Lattice pillar component and mounting method thereof

A lattice column and component technology, applied in the directions of columns, piers, pillars, etc., can solve the problems of insufficient installation strength, large overall deformation, rotation and torsion of lattice columns, and achieves reduction of overlapping vacancies, no welding deformation, The effect of reducing disturbance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

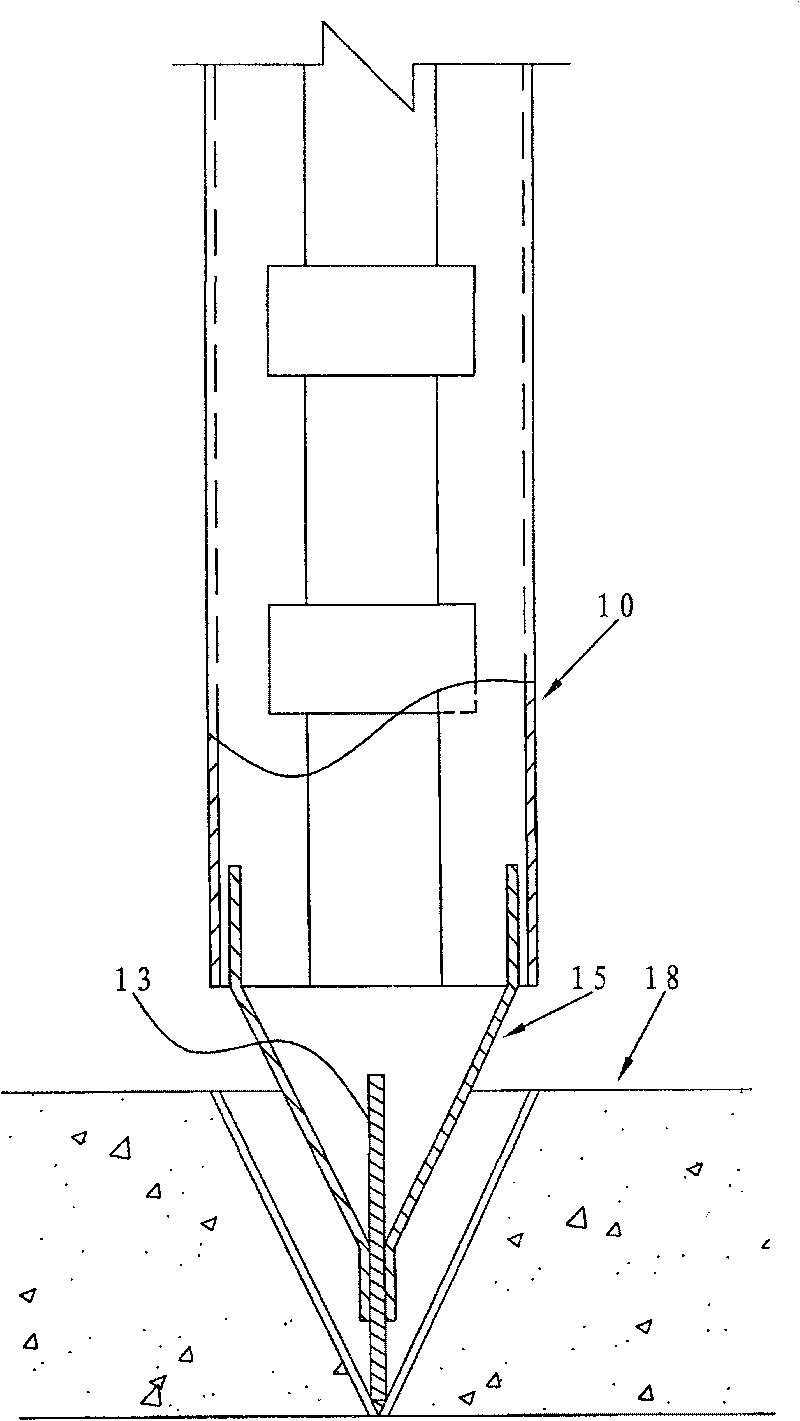

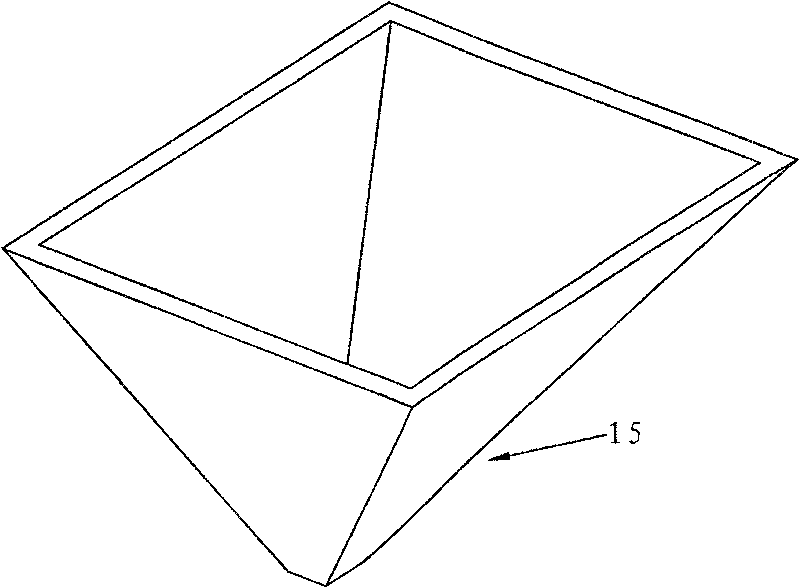

[0034] refer to Figure 4 , the figure shows the lattice column assembly provided by the present invention and its installation state. The lattice column assembly includes a lattice column 30 , a bottom positioner 20 and a top positioner 40 .

[0035] The above-mentioned lattice column 30 is a lattice column used in piles. For example, when constructing a construction site, especially in a basement by reverse construction, first build the peripheral wall 50 of the pile and the pile core concrete 52 at the bottom, and then Then install the lattice column assembly on the pile core concrete in the retaining wall 50 .

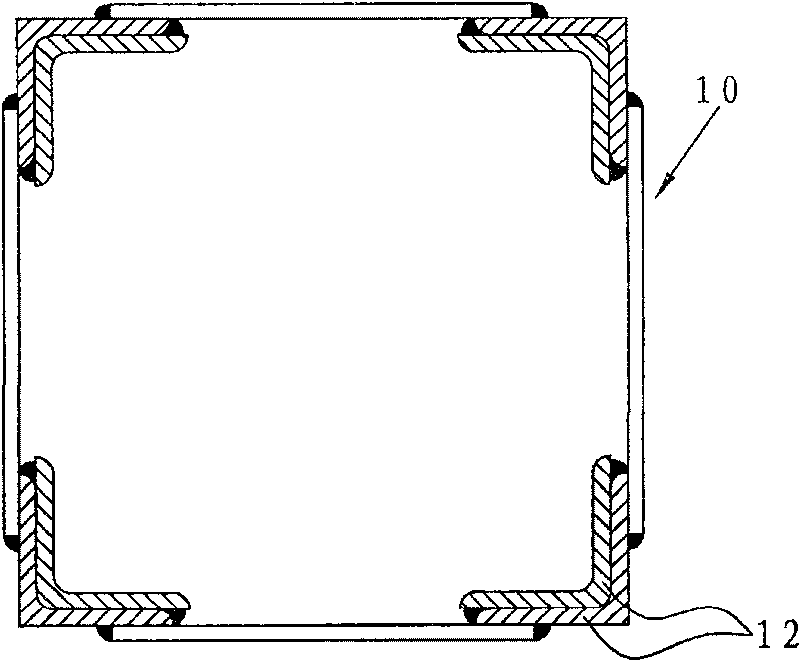

[0036] refer to Figure 5 , the figure shows the cross-sectional shape of the lattice column 30 provided by the present invention. The above-mentioned lattice column 30 is a combined frame surrounded by two or more section steel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com