Method for producing an electrode unit for a battery cell and electrode unit

An electrode unit, battery pack technology, applied in battery pack components, electrical components, secondary batteries, etc., can solve the problems of electrode expansion, delamination, offset, etc., to achieve high processing speed and improve safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

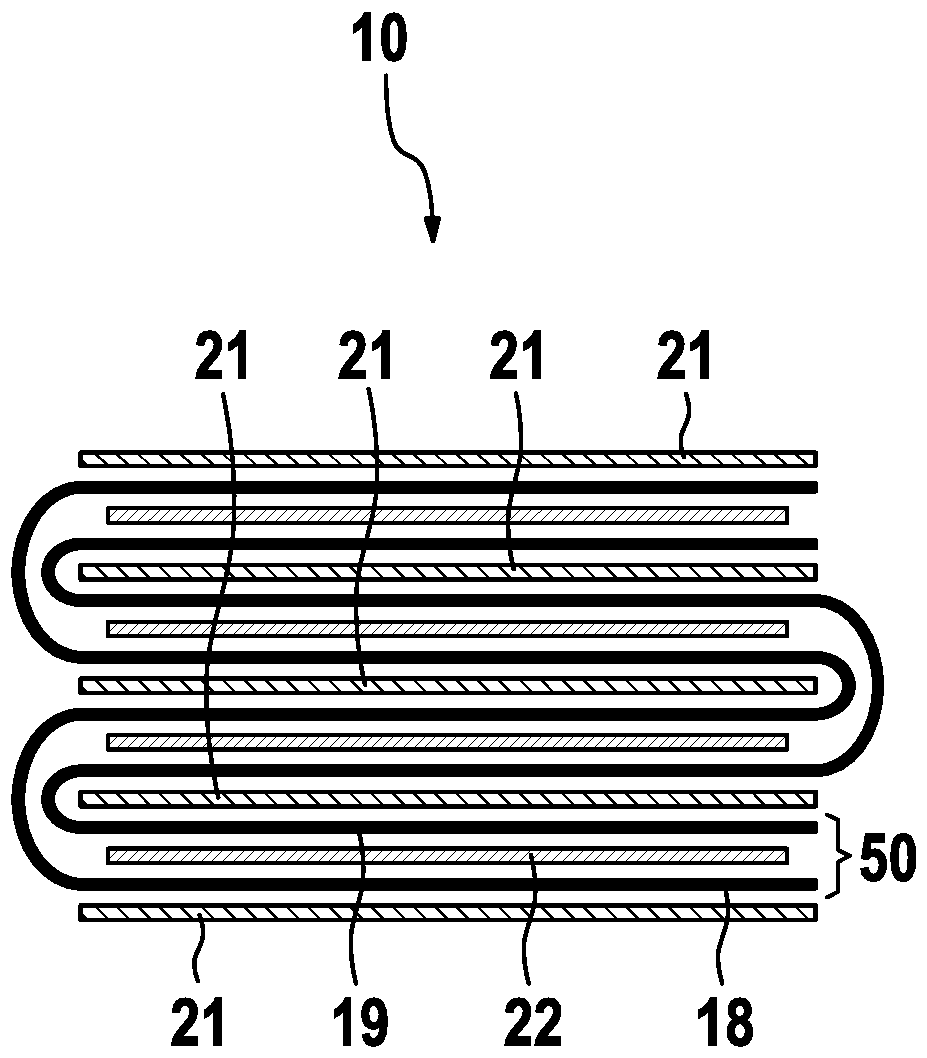

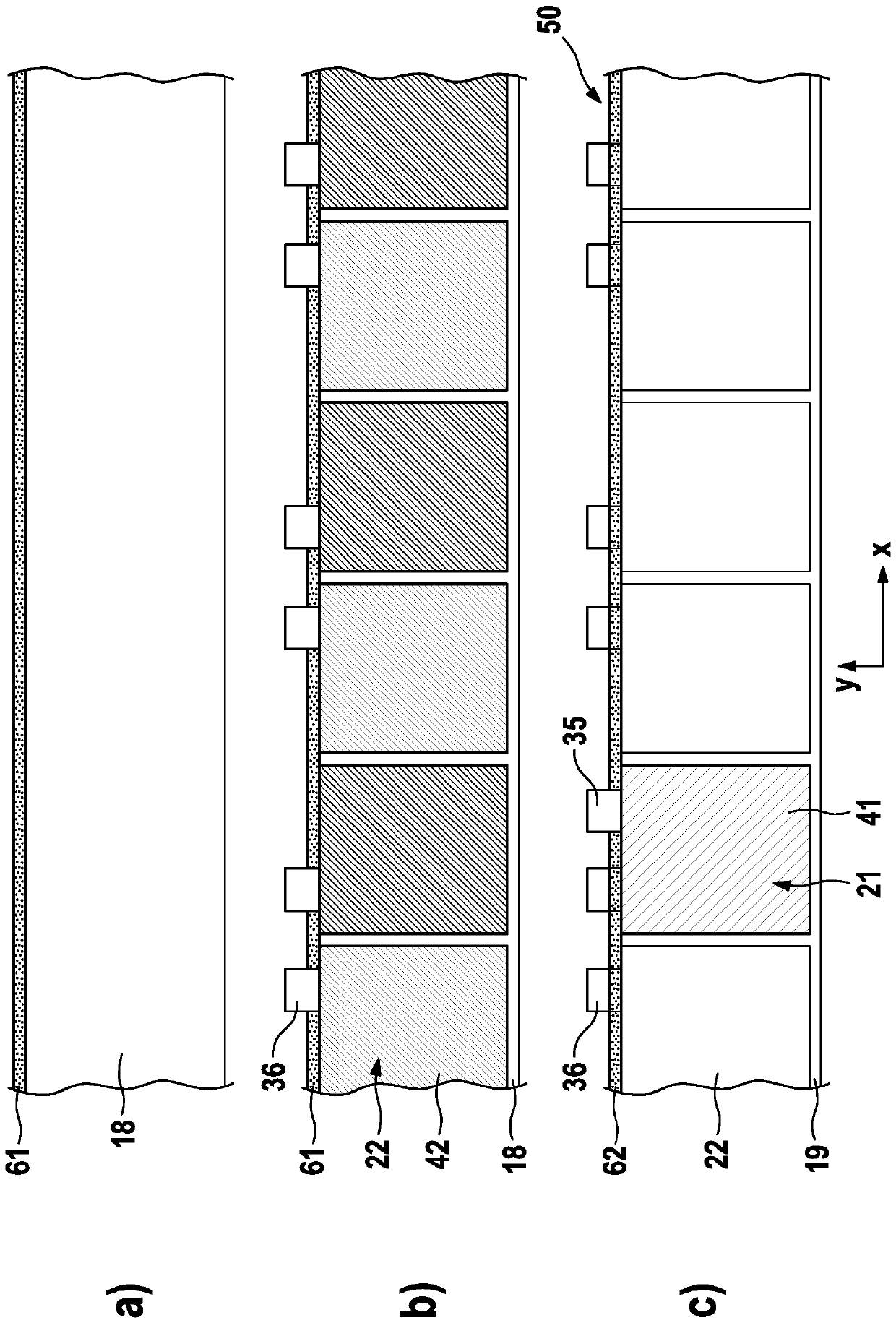

[0046] In the subsequent description of embodiments of the invention, identical or similar elements are identified with the same reference numerals, a repeated description of these elements being omitted in individual cases. The figures only schematically show the subject matter of the invention.

[0047] figure 1 A schematic diagram of a battery cell 2 is shown. The battery cell 2 comprises a housing 3 which is configured prismatically, in the present invention cuboidally. The housing 3 is embodied in an electrically conductive manner according to the invention and is made, for example, of aluminum.

[0048] The battery cell 2 includes a negative terminal 11 and a positive terminal 12 . The voltage provided by the battery cells 2 can be tapped off via the terminals 11 , 12 . Furthermore, the battery cells 2 can also be charged via the terminals 11 , 12 .

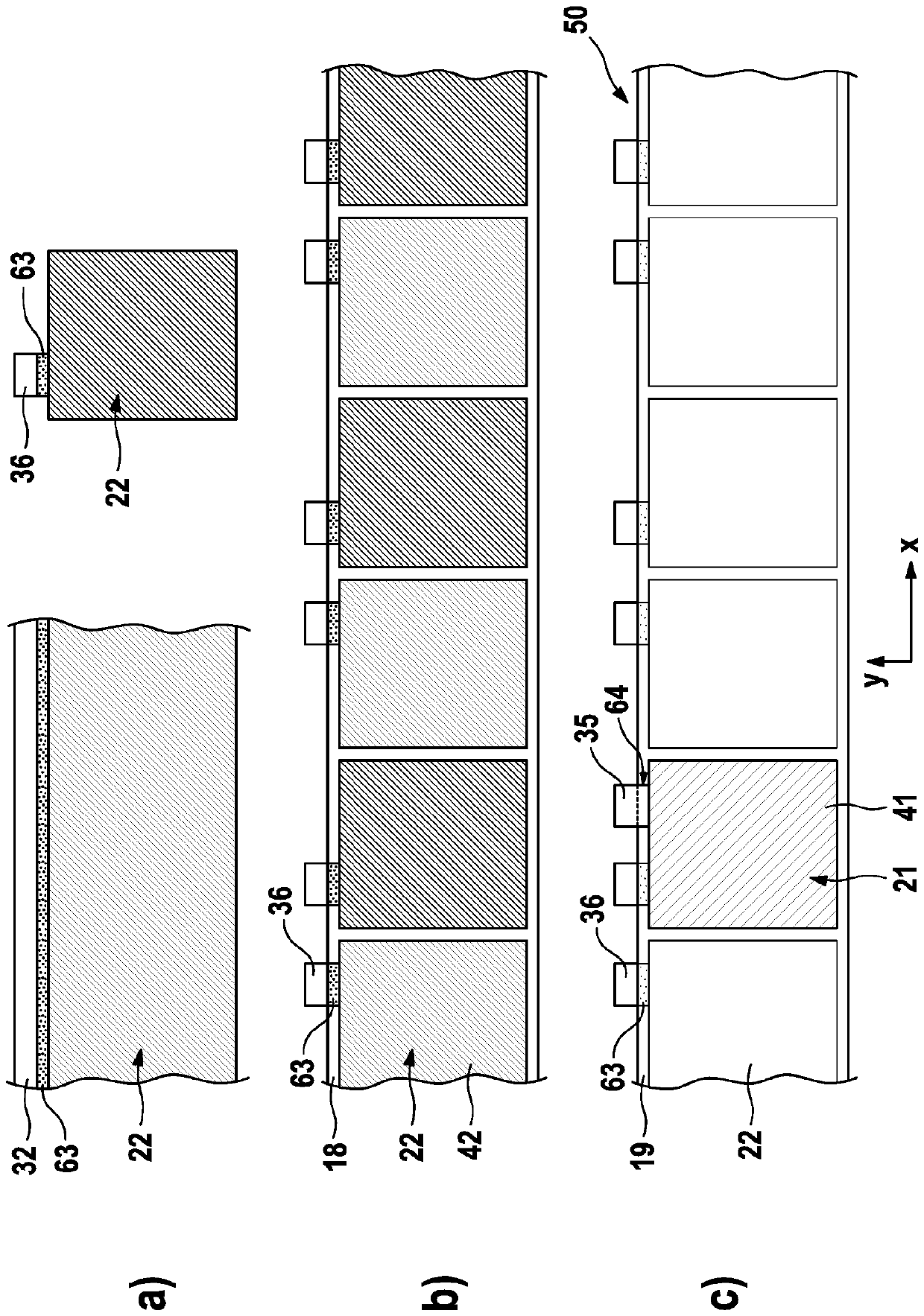

[0049] Arranged within the housing 3 of the battery cell 2 is an electrode unit 10 , which is embodied in the invent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com