Light composite slat system and construction method thereof

A technology of composite slats and construction methods, which is applied to building components, walls, buildings, etc., can solve the problems of cumbersome, time-consuming and labor-intensive construction of exterior walls, and achieve the effects of fast construction, improved air permeability, and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

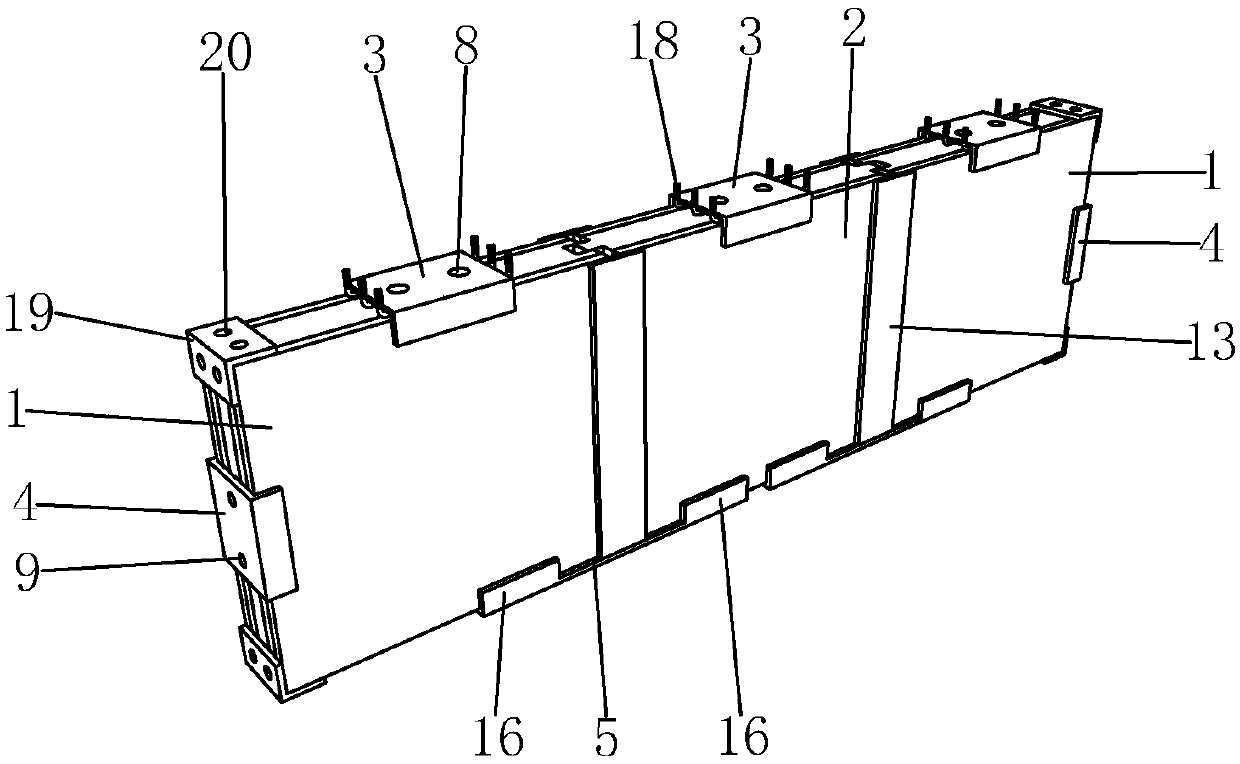

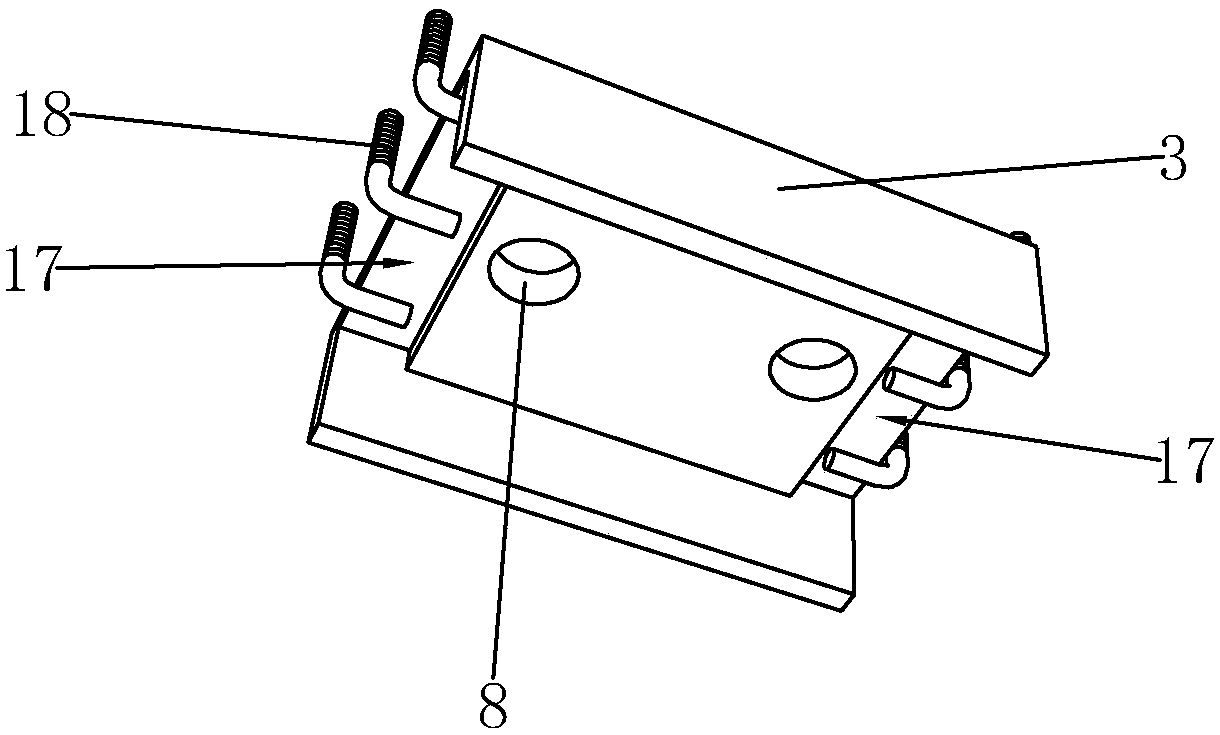

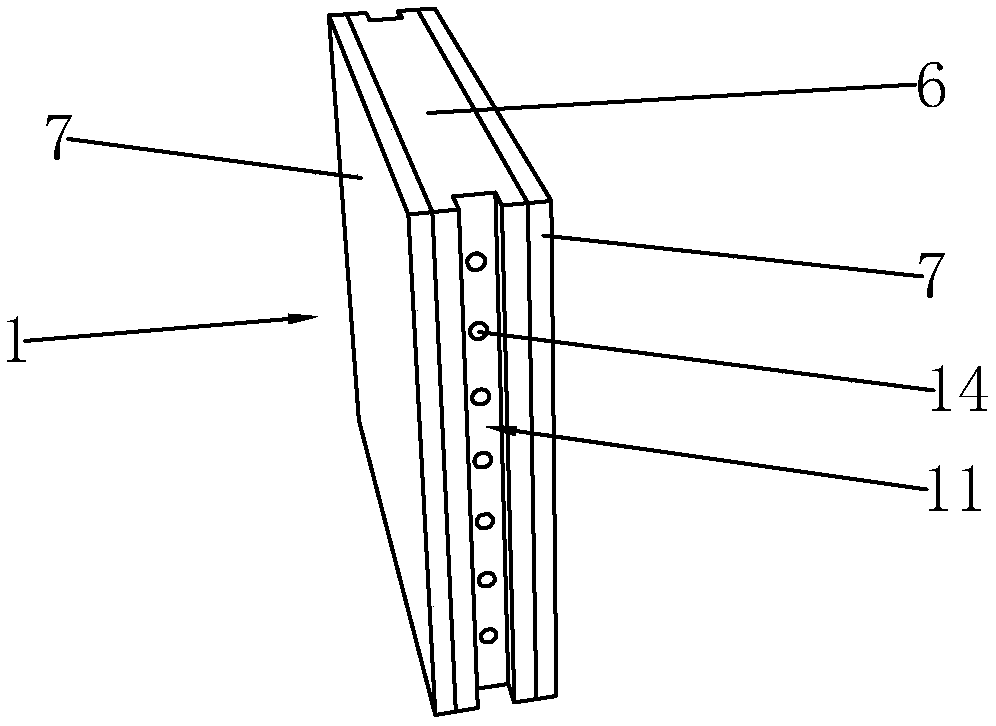

[0031] Such as Figure 1 to Figure 5 As shown, it is a lightweight composite strip system of the present invention, including a first strip 1, a second strip 2, a U-shaped top block 3, a U-shaped side block 4 and a supporting bottom block 5, the first strip The board 1 and the second board 2 have the same thickness. The first board 1 and the second board 2 both include an ALC board 6 and a fiber cement board 7. The fiber cement board 7 is arranged on the upper and lower sides of the ALC board 6. The self-adhesiveness of the foam organically combines the ALC board 6 and the fiber cement board 7 to form a whole. ALC board 6 has the characteristics of light bulk density, high strength, good thermal insulation, good sound insulation, good fire resistance, and good durability. Fiber cement board 7 has fire insulation, waterproof and moisture-proof, heat insulation and sound insulation, light weight, high strength, The characteristics of long service life, machinability and good pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com