Coupling device

A coupling and axial technology, which is applied in the direction of couplings, elastic couplings, machines/engines, etc., can solve the problem of impossible installation space, etc., and achieve low manufacturing tolerance, easy manufacturing, and easy axial displacement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

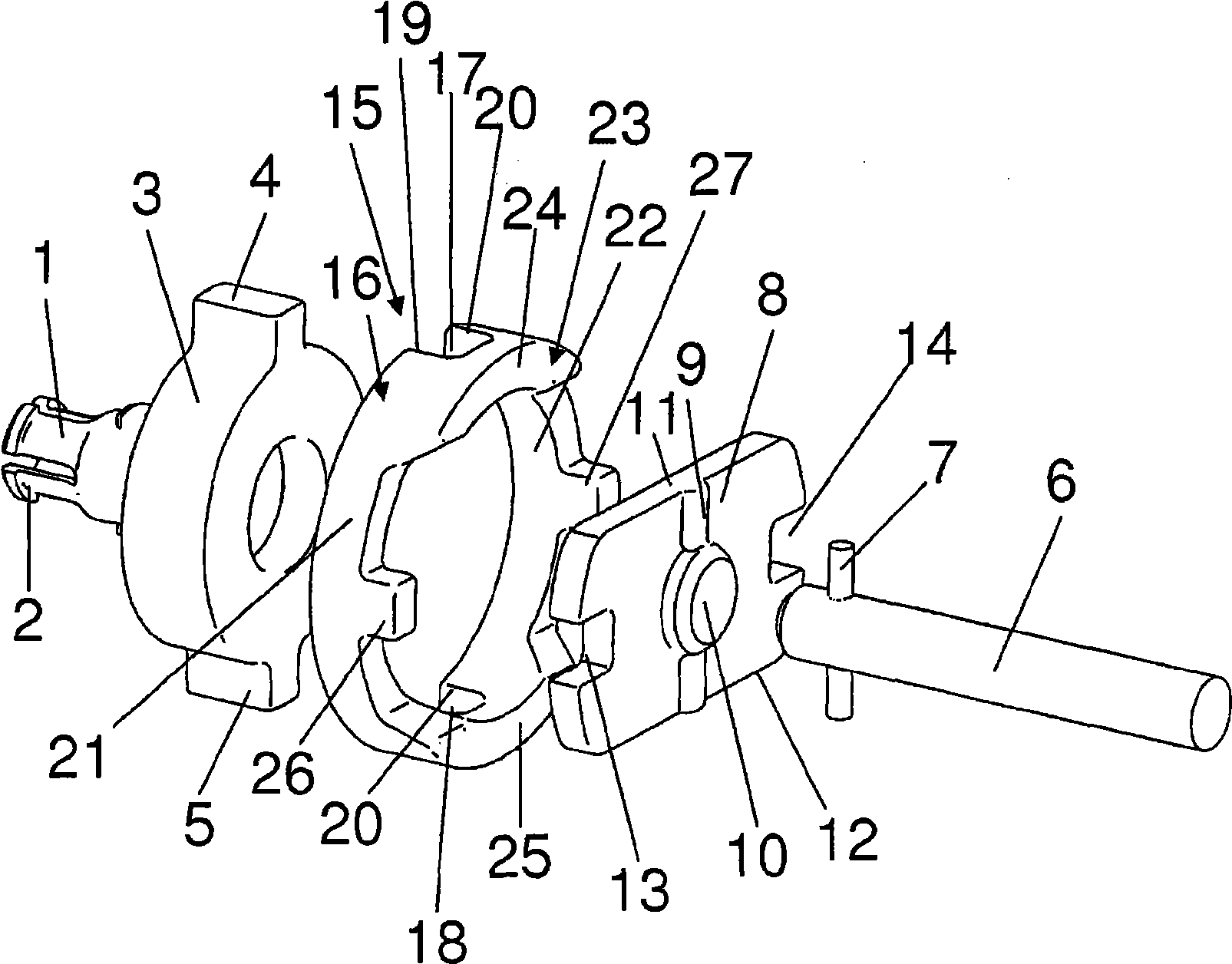

[0017] The coupling of the invention shown in the figures comprises a first shaft 1, which in this embodiment is formed as a shaft stub, which can be connected, for example via a clip connection, to a shaft of an actuating device. Correspondingly shaped output shaft.

[0018] The shaft 1 comprises an end section 3 which is considerably widened compared to the shaft diameter and which comprises two radially outward projections 4 , 5 . Apart from the protrusions, the end section 3 is shaped as a short cylindrical body. Arranged substantially opposite the first shaft 1 is a second shaft 6 having a pin 7 extending radially through the second shaft 6 for establishing a connection to an end section 8 for rotation therewith. A groove 9 and a through hole 10 corresponding to the pin 7 are provided for connecting the second shaft 6 to the end section 8 . Of course, it is also possible to manufacture the shaft integrally with said second end section 8 or to injection mold the end sect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com