Patents

Literature

69results about How to "Save axial installation space" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

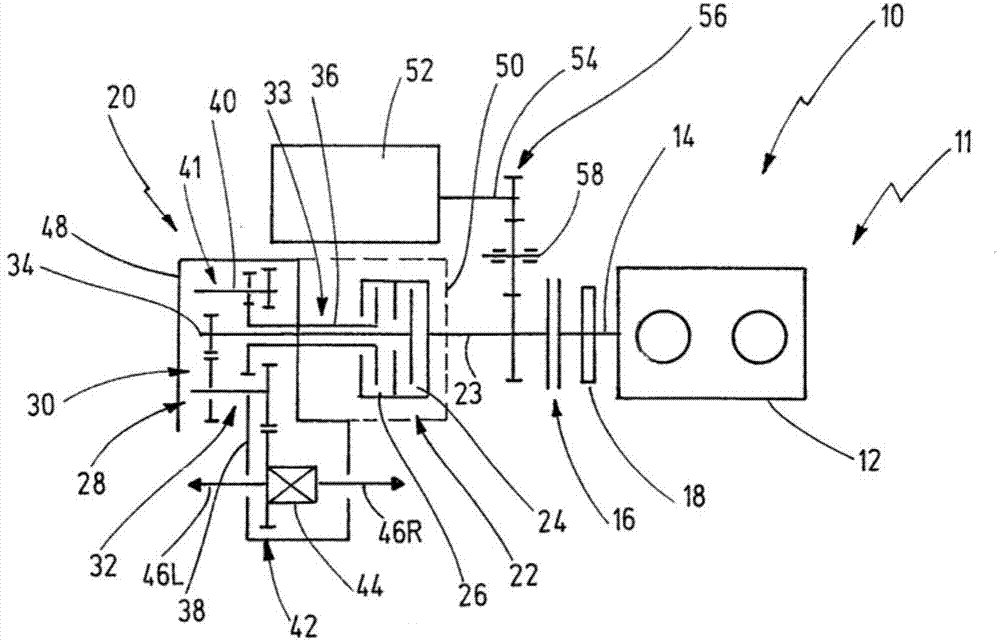

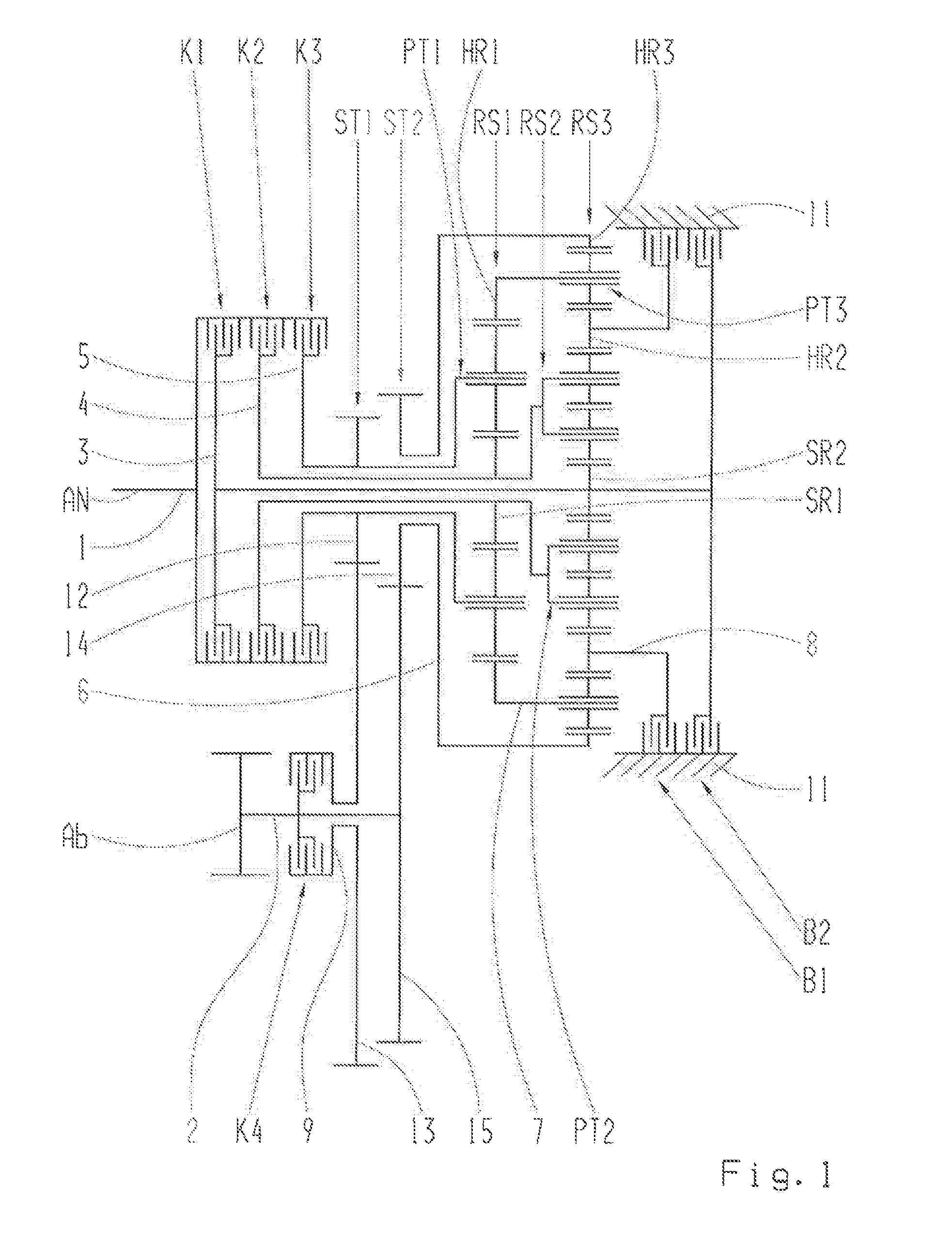

Hybrid power train for a motor vehicle

ActiveCN104723862AReduce weightSave axial installation spaceHybrid vehiclesGas pressure propulsion mountingMotor vehicle partClutch

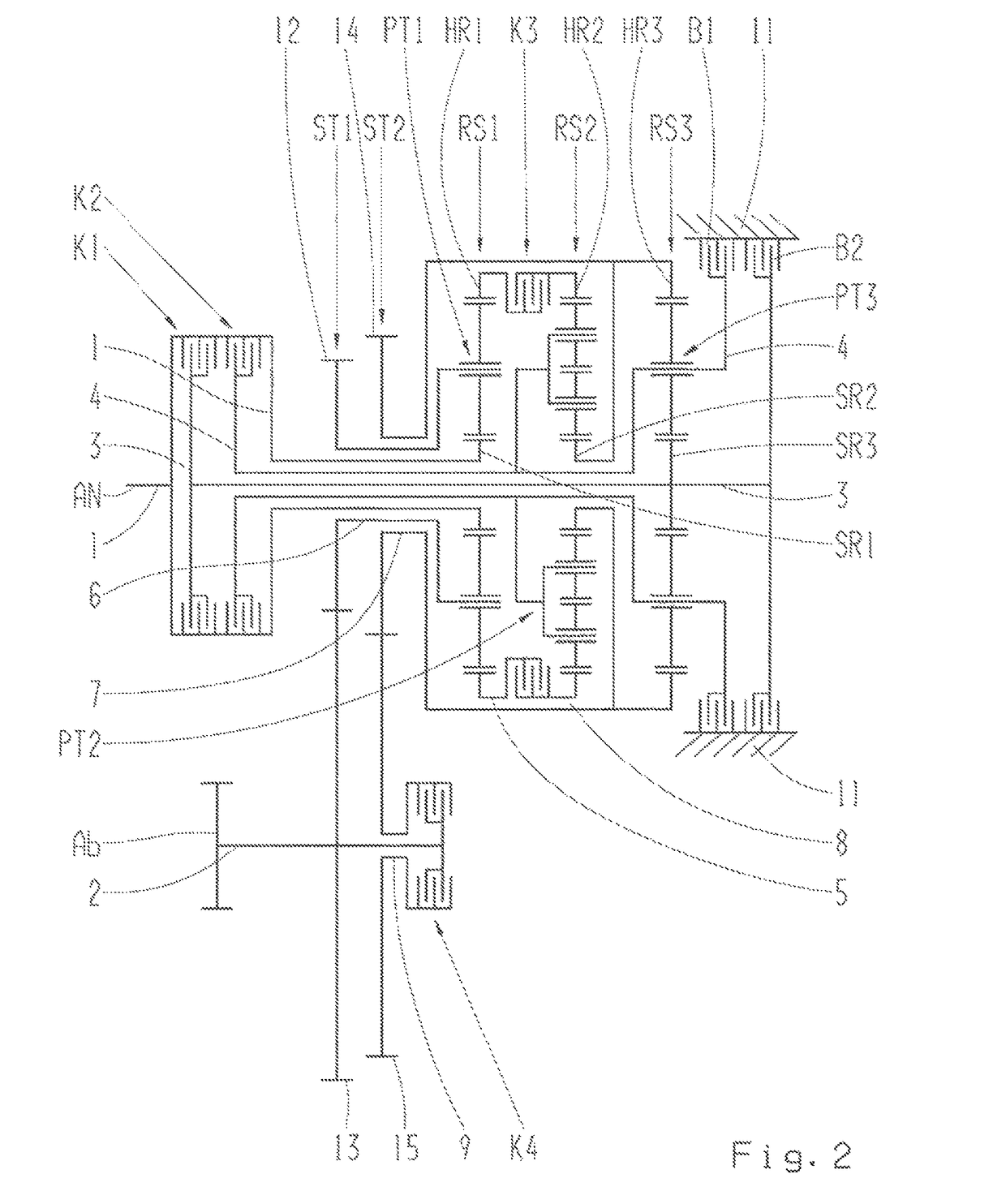

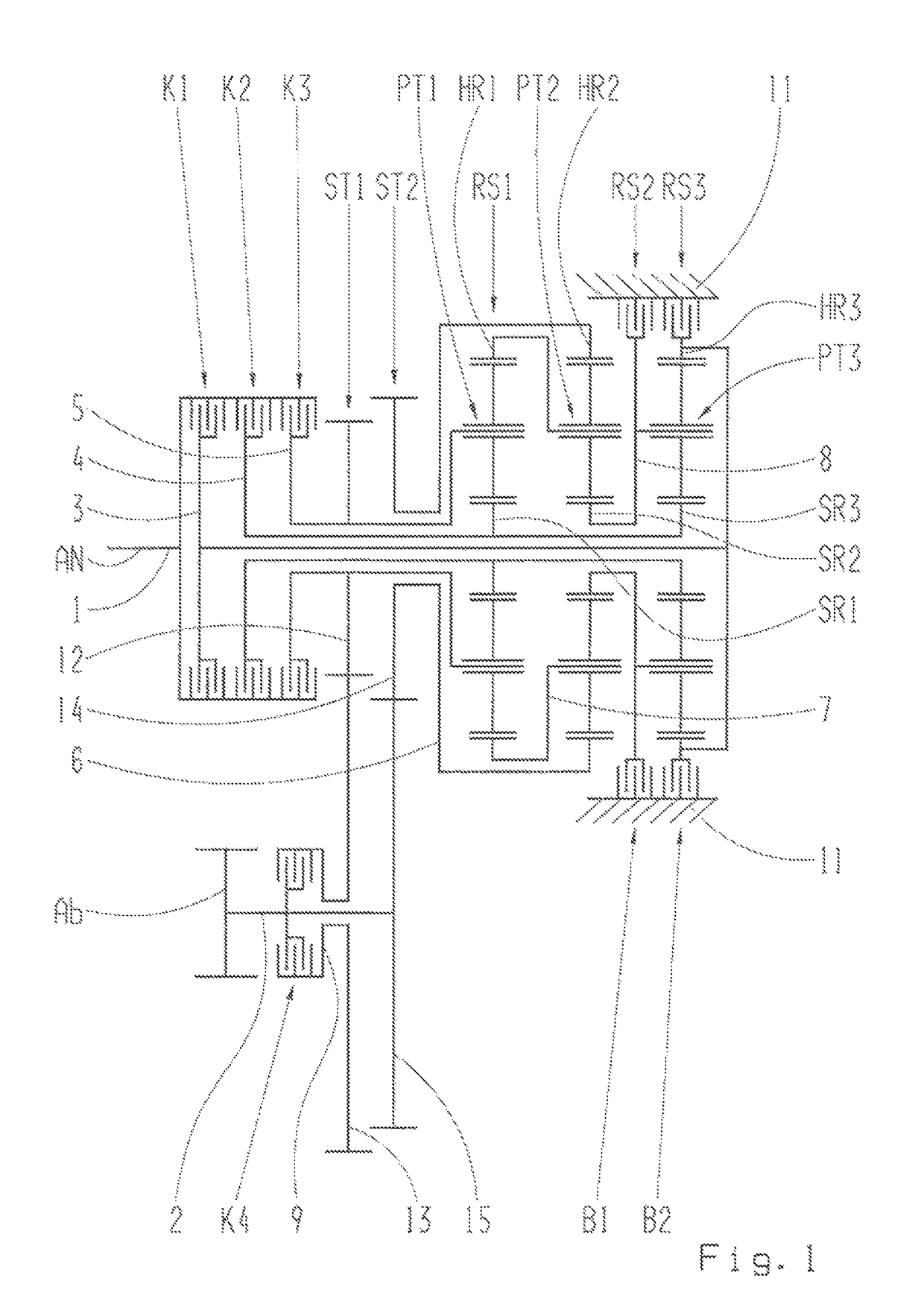

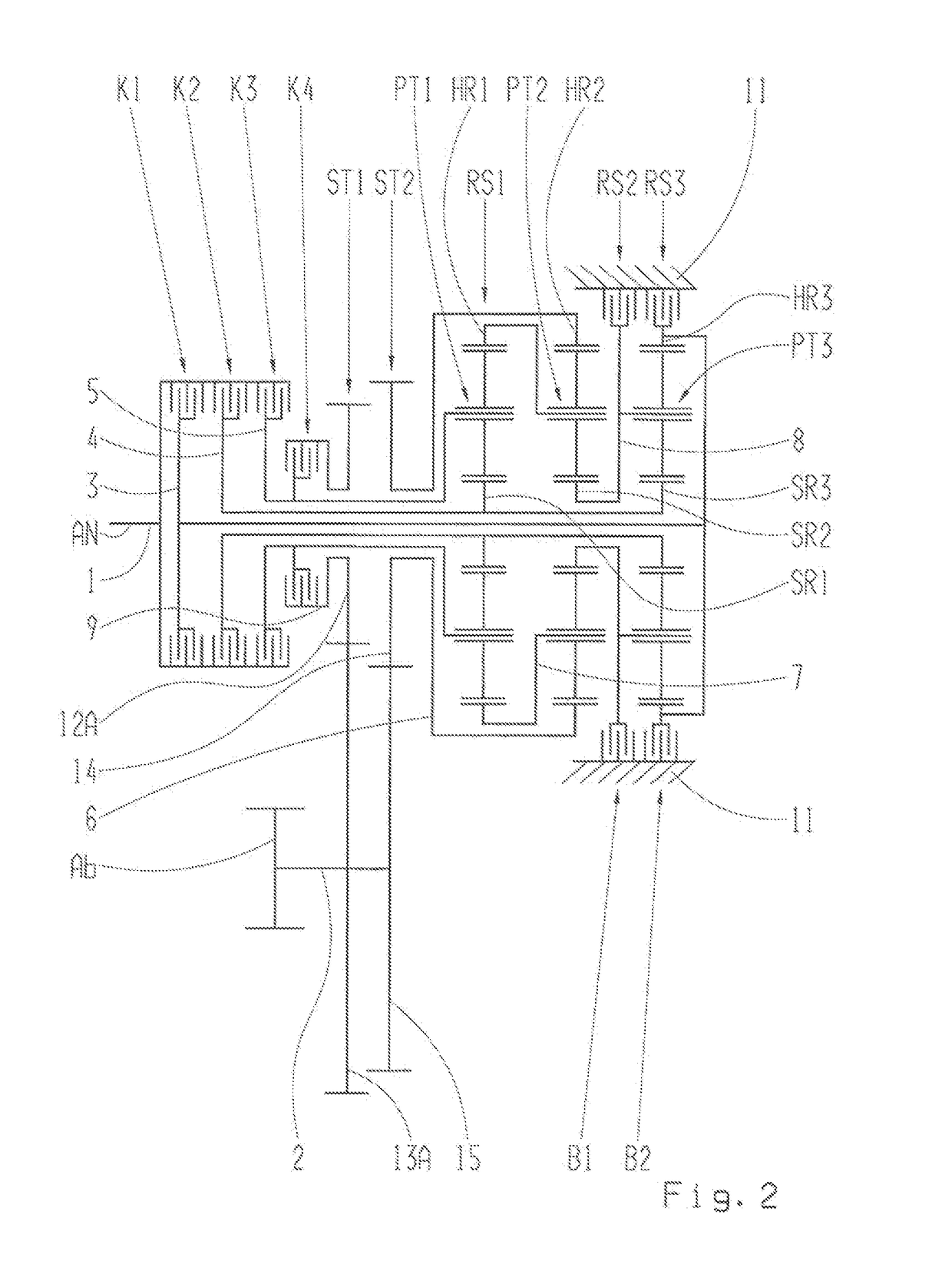

Hybrid drive train for a motor vehicle, comprising an internal combustion engine, an electric machine and a dual clutch transmission. The transmission has a dual clutch arrangement and a spur gear transmission arrangement with two part-transmissions. The spur gear transmission arrangement is configured to set exactly three forward gear stages, or is configured to set exactly four forward gear stages. The spur gear transmission arrangement being configured with three parallel shaft arrangements which are connected to one another via gear set arrangements in such a way that motive power is transmitted via at least two of the shaft arrangements, depending on the forward gear stage engaged.

Owner:GETRAG GETRIEBE & ZAHNRADFABRIK HERMANN HAGENMEYER GMBH & CO KG

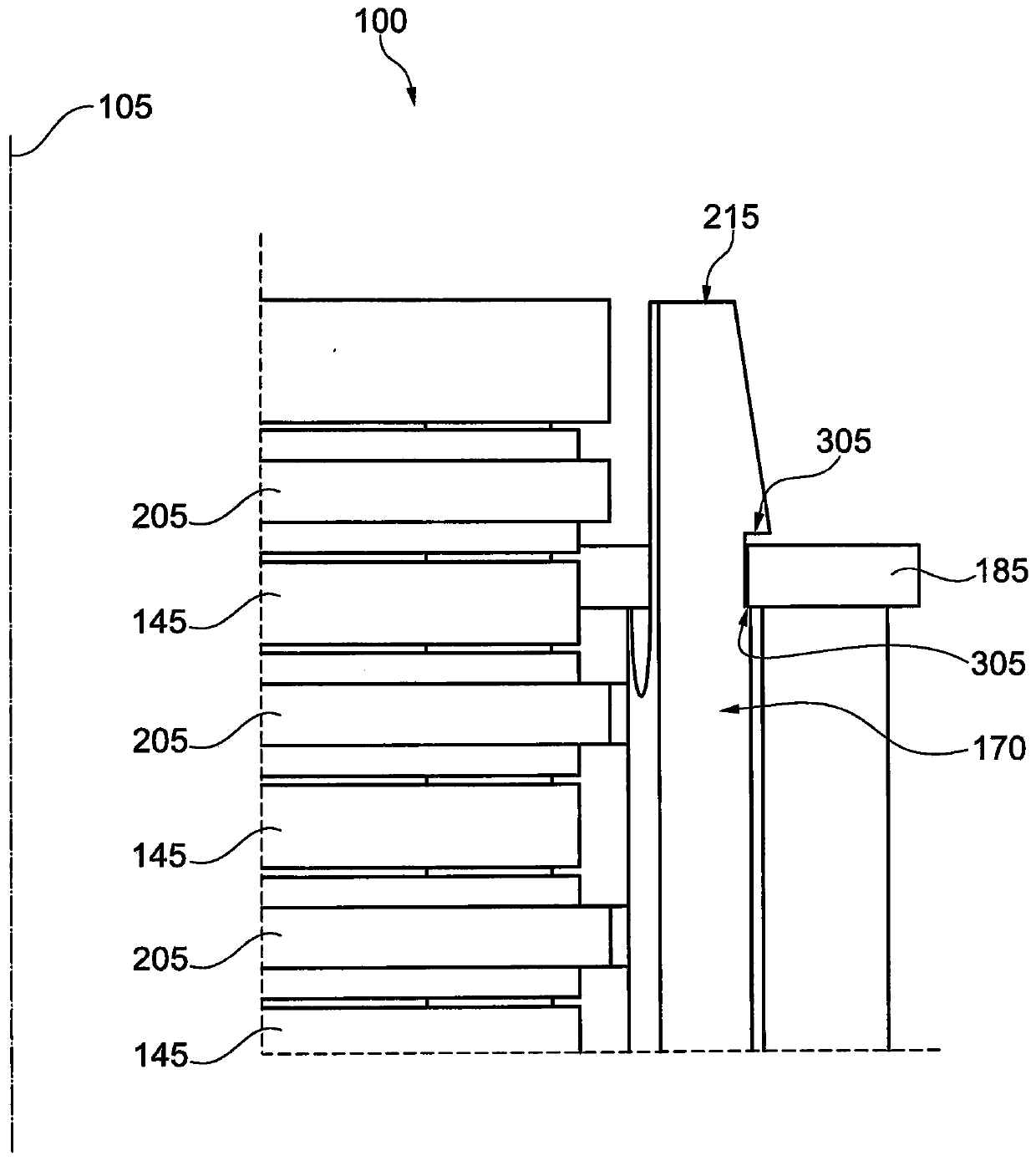

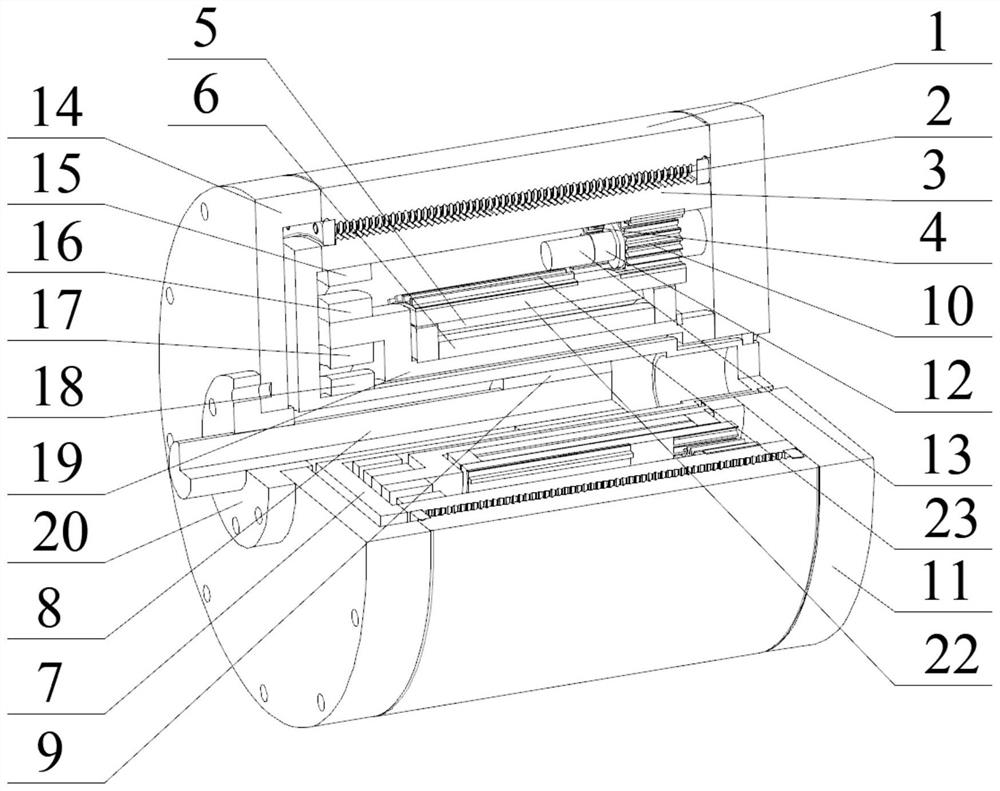

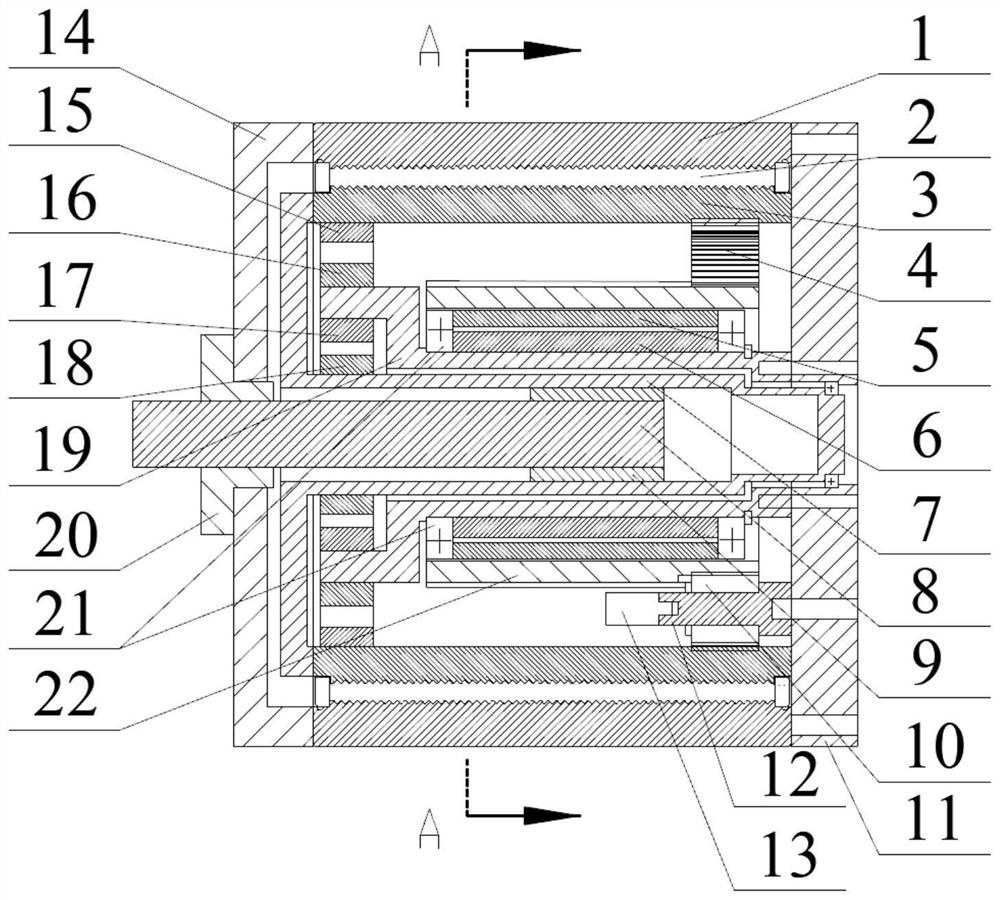

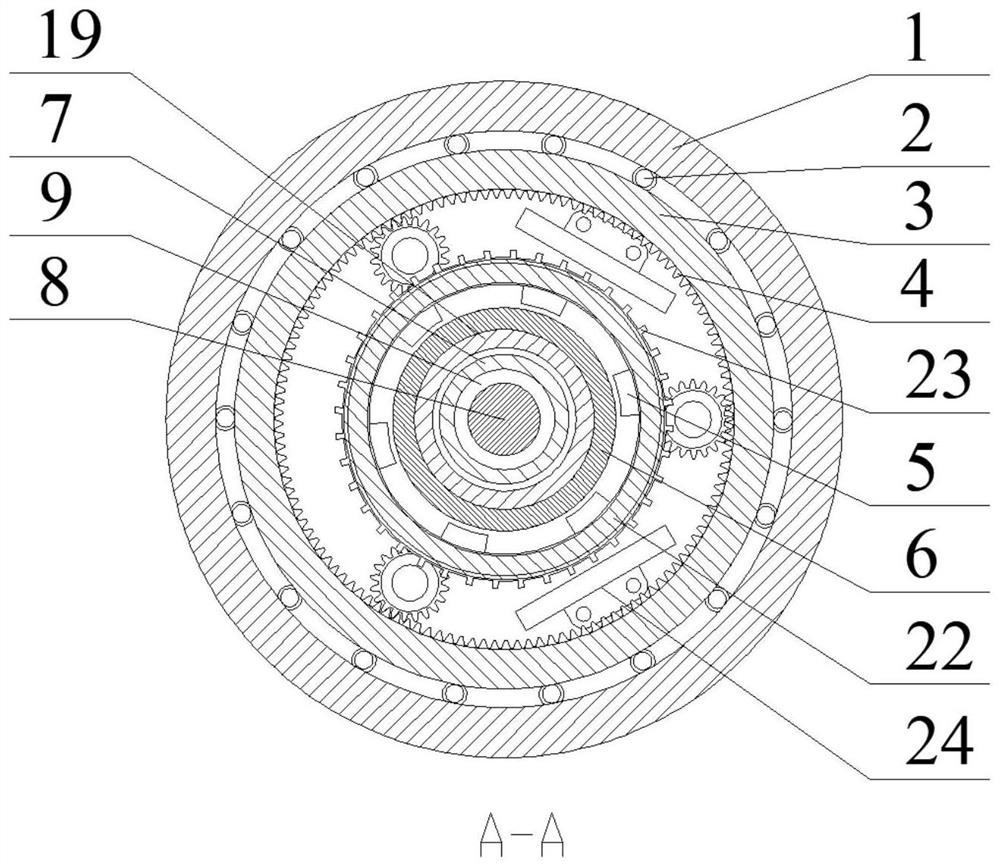

Multi-Stage Planetary Transmission

ActiveUS20160131227A1Easy accessGood gear efficiencyToothed gearingsTransmission elementsMechanical engineeringEpicyclic gearing

A planetary multi-speed transmission for a vehicle with a housing is proposed. A first shaft is provided as a drive and a second shaft is provided as an output that is axially parallel to the drive. Three planetary gear sets and additional shafts, along with six shifting elements, are provided, through which the actuation of several gears can be realized. Machine elements are provided for the transfer of torque between the drive and the output. The first shaft is connectable, as the drive, to the sun gear of the second planetary gear set, to the sun gear of the first planetary gear set, to the planetary gear carrier of the second planetary gear set, to the planetary gear carrier of the first planetary gear set, and to the first machine element. The second shaft is connected or connectable, as a drive, to the first machine element and to the second machine element.

Owner:ZF FRIEDRICHSHAFEN AG

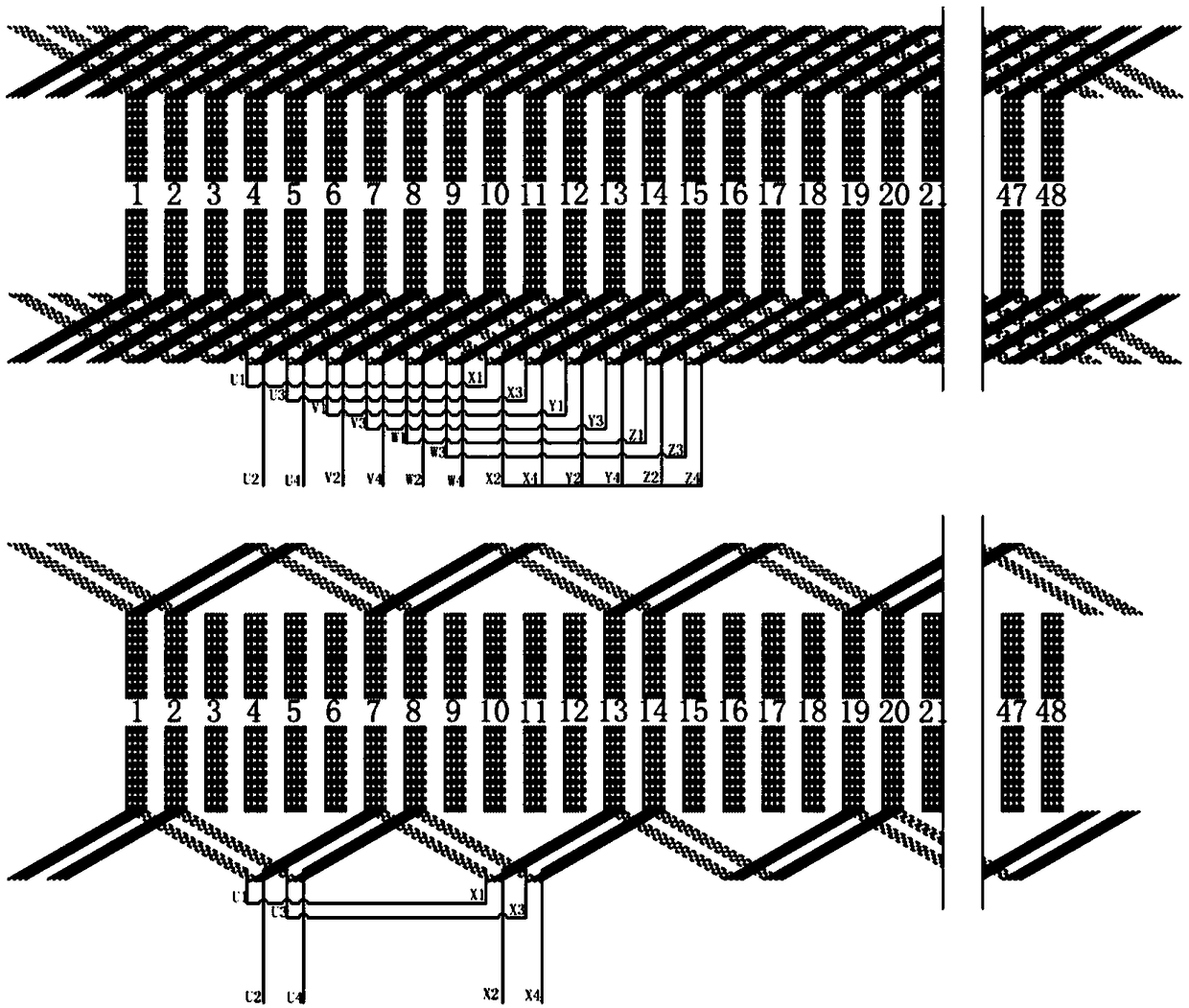

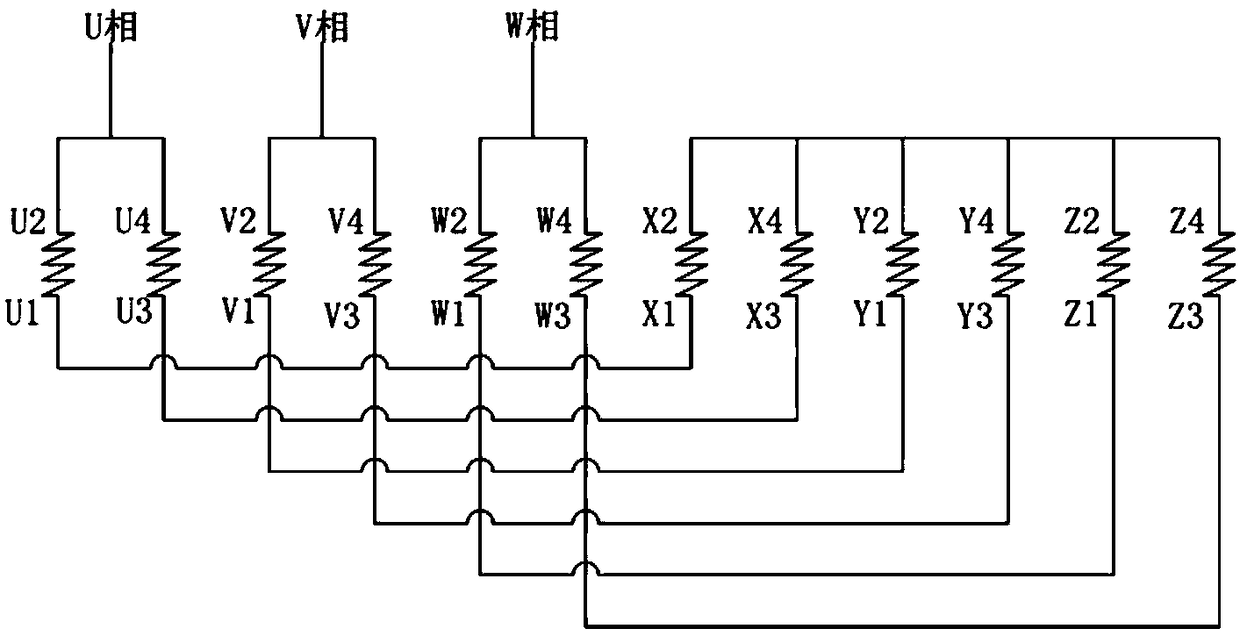

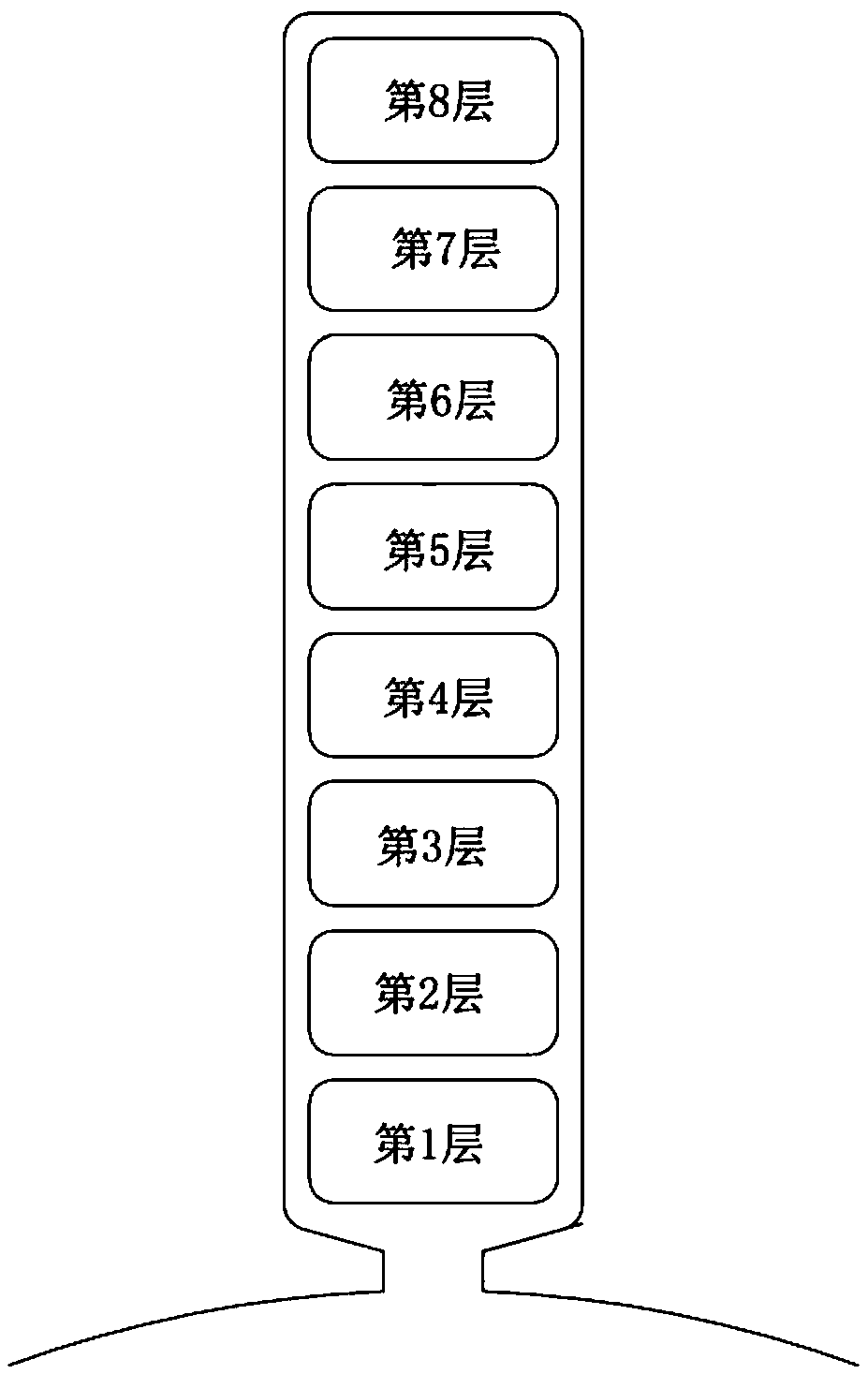

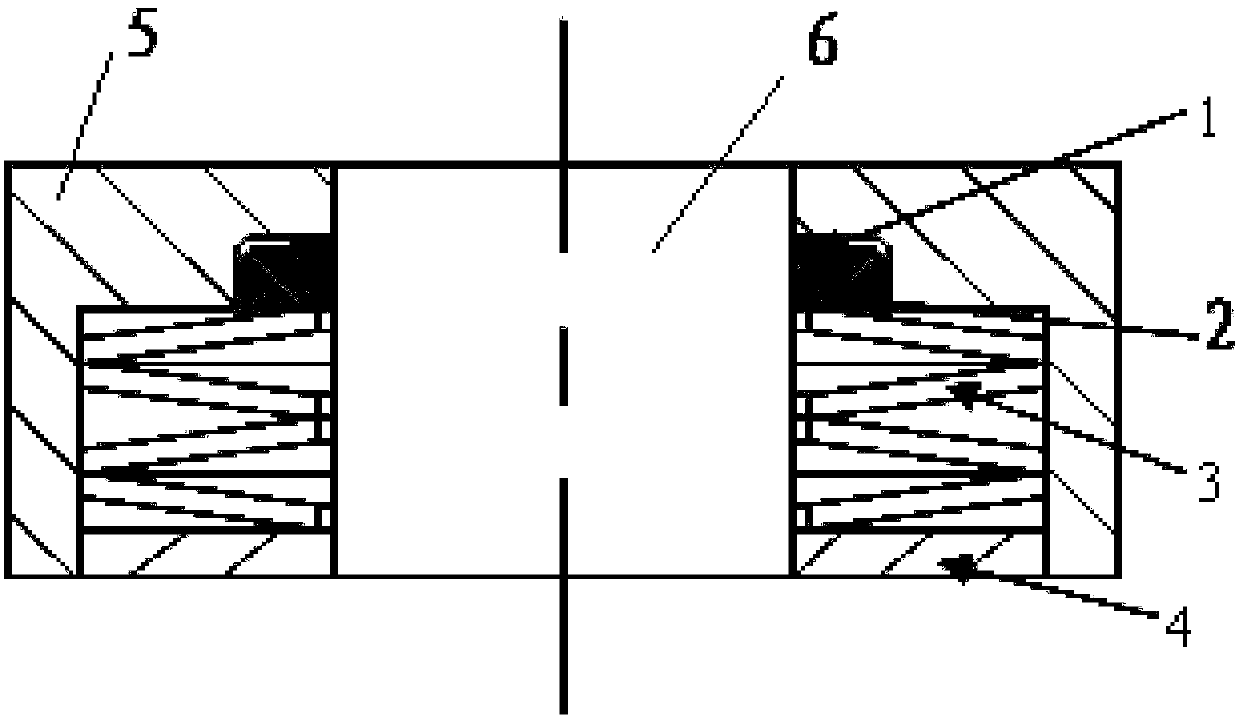

Three-phase flat wire motor stator winding

PendingCN109510356ARealize mechanical automatic off-lineReduce in quantityWindings conductor shape/form/constructionElectrical conductorDrive motor

The invention provides a three-phase flat wire motor stator winding. The three-phase flat wire motor stator winding is characterized in that a stator comprises eight poles and 48 rectangular stator slots formed at equal intervals, a number of layers of conductors in each rectangular stator slot is eight, the stator has three phases of winding structures in total, each phase of winding structure comprises two branch circuits which are connected in series, each phase of winding structure comprises an insertion side and a welding side, each welding side is provided with a power supply leading-outwire, pitch of the insertion sides is 6, each phase of winding structure is a U-shaped wire, an inner layer of the stator winding leads out a serial leading-out wire, and an outer layer of the winding leads out the power supply leading-out wires and a star point connecting wire; and the three-phase flat wire motor stator winding processes the serial leading-out wire connection, star point connecting wire connection and power supply leading-out wire connection of the two branch circuits of the same phase on the outer layer in a centralized manner. The three-phase flat wire motor stator windingsimplifies the winding structure, improves the winding insertion and manufacturing processability, realizes mechanical automatic wire insertion, shortens the size of end portions of the winding, reduces the overall size of the flat wire motor, and reduces the axial installation space of a driving motor.

Owner:CHINA FIRST AUTOMOBILE

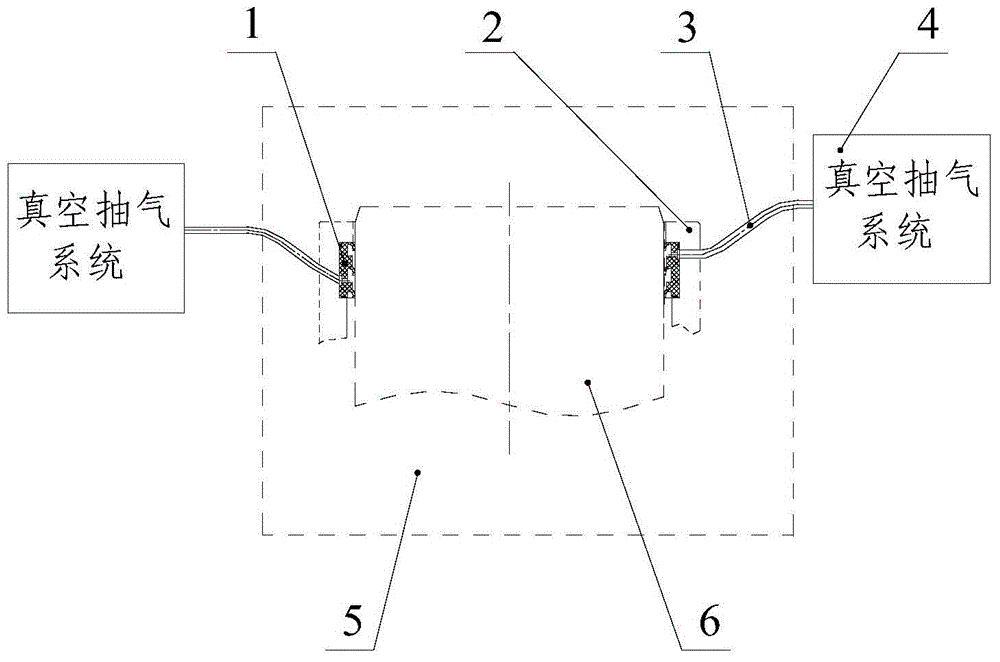

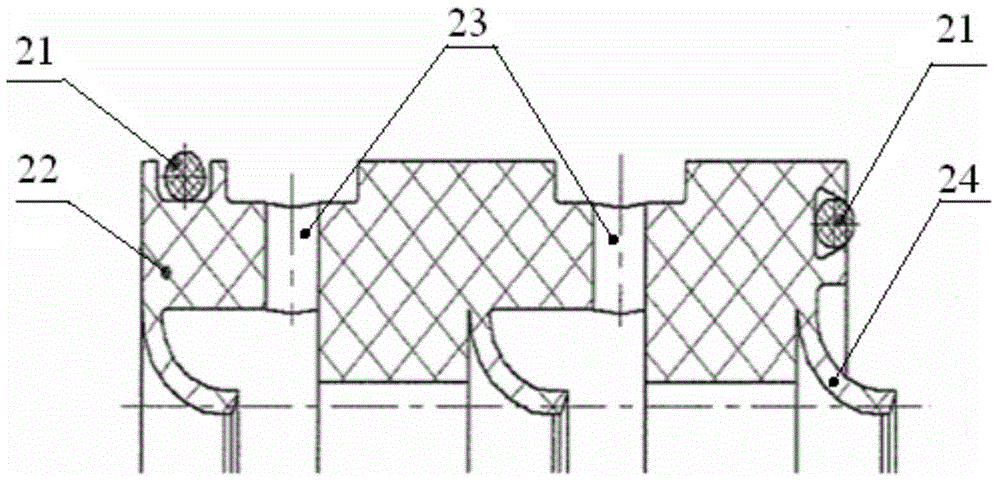

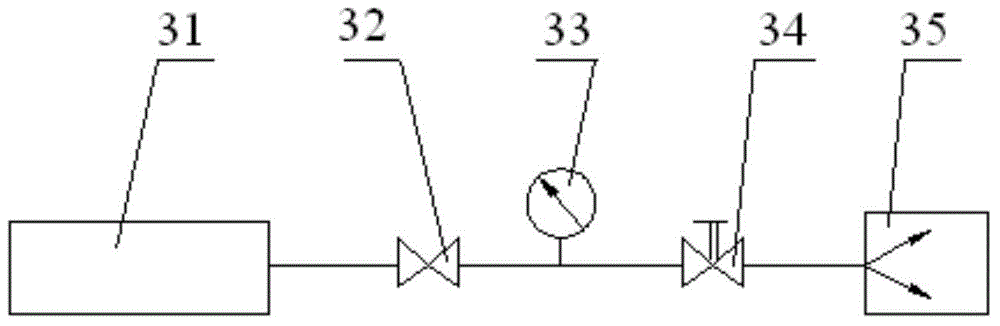

Dynamical sealing system with heavy caliber in vacuum and low temperature environment

ActiveCN103603954AWork reliablyAddresses premature wearEngine sealsThermal insulationVacuum pumpingPlastic materials

The invention discloses a dynamical sealing system with heavy caliber in vacuum and low temperature environment. The dynamical sealing system with heavy caliber in vacuum and low temperature environment comprises a dynamic sealing ring, two static sealing rings and two sets of parallel vacuum pumping system. The dynamic sealing ring comprises an one-piece three lines lip-shaped check ring. Cylindrical blank which is made by plastic material processes successively equidistant three lines lip on the lateral side of the dynamic sealing, which is equal to three lines of seal. Radical direction of the above-mentioned cylindrical blank establishes a through-hole between every two lips. Two sets of parallel vacuum pumping system which is equipped outside the vacuum container exhaust air outside the container by two through-hole between the lips and the static sealing ring is equipped on the installation surface of the dynamic sealing ring. The sealing system of the invention obviously improves the dynamical sealing effect with heavy caliber in vacuum; meanwhile the shaft installation space of the system is small and the requirements of the dynamical sealing effect with heavy caliber in vacuum can be solved in the small installation space; the deformation of lips of optimized sealing ring is large and has recovery effects, which not only make sure the sealing effects but also solve the problem that the sealing ring is worn prematurely.

Owner:BEIJING INST OF SPACECRAFT ENVIRONMENT ENG

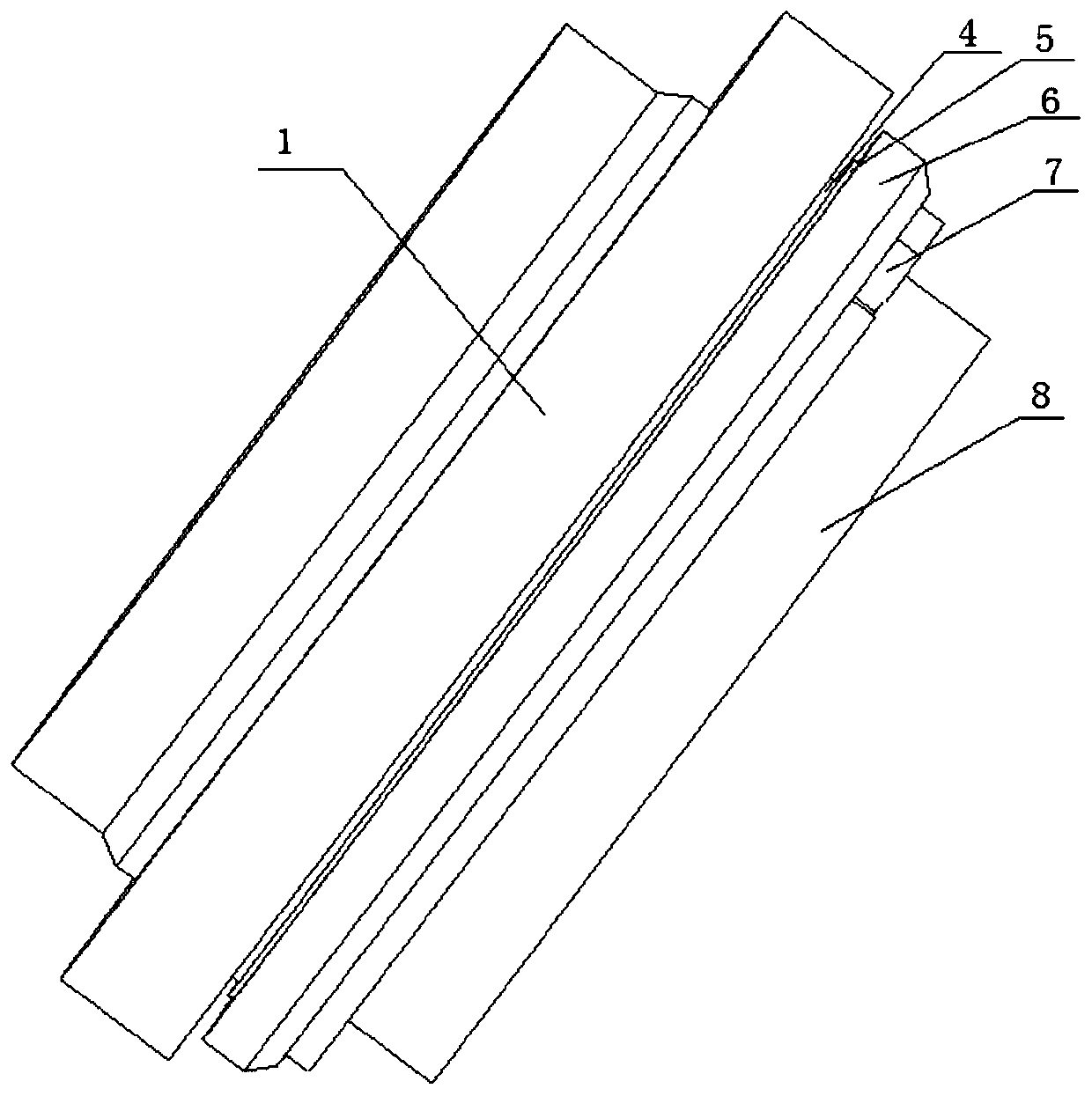

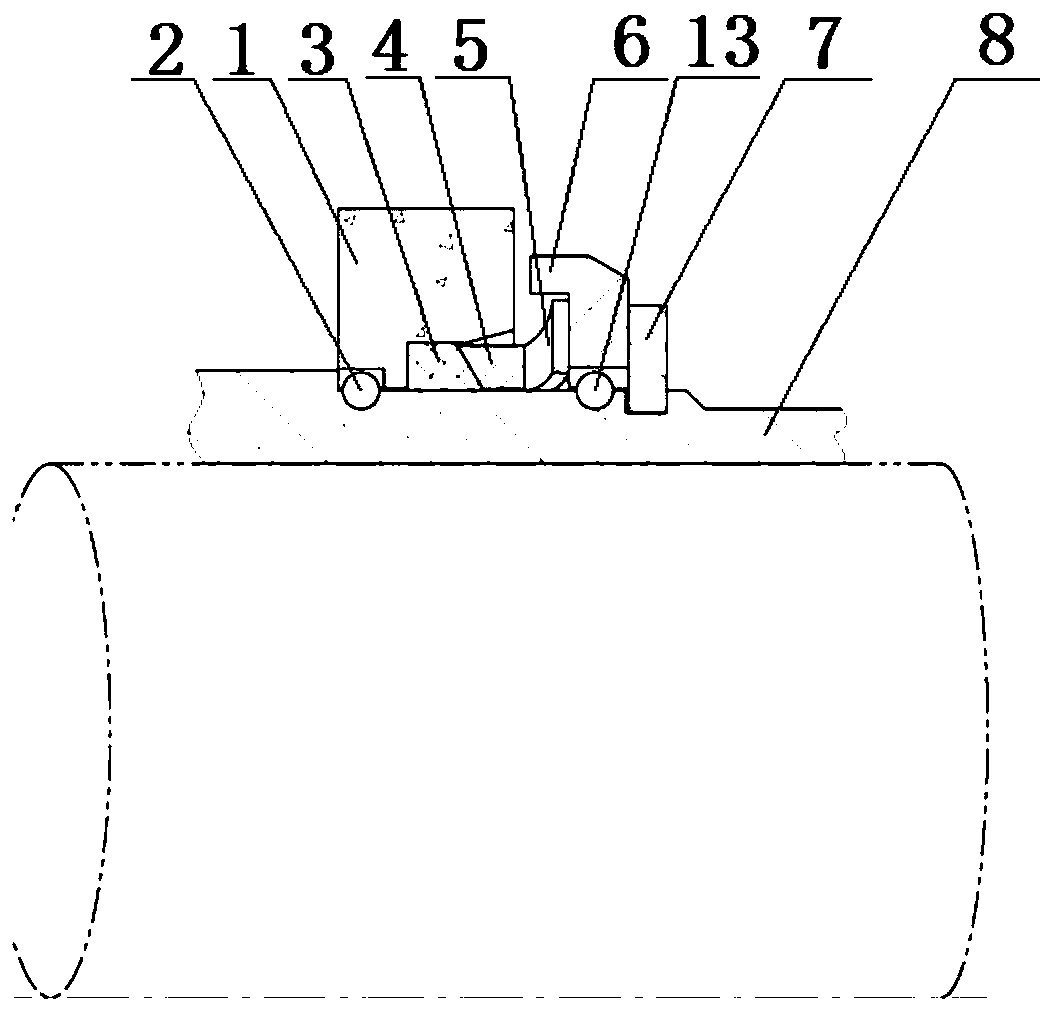

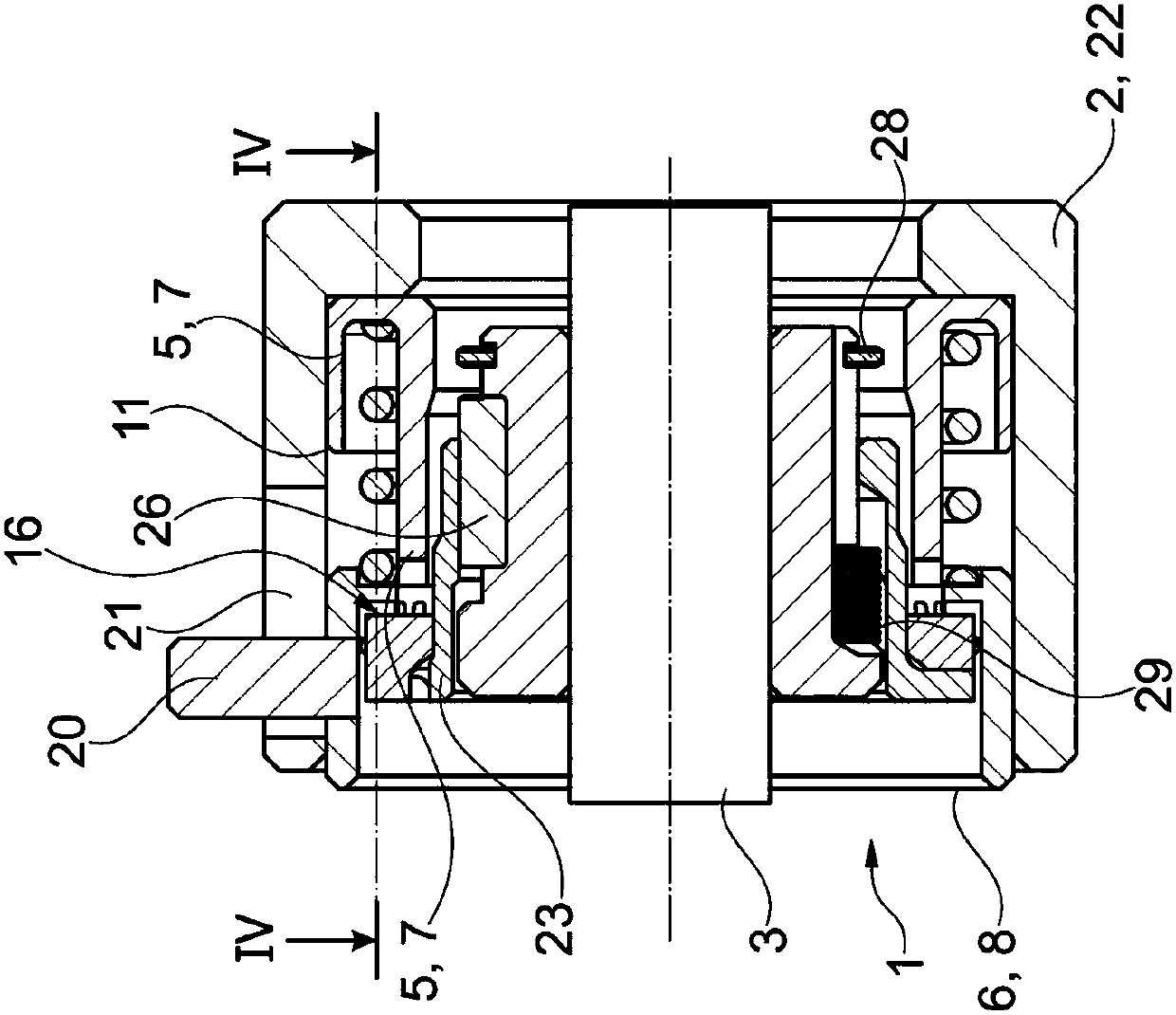

Coupling device

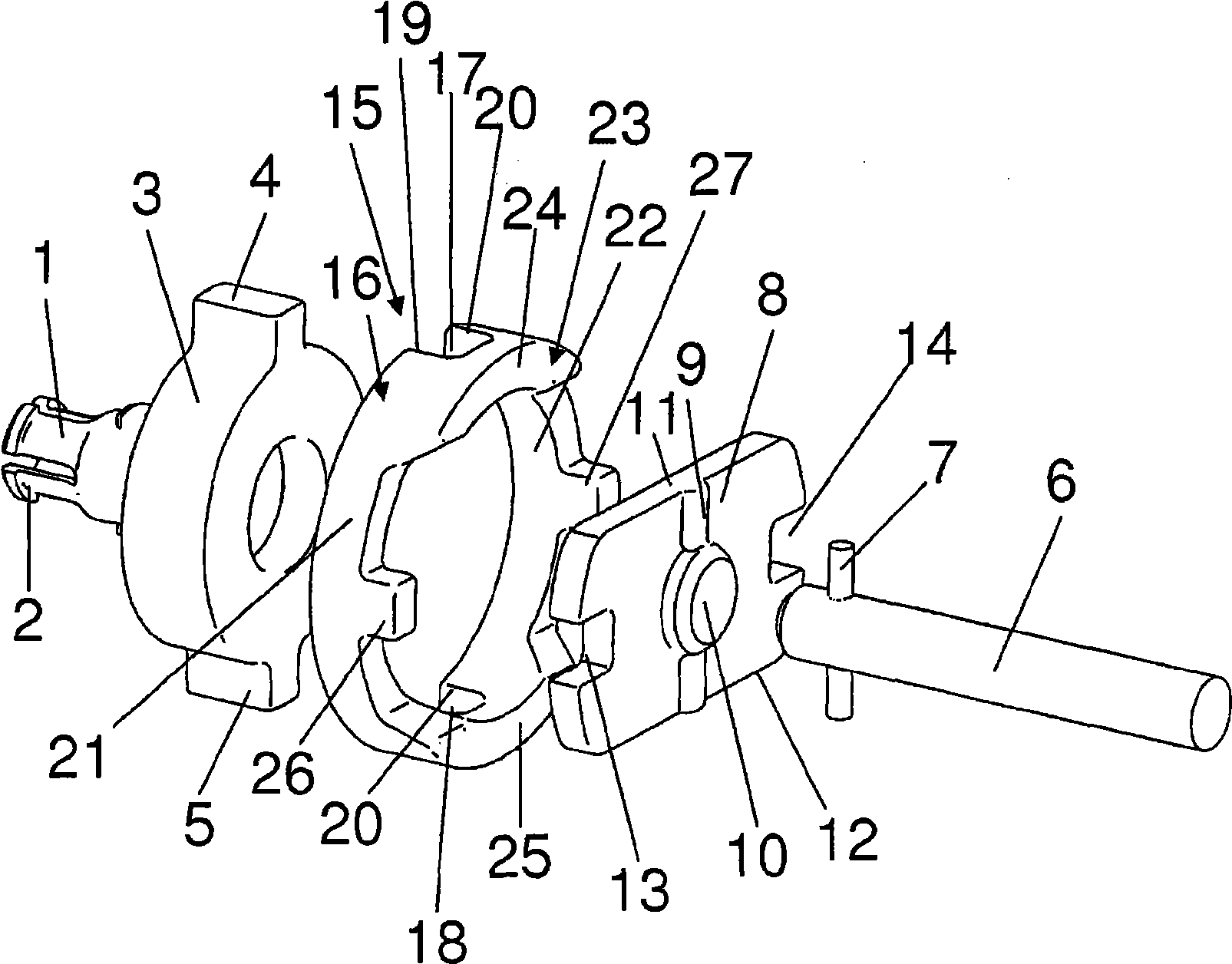

InactiveCN101523069ASmall manufacturing tolerancesEasy to manufactureYielding couplingEngine controllersCouplingEngineering

It is known that two shafts can be connected via Oldham couplings. According to the invention, a coupling device is proposed, wherein recesses (13, 14) and projections (4, 5) of end sections (3, 8) of the shafts (1, 6) extend radially and a coupling member (15) substantially surrounds the two end sections (3, 8) of the two shafts (1, 6), wherein both end sections (3, 8) lie directly opposite each other. Accordingly, corresponding projections (26, 27) and recesses (17, 18) are provided on the coupling member (15) for the transmission of torque. Such a device reduces the axial installation length of a coupling device of this type.

Owner:PIERBURG GMBH & CO KG NEUSS

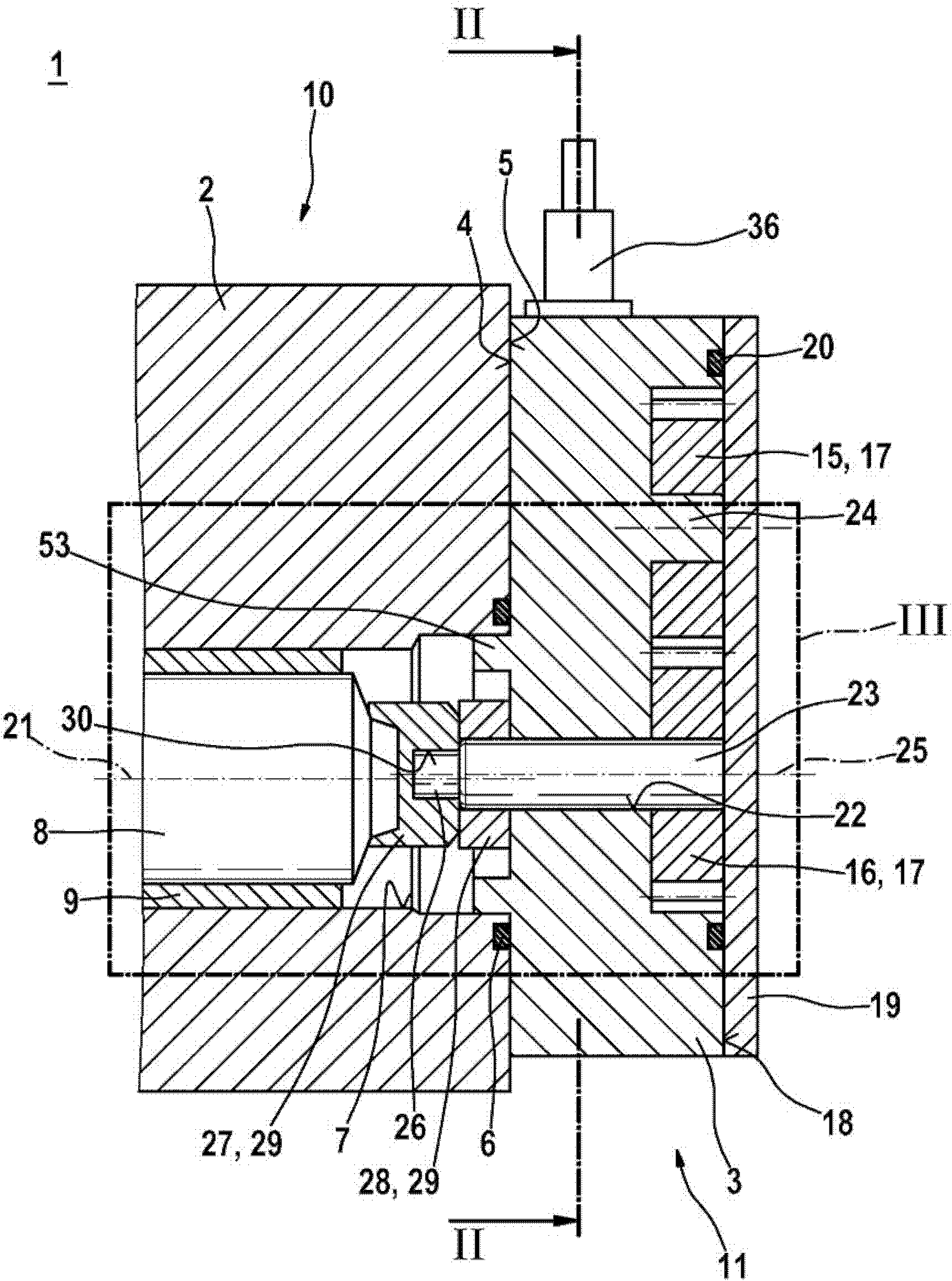

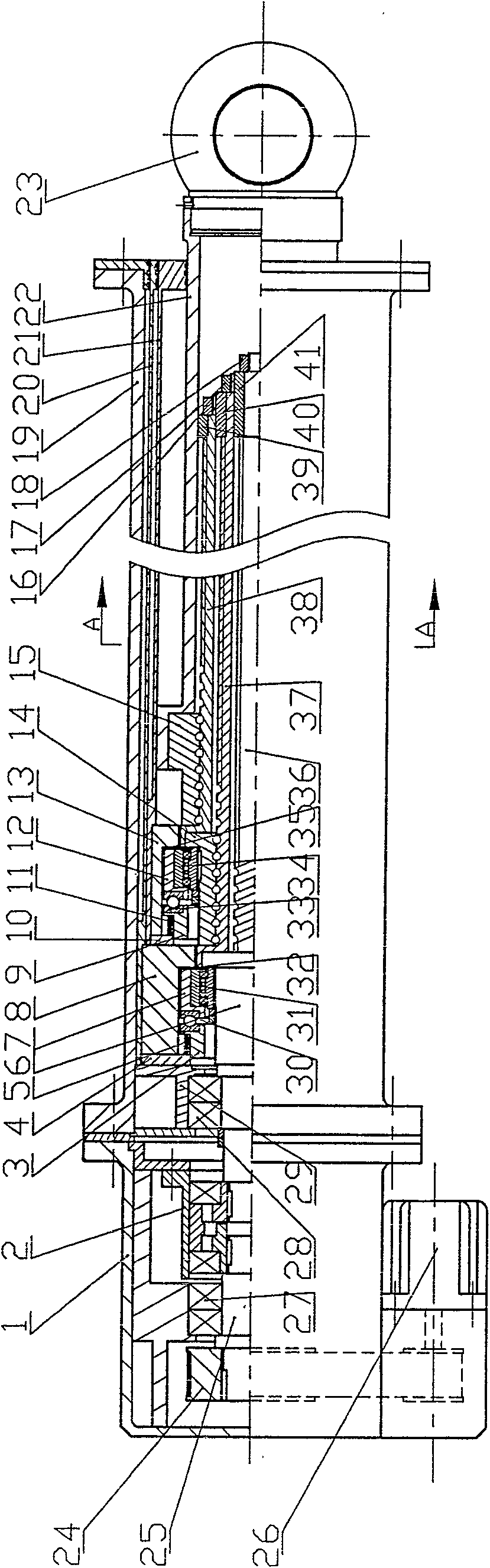

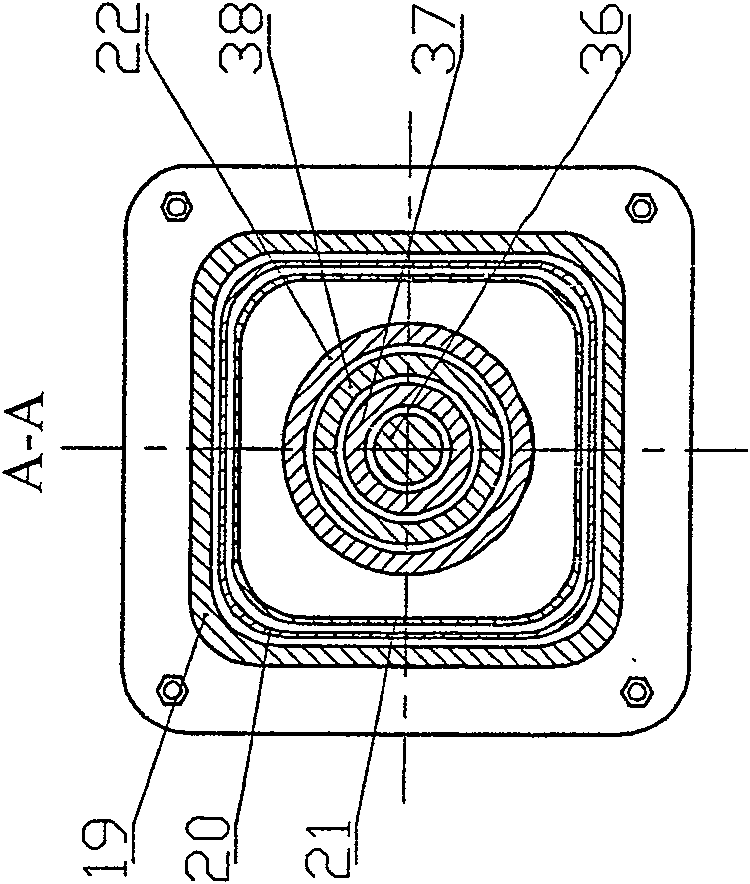

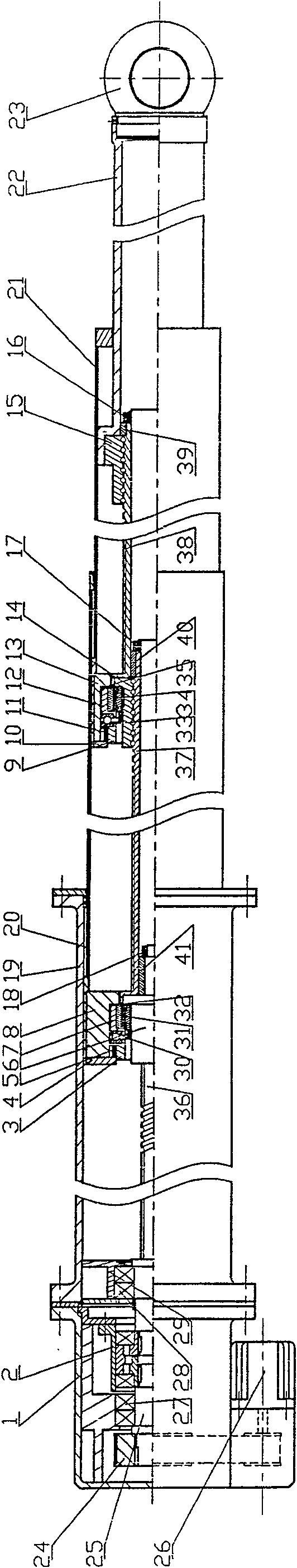

Pressure cylinder having motion sleeve, in paticular to active cylinder

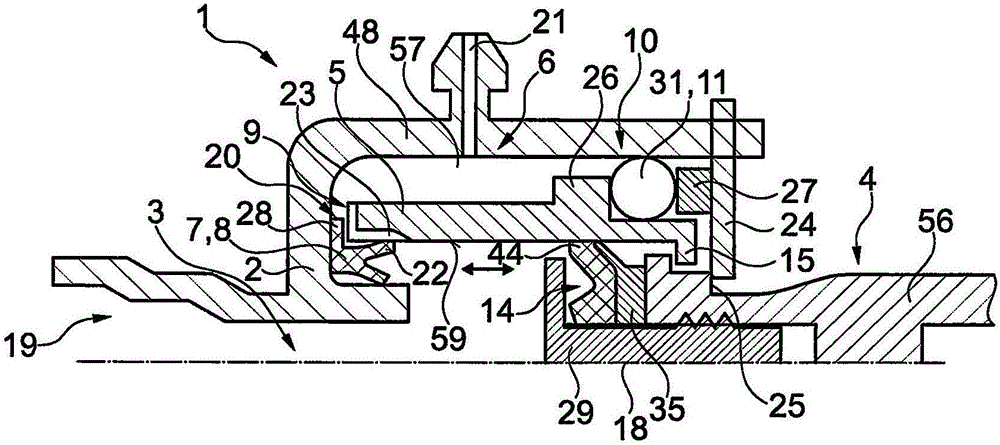

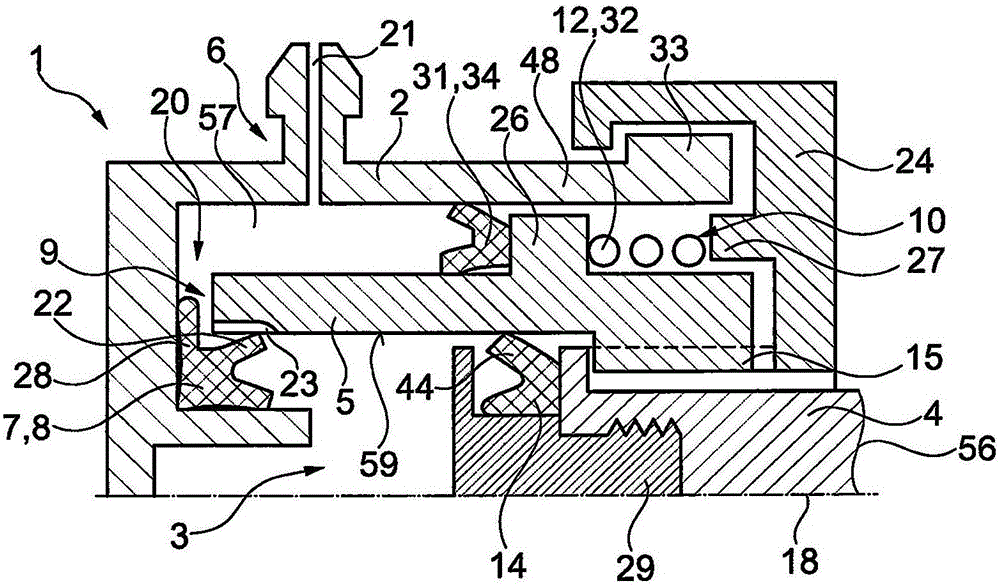

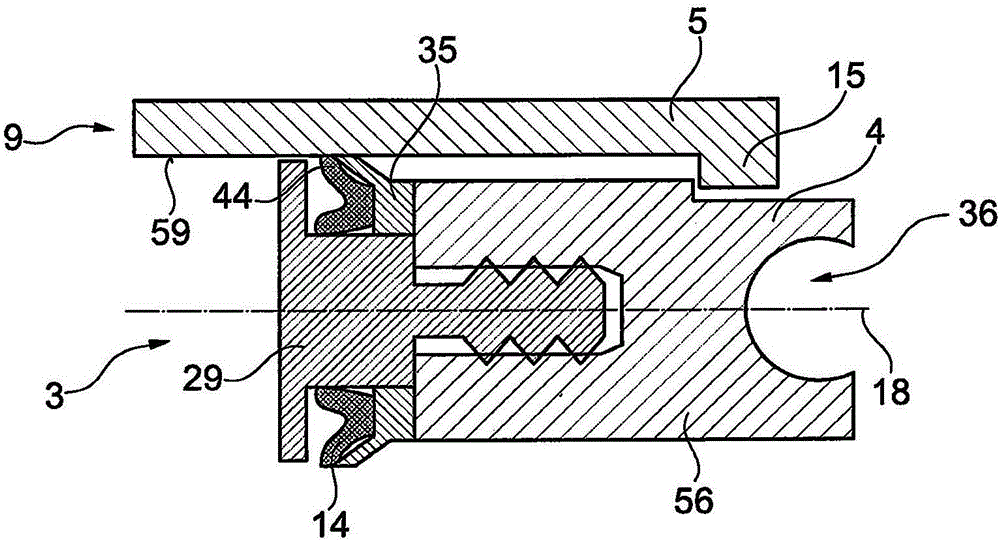

ActiveCN106837897AControl and reliable reproductionEffective manipulationFluid actuated clutchesTelemotorsEngineeringPiston

The invention relates to a pressure cylinder (1) for actuating a clutch of a motor vehicle drive train, comprising a housing (2), a pressure piston (4) which is movably mounted in said housing (2) and forms a fluidic pressure chamber (3) with the housing (2) (5) guide sleeve which is accommodated in the housing (2) and is designed to guide the pressure piston (4) in at least one partial section of its displacement path, the guide sleeve (5) being displaceable relative to the housing (2) in such a way that thepressure chamber (3) is fluidically connected to a side channel (6) which can be connected to a fluid reservoir in an opening position of the guide sleeve (5) and is fluidically separated from the side channel (6) in a closed position of the guide sleeve (5); and the invention also relates to a clutch for a drive train with such a pressure cylinder (1).

Owner:SCHAEFFLER TECH AG & CO KG

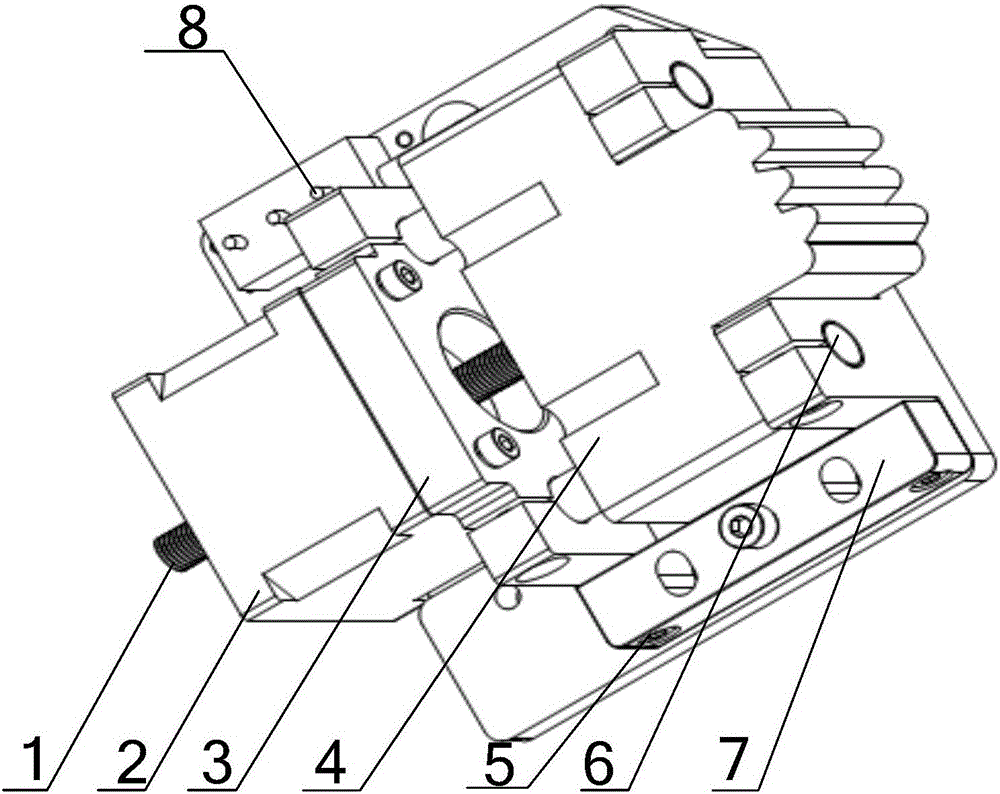

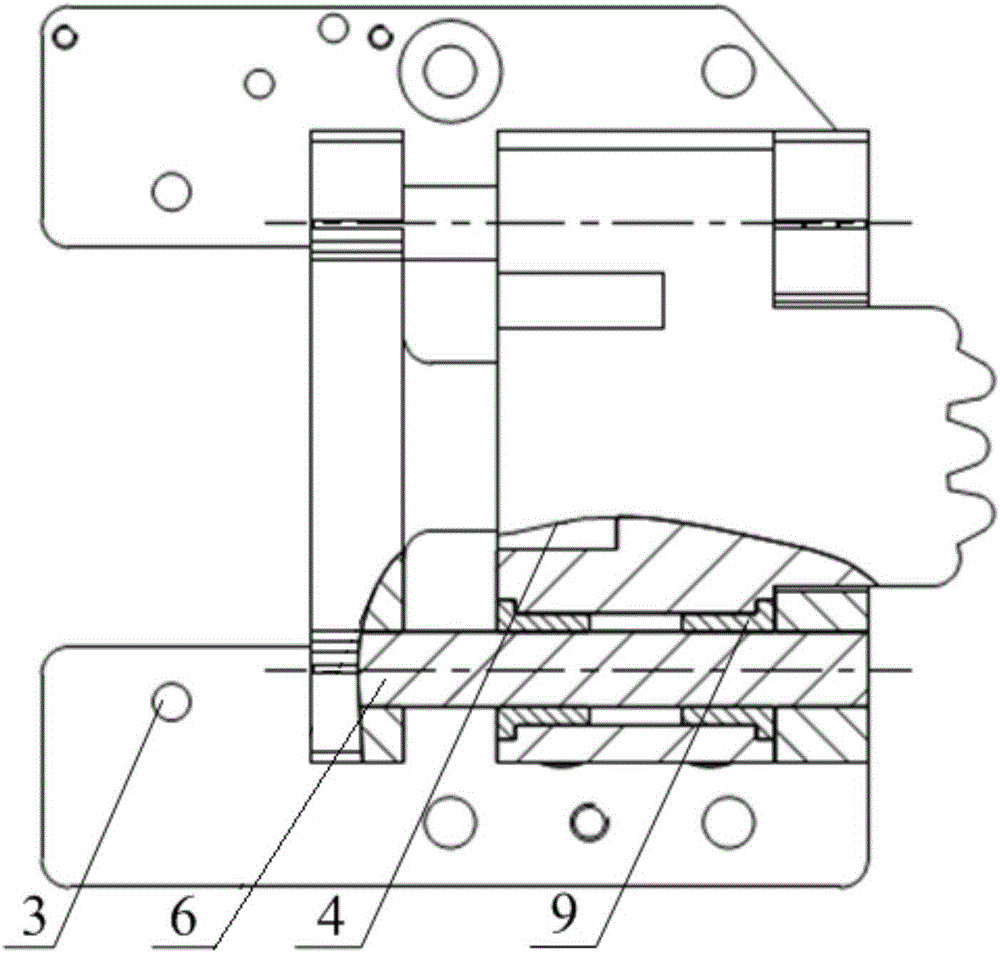

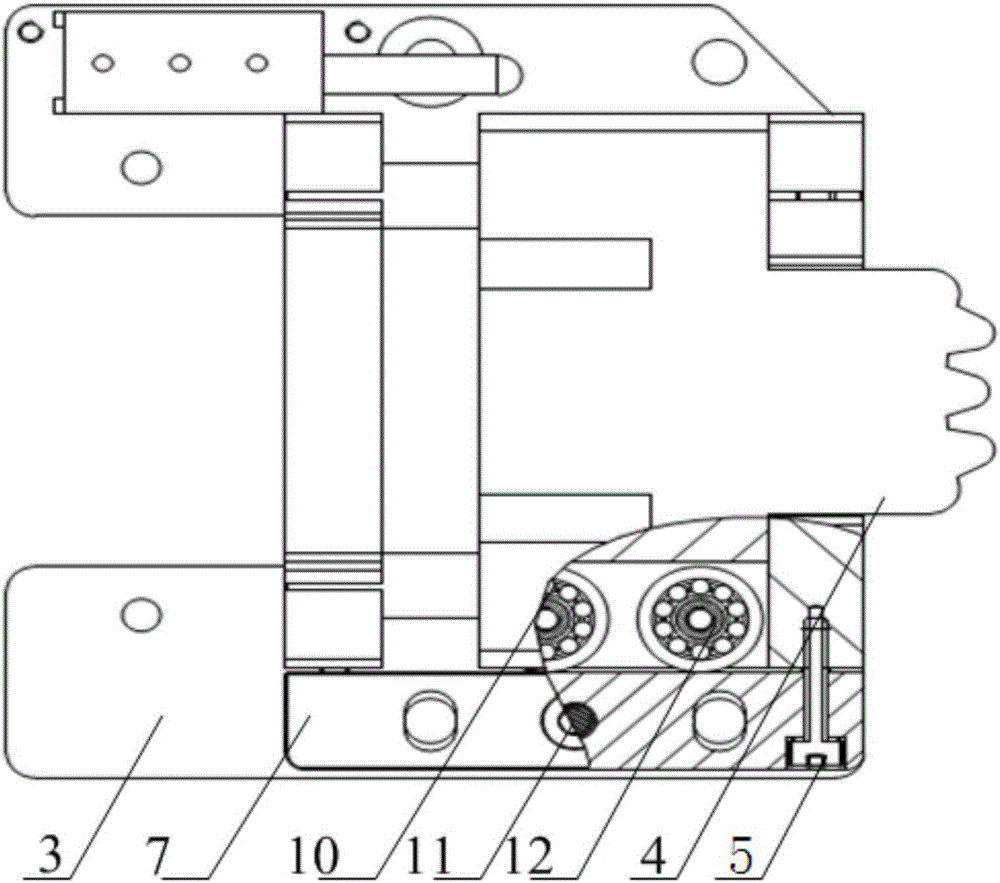

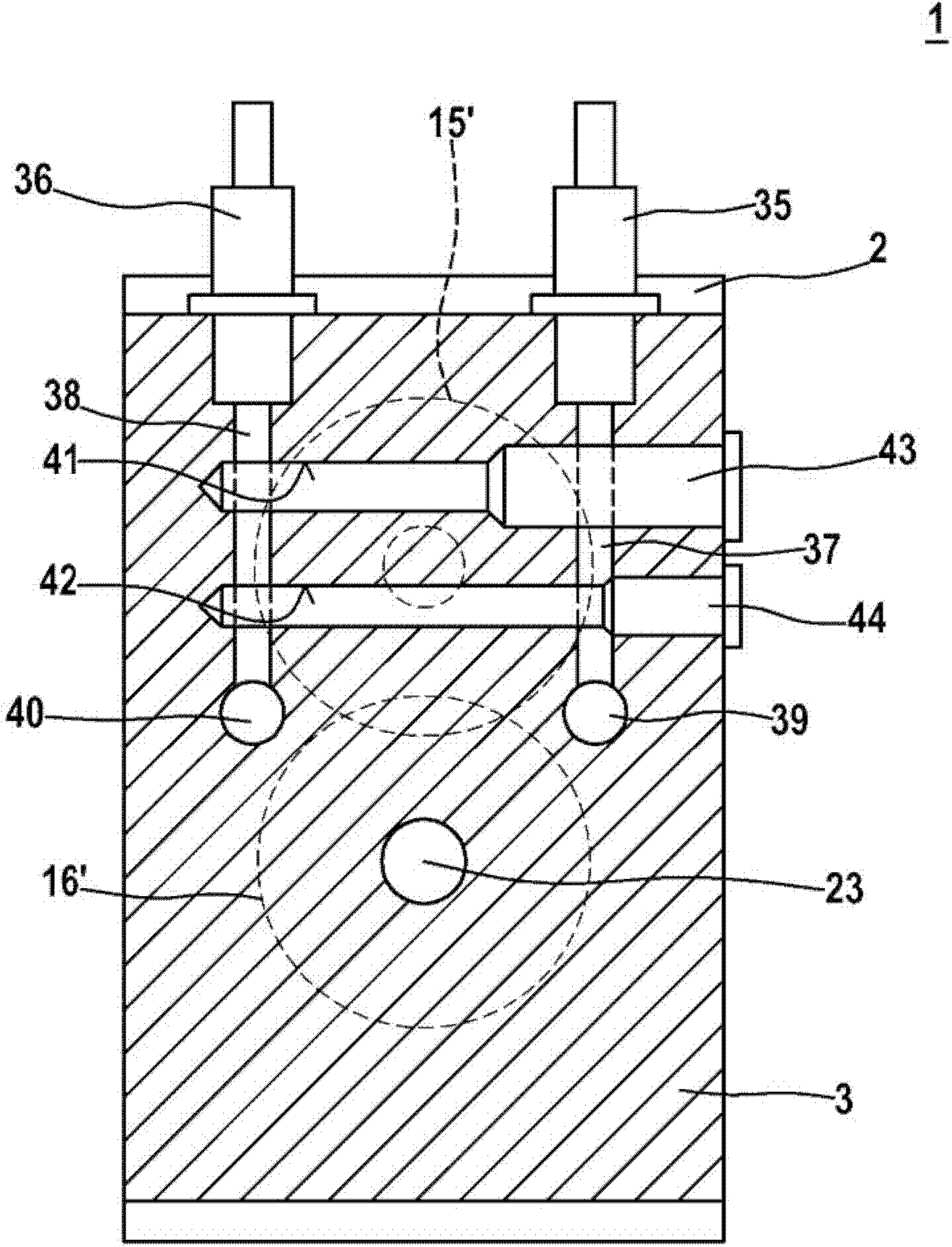

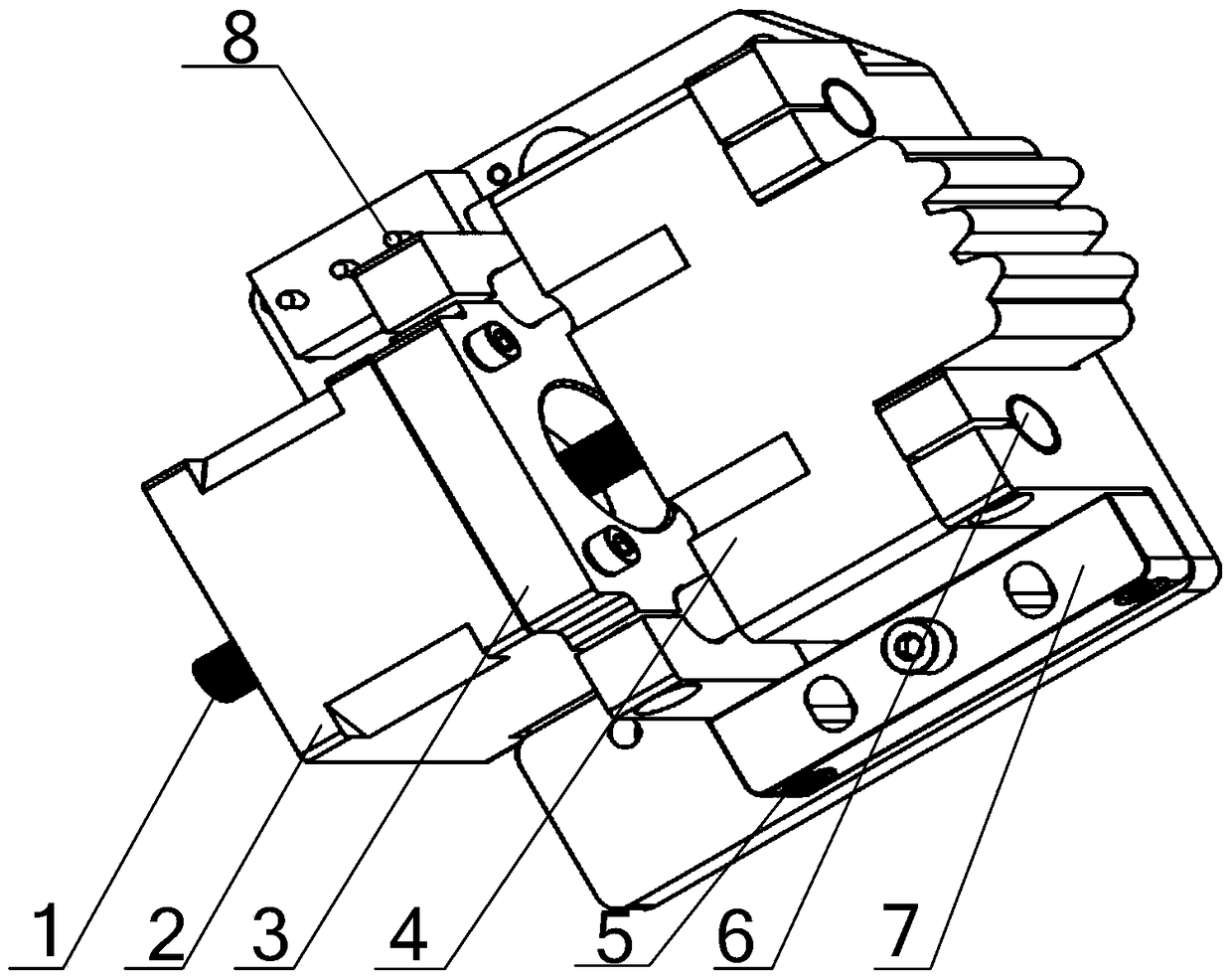

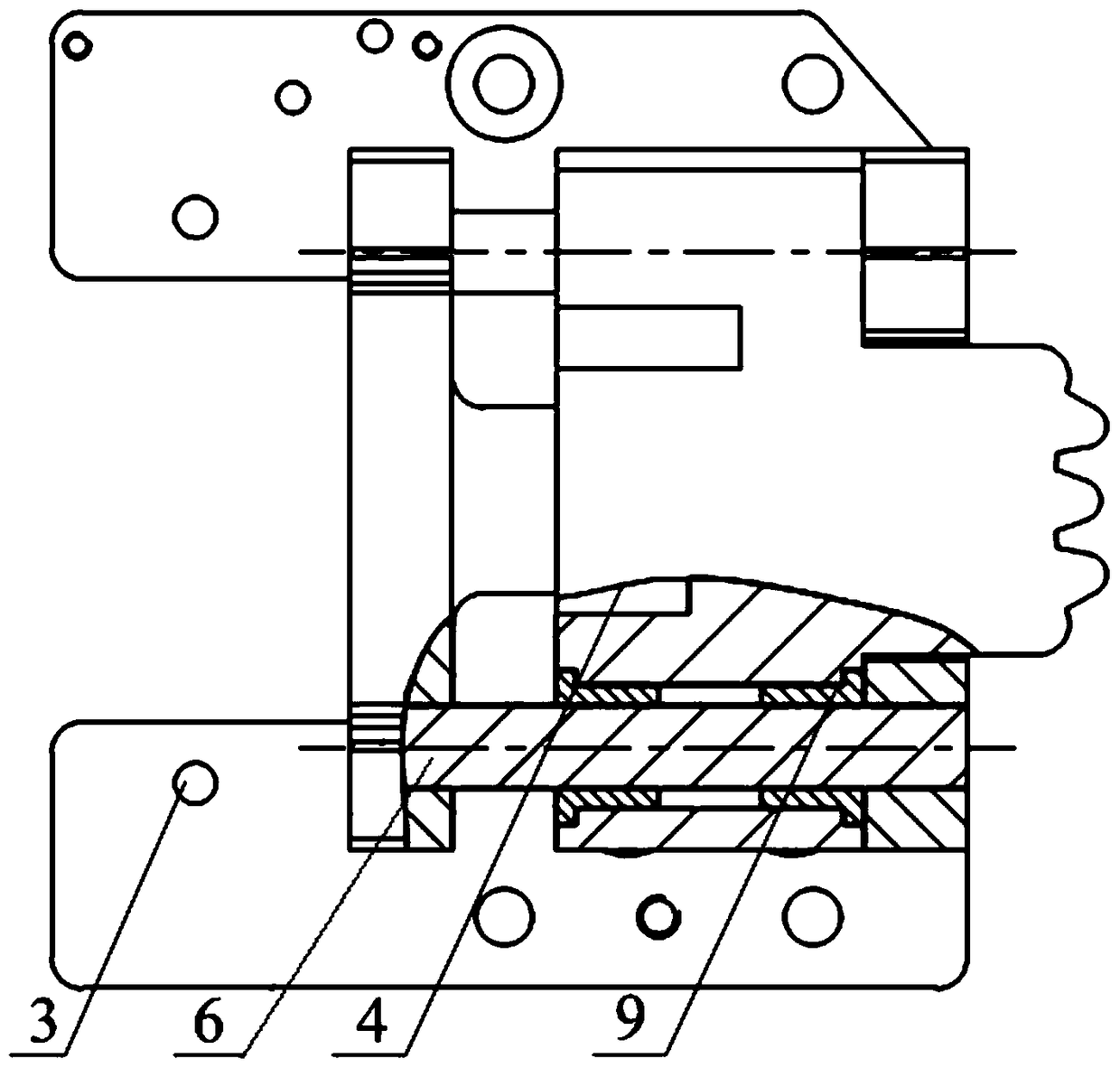

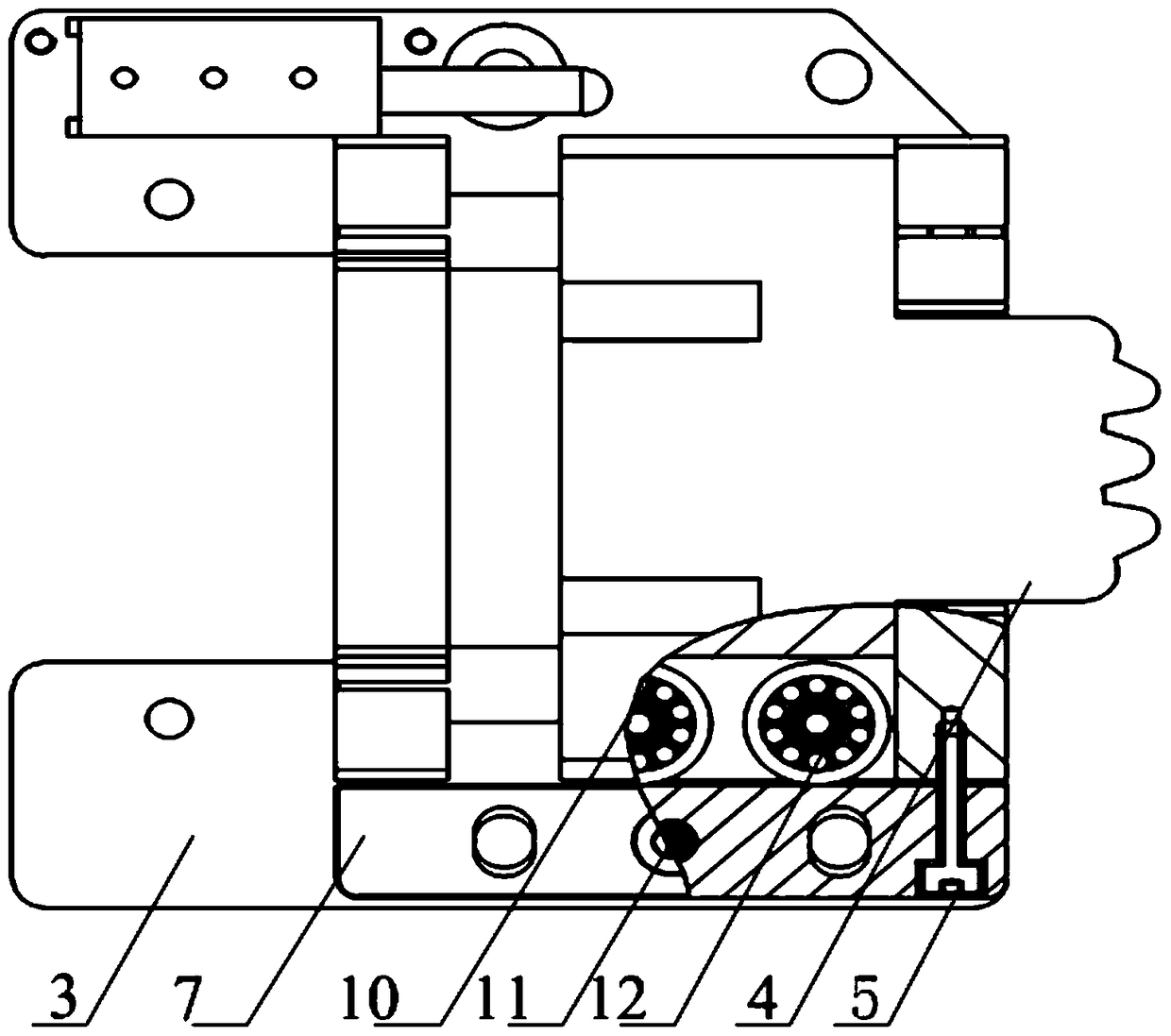

Rotating shaft locking device of transmission mechanism

ActiveCN105156451ASolve the automatic locking functionHigh locking reliabilityShaft for rotary movementMechanical energy handlingSelf lockingDrive motor

The invention discloses a rotating shaft locking device of a transmission mechanism. The rotating shaft locking device comprises a transmission locking device and a locking gear fixedly connected onto a rotating shaft of the transmission mechanism; the transmission locking device comprises a lead screw, a driving motor, a base, a locking block and guide rails which are parallelly fixed on the base; the two sides of the locking block sleeve the guide rails; one end of the locking block is provided with teeth meshed with the locking gear, and the other end of the locking block is connected with the driving motor which is fixed on the base through the lead screw; the driving motor drives the locking block to move along the guide rails to be meshed with the locking gear for locking or to be separated from the locking gear for unlocking through the lead screw; the driving motor is utilized for providing power for the locking block to ensure the insertion and the separation of the teeth; the automatic locking function of the rotating shaft is effectively solved; the locking force can be set by controlling the rotation speed of the driving motor and the backoff amount after locking; the maintenance of a locking load is realized through the self-locking ability of a screw-nut pair; the locking reliability is high; and the assembly is convenient.

Owner:NO 771 INST OF NO 9 RES INST CHINA AEROSPACE SCI & TECH

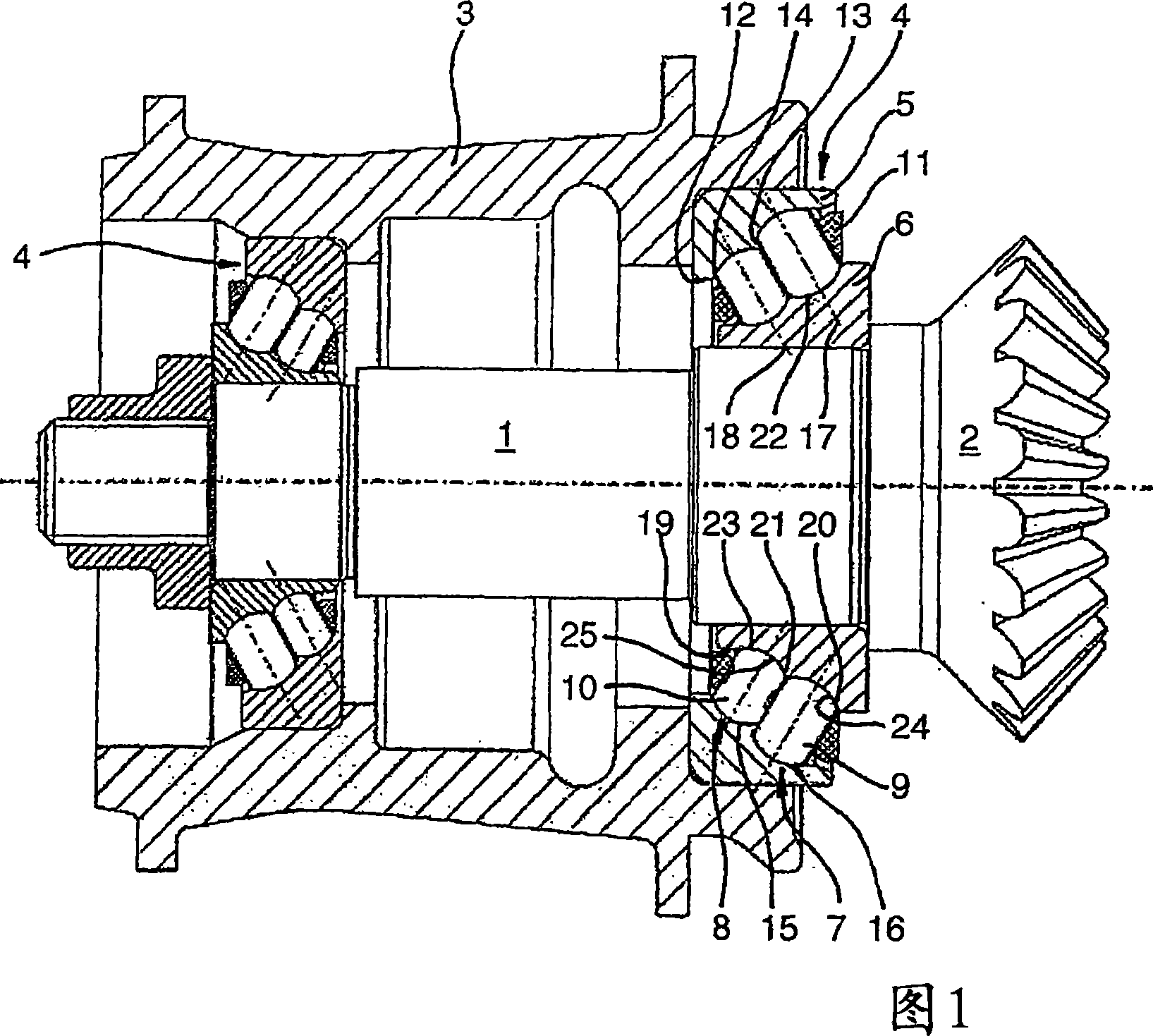

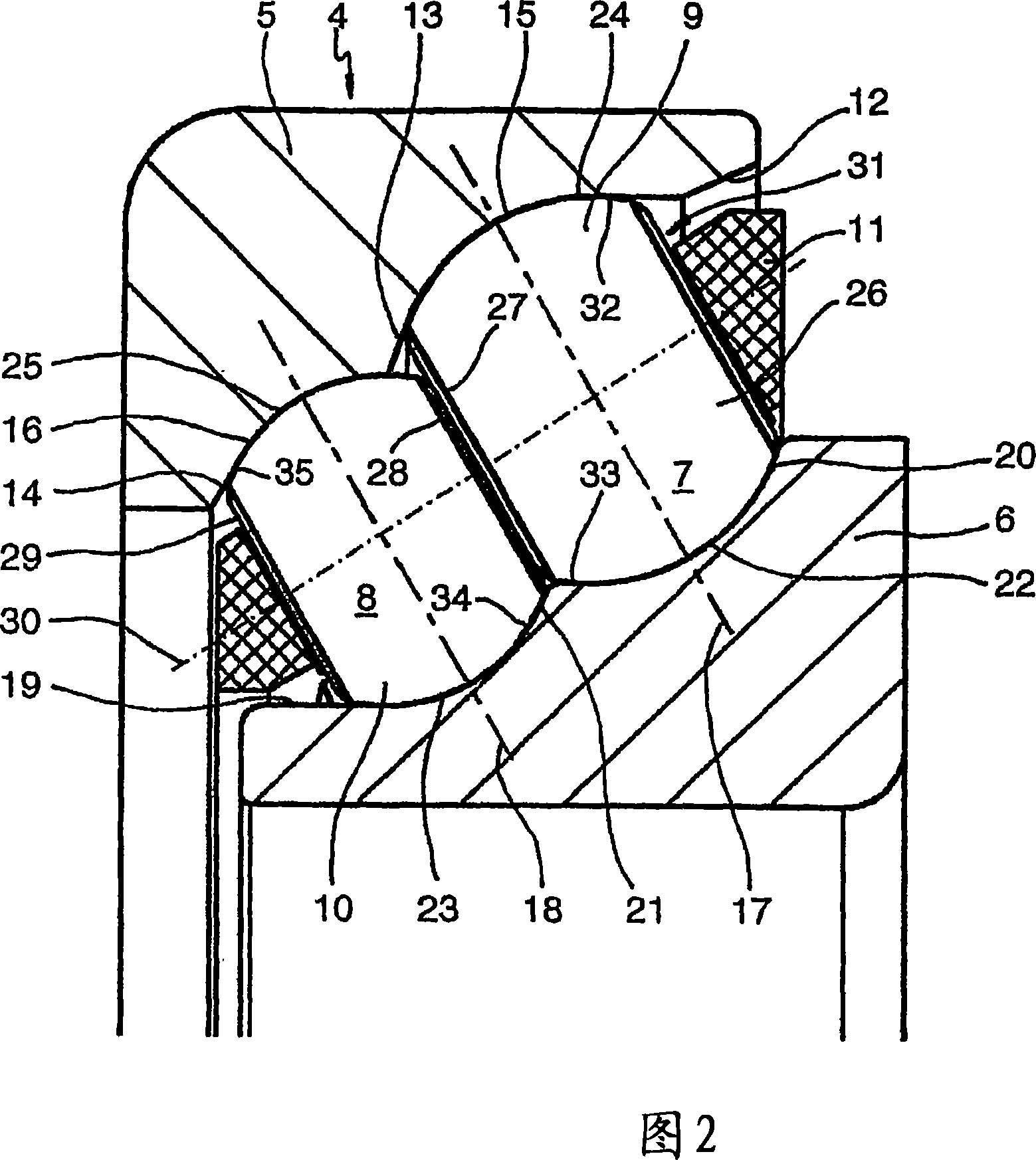

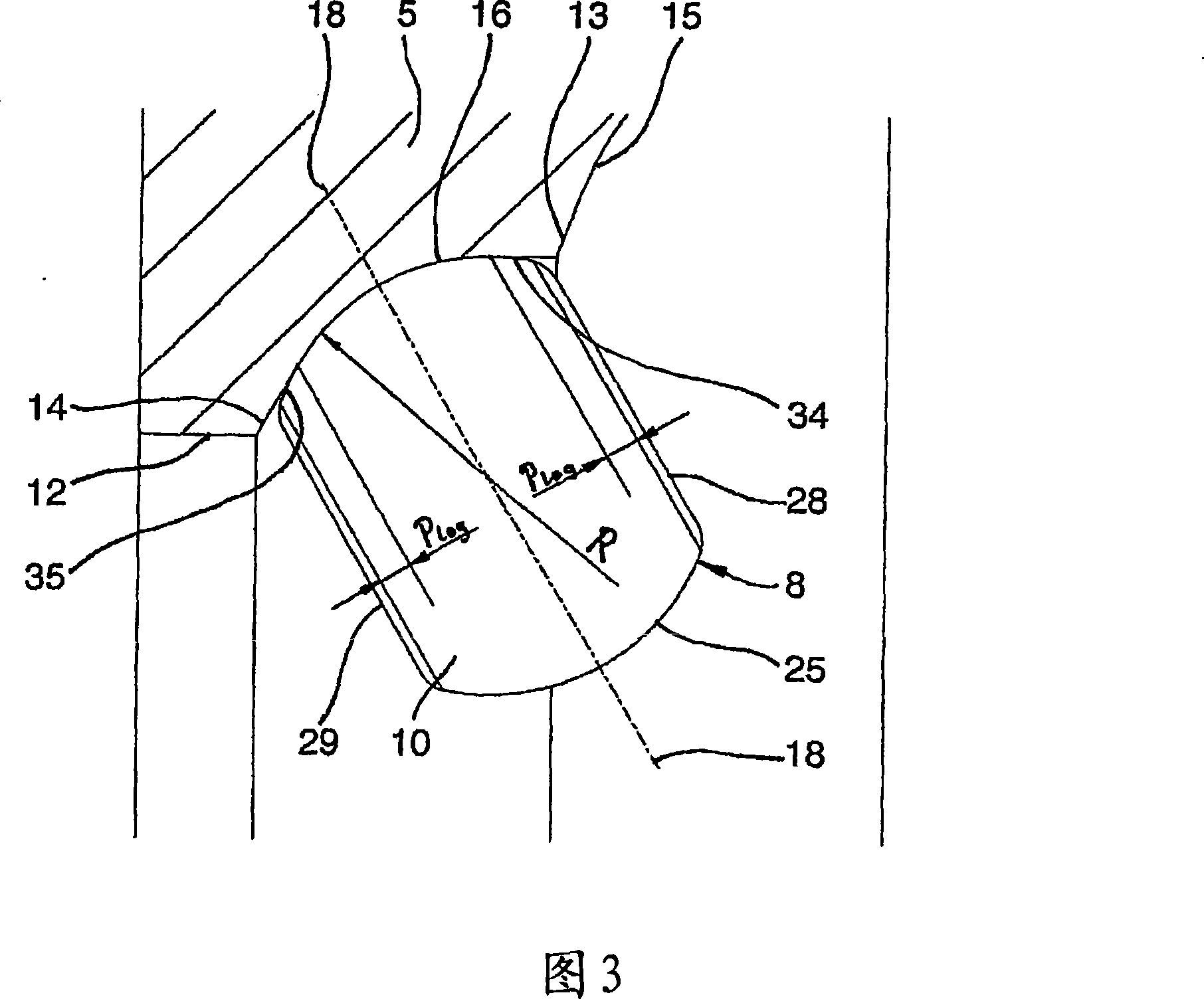

Multiple-row angular contact antifriction bearing, particularly for mounting the bevel pinion shaft in a motor vehicle rear axle differential

InactiveCN101213381ANo need to endure reduced load carrying capacitySave axial installation spaceRoller bearingsGearboxesRolling-element bearingGear wheel

The multiple-row angular contact antifriction bearing has an outer bearing ring, an inner bearing ring, and roll bodies, which are arranged at least in two rows next to one another between the bearing rings. The roll bodies are ball discs having two lateral surfaces that are symmetrically flattened from a spherical basic shape whose raceways are arranged inside the bearing rings, abutting against one another so that the respectively adjacent roll bodies of each row have their lateral surface pointing toward one another and arranged directly next to one another on a transversal axis situated at a right angle to the pressure angle axes. These lateral surfaces also provide mutual guide surfaces.

Owner:SCHAEFFLER TECH AG & CO KG

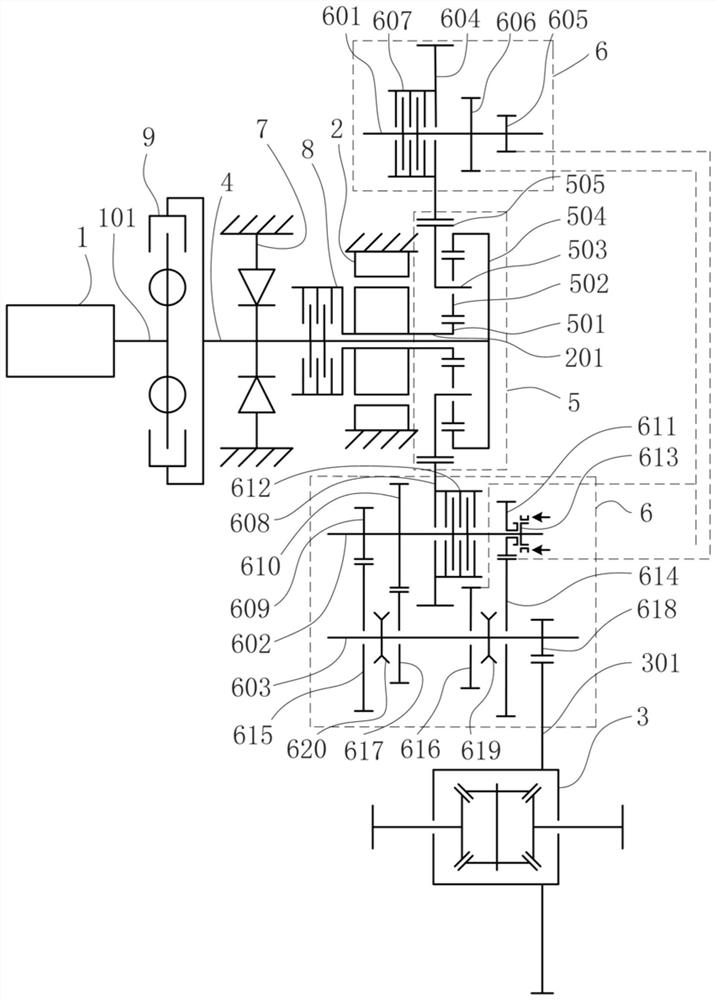

Hybrid power speed changer transmission structure and vehicle

ActiveCN112780734AZoom in on the working areaGuaranteed powerHybrid vehiclesToothed gearingsGear driveGear wheel

The invention discloses a hybrid power speed changer transmission structure and a vehicle. An engine and a motor are included, and an input shaft of a speed changer is connected with an output shaft of the engine and an outer gear ring and further connected with a speed changer shell through a one-way clutch or a brake. The motor is connected with the input shaft of the speed changer through a fourth clutch, and a motor output shaft is connected with a sun gear. A planet row output gear is connected with a planet carrier. A first input gear, a first-gear driving gear and a third-gear driving gear are arranged on a first intermediate shaft, a second input gear, a reverse gear, a second-gear driving gear and a fourth-gear driving gear are arranged on a second intermediate shaft, and a first-gear driven gear, a second-gear driven gear, a third-gear driven gear, a fourth-gear driven gear and an output shaft main reduction gear are arranged on an output shaft of the speed changer. The first input gear and the second input gear are both meshed with the planet row output gear and correspondingly output power to the first intermediate shaft and the second intermediate shaft through a first clutch and a second clutch. The reverse gear is meshed with the first-gear driven gear and outputs power to the second intermediate shaft through the third clutch. The transmission efficiency is high, engine intervention and exit are smooth, and the axial size is small.

Owner:GUANGZHOU AUTOMOBILE GROUP CO LTD

Fuel pump with an overflow and a bypass valves

InactiveCN102498297ASimple structureSimplify installation spaceRotary piston pumpsRotary piston liquid enginesCombustionEngineering

The invention relates to a fuel pump (1), which in particular serves as a pump arrangement for fuel injection systems of air-compressing, self-igniting internal combustion engines, comprising at least one housing part (3), a first toothed wheel (15) and a second toothed wheel (16). The toothed wheels (15, 16) are arranged in the housing part (3). Furthermore, the toothed wheels (15, 16) intermesh in order to form a gear pump (17). The invention further relates to an inlet or return (35, 36) for the gear pump (17), which is provided in the housing part (3).

Owner:ROBERT BOSCH GMBH

Disc spring loading type wedge-shaped dynamic sealing structure for ultralow-temperature device

PendingCN107701800ASave axial installation spaceSmall structure sizeSpindle sealingsEngine sealsControl functionEngineering

The invention discloses a disc spring loading type wedge-shaped dynamic sealing structure for an ultralow-temperature device and relates to the field of rotating shaft dynamic sealing structures for ultralow-temperature devices. The structure comprises a non-metal wedge-shaped sealing ring, a metal retainer ring, a loading disc spring set and an adjusting gasket; the non-metal wedge-shaped sealingring is located at the joint of an outer valve shell and an outer valve rotating shaft; the metal retainer ring is arranged on the outer wall of the outer valve rotating shaft in a sleeving mode; themetal retainer ring is fixedly arranged in a small-diameter groove in the top in the outer valve shell; the loading disc spring set is fixedly installed in a large-diameter groove in the lower end ofthe outer valve shell; the upper surface of the loading disc spring set is in contact with the lower surface of the metal retainer ring; the upper surface of the adjusting gasket is in contact with the lower surface of the loading disc spring set; the lower surface of the adjusting gasket and the lower surface of the outer valve shell are located on the same plane. The structure has the functionsof isolating an engine medium and controlling gas, and has the advantages of being small in structural size, low in weight, high in reliability, simple in forming process and the like.

Owner:BEIJING AEROSPACE PROPULSION INST

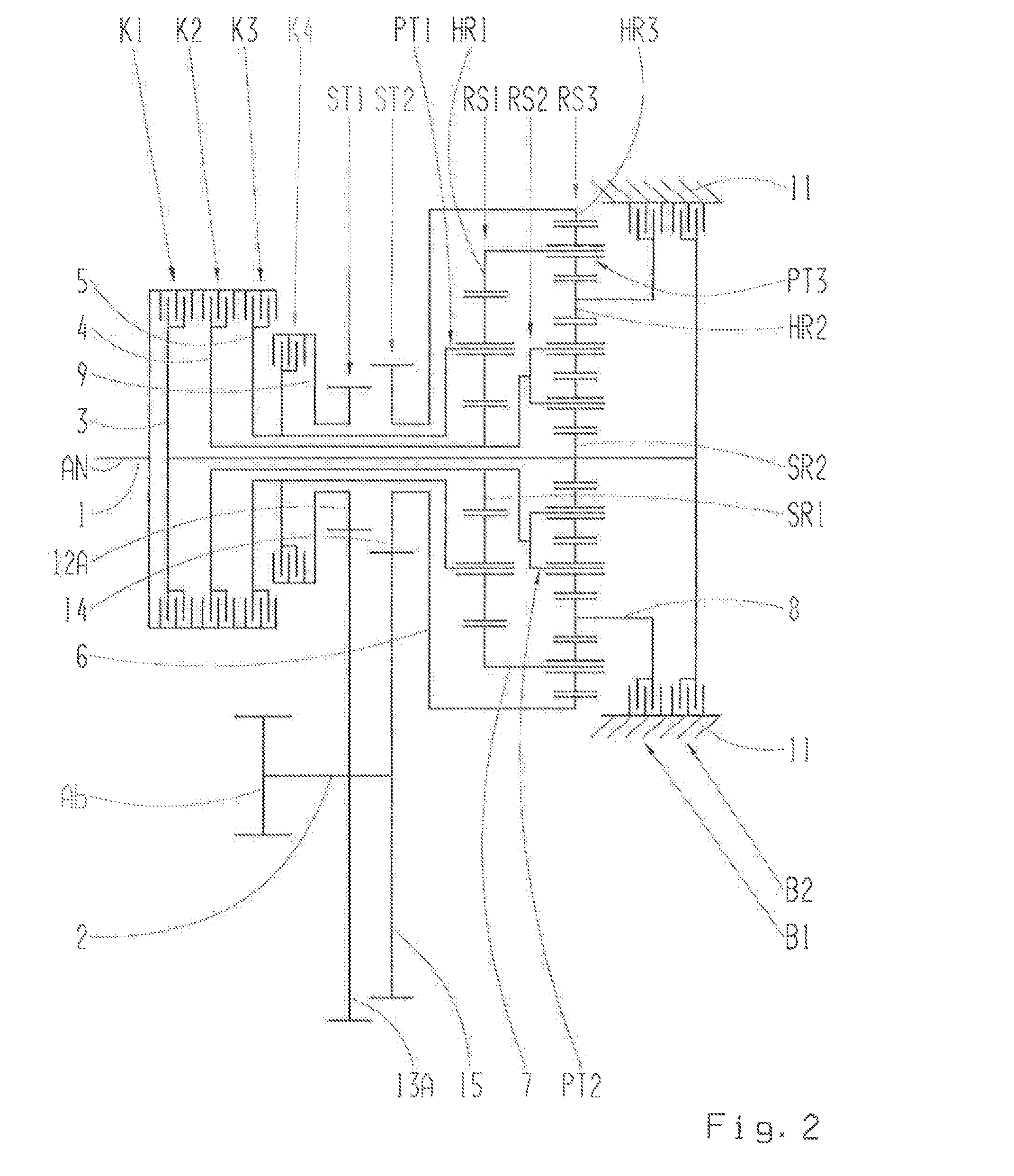

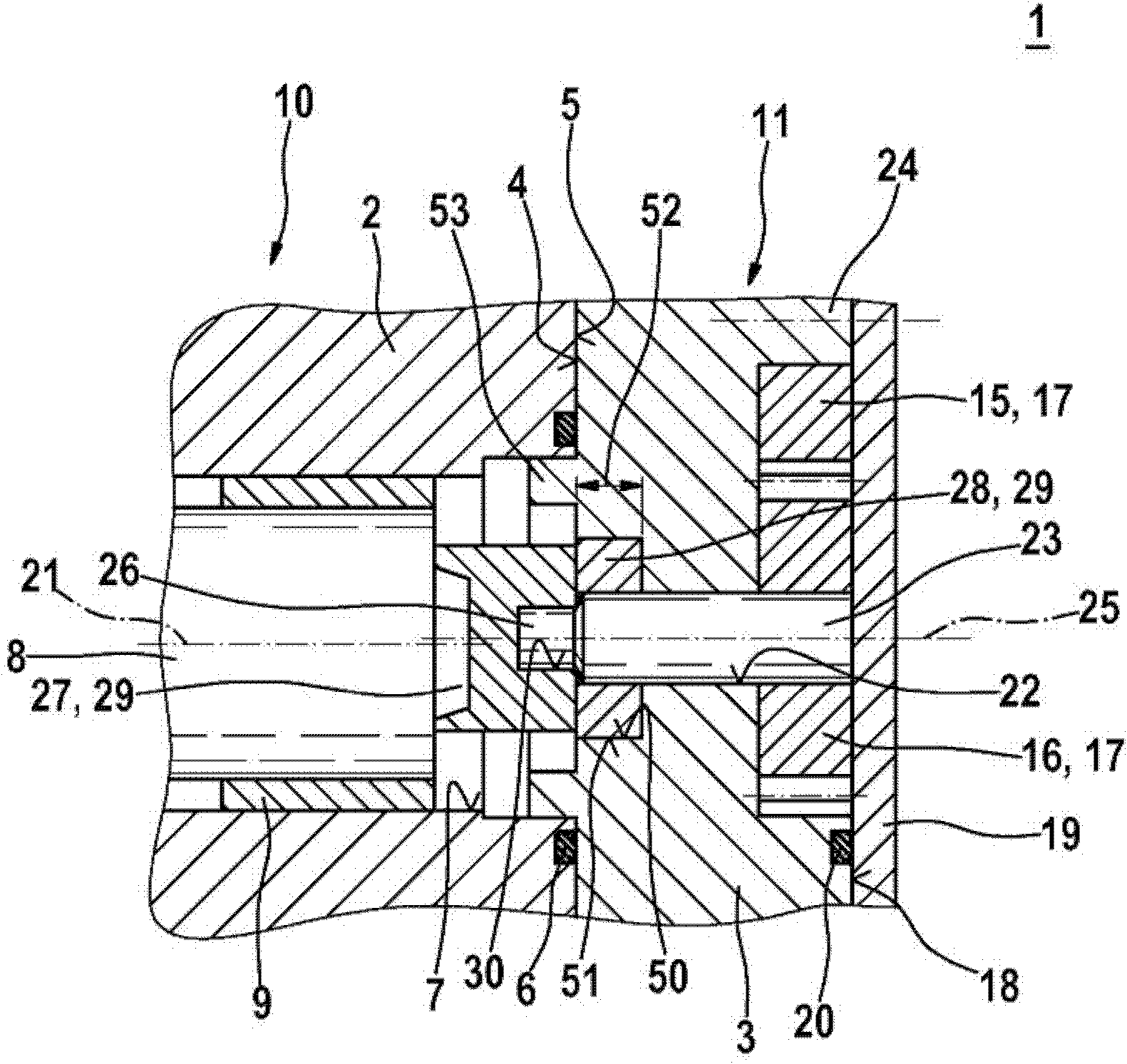

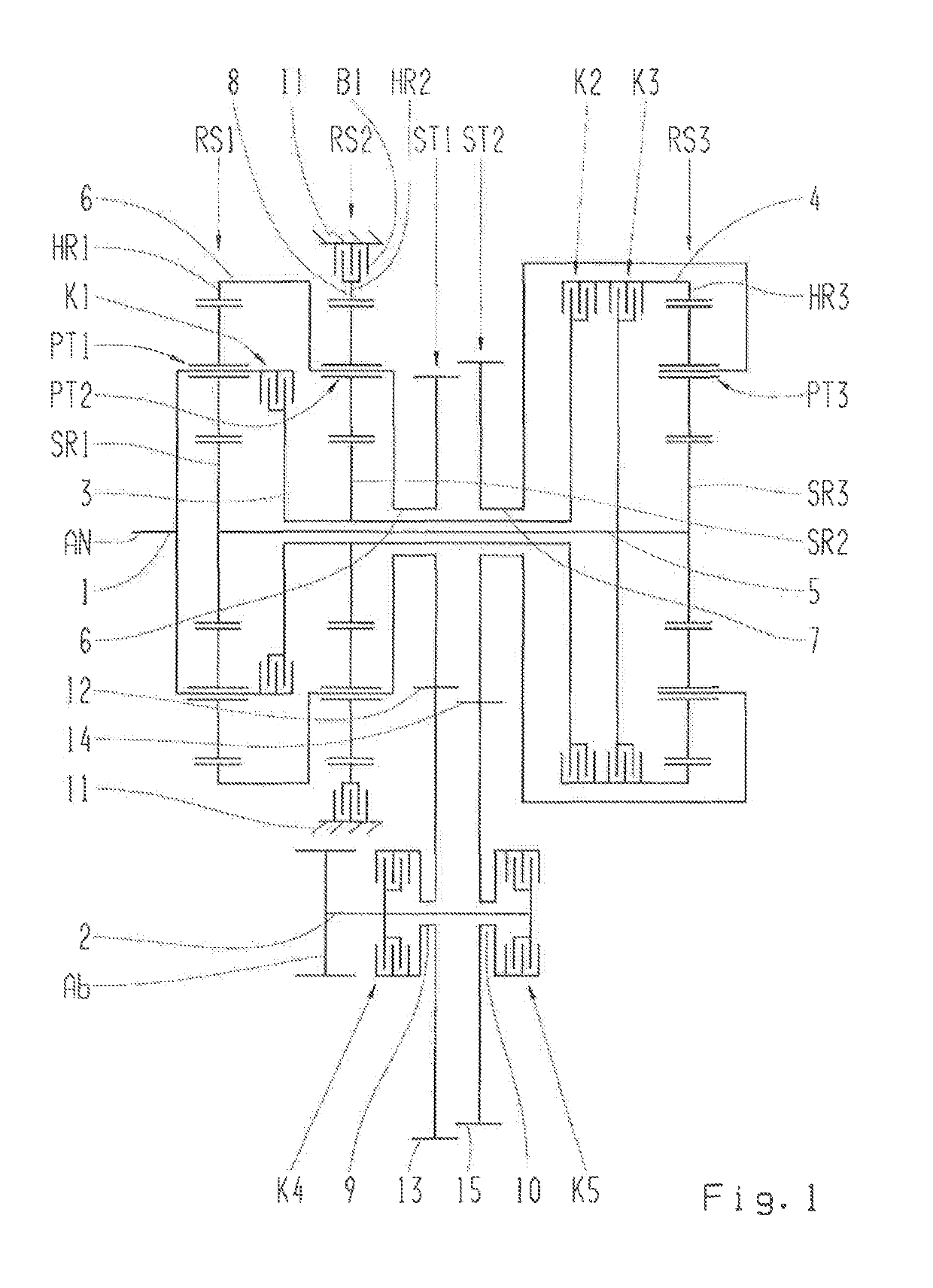

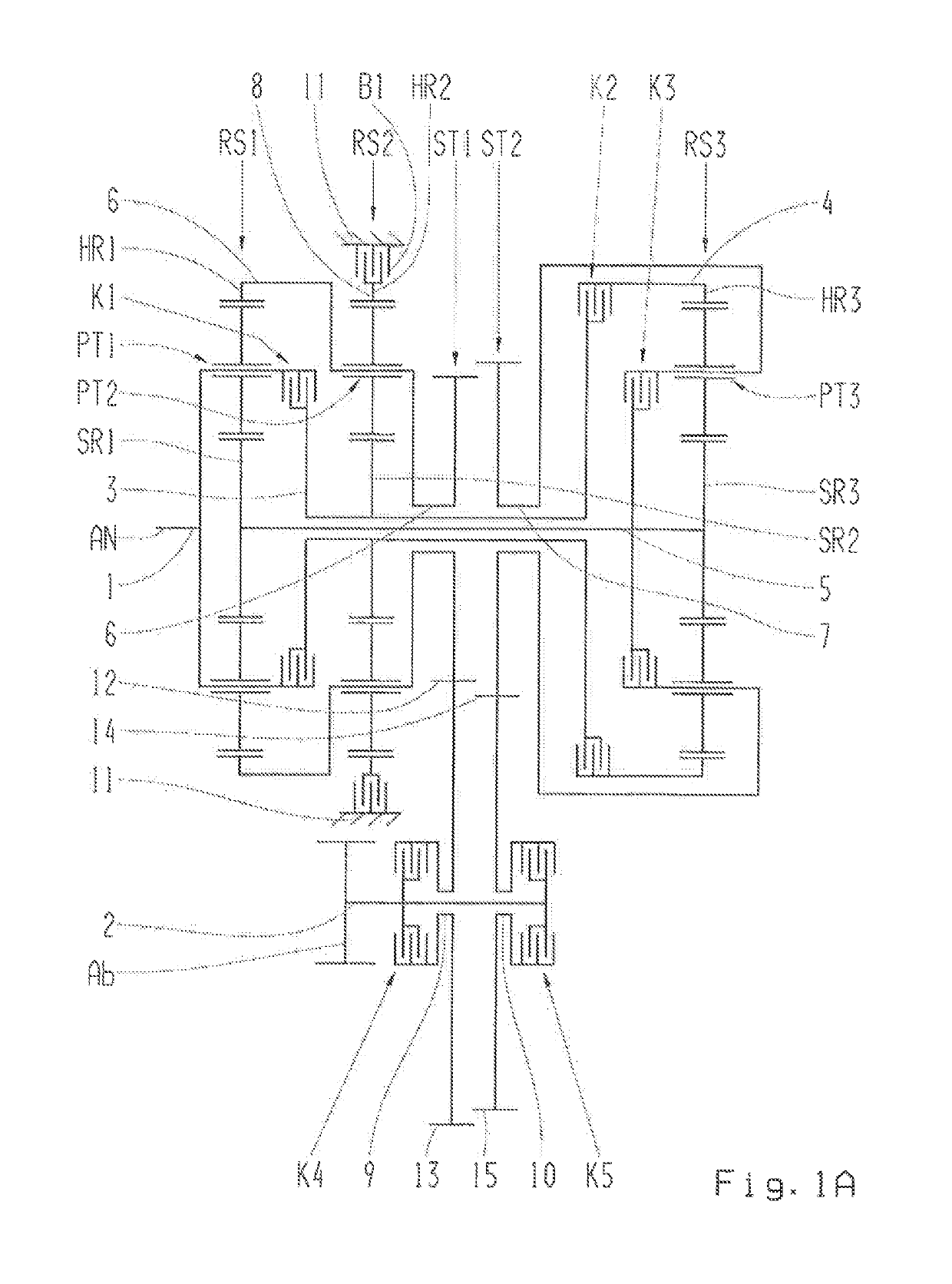

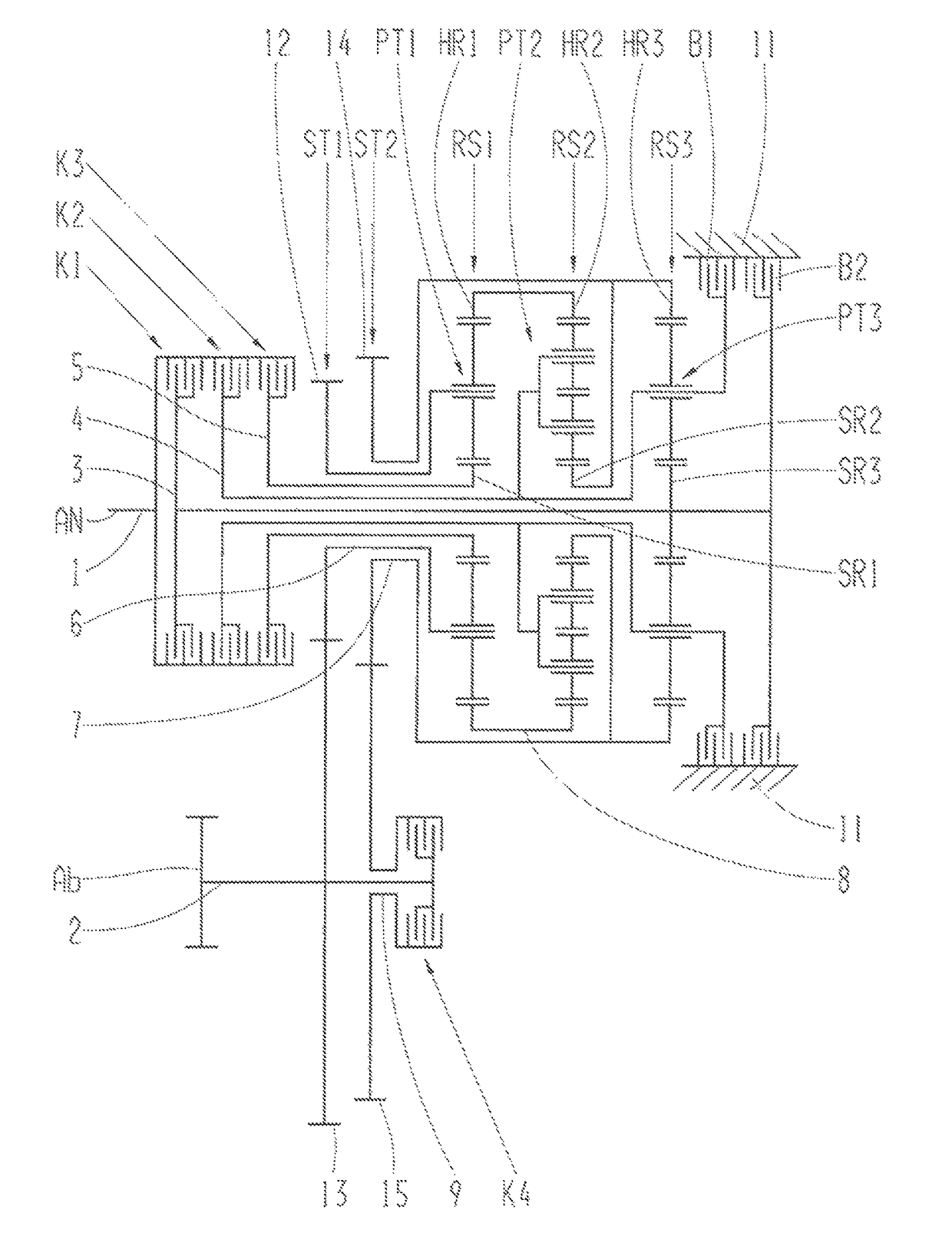

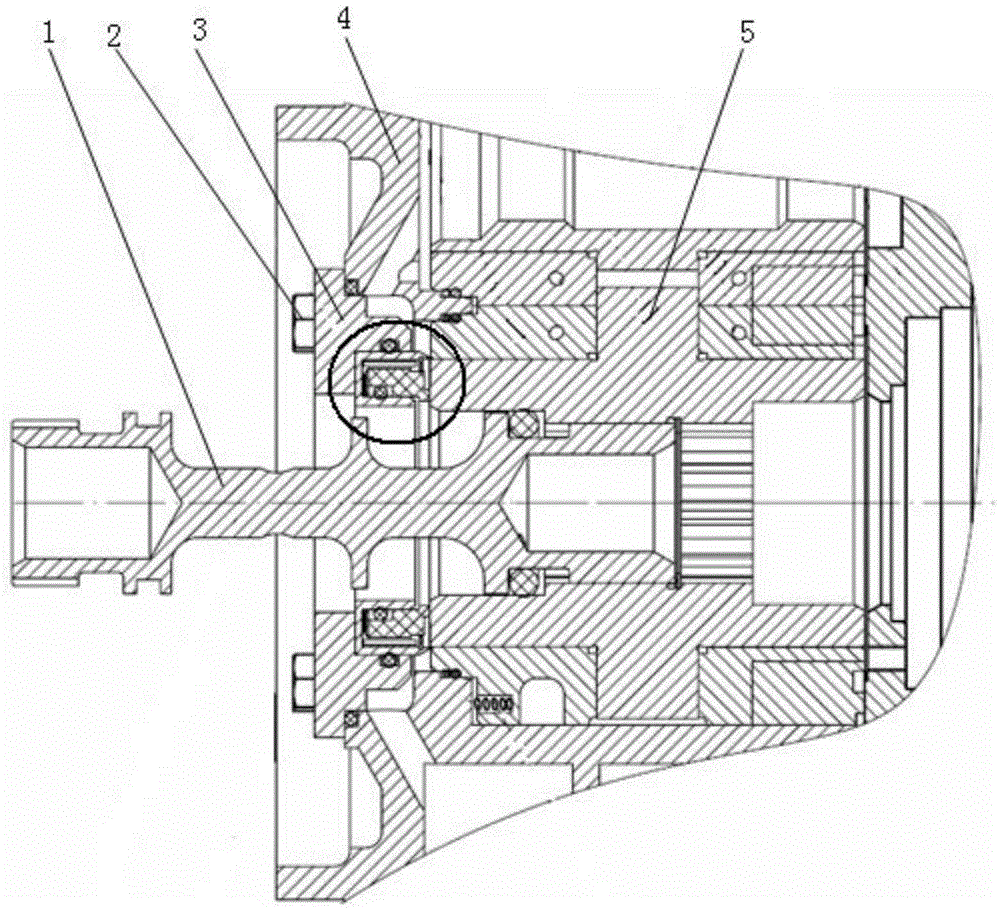

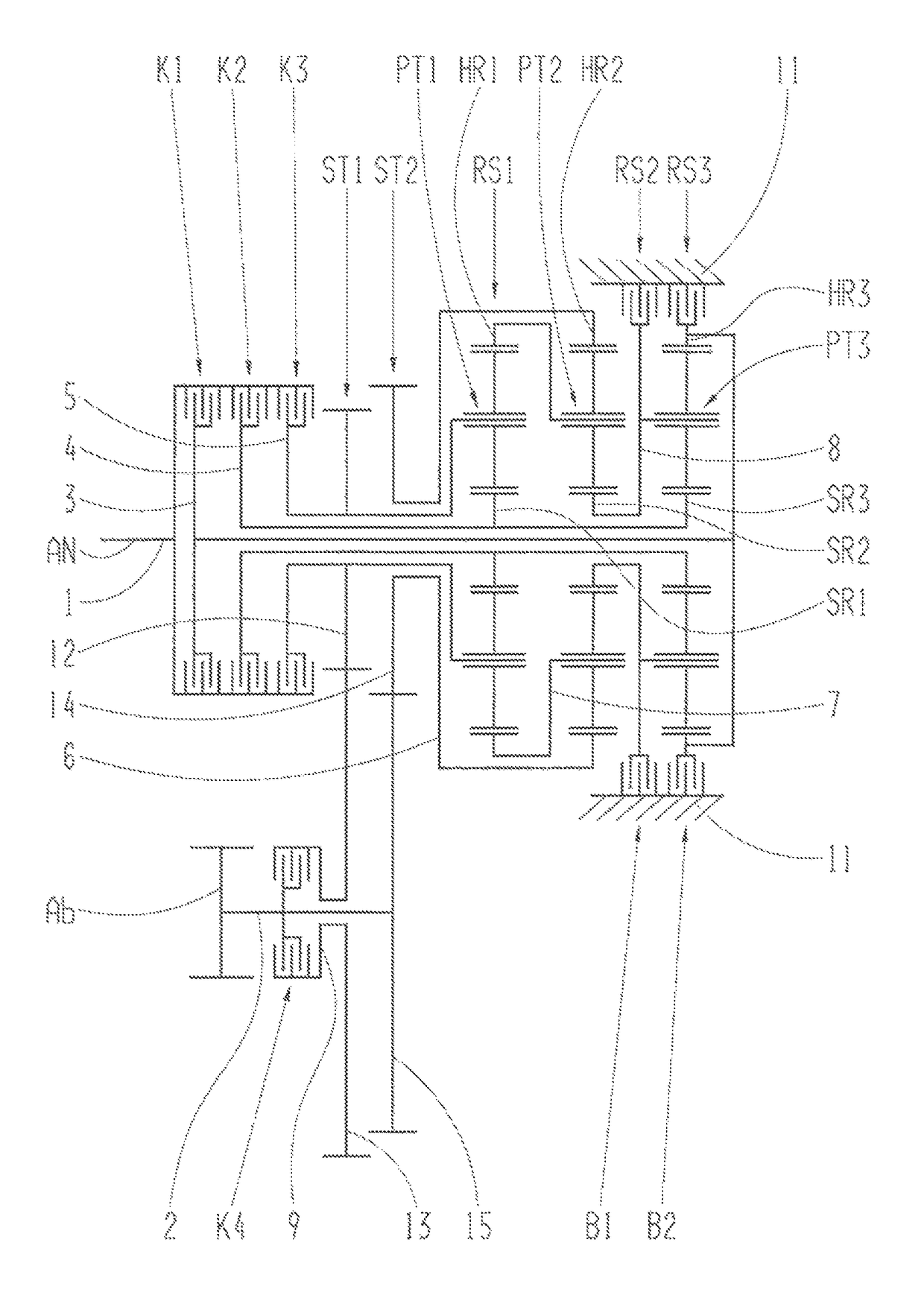

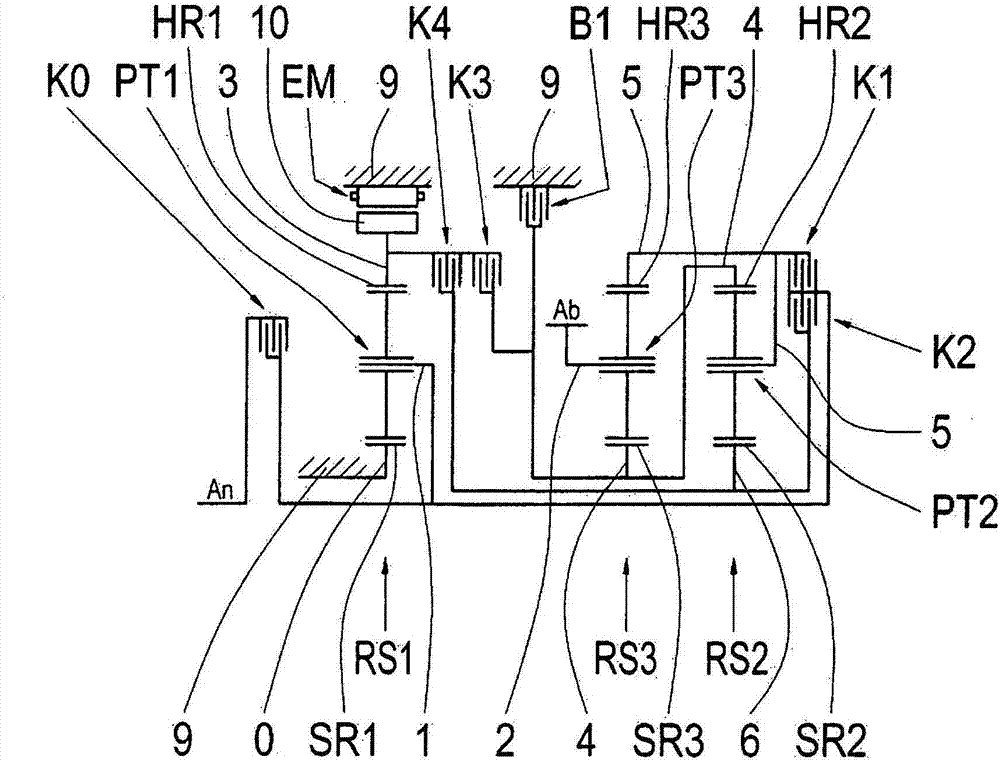

Multi-stage planetary transmission

InactiveUS10436287B2Save axial installation spaceImprove efficiencyToothed gearingsTransmission elementsEngineeringSpur gear

A multi speed transmission in planetary design for a vehicle, the transmission having a housing, a first shaft (1) as a drive (AN), a second shaft (2) as an output (Ab) axially parallel to the drive, three planetary gear sets (RS1, RS2, RS3), additional shafts (3-10), and six shifting elements (K1, K2, K3, K4, K5, B1) actuatable to realize several gear ratios. The transmission further includes machine elements (ST1, ST2) that transfer torque between the drive (AN) and the output (Ab). The first shaft (1) is connected to the planetary gear carrier (PT1) of the first planetary gear set (RS1) and is connectable at least to the sun gear (SR2) of the second planetary gear set (RS2) and to the ring gear (HR3) of the third planetary gear set (RS3). Additionally, the second shaft (2) is connected to the first machine element (ST1) and to the second machine element (ST2).

Owner:ZF FRIEDRICHSHAFEN AG

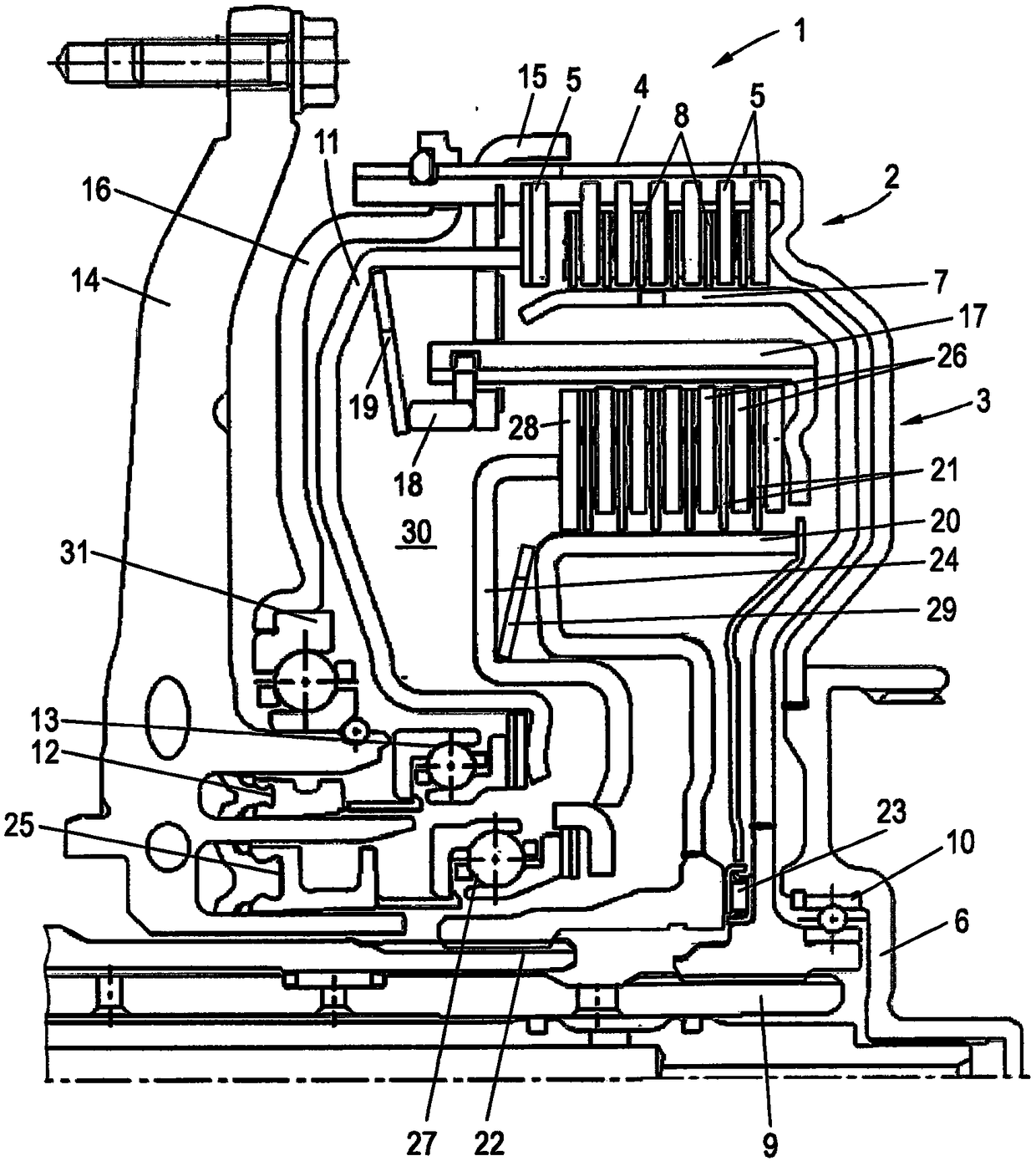

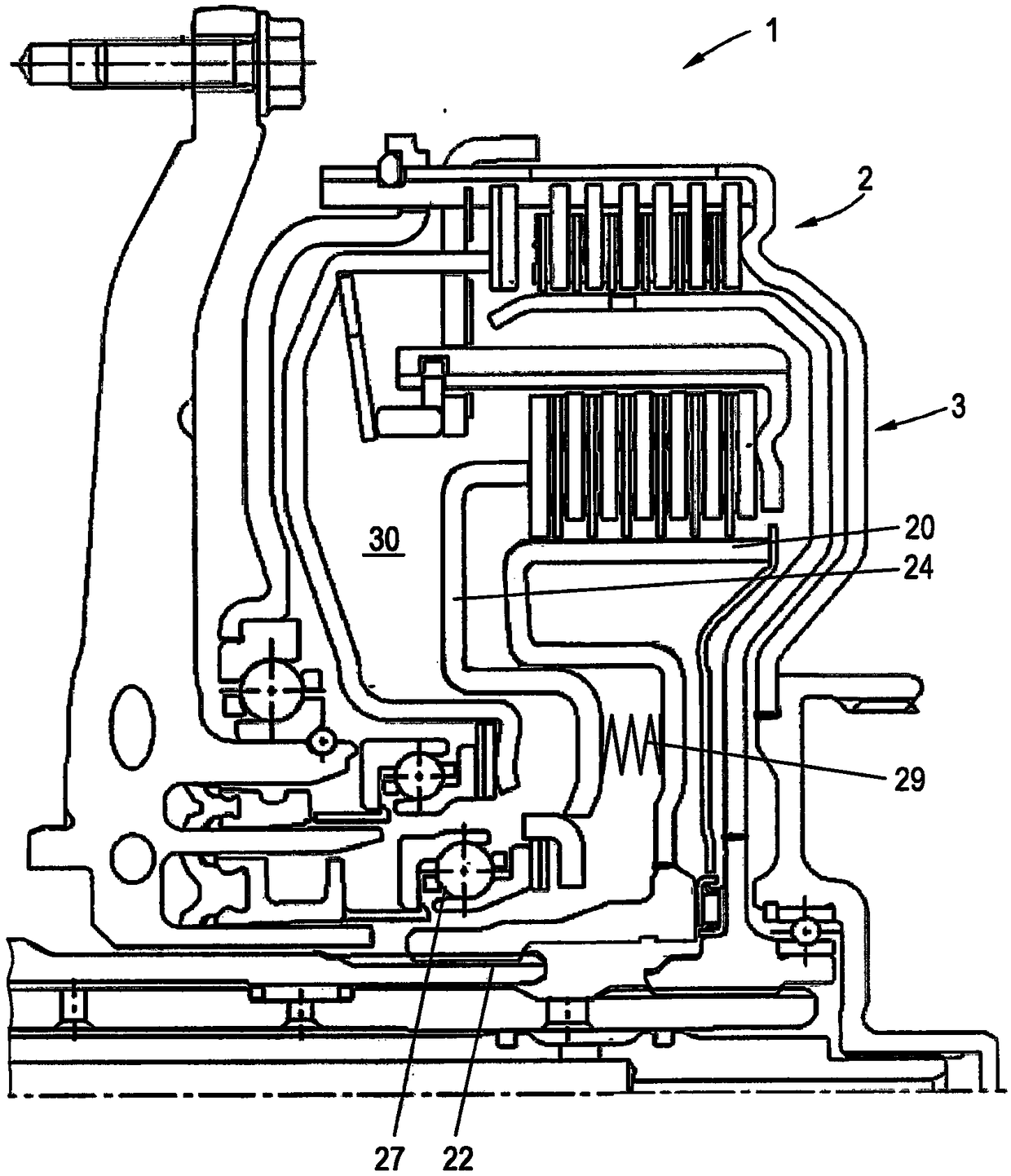

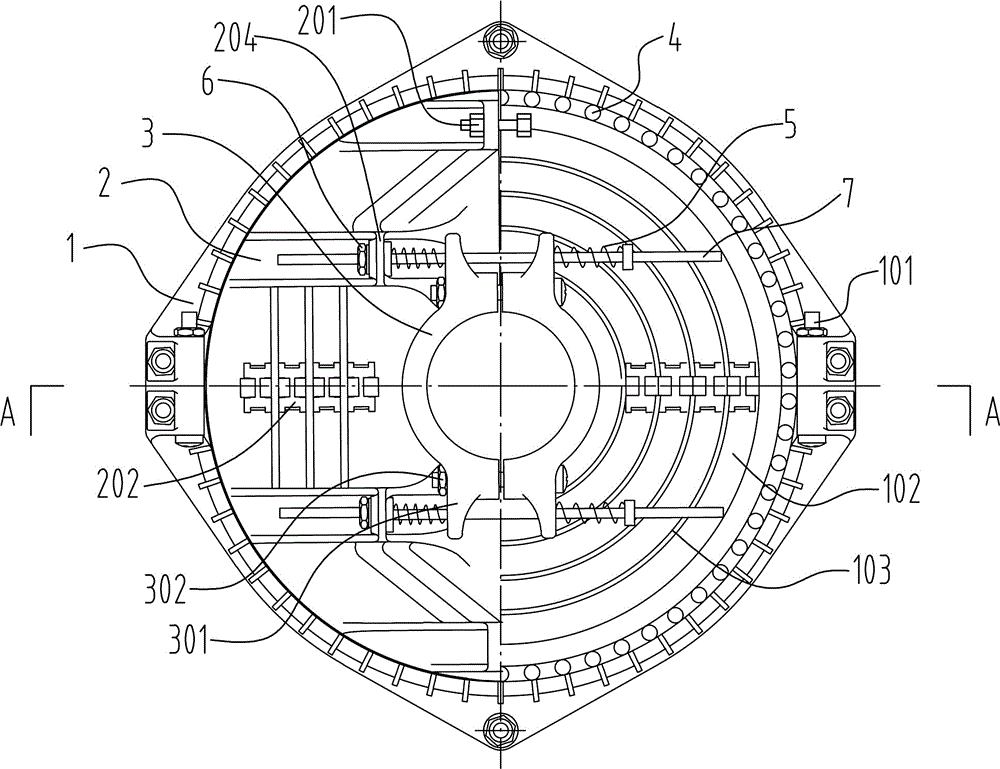

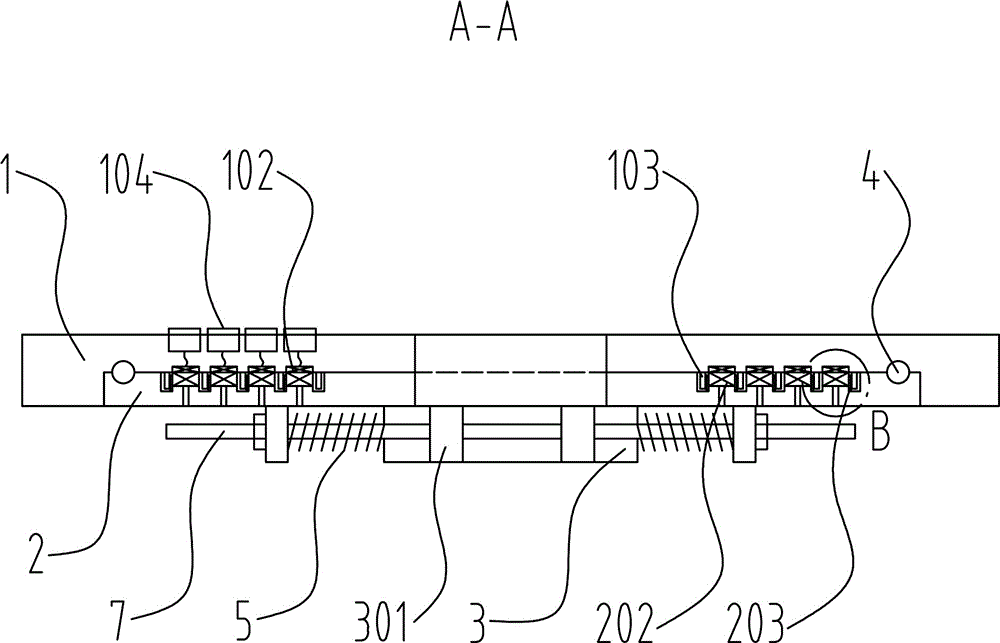

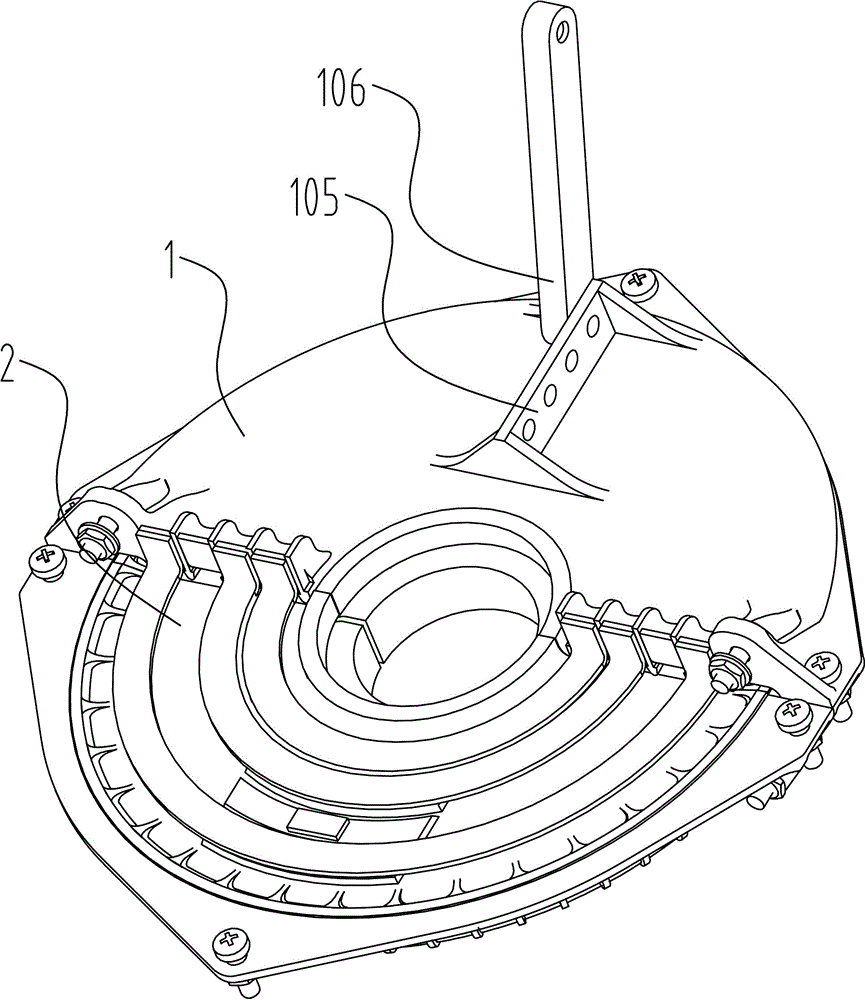

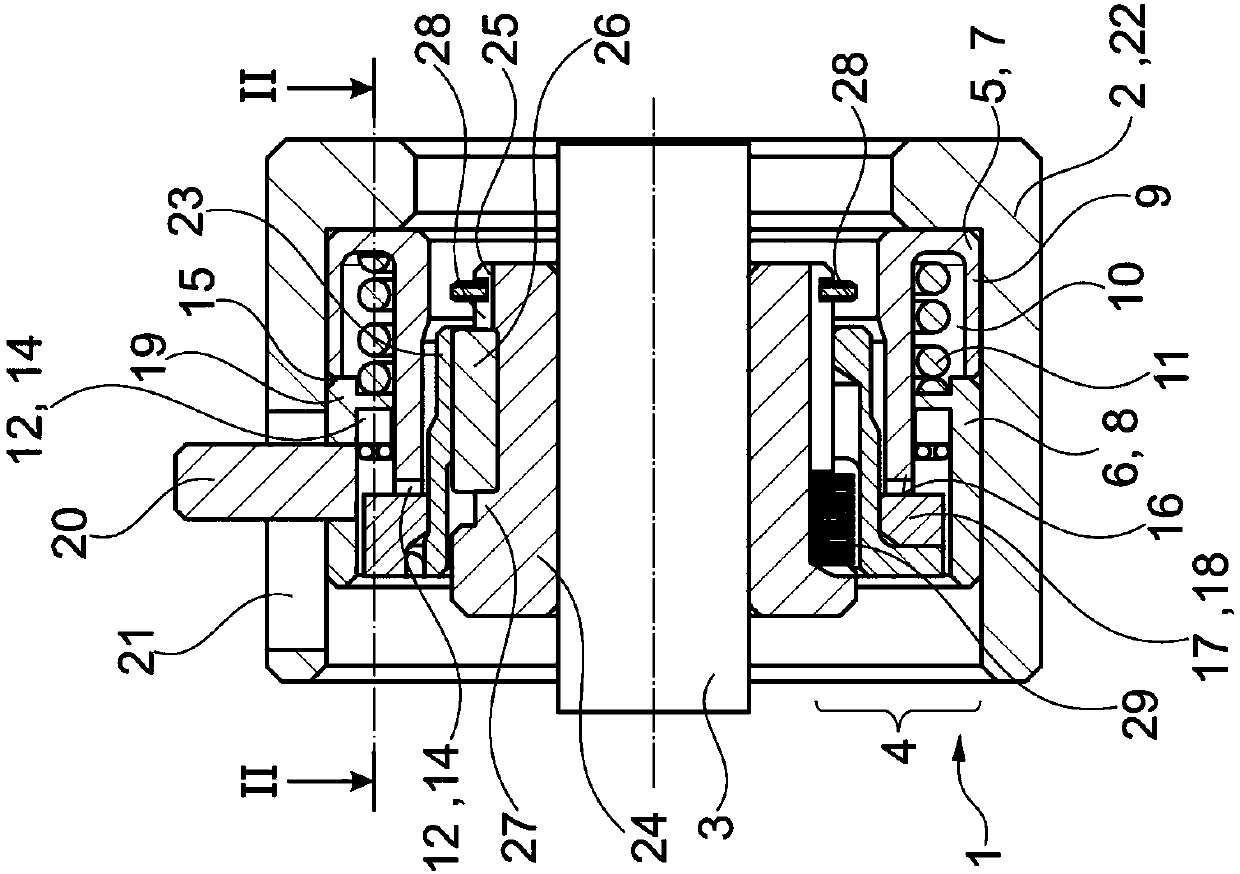

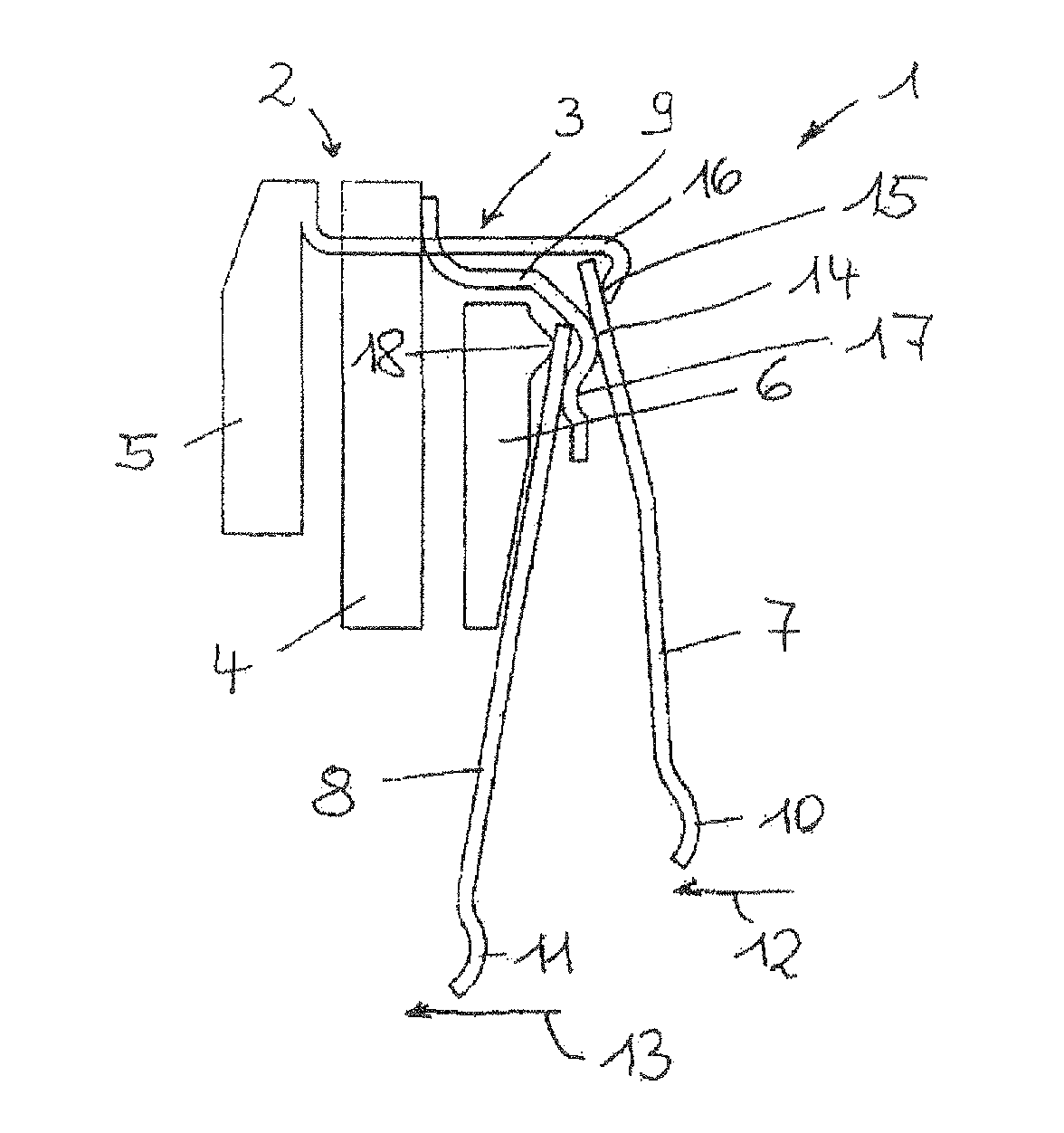

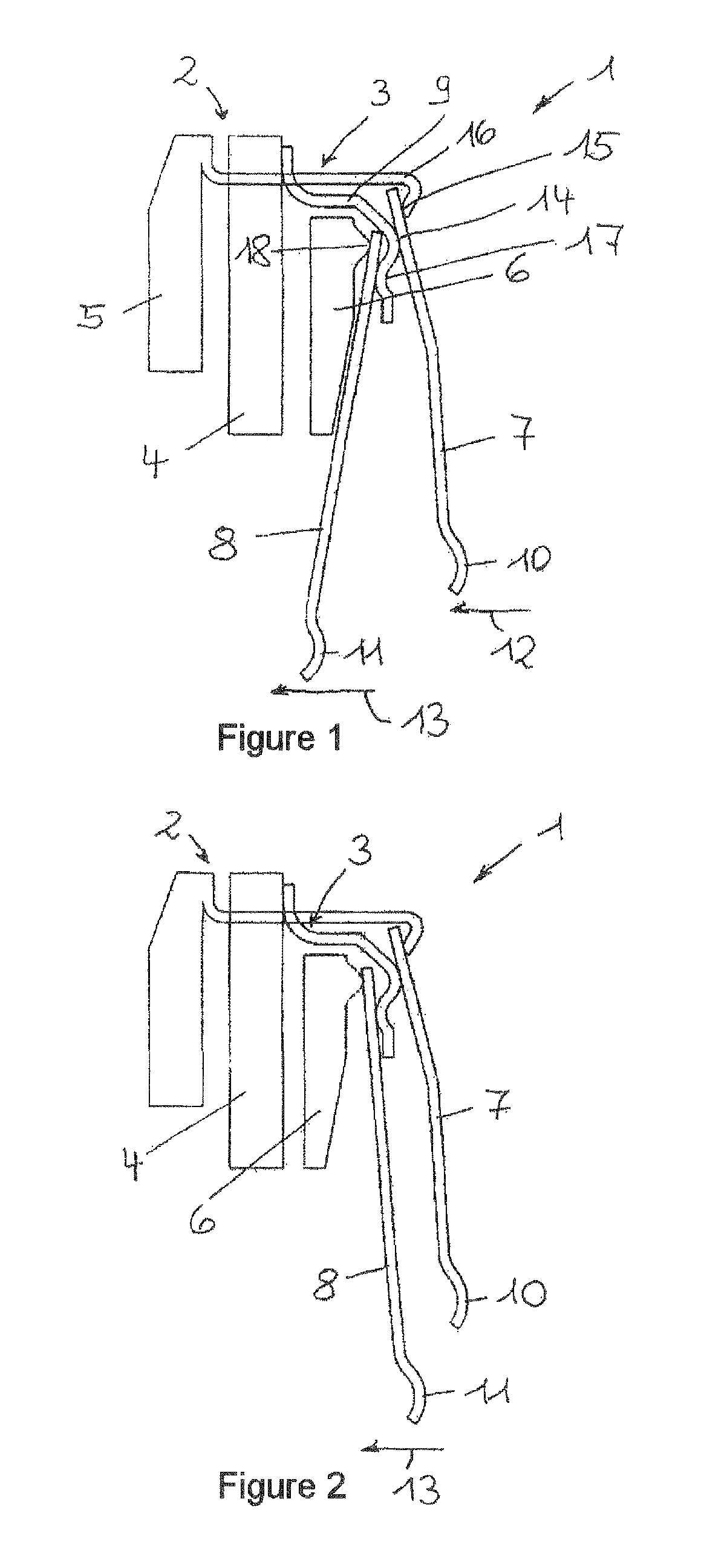

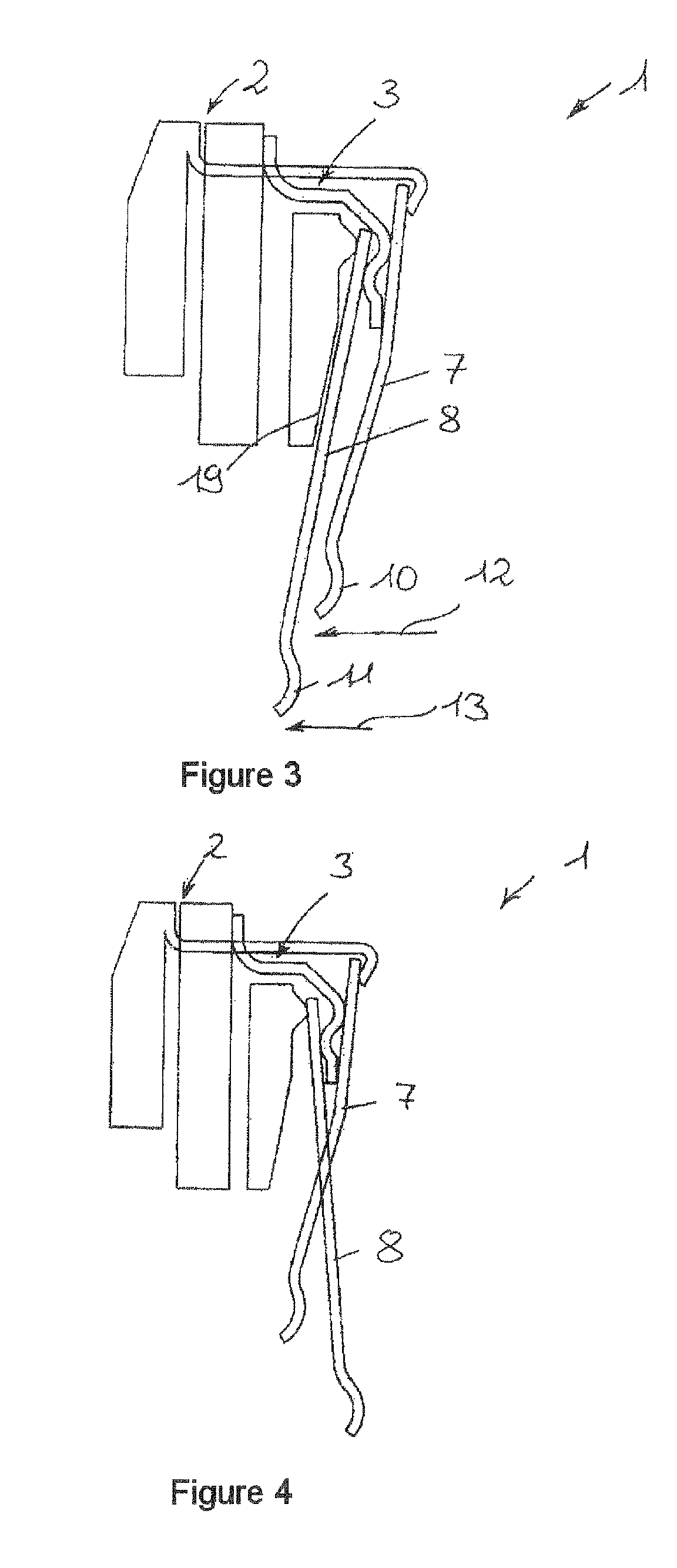

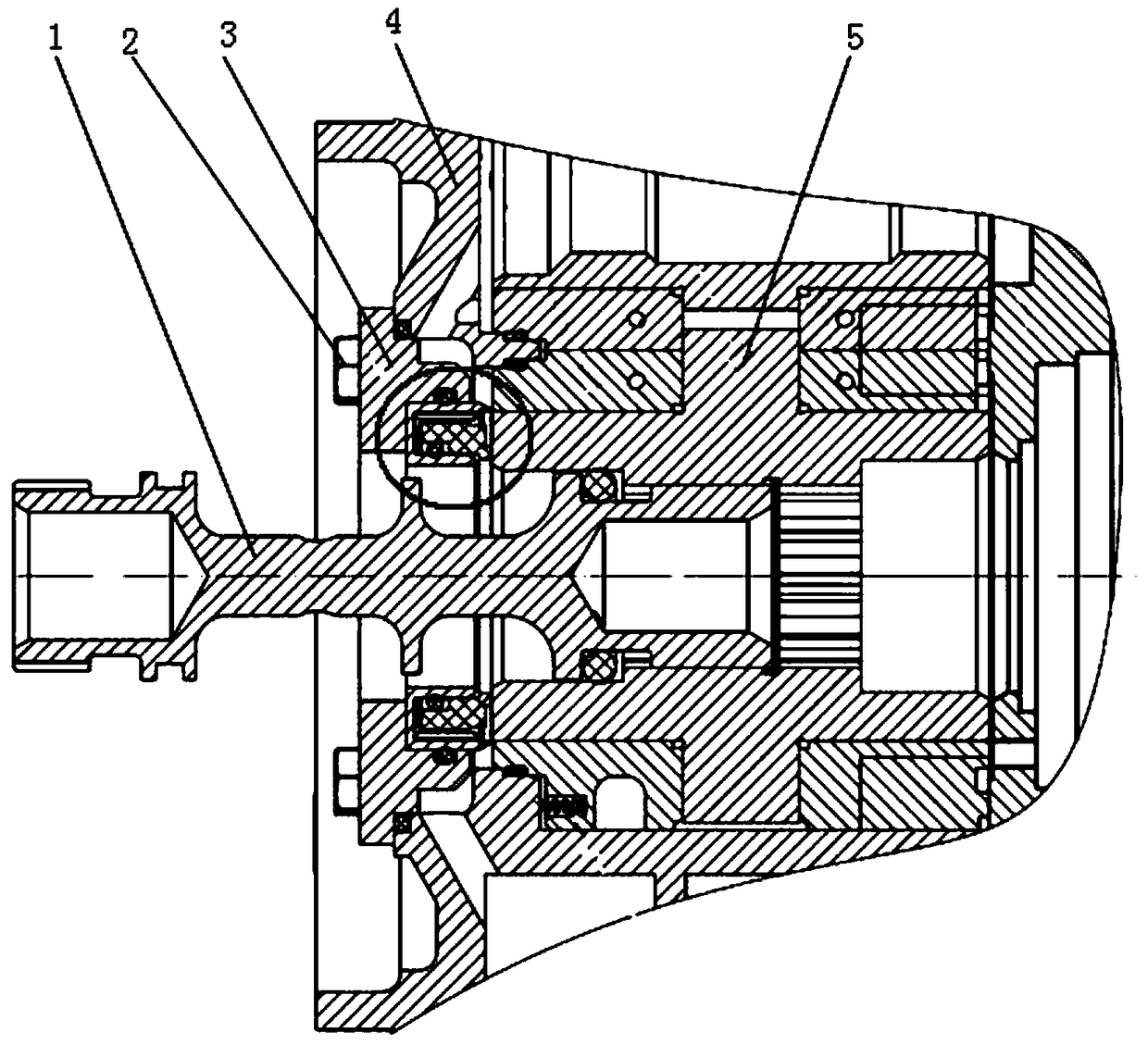

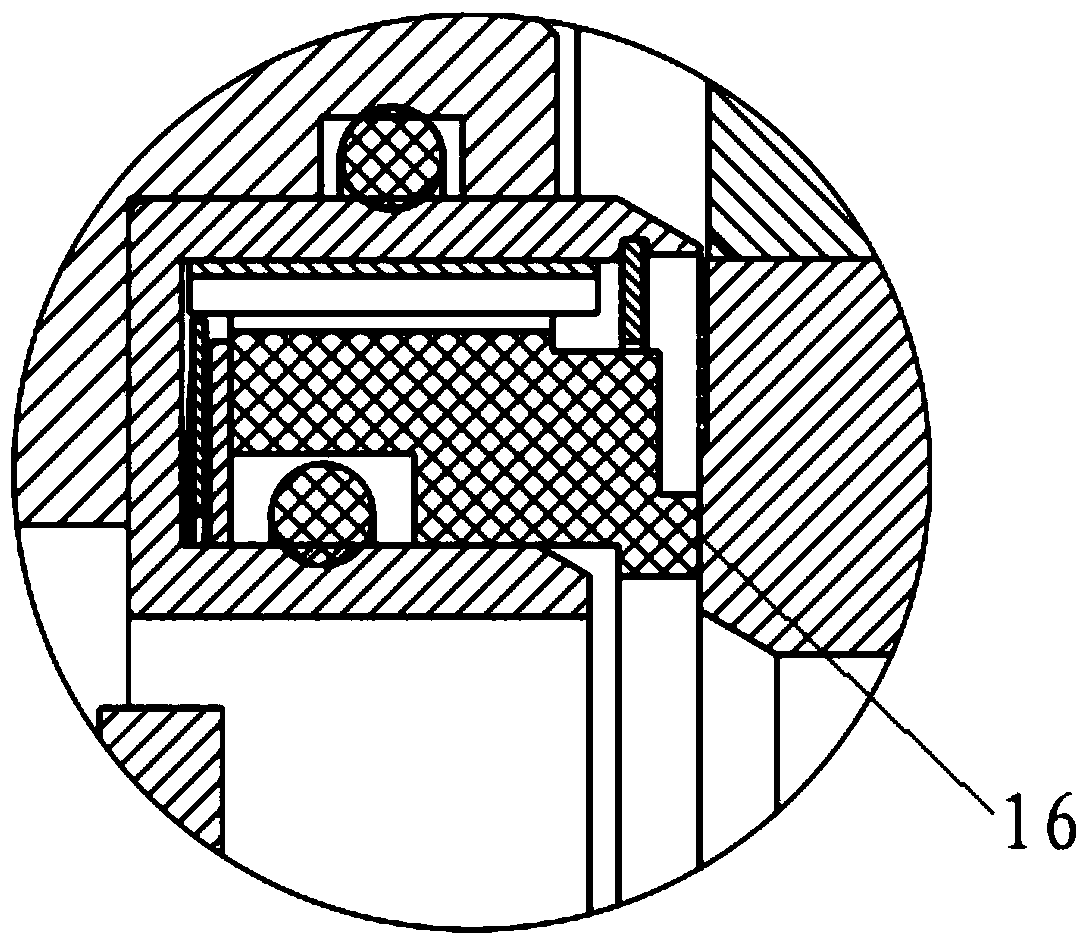

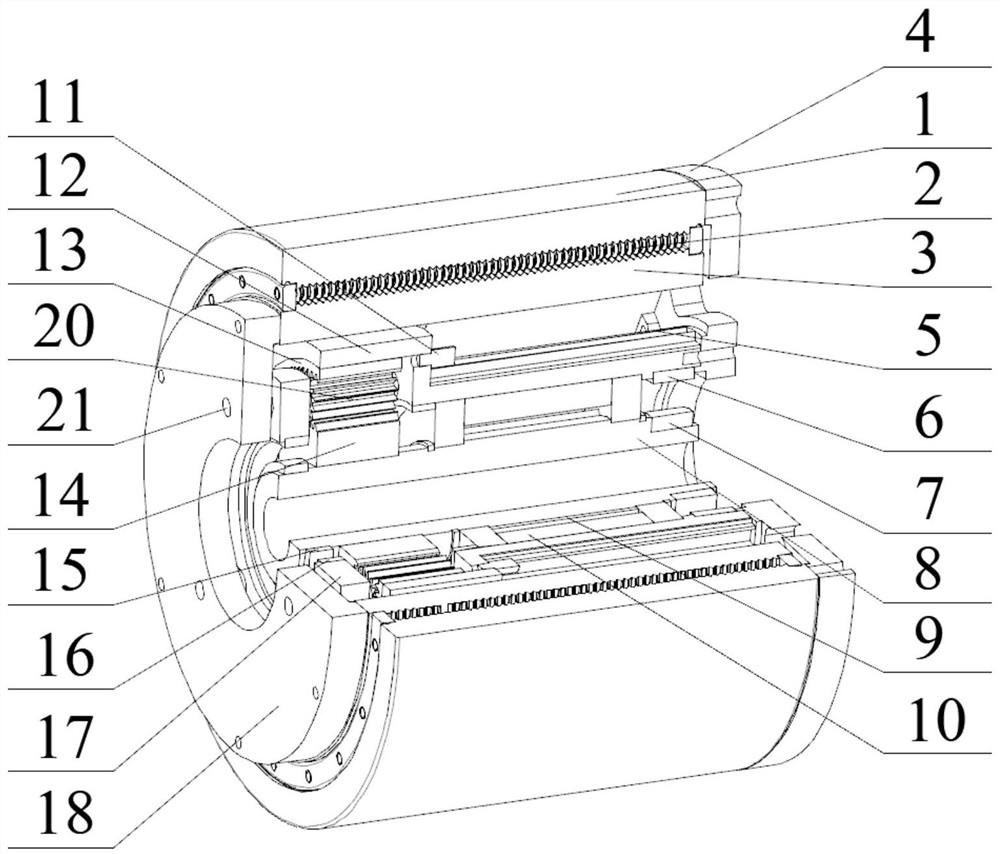

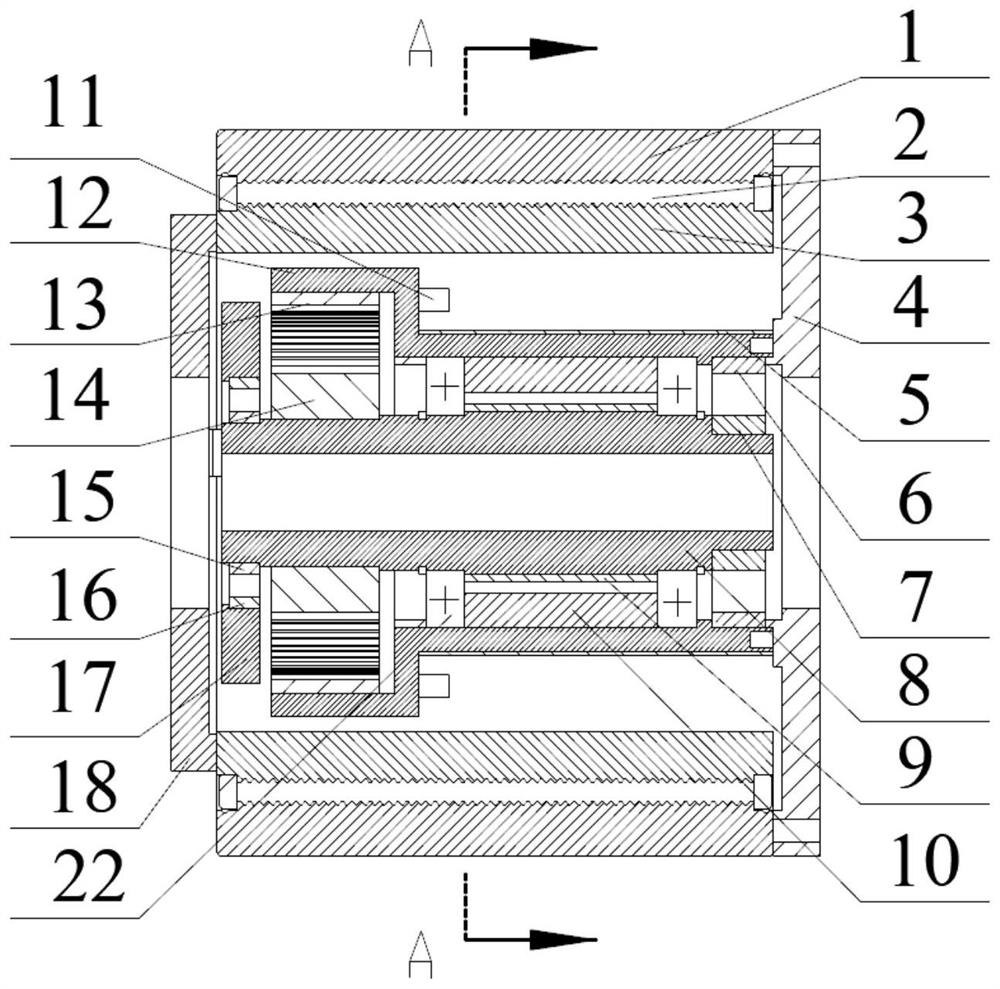

Clutch device

The invention relates to a clutch device comprising two sub-clutches (2, 3) having a common torque input element on the drive side and transmitting torque on the driven side to two separate output elements, and The sub-clutches respectively comprise an outer plate holder (4, 17) having an outer piece (5, 26) and an inner piece holder (7, 20) having an inner piece (8, 21) and an axially movable operating element ( 11, 24), by means of the actuating element, the set of sheets respectively formed by the outer piece and the inner piece (5, 8, 26, 21) can be pressed, wherein at least one sub-clutch(2, 3) The actuating elements (11, 24) are arranged in a rotatable manner on the driven side.

Owner:SCHAEFFLER TECH AG & CO KG

Conductive slip ring capable of being used for oil pumping unit balancing unit

InactiveCN106257775ASave axial installation spaceEasy to assemble and disassembleRotary current collectorFlexible member pumpsElectricityEngineering

The invention provides a conductive slip ring comprising a fixing disc which is used for being connected with a fixing component and connected with electric input; a rotary disc which can be rotatably installed in the fixing disc, wherein the rotary disc and the fixing disc are conductively connected and the rotary disc is connected with electric output; and a shaft fixing ring which is used for being fixedly connected with a rotary part and connected with the rotary disc. As for a rotary electrode, a rotary electric brush is fixedly connected with an electrode stud, and the electrode stud is connected with one end of a fixing threaded sleeve through threads. The fixing threaded sleeve is provided with a through hole. The free end of the electrode stud is provided with internal threads. A fastening screw penetrates through the through hole to be connected with the electrode stud. The other end of the fixing threaded sleeve is provided with a connecting post. The axial installing space is reduced by using the disc structure, installation can be performed between the decelerator and the crank arm of an oil pumping unit and a power supply and control electric signals can be reliability transmitted.

Owner:WUHAN UNIV OF SCI & TECH +1

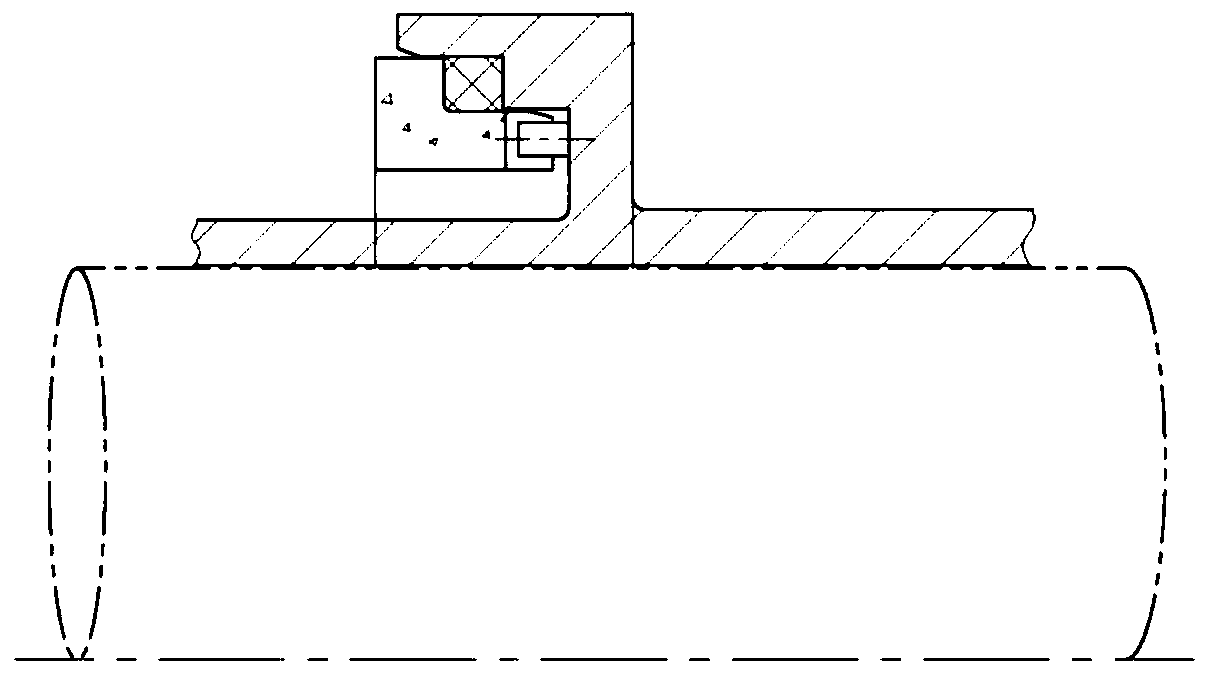

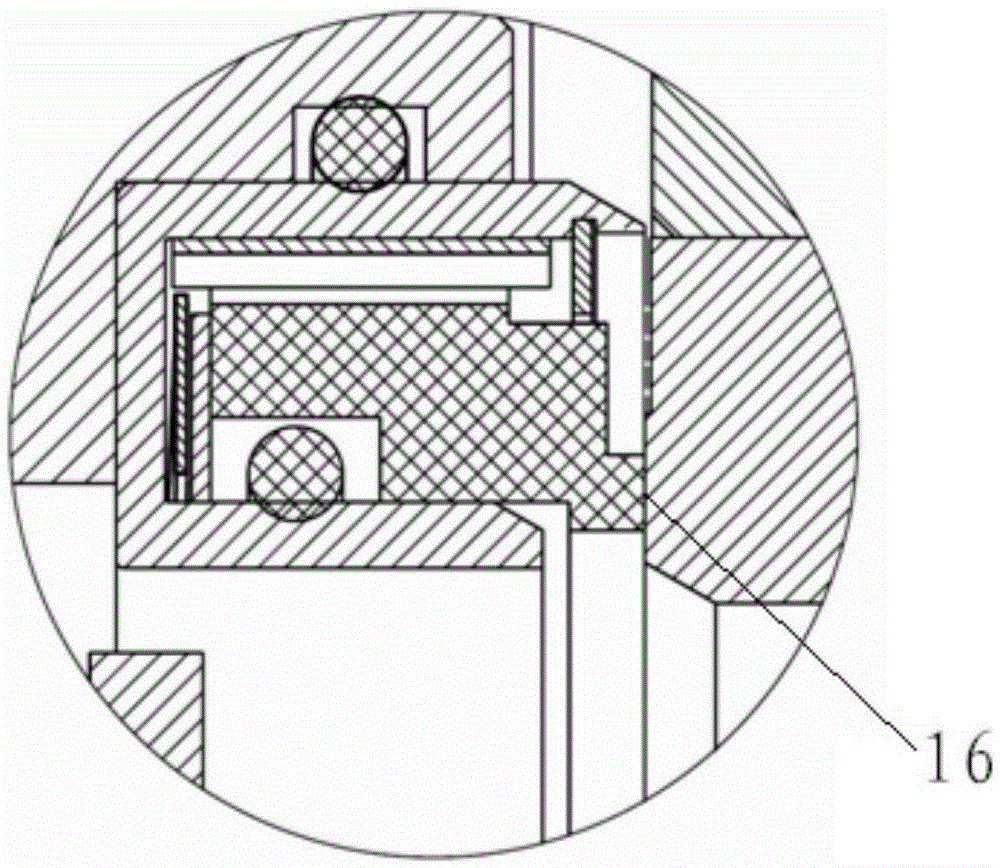

Movable ring assembly sealing device

PendingCN110107692AAxial dimension shortSave axial installation spaceEngine sealsEngineeringMechanical engineering

The invention discloses a movable ring assembly sealing device. The movable ring assembly sealing device is composed of a movable ring assembly and a shaft sleeve. The movable ring assembly is composed of a movable ring, a first steel ball, a sealing gasket, a pressing ring, a wave spring, a wave spring seat, a shaft retainer ring and a second steel ball. A shaft sleeve step is arranged at one endof the shaft sleeve. A first steel ball socket is arranged on the right side of the shaft sleeve step, a spring clamping groove is formed in the other end of the shaft sleeve, and a second steel ballsocket is arranged on the left side of the spring clamping groove. The first steel ball is arranged in the first steel ball socket. The movable ring abuts against the shaft sleeve step. The sealing gasket is pressed into an inner hole of the movable ring and pressed by the pressing ring. The wave spring abuts against the pressing ring. The second steel ball is arranged in the second steel ball socket. The wave spring seat abuts against the wave spring. The shaft retainer ring is clamped in the spring clamping groove and is integrated with the spring clamping groove. The movable ring sealing assembly is small in axial size and convenient to install, the flatness and perpendicularity of the end face of the movable ring are high, and the load around the end face is uniform.

Owner:XIAN YONGHUA GROUP

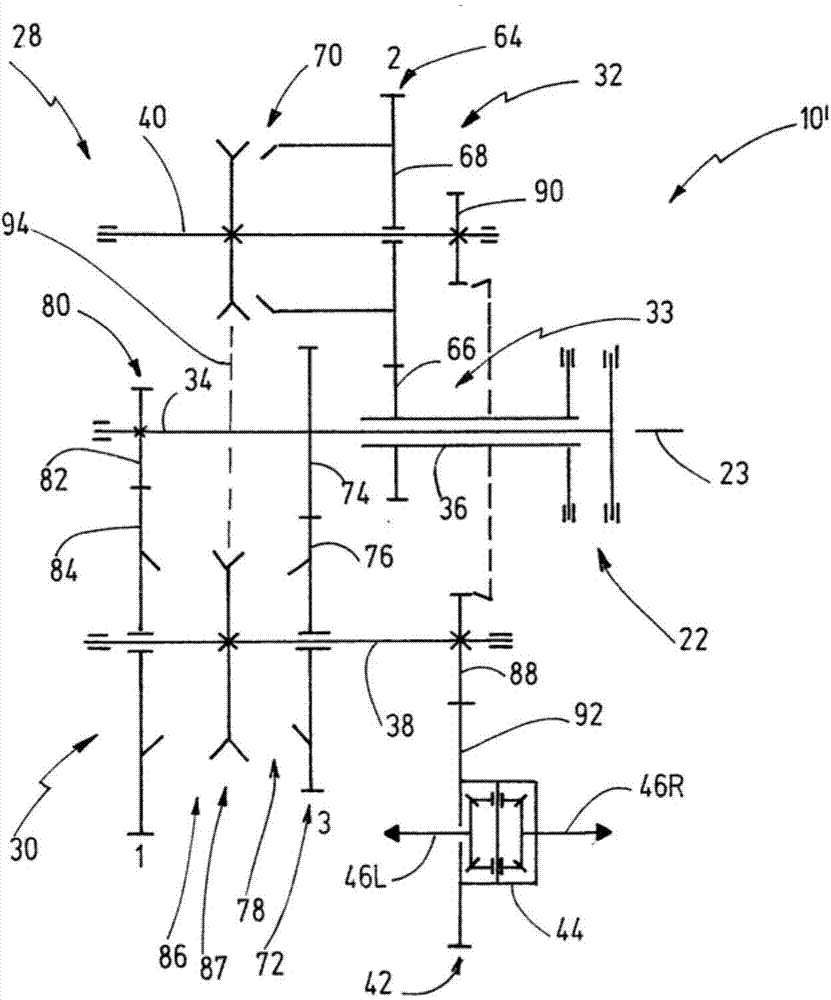

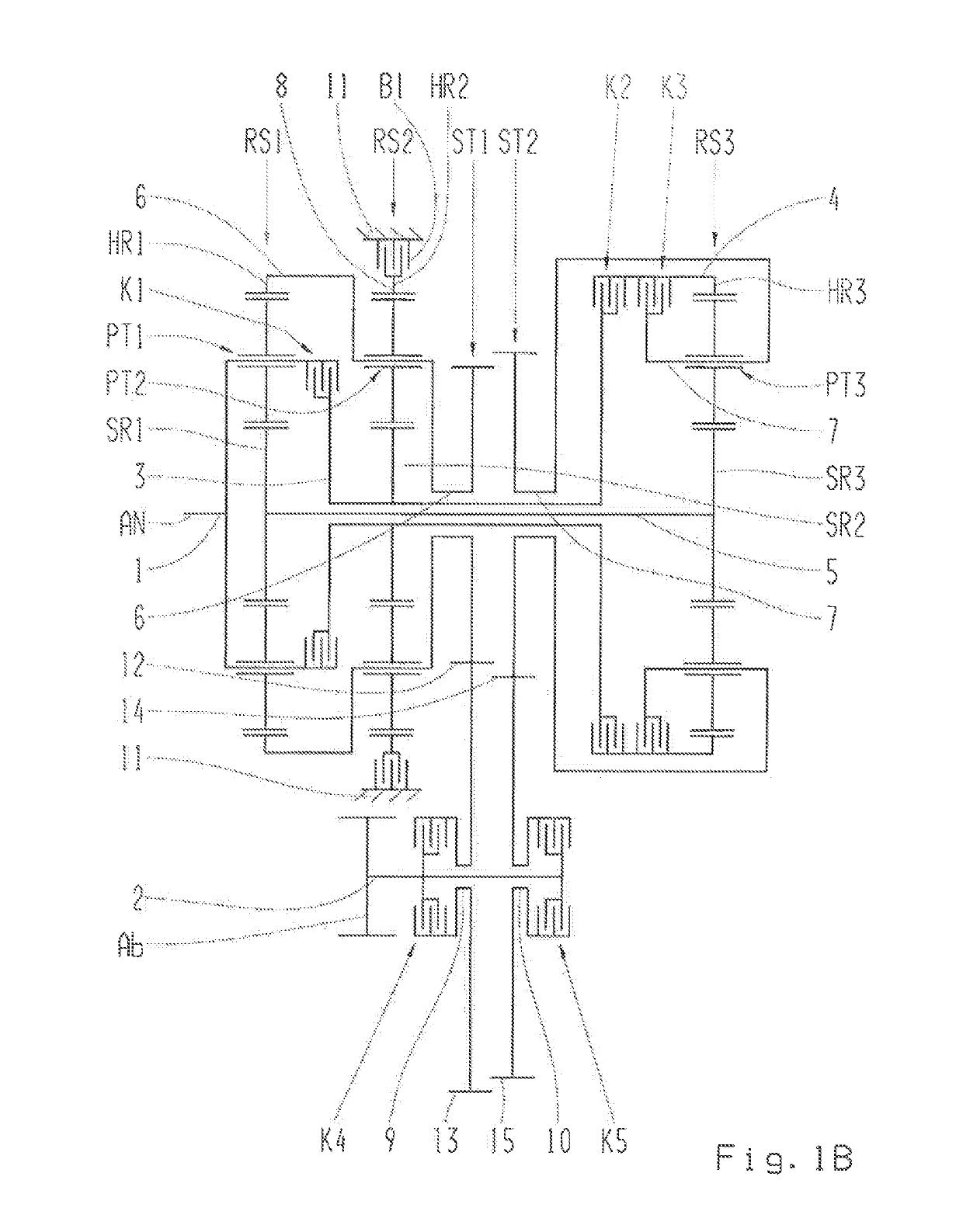

Multi-speed transmission in planetary design

InactiveUS9618088B2Save axial installation spaceImprove efficiencyToothed gearingsTransmission elementsEngineeringMechanical engineering

A multi-speed transmission in planetary design for a vehicle with a housing includes a first shaft provided as a drive and a second shaft provided as an output that is arranged axially parallel to the drive. Three planetary gear sets and additional shafts along with six shifting elements are provided, through which the actuation of several gears are realized. Machine elements are provided for the transfer of torque between the drive and the output. The first shaft is connectable, as a drive, to the sun gear of the third planetary gear set, to the planetary gear carrier of the second planetary gear set, to the planetary gear carrier of the third planetary gear set, and is connectable or connected to the sun gear of the first planetary gear set. The second shaft is connected or connectable, as a drive, to the first machine element and to the second machine element.

Owner:ZF FRIEDRICHSHAFEN AG

Crossed roller bearing and speed reducer

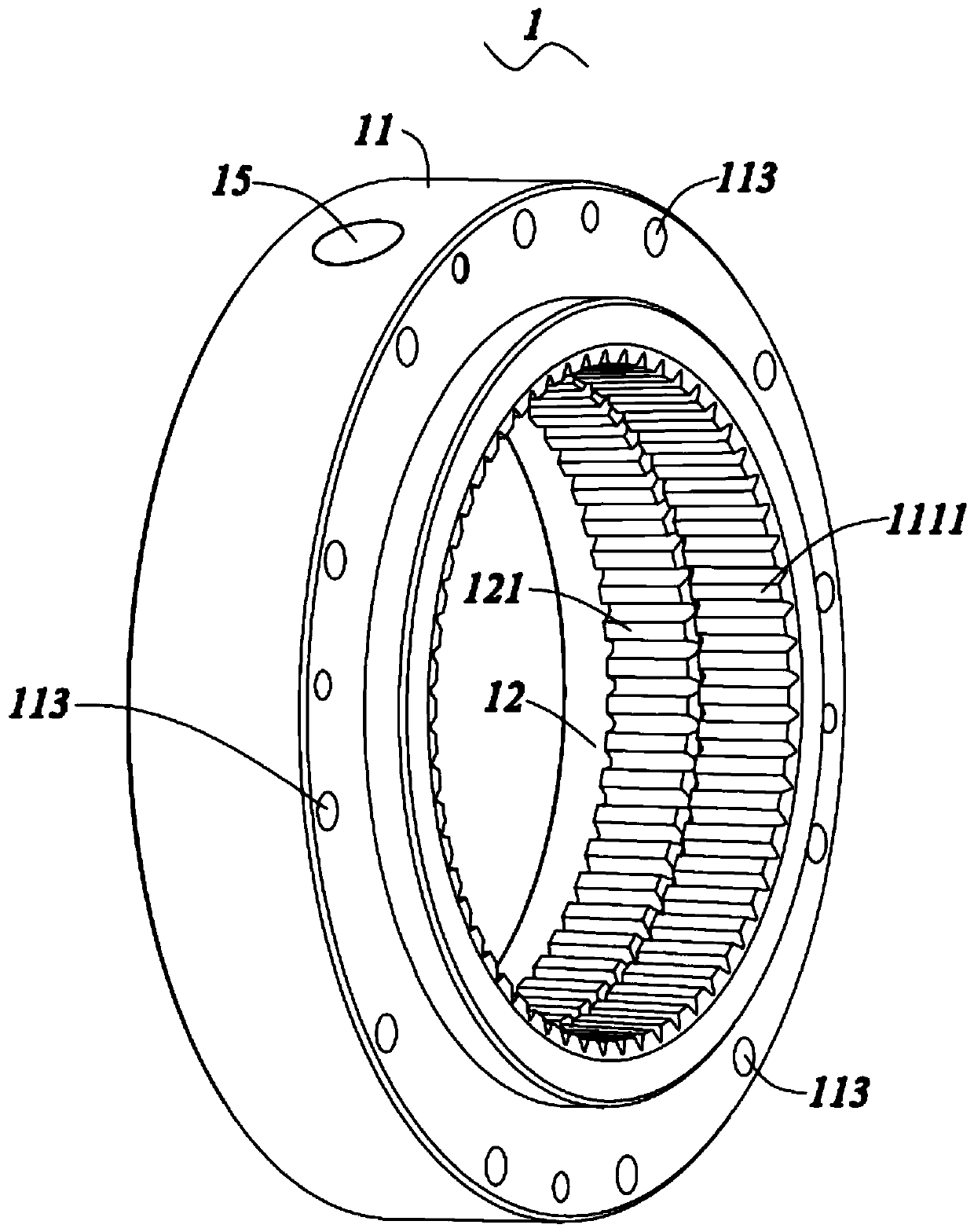

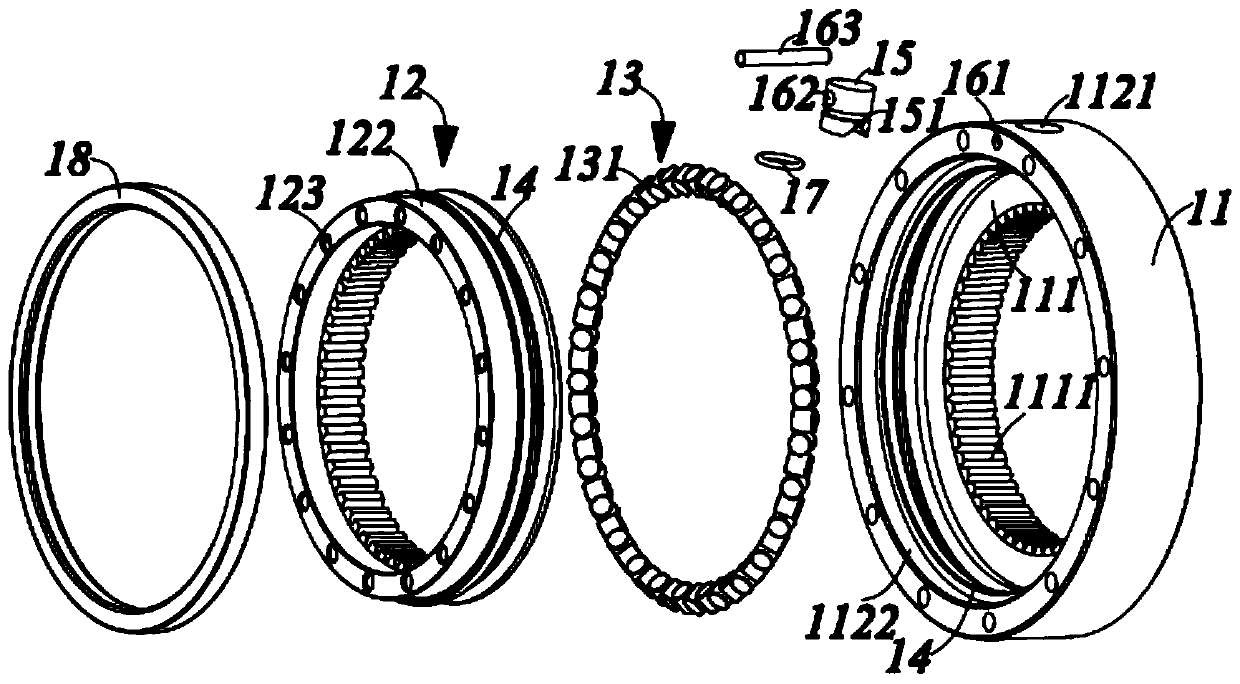

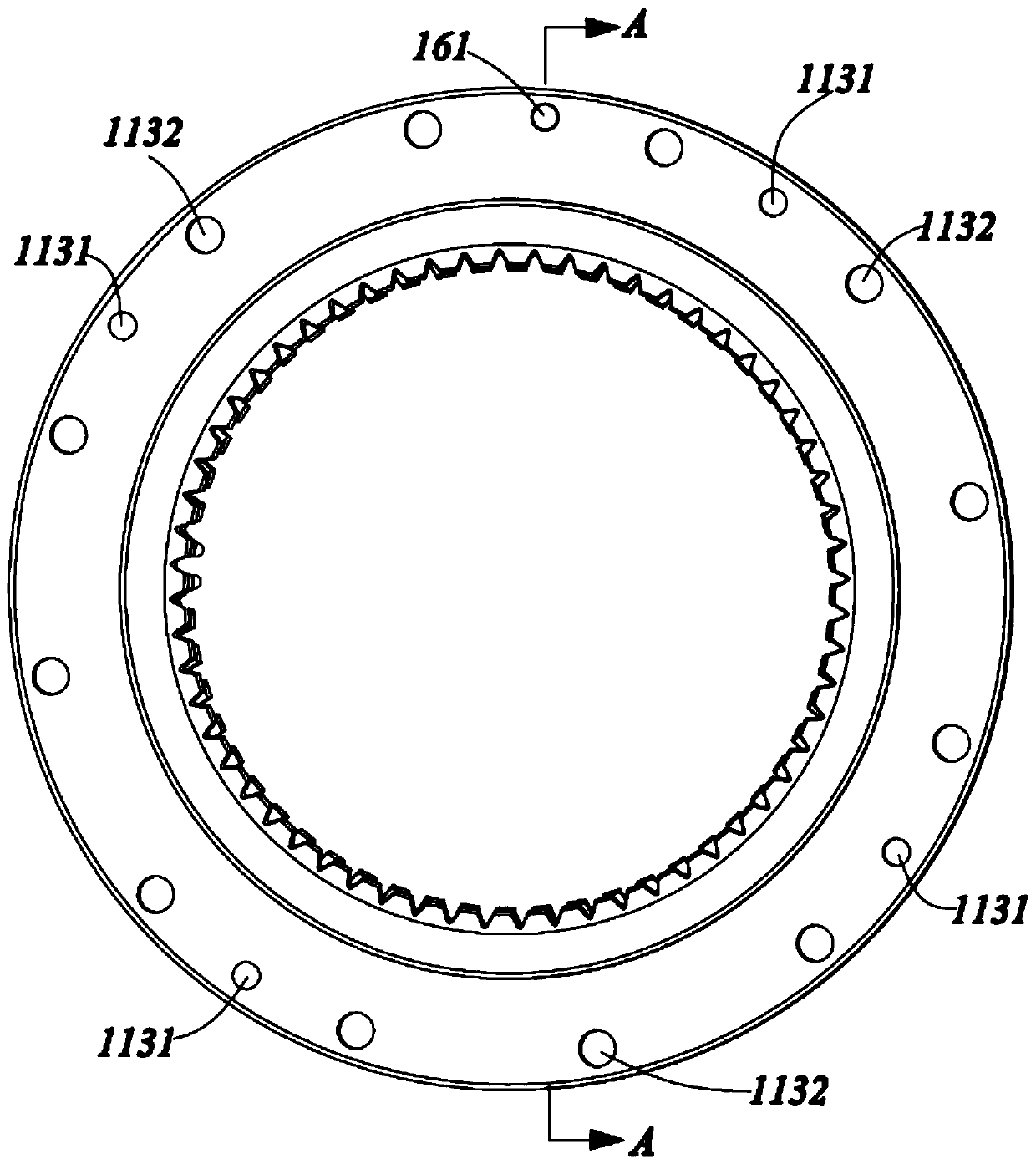

PendingCN110836223ASave axial installation spaceCompact structureRoller bearingsGearboxesReduction driveEngineering

The invention provides a crossed roller bearing and a speed reducer. The crossed roller bearing comprises an outer ring bearing, an inner ring bearing arranged coaxial with the outer ring bearing, anda rolling assembly arranged between the outer ring bearing and the inner ring bearing, wherein the outer ring bearing is provided with a first outer circular ring and a second outer circular ring which are coaxially arranged along the axial direction of the outer ring bearing, the inner diameter of the first outer circular ring is smaller than the inner diameter of the second outer circular ring,the inner ring bearing is located on the inner side of the second outer circular ring, and the rolling assembly is located between the inner ring bearing and the second outer circular ring; and the inner circumference of the first outer circular ring is provided with a first inner gear ring, and the inner circumference of the inner ring bearing is provided with a second inner gear ring. The crossed roller bearing can be directly applied to the NGWN type speed reducer or the NN type speed reducer, and can substantially reduce the axial installation space required by the NGWN type speed reduceror the NN type speed reducer at the same time, so that the speed reducer is compact in structure, simple and good in reliability, and can achieve high-precision and high-rigidity transmission.

Owner:QUANTA MACHINERY CO LTD +1

End face sealing structure of shaft tail of fuel pump

ActiveCN106763794ASimple sealing structureReduce difficultyEngine sealsMachines/enginesEngineeringAero engine

The invention relates to an end face sealing structure of a shaft tail of a fuel pump and belongs to the technical field of product structures. The end face sealing structure of the shaft tail is simplified, the axial mounting space of the shaft tail sealing device of the gear pump is reduced, reduction of weight of a product is achieved, meanwhile, the shaft tail assembling difficulty is reduced, and defects in the prior art are overcome. According to the technical scheme adopted for achieving the purposes, according to the end face sealing structure of the shaft tail of the fuel gear pump, the fuel pump is used for aero-engines; and the sealing structure is a movable and static ring sealing structure which comprises a static ring assembly (a static ring) and a sealing end face (a movable ring) of a driving gear of the fuel pump.

Owner:XIAN AERO ENGINE CONTROLS

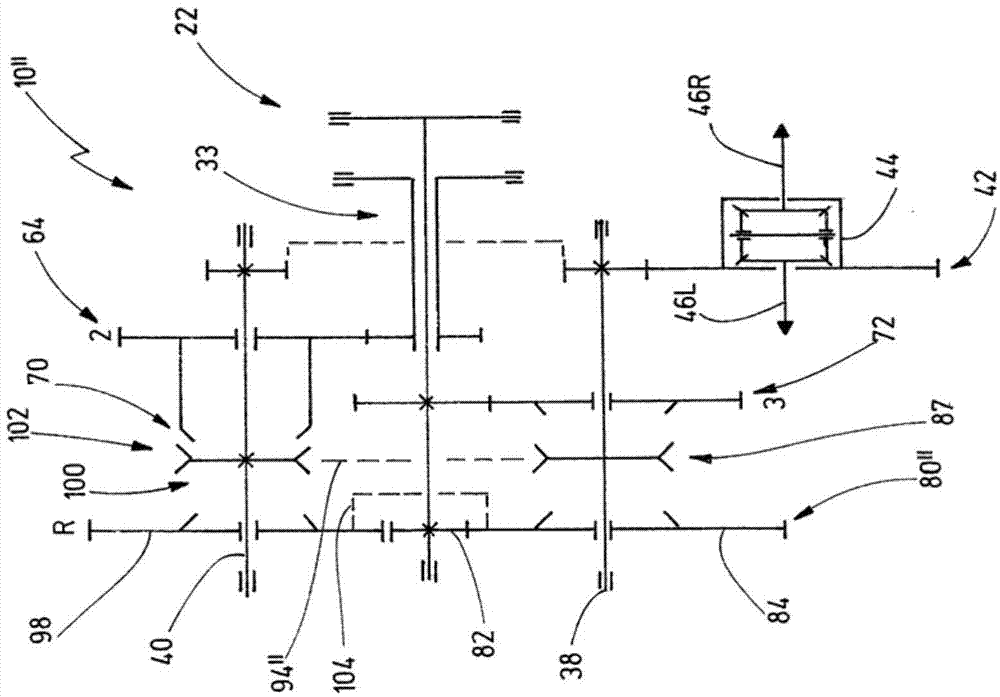

Multi-speed transmission in planetary design

InactiveUS9829074B2Easy accessGood gear efficiencyToothed gearingsTransmission elementsEngineeringMechanical engineering

A multi-speed transmission in planetary design for a vehicle includes a housing, a first shaft is provided as a drive (An), and a second shaft provided as an output arranged axially parallel to the drive. Three planetary gear sets and additional shafts along with six shifting elements are provided. Machine elements (ST1, ST2) are provided for transfer of torque between the drive (An) and the output (Ab). The first shaft (1) is connectable to the ring gear of the third planetary gear set, to the sun gear of the first planetary gear set, to the sun gear of the third planetary gear set, to the planetary gear carrier of the first planetary gear set and to the first machine element. The second shaft is connected or connectable to the first machine element and to the second machine element.

Owner:ZF FRIEDRICHSHAFEN AG

Three level electric jar for bearing ball silk bar

InactiveCN100541981CPrevent pressure rollbackPrevent fallbackGearingMechanical energy handlingThree levelMotor drive

Owner:ZHEJIANG UNIV

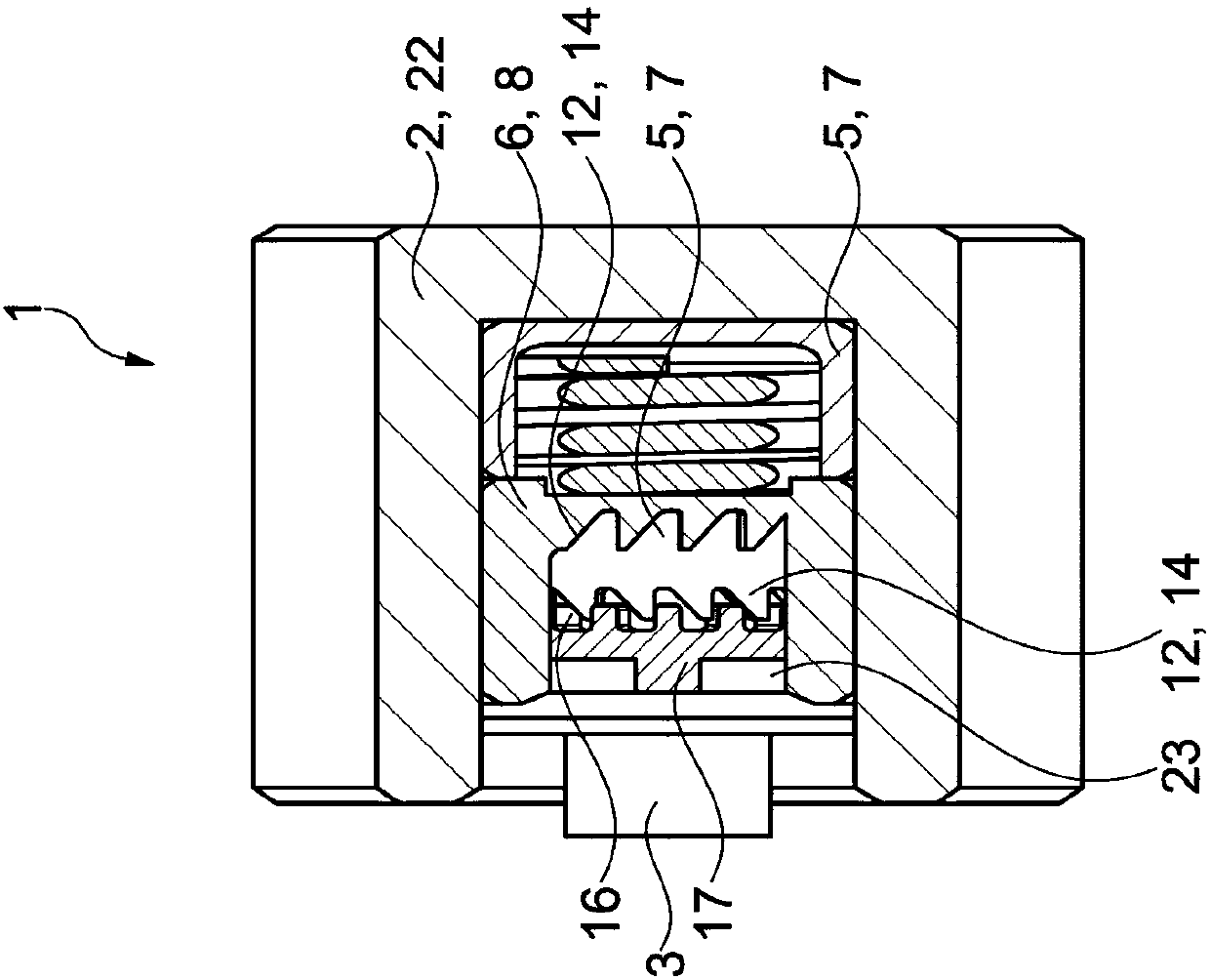

Space-saving ratchet unit with freewheel

The invention relates to a ratchet (1) for a medical device (30), comprising a torque-guiding element (2) and a torque discharging element (3), between which a switchable toothed unit (4) is arrangedso that, in accordance with a switching position of the toothed unit (4), torque from the torque-guiding element (2) is transferred to the torque discharging element, said toothed unit (4) comprises two torque transfer sleeves (5, 6) arranged in a nested manner and which are arranged and produced such that both can be brought into torque-transmitting contact with an intermediate sleeve (17). The invention also relates to a medical device (30) comprising a ratchet of said type (1).

Owner:AESCULAP AG

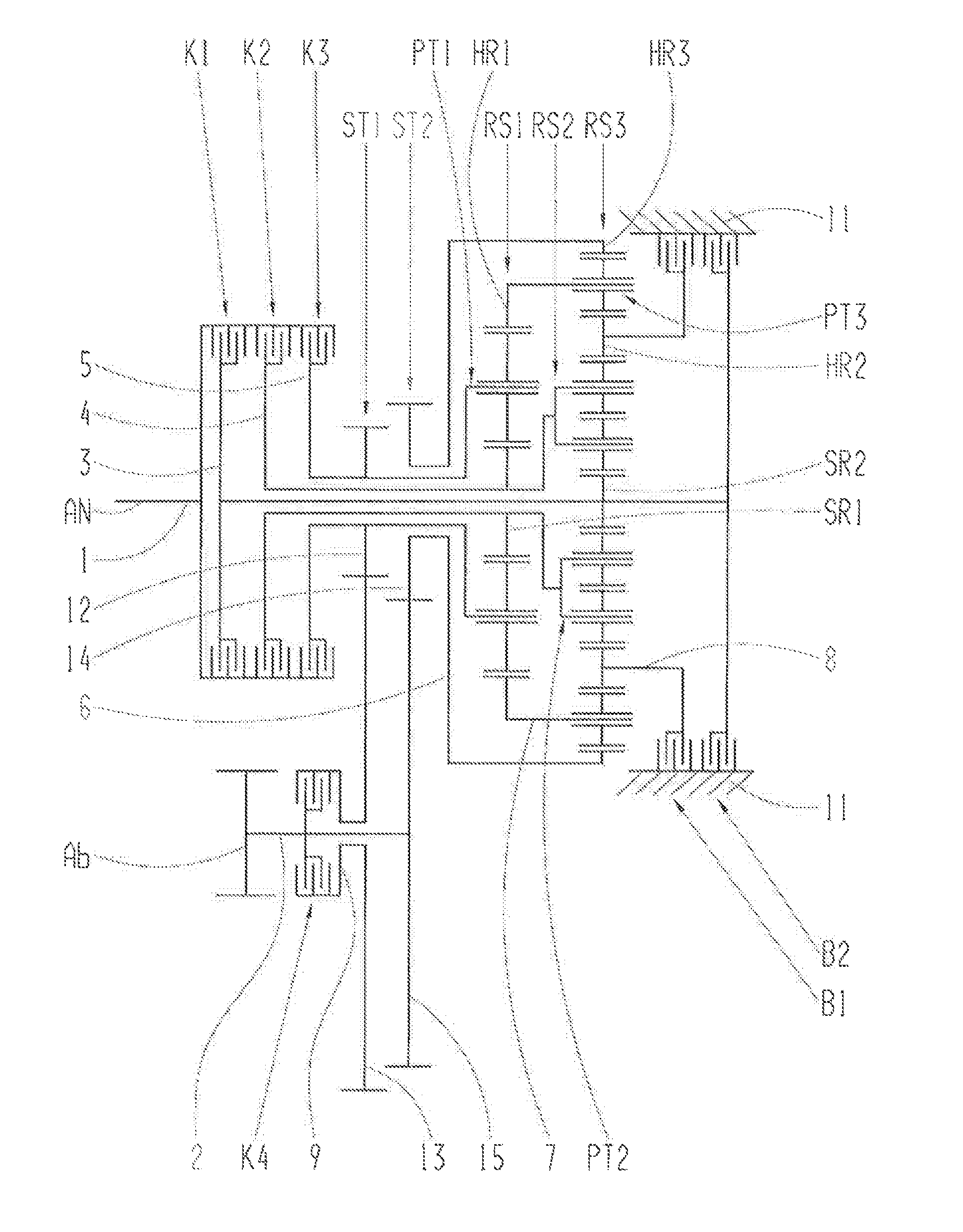

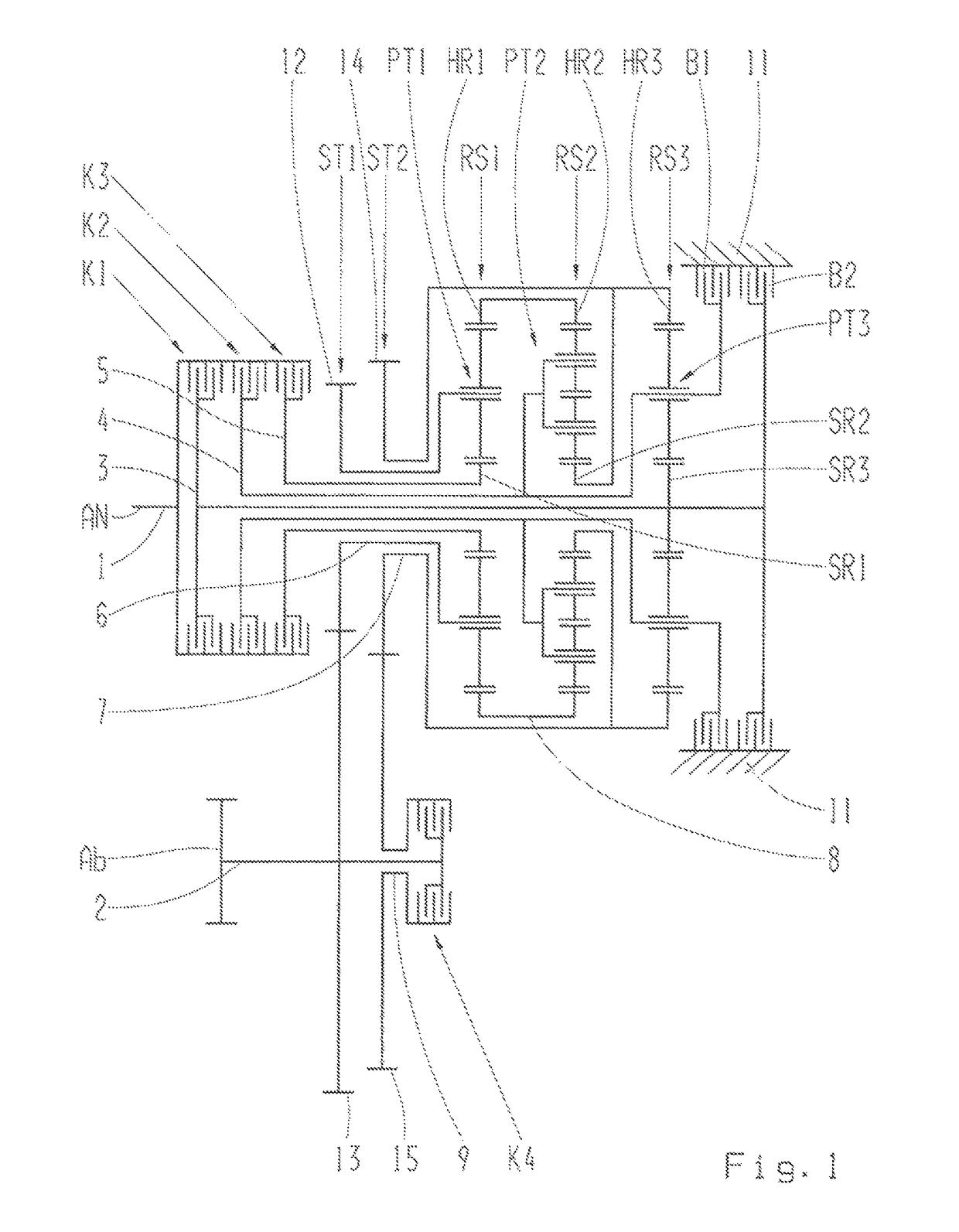

Multi-Stage Planetary Transmission

InactiveUS20160003329A1Easy accessGood gear efficiencyToothed gearingsTransmission elementsEngineeringMechanical engineering

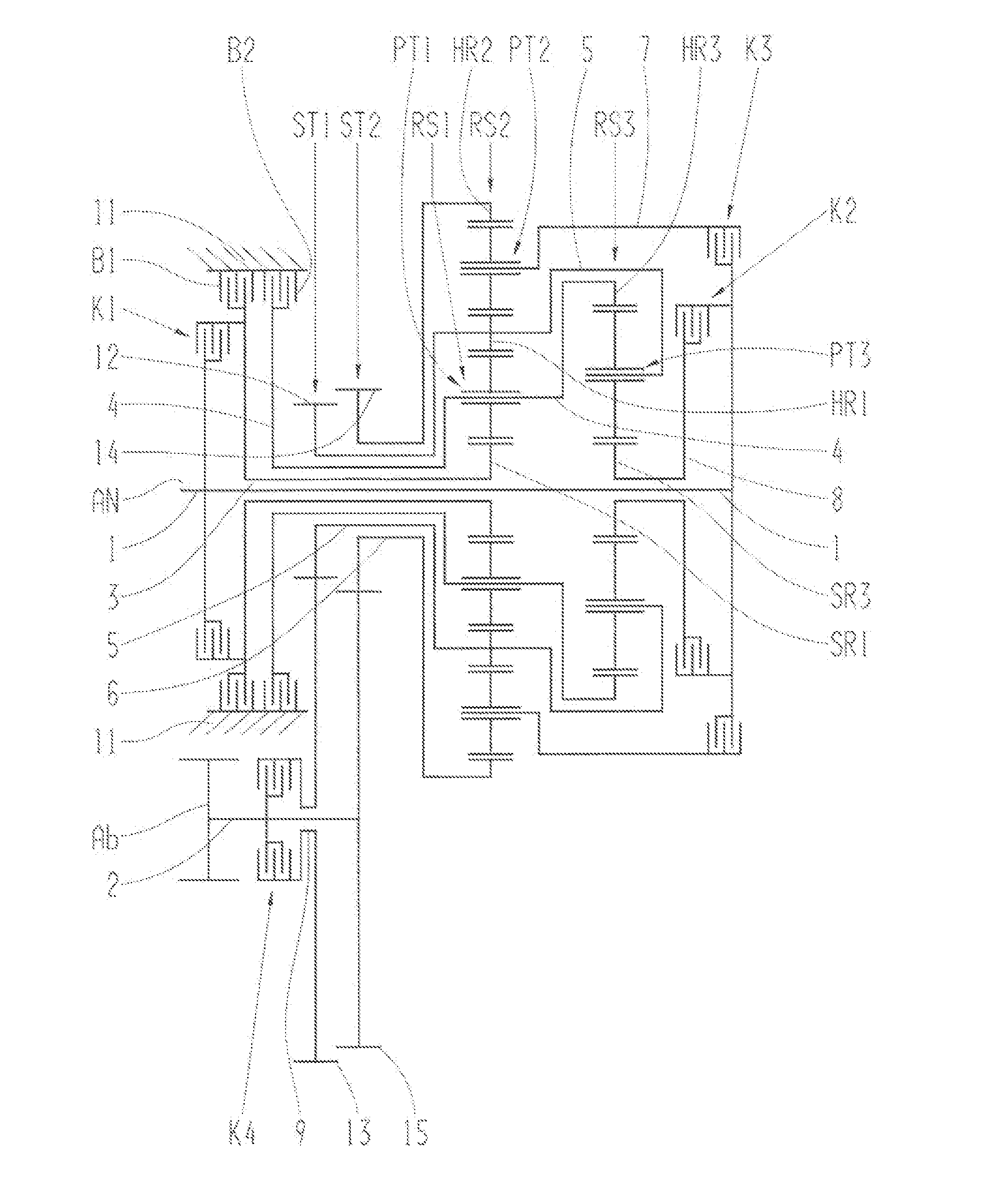

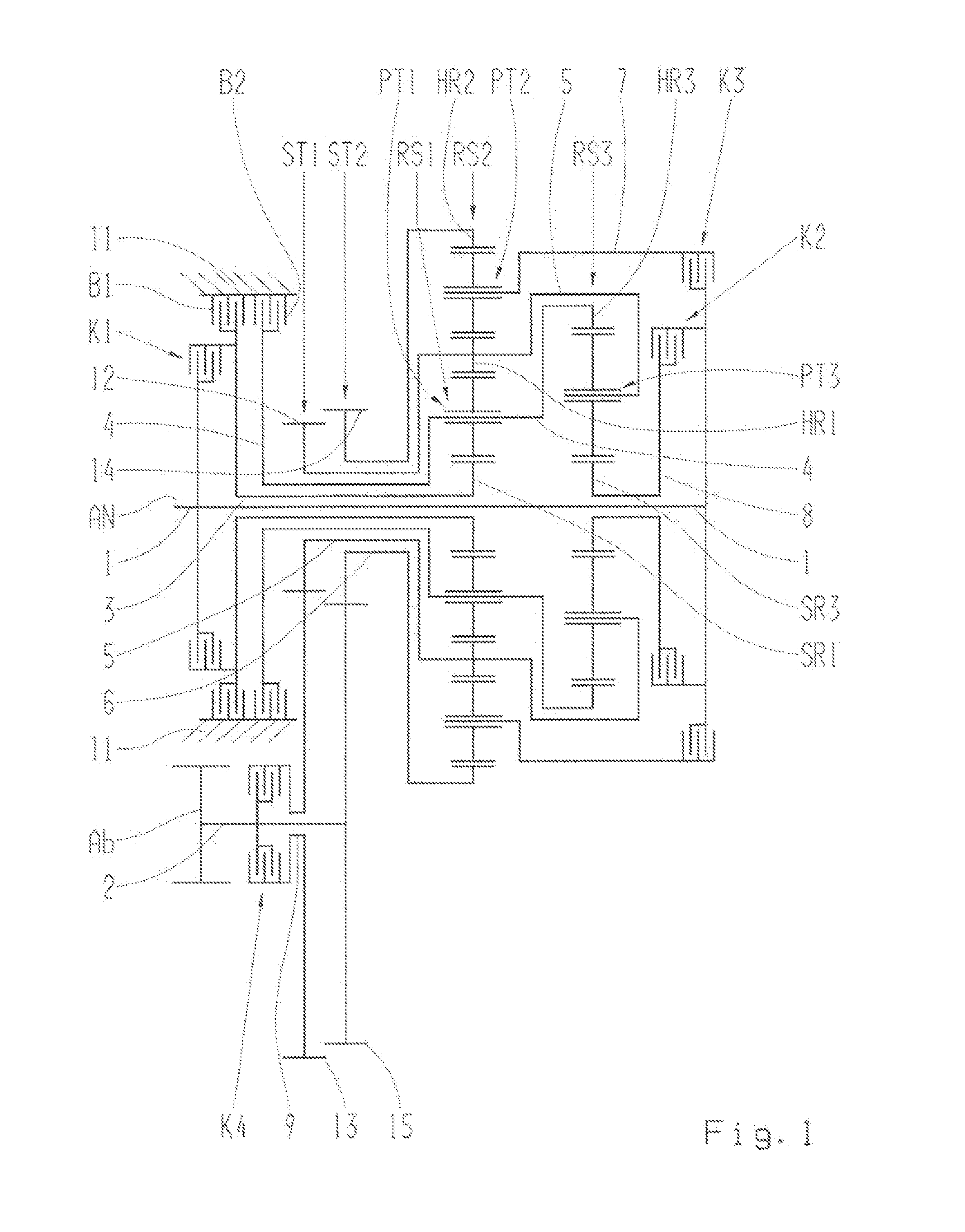

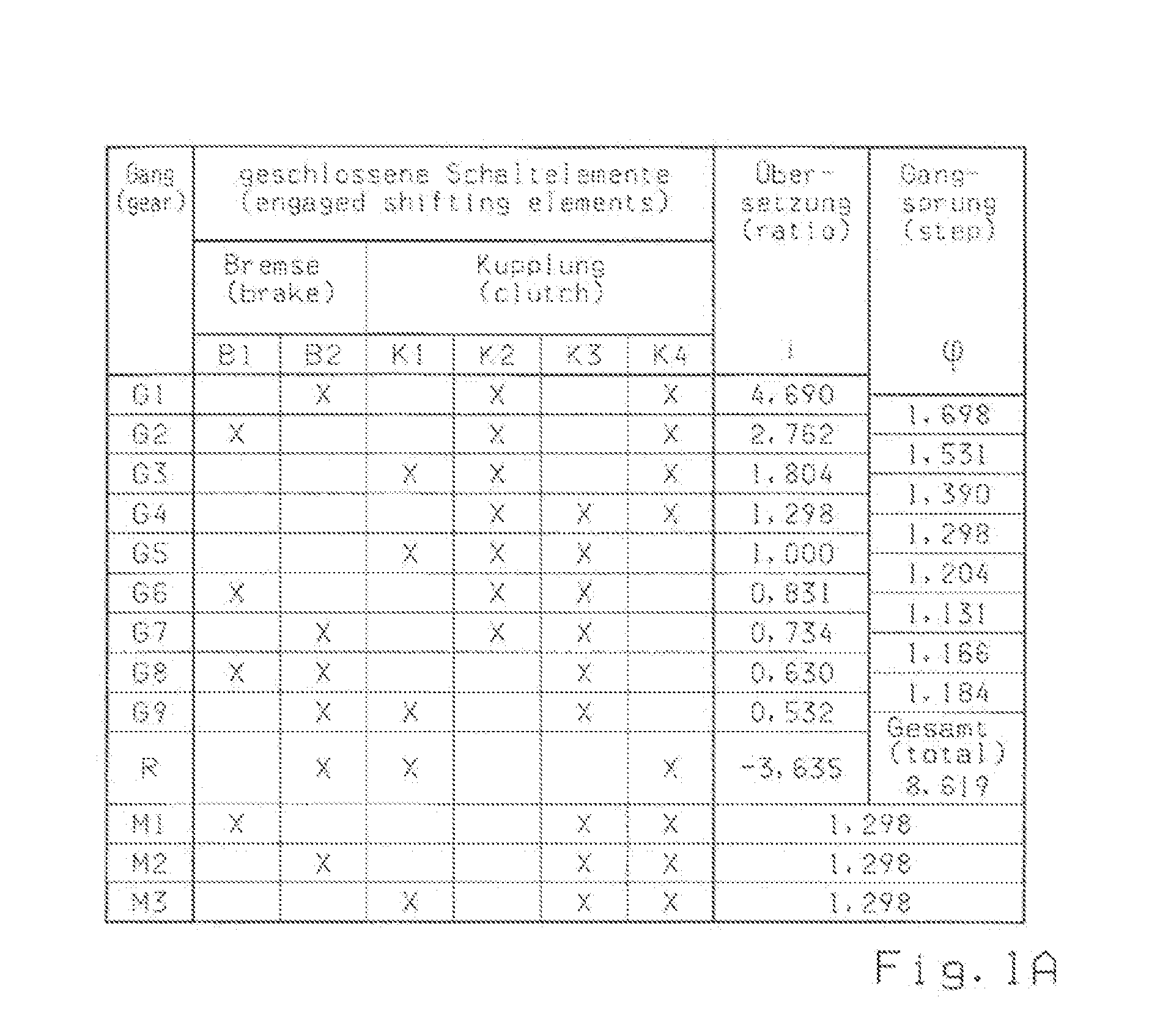

A multi-speed transmission in planetary design with a housing is proposed. A first shaft (1) is provided as a drive (AN) and a second shaft (2) is provided as an output (Ab) arranged axially parallel to the drive. Three planetary gear sets (RS1, RS2, RS3) and additional shafts (3-9) along with six shifting elements (K1, K2, K3, K4, B1, B2) are provided for the actuation of several gears. Machine elements (ST1, ST2) are provided for the transfer of torque between the drive (AN) and the output (Ab). The first shaft (1) is connectable or connected, as a drive, to a sun gear (SR1) of the first planetary gear set (RS1), to the sun gear (SR3) of the third planetary gear set (RS3), and to the planetary gear carrier (PT2) of the second planetary gear set (RS2). The second shaft (2), as an output shaft (Ab), is connectable or connected to the first machine element (ST1) and to the second machine element (ST2).

Owner:ZF FRIEDRICHSHAFEN AG

Planetary multi-stage transmission

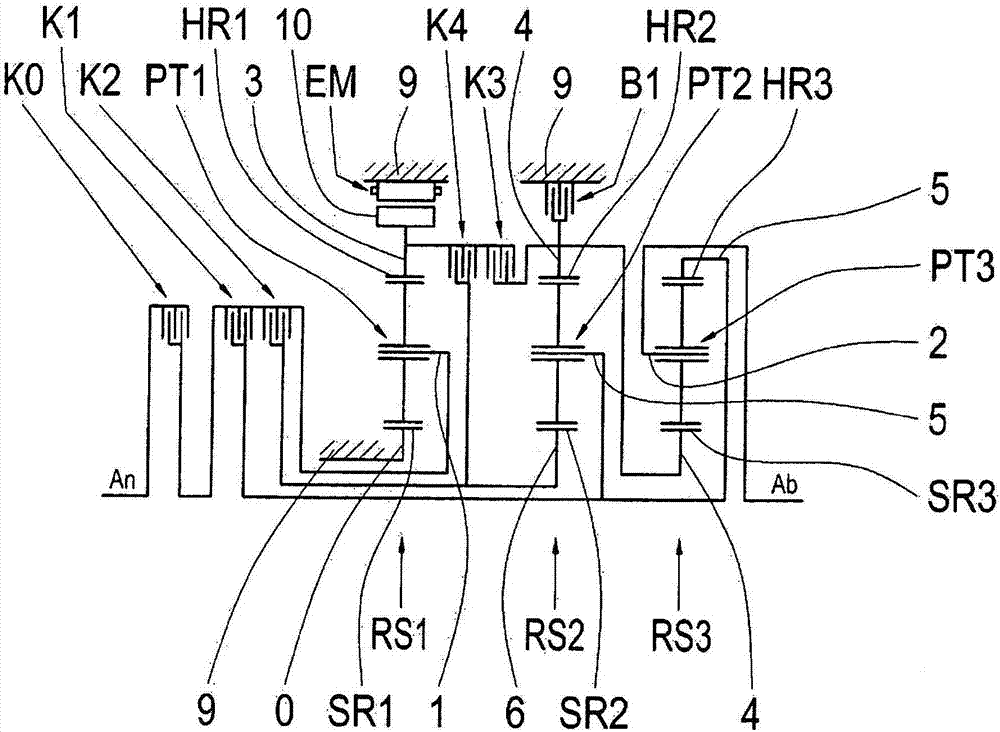

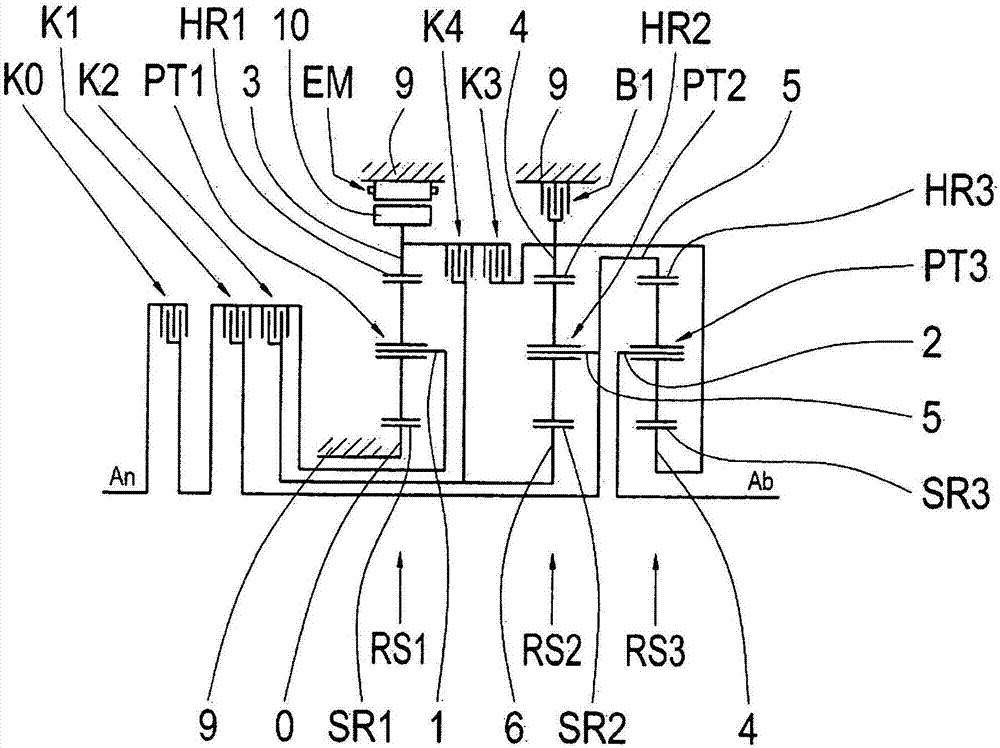

ActiveCN107074093AReduce torqueIncrease speedHybrid vehiclesToothed gearingsElectric machineEngineering

The invention relates to a planetary multi-stage transmission for a vehicle, comprising at least one electric machine (EM) and three planetary gear sets (RS1, RS2, RS3) in a housing (9), wherein a driving device (An) can be connected to a first shaft (1) by means of a shifting element (K0) and an output (Ab) is connected to a second shaft (2), wherein four further shafts (3, 4, 5, 6) and at least five further shifting elements (B1, K1, K2, K3, K4) are provided, by means of the actuation of which shifting elements at least eight forward gears (G1, G2, G3, G4, G5, G6, G7, G8) can be realized. According to the invention, the first element of the first planetary gear set (RS1) is connected to the housing (9), wherein the first shaft (1) is connected to the second element of the first planetary gear set (RS1) in a fixed manner, wherein the rotor (10) of the electric machine (EM) is connected to the third element of the first planetary gear set (RS1) and wherein the third element of the first planetary gear set (RS1) can be connected to at least one element of at least one further planetary gear set (RS2, RS3) by means of at least one shifting element (K3, K4).

Owner:ZF FRIEDRICHSHAFEN AG

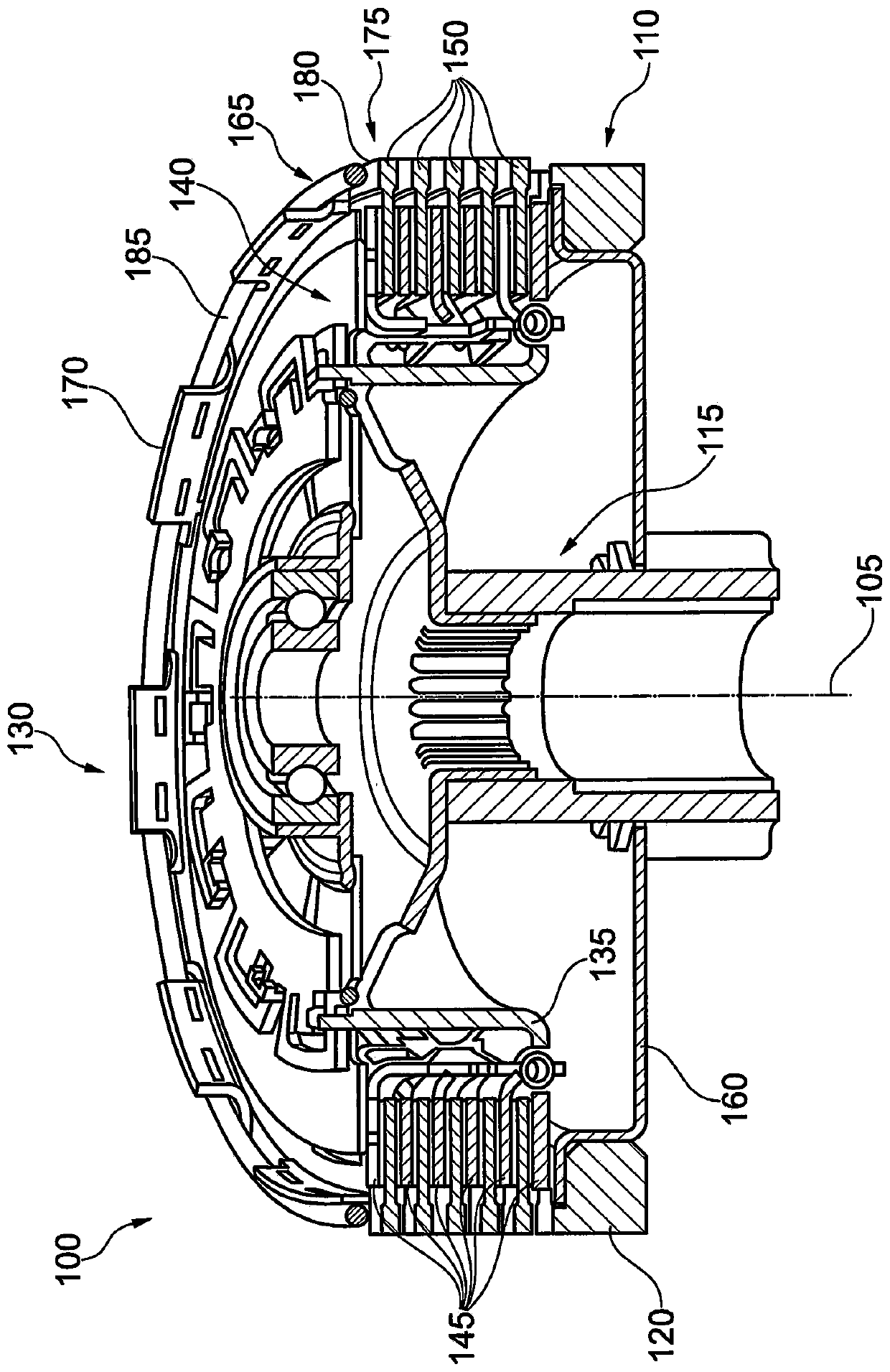

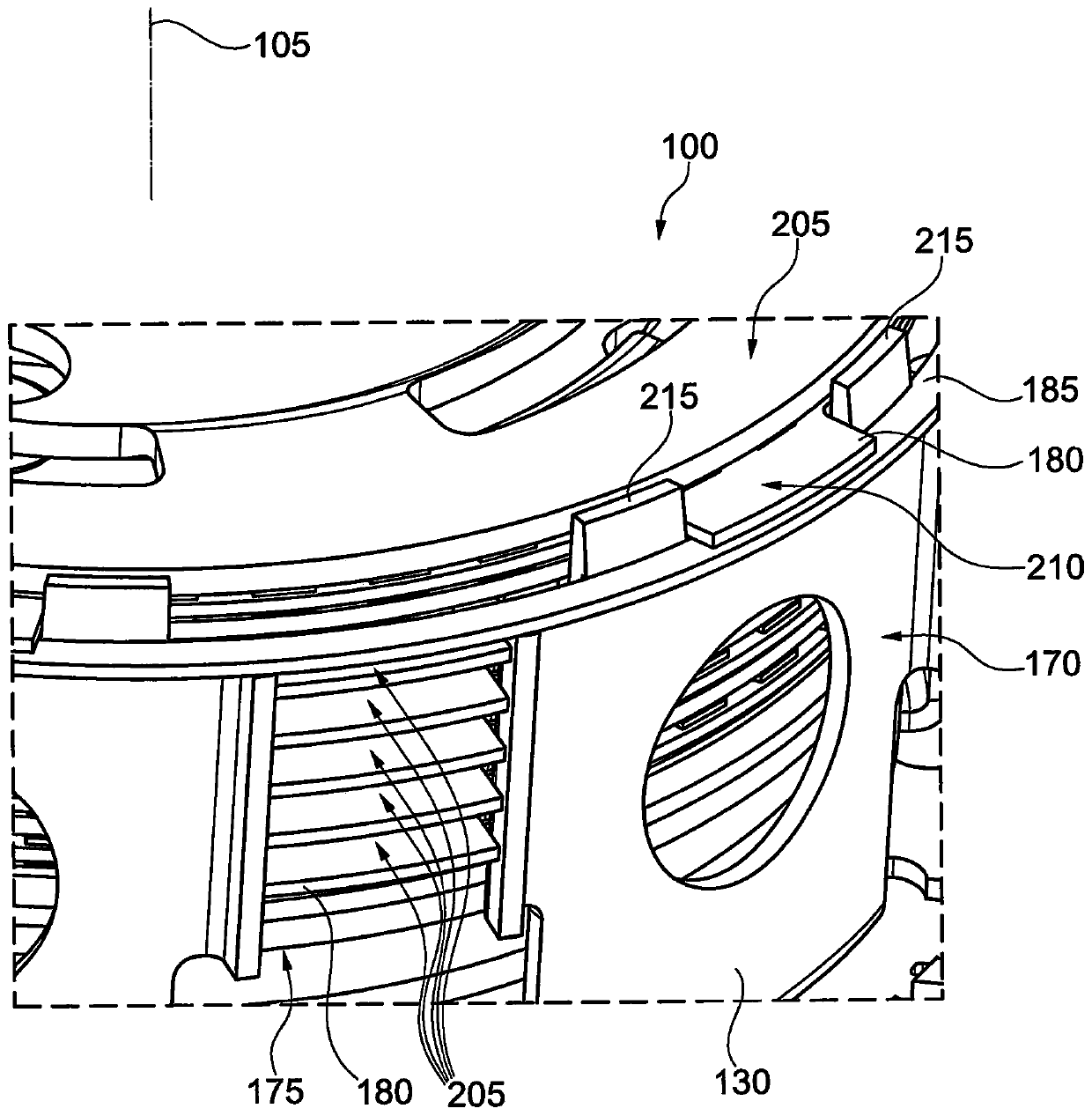

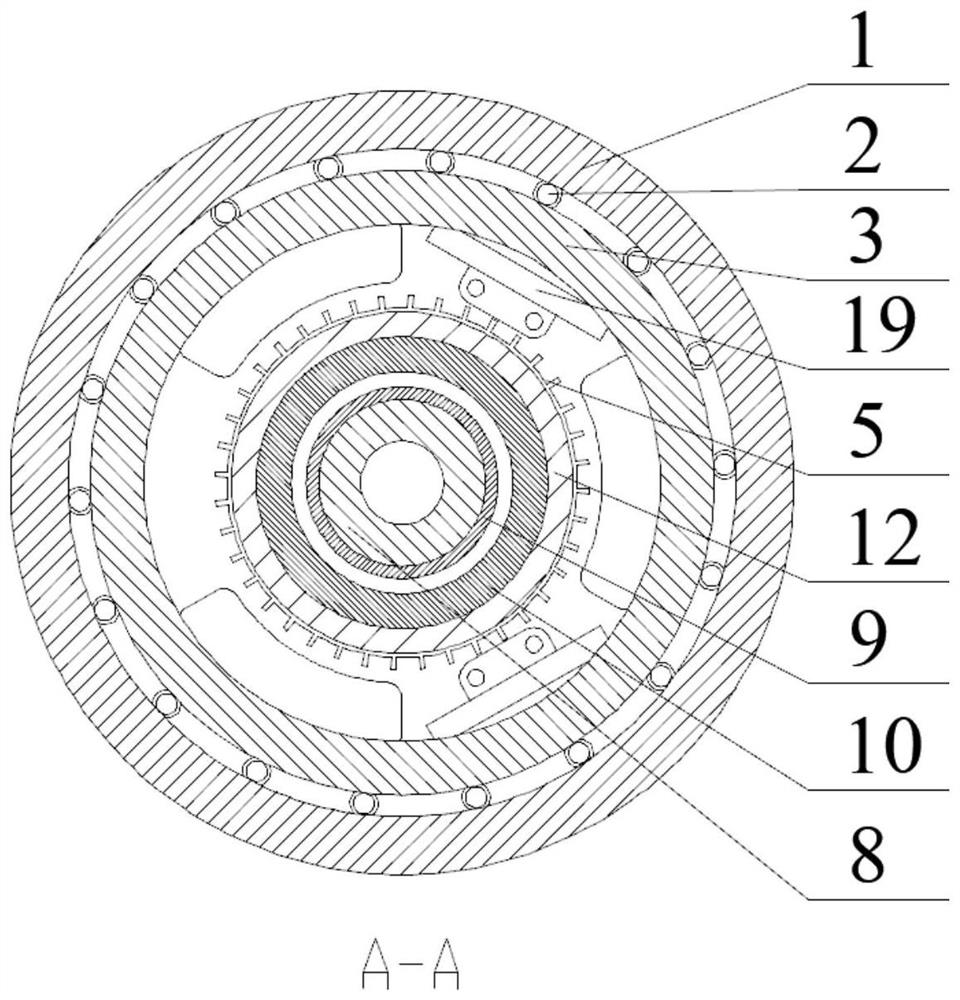

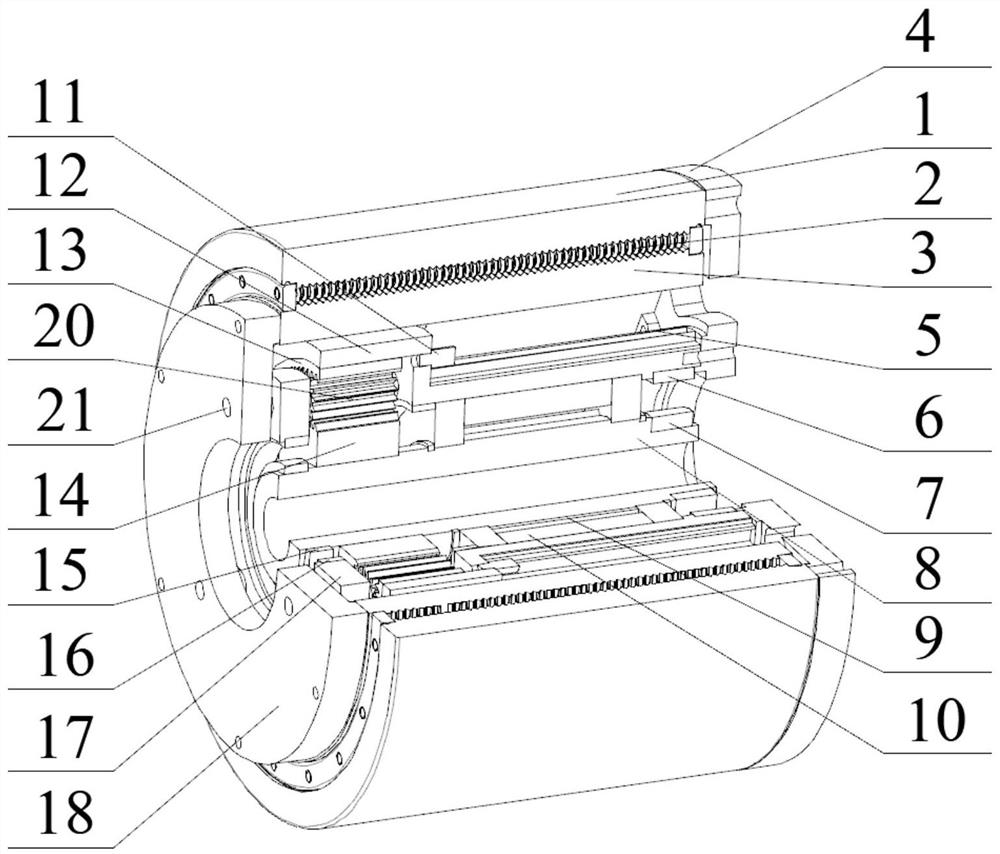

Multiple Disc Clutch

ActiveCN106895088BSave axial installation spaceTake advantage ofFriction clutchesRotational axisEngineering

A multi-plate clutch comprises an outer carrier rotatable about an axis of rotation; plurality of friction elements each having a radial extension, the outer carrier having recesses corresponding to the extensions through which the extensions extend to establish torque-locking connections; and a support ring which rests on the radial outer side of the outer support. In this case, the support ring lies axially between a first and an adjacent second friction element located at an axial end.

Owner:SCHAEFFLER TECH AG & CO KG

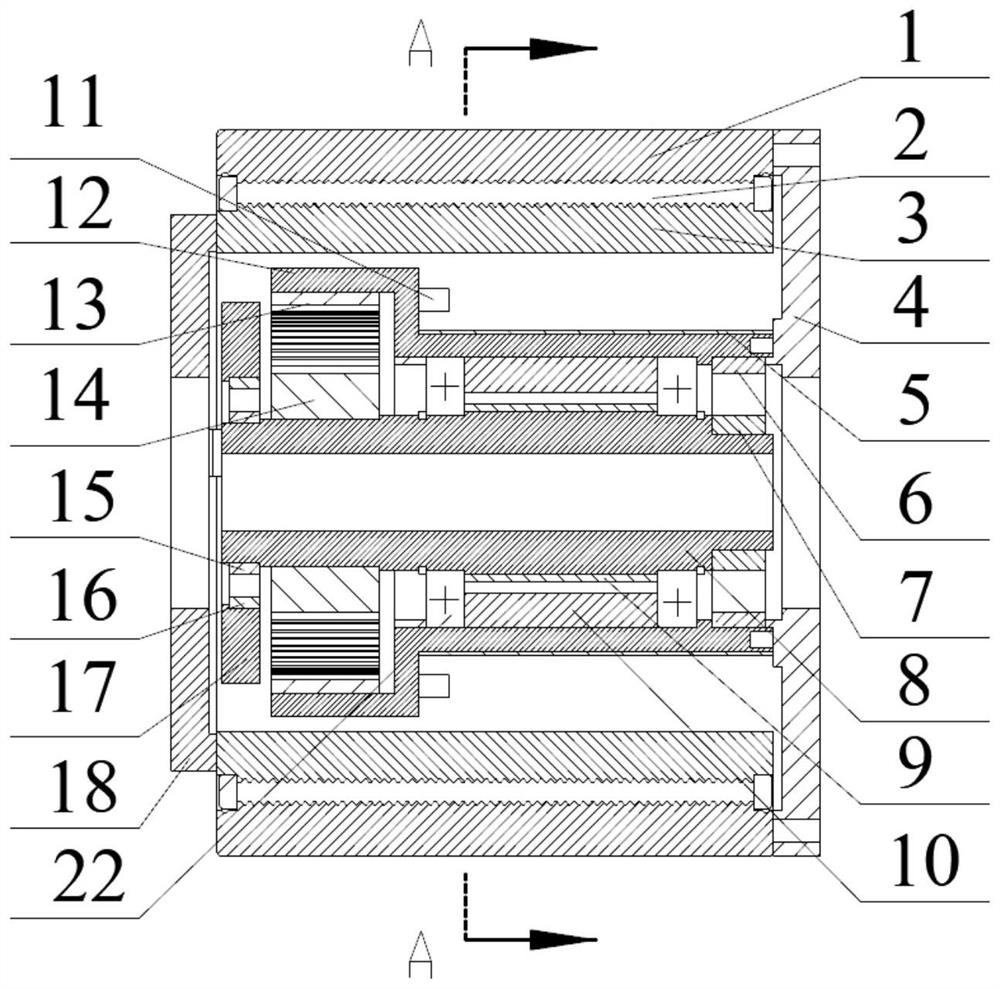

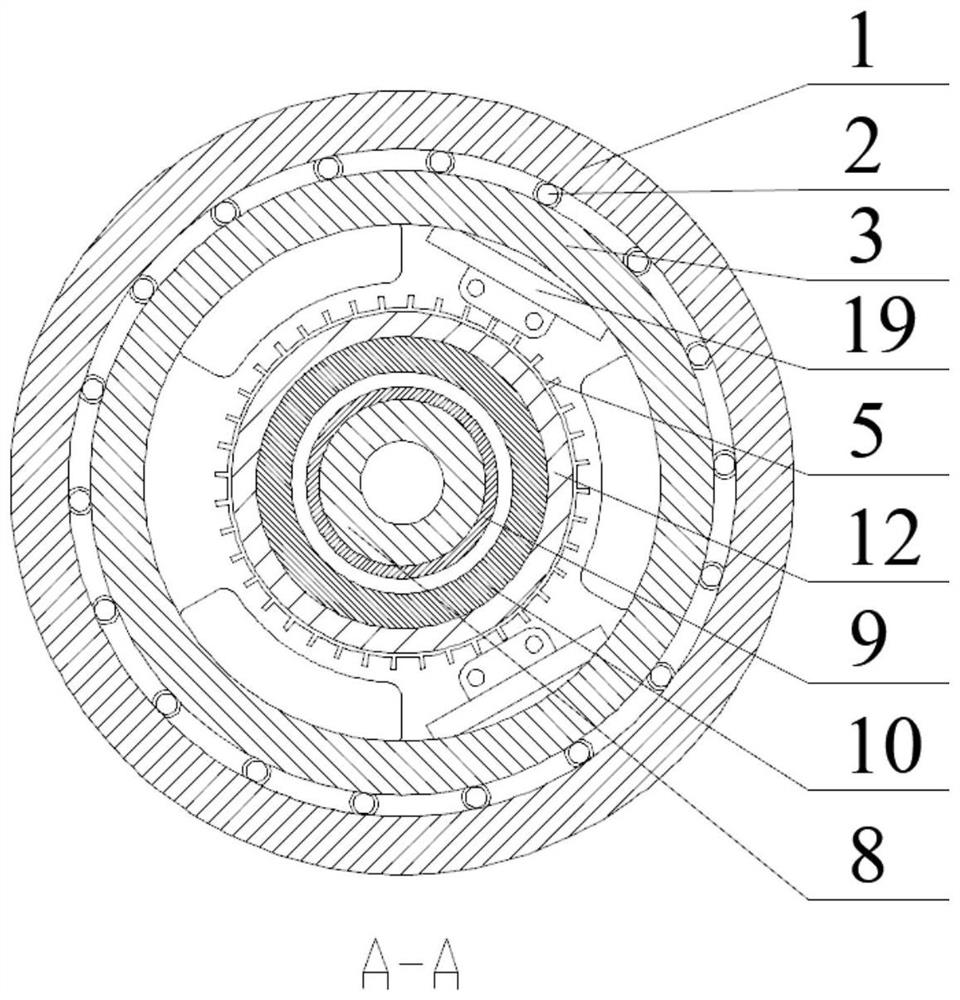

Dual clutch and method for controlling the same

InactiveUS8733522B2Save axial installation spaceIncrease the actuating pathFriction clutchesEngineeringInternal combustion engine

A dual clutch and a method for controlling the same in a drive train of a motor vehicle which has two friction clutches that transmit a torque from an internal combustion engine to respective transmission input shafts of a dual clutch transmission and which have a common counterpressure plate firmly connected to a crankshaft of the internal combustion engine and two contact plates that are fixed in terms of rotation relative to the counterpressure plate and can be moved axially by respective lever springs supported on a housing part firmly connected to the counterpressure plate. To limit the axial installation space for the dual clutch, the lever springs for actuating the friction clutches are actuated radially on the inside in the same direction by respective actuating systems in the case of a change from one friction clutch to the other of a torque to be transmitted via the friction clutches.

Owner:SCHAEFFLER TECH AG & CO KG

An all-electric linear actuator with high power-to-weight ratio integrated and large load

ActiveCN113381556BSave axial installation spaceReduce volumeGearingStructural associationReduction driveGear wheel

The invention is an all-electric linear actuating device with high power-to-weight ratio integration and large load, including: an intermediate cavity, a threaded roller, an inner cavity, a planetary wheel, a stator sleeve, a screw transmission component, an output screw, etc. . The motor stator and permanent magnet are installed on the outside of the stator sleeve and the inside of the sun gear respectively, and the motor stator and permanent magnet form an integrated permanent magnet synchronous motor; the outer ring gear processed on the outside of the planetary gear and the sun gear, and the inner teeth processed on the inside of the inner cavity The ring forms a planetary gear reducer; the multi-segment annular raceway of the middle cavity and the inner cavity meshes with the threaded roller zero-lead thread to form a high-load integrated bearing; the large nut, the output screw, and the screw transmission assembly form a planetary roller The screw pair, the output screw converts the rotary motion of the large nut into a linear motion to drive the load; a variety of sensors are integrated inside the device; this invention solves the problem of large volume and weight of the existing linear actuator, and improves the performance of the electric motor. The integration degree, power-to-weight ratio and load capacity of the actuator.

Owner:BEIHANG UNIV

An end face sealing structure of a fuel pump shaft tail

ActiveCN106763794BSimple sealing structureReduce difficultyEngine sealsMachines/enginesAviationState of art

The invention relates to a sealing structure of a shaft end face of a fuel gear pump, belonging to the technical field of product structures. The purpose of the present invention is to simplify the seal structure of the shaft tail end face, shorten the axial installation space of the gear pump shaft tail sealing device, realize product weight reduction, reduce the difficulty of shaft tail assembly, and overcome the deficiencies of the prior art. In order to achieve the above object, the technical solution adopted by the present invention is: a kind of end face sealing structure of fuel gear pump shaft tail, and described fuel pump is used in aircraft engine; Described sealing structure is dynamic and static ring sealing structure including static ring assembly ( static ring) and the sealing end face (moving ring) of the driving gear of the fuel pump.

Owner:XIAN AERO ENGINE CONTROLS

An all-electric rotary actuation device with high power-to-weight ratio integrated and large load

ActiveCN113178984BSave axial installation spaceReduce volumeToothed gearingsMechanical energy handlingReduction driveGear wheel

The invention is an all-electric rotary actuating device with high power-to-weight ratio integration and large load, including: outer cavity body, threaded roller, inner cavity body, planetary wheel, planetary carrier, stator sleeve, stator sleeve, sun wheel etc. The stator heat sink is installed outside the stator sleeve to dissipate heat for the motor stator; the motor stator and permanent magnet are respectively installed inside the stator sleeve and outside the rotor sleeve, and the motor stator and permanent magnet form an integrated permanent magnet synchronous motor; planetary gear and installation The sun gear on the outside of the rotor sleeve and the outer ring gear on the inside of the stator sleeve form a planetary gear reducer; the multi-segment annular raceways of the outer cavity and inner cavity mesh with the threaded roller zero-lead thread to form a high-load integrated type Bearing; the outer cavity is installed on the end face of the fixed shell, and the inner cavity is fixedly connected with the output flange; various sensors are integrated inside the device. This invention solves the problems of large volume and weight of the existing rotary actuating device, and improves the integration degree, power-to-weight ratio and load capacity of the all-electric actuating device.

Owner:BEIHANG UNIV

A shaft locking device for a transmission mechanism

ActiveCN105156451BSolve the automatic locking functionHigh locking reliabilityShaft for rotary movementMechanical energy handlingEngineeringDrive motor

The invention discloses a rotating shaft locking device of a transmission mechanism. The rotating shaft locking device comprises a transmission locking device and a locking gear fixedly connected onto a rotating shaft of the transmission mechanism; the transmission locking device comprises a lead screw, a driving motor, a base, a locking block and guide rails which are parallelly fixed on the base; the two sides of the locking block sleeve the guide rails; one end of the locking block is provided with teeth meshed with the locking gear, and the other end of the locking block is connected with the driving motor which is fixed on the base through the lead screw; the driving motor drives the locking block to move along the guide rails to be meshed with the locking gear for locking or to be separated from the locking gear for unlocking through the lead screw; the driving motor is utilized for providing power for the locking block to ensure the insertion and the separation of the teeth; the automatic locking function of the rotating shaft is effectively solved; the locking force can be set by controlling the rotation speed of the driving motor and the backoff amount after locking; the maintenance of a locking load is realized through the self-locking ability of a screw-nut pair; the locking reliability is high; and the assembly is convenient.

Owner:NO 771 INST OF NO 9 RES INST CHINA AEROSPACE SCI & TECH

High-power-to-weight-ratio integrated large-load-bearing all-electric rotation actuating device

ActiveCN113178984ASave axial installation spaceReduce volumeToothed gearingsStructural associationElectric machineReduction drive

The invention relates to a high-power-to-weight-ratio integrated large-load-bearing all-electric rotation actuating device which comprises an outer cavity, threaded rollers, an inner cavity, a planet gear, a planet carrier, a stator sleeve, a rotor sleeve, a sun gear and the like. The stator cooling fins are mounted at the outer side of the stator sleeve and are used for cooling a motor stator; the motor stator and a permanent magnet are respectively arranged at the inner side of the stator sleeve and the outer side of the rotor sleeve, the motor stator and the permanent magnet form an integrated permanent magnet synchronous motor; the planet gear, the sun gear arranged at the outer side of the rotor sleeve and an outer gear ring arranged at the inner side of the stator sleeve form a planet gear reducer; multiple sections of annular raceways of the outer cavity and the inner cavity are meshed with the zero-lead threads of the threaded rollers to form a high-load-bearing integrated bearing; the outer cavity is installed on the end face of a fixed shell, and the inner cavity is fixedly connected with an output flange, and various sensors are integrated in the device. According to the present invention, the problems that an existing rotary actuating device is large in size and weight are solved, and the integration degree, the power-to-weight ratio and the loading capacity of the all-electric actuating device are improved.

Owner:BEIHANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com