-holding frame as a whole during use. After the negative-pressure cylinder 3 has fixed the pile-holding frame, the guide cylinder 2 can be used to install steel piles, etc., to realize The positioning function is realized for the pile sinking in the high pile cap foundation, so as to facilitate the construction of the high pile cap foundation.

[0038] The working principle of the negative pressure cylinder 3 is to extract the water and air in the cylinder to the outside, so as to gradually reduce the pressure in...

Embodiment 2

[0051] This embodiment provides a high pile cap foundation installation system suitable for extremely shallow waters, including the pile holding frame described in any one of the above embodiments, and has all its technical advantages, which will not be repeated here A repeat.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com