Patents

Literature

55results about How to "Small manufacturing tolerances" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

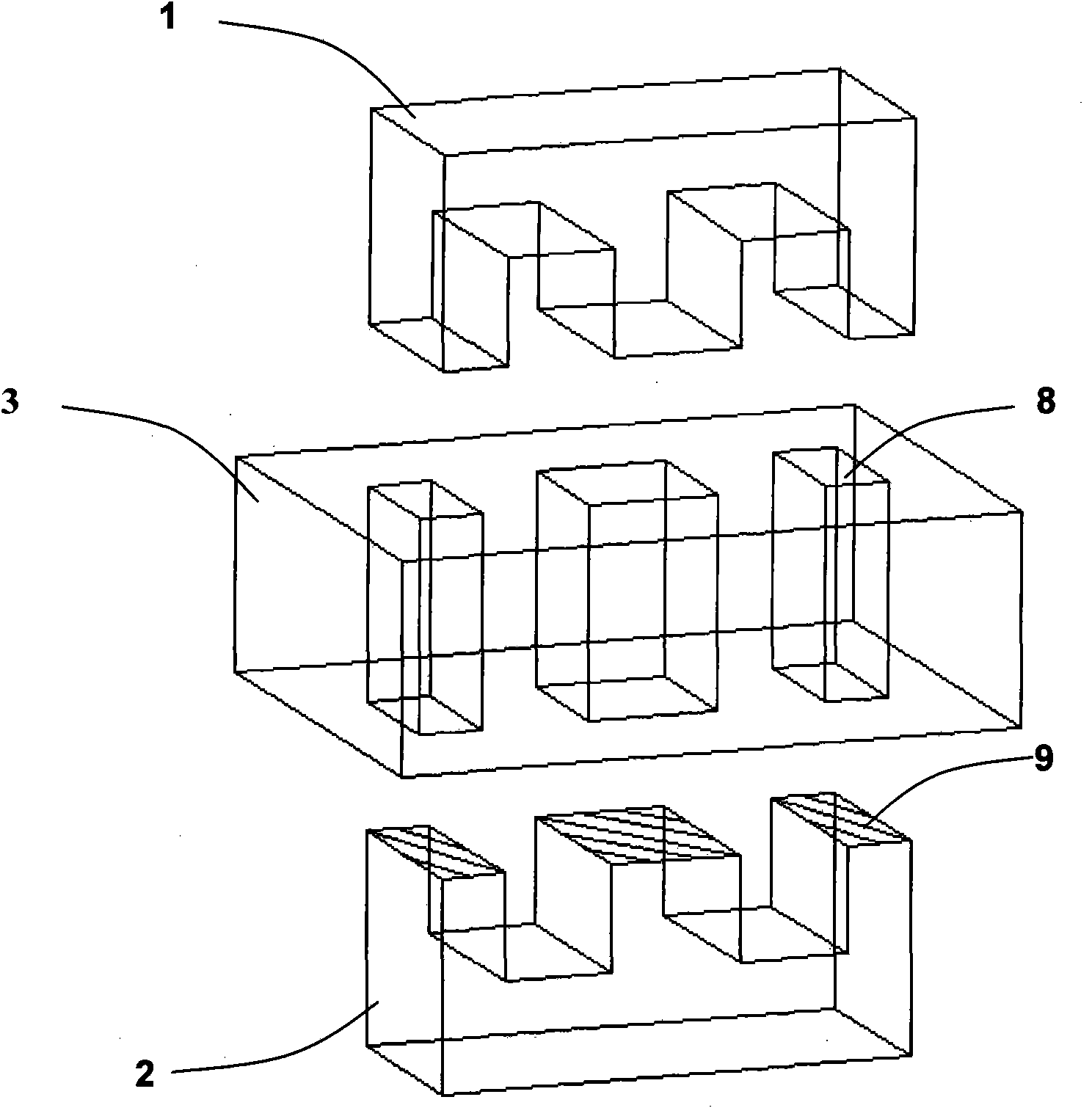

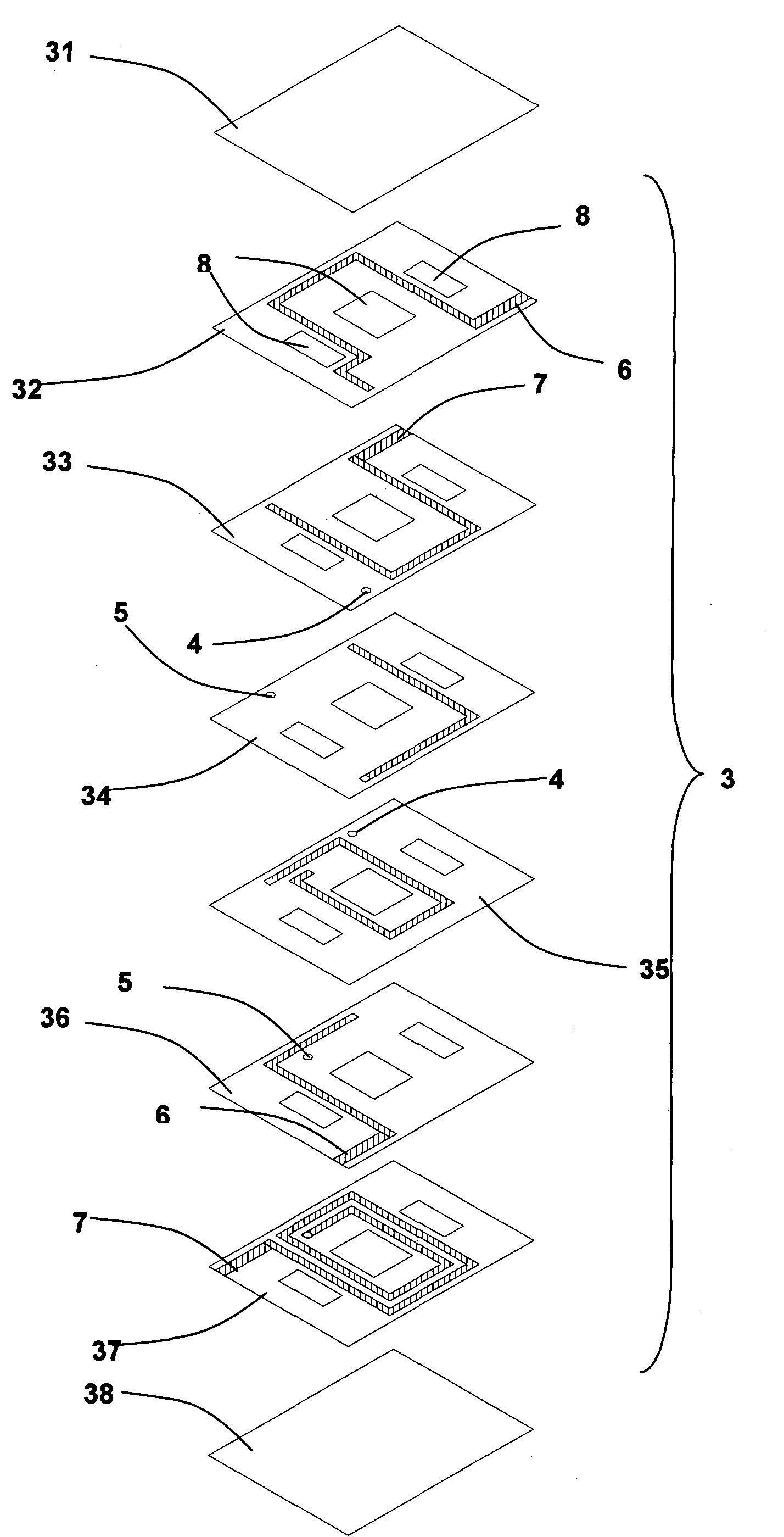

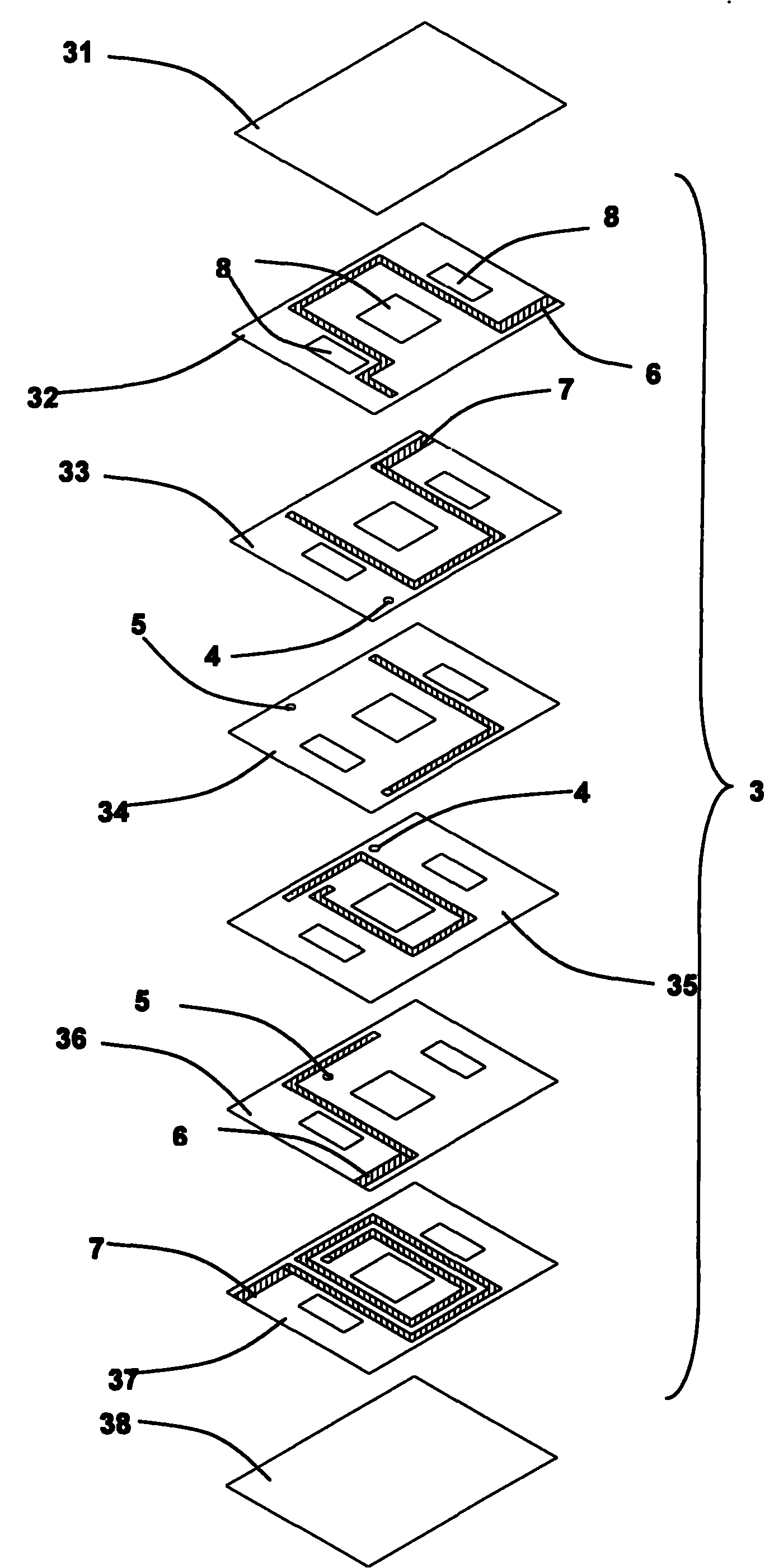

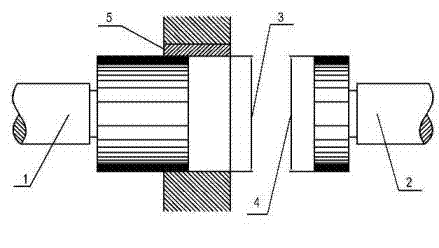

LTCC low temperature co-fired ceramic flat surface transformer

InactiveCN101789311AIncreasing the thicknessMiniaturizationTransformers/inductances coils/windings/connectionsTransformers/inductances magnetic coresCapacitanceCoupling

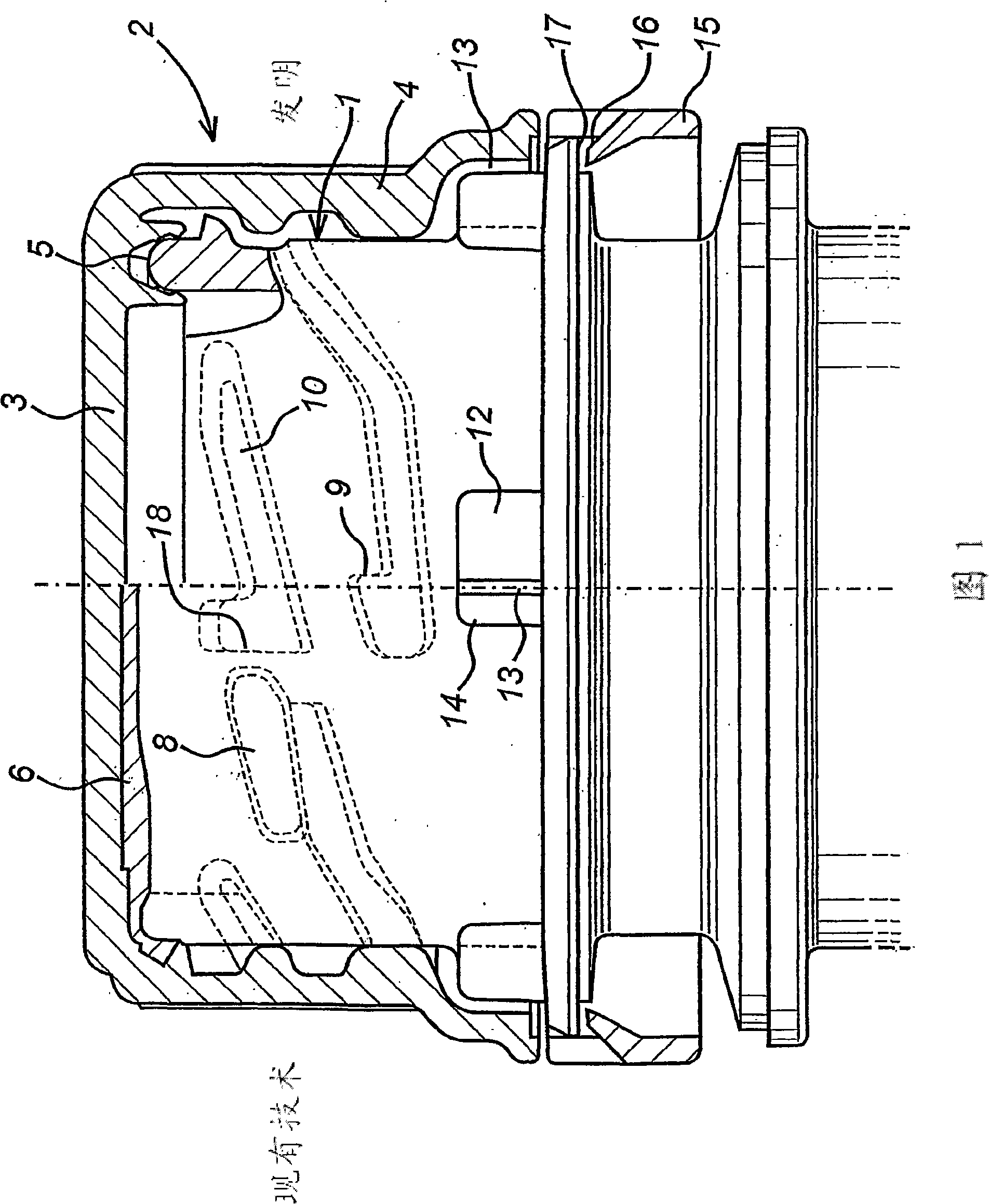

The invention relates to an LTCC low temperature co-fired ceramic planar transformer. The transformer comprises a ferrite magnetic core composed of an upper magnetic core and a lower magnetic core. The transformer is characterized in that the transformer also comprises an LTCC planar transformer base plate provided with at least one group of planar coil component, each planar coil component comprises a primary coil with high coupling coefficient and a secondary coil; the LTCC planar transformer base plate is provided with one or three penetrating holes used for assembling the ferrite magnetic core; and the upper and lower magnetic cores separately penetrate the penetrating holes from the upper and lower sides of the LTCC planar transformer base plate and are butted and adhered together to form the ferrite magnetic core. Compared with the traditional planar transformer, the LTCC low temperature co-fired ceramic planar transformer of the invention has the following beneficial effects: the transformer of the invention has low direct current impedance, leakage inductance and distributed capacitance and can satisfy the design requirement of the resonance circuit; and as the magnetic core has good magnetic shielding, the transformer can inhibit the radio frequency interference.

Owner:SHENZHEN SUNLORD ELECTRONICS

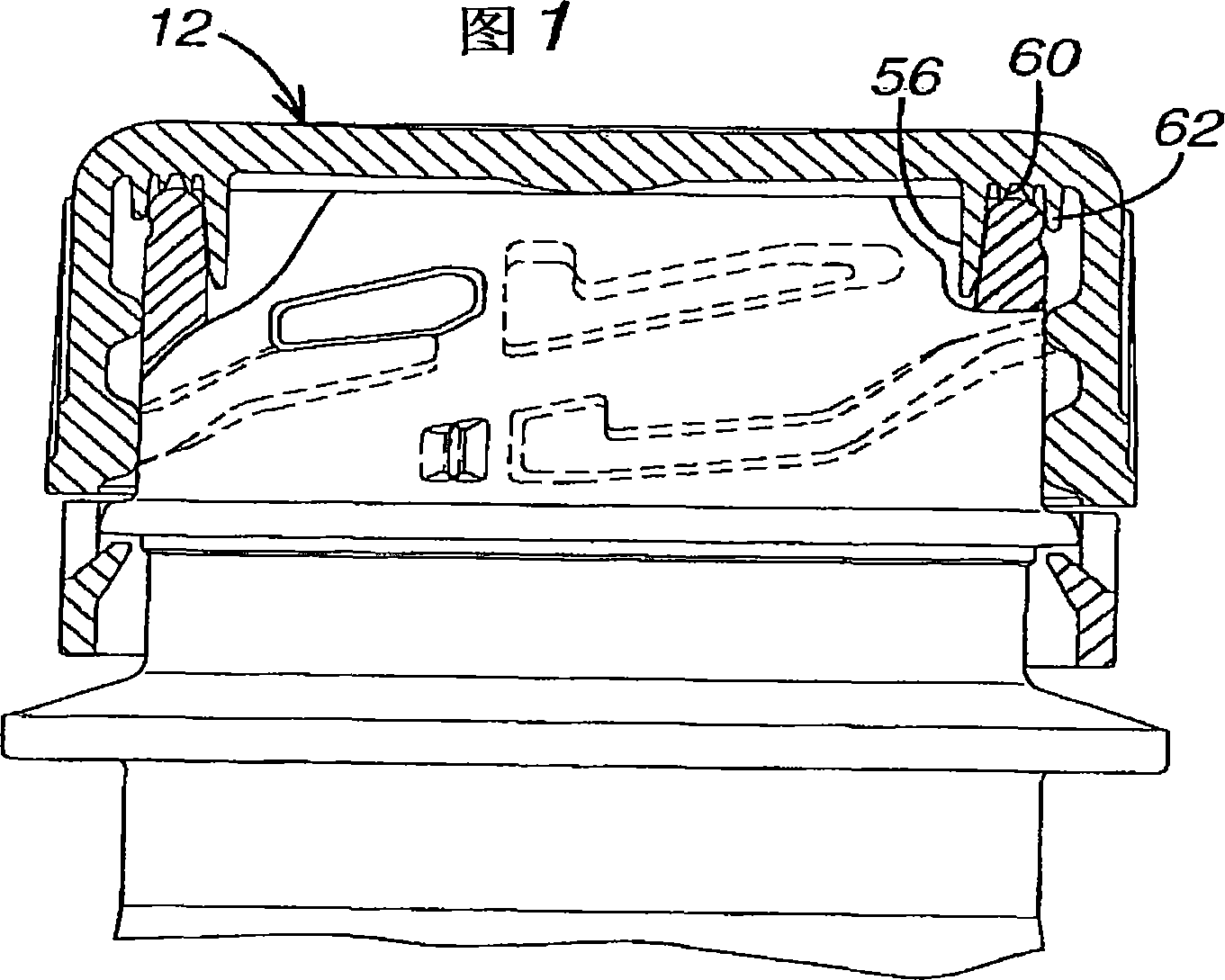

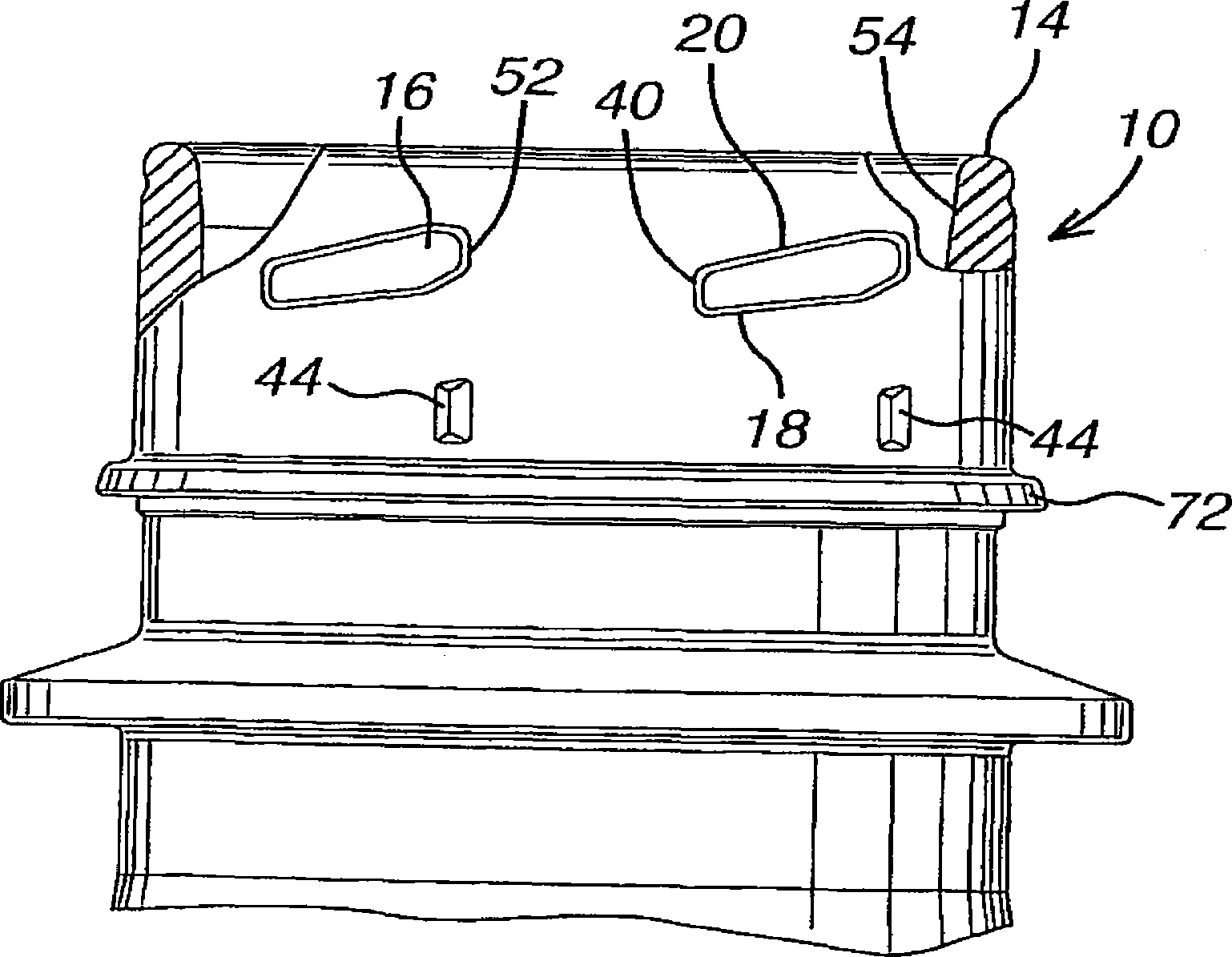

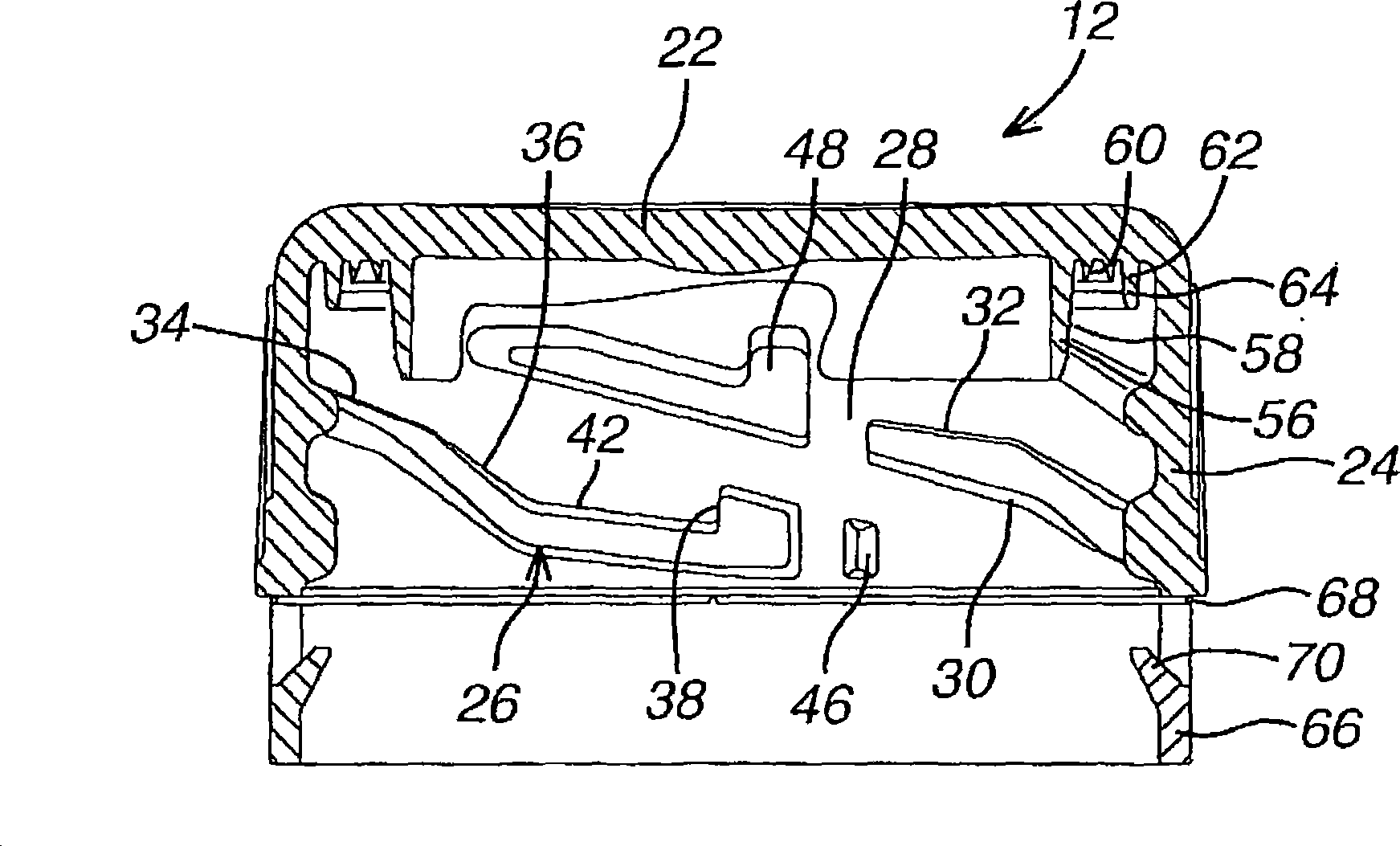

Bottle and closure assembly with locking elements

A threaded container closure assembly, comprising: a container neck (10) having an opening; a closure (12) for said neck, the closure having a base portion (22) and a skirt portion (24); a first screw thread on the neck, said first screw thread comprising one or more first thread segments (16), and a second screw thread on an inner surface of the skirt of the closure, said second screw thread comprising one or more second thread segments (26); a first locking projection (44) on the container neck separate from the first thread segments and a second locking projection (46) on the inner surface of the skirt of the closure separate from the second thread segments, said first and second locking projections being configured to resist unscrewing of the closure from the fully engaged position on the container neck after the closure has been secured or resecured on the container neck until a predetermined minimum opening torque is applied; wherein said first and second locking projections longitudinally overlap the first or the second thread segments when the closure is in the fully engaged position on the container neck.

Owner:BEESON & SONS

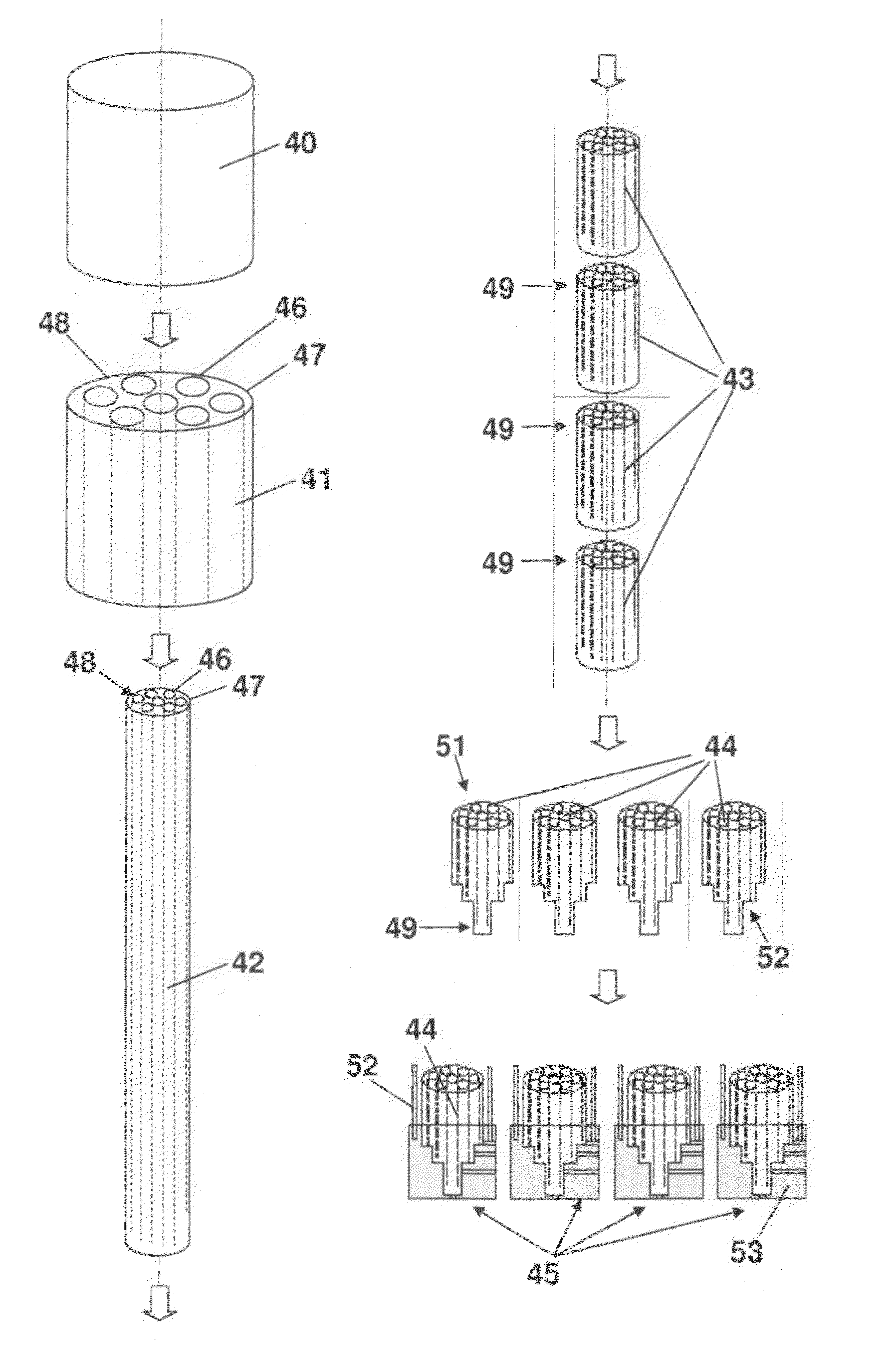

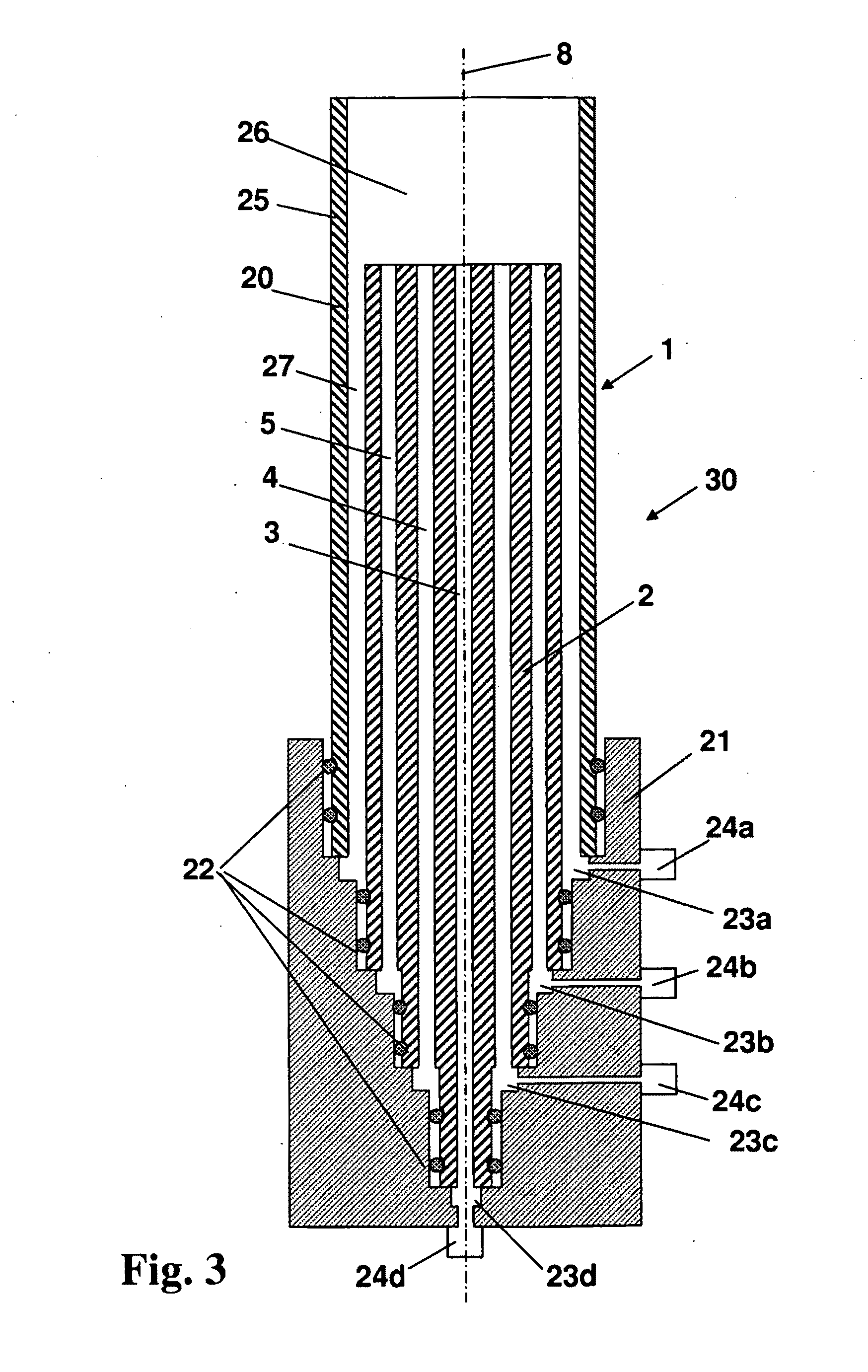

Deposition burner and method for the manufacture thereof, use of the deposition burner and method for the production of a quartz glass body by using the deposition burner

ActiveUS20100132406A1Small manufacturing tolerancesLow costLiquid surface applicatorsRotary drum furnacesCombustorVitreous Bodies

To provide a method for the inexpensive manufacture of a deposition burner with small manufacturing tolerances for use in the synthesis of quartz glass, and wherein moreover, when the deposition burner is used as intended, the risk of contamination of the quartz glass to be produced is low, the invention suggests the following method steps: (a) providing a start cylinder of quartz glass (40) which is mechanically provided with longitudinal bores (46, 47); (b) elongating the start cylinder with formation of a burner strand (42), the longitudinal bores being shaped as elongated channels extending in parallel with one another; (c) cutting the burner strand into pieces in the form of cylindrical quartz glass blocks (43), each being provided with passage lines extending in parallel with a central axis of the quartz glass block; and (d) manufacturing the deposition burner by using a respective one of such quartz glass blocks as burner head which has a proximal end and a distal end, the passage lines serving the supply of process media from the distal to the proximal, burner head end.

Owner:HERAEUS QUARZGLAS

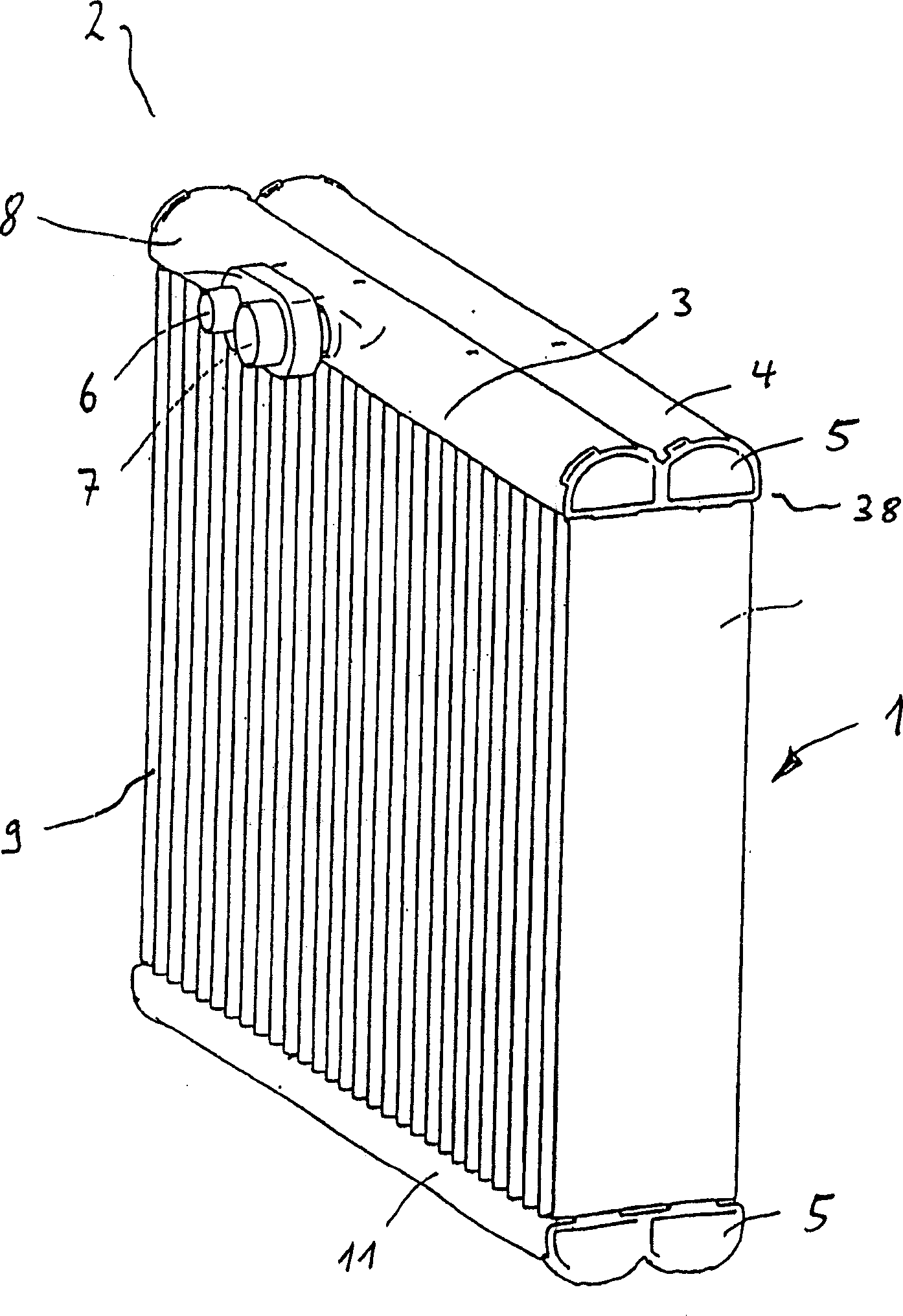

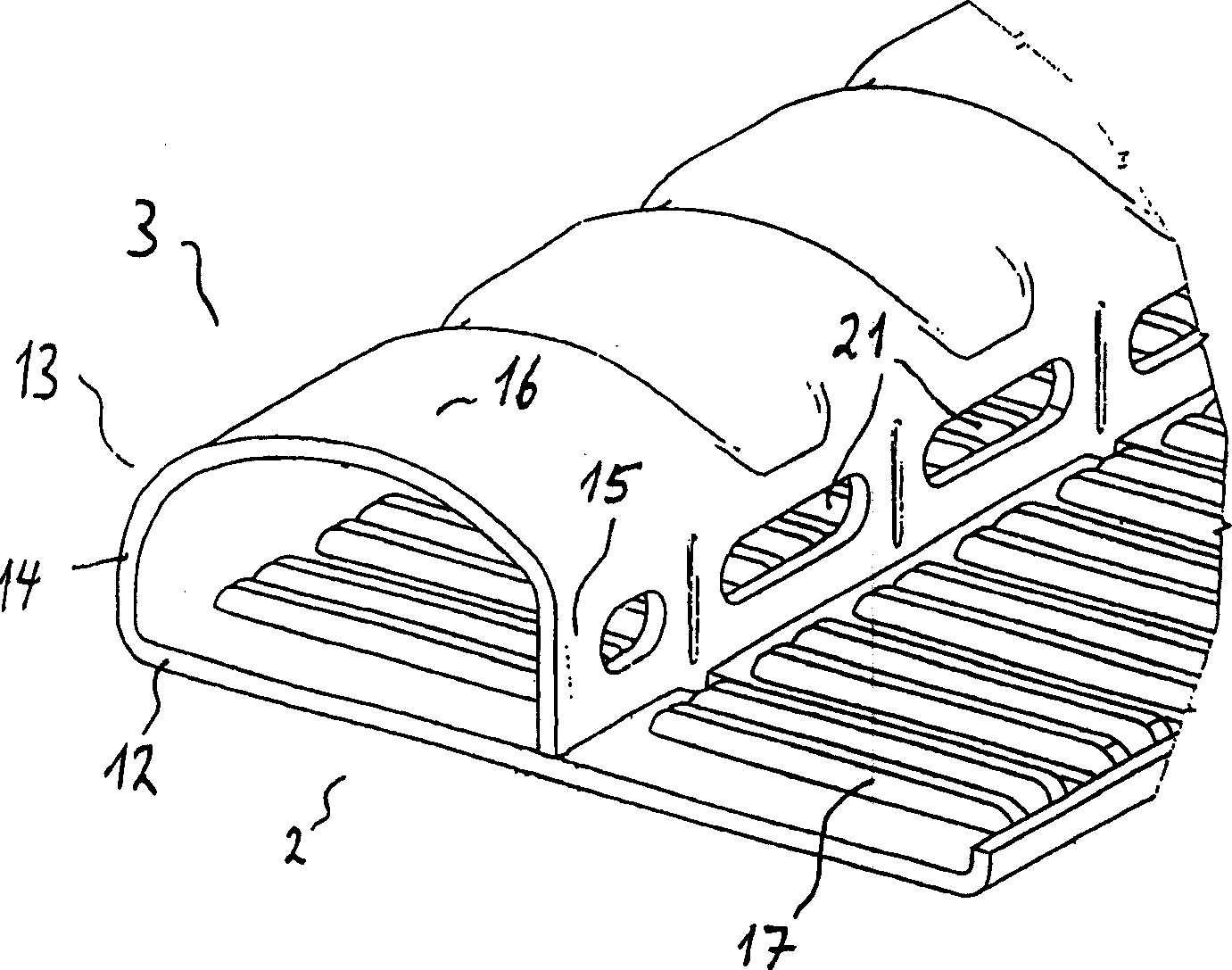

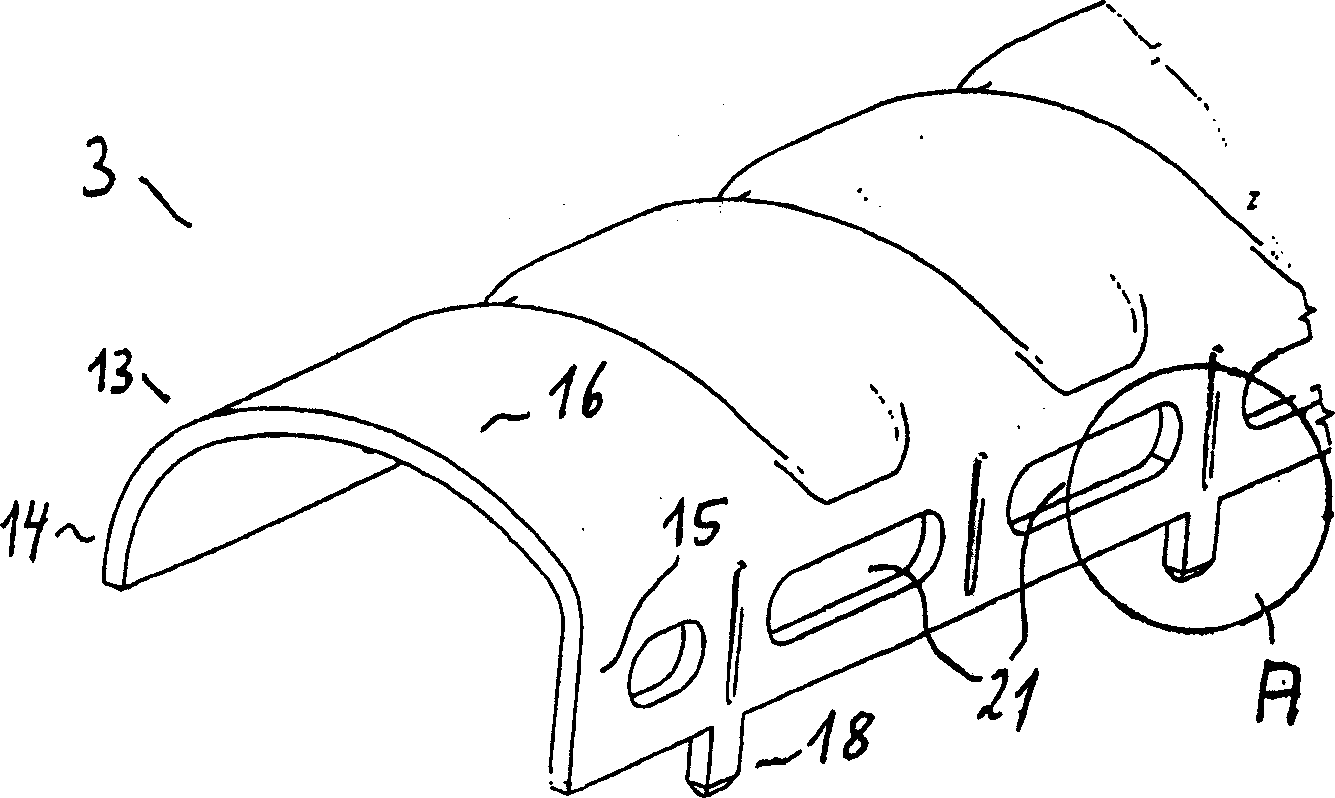

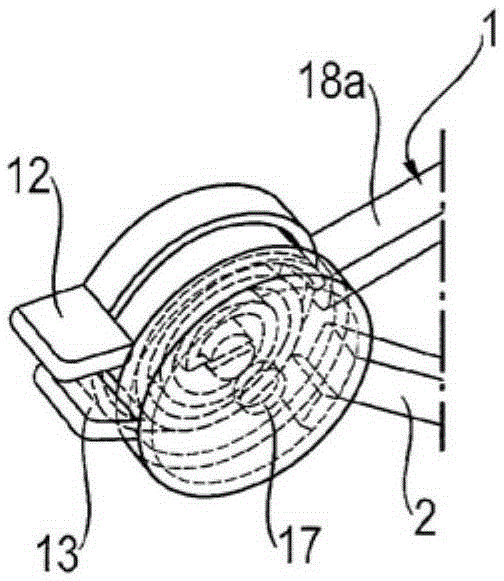

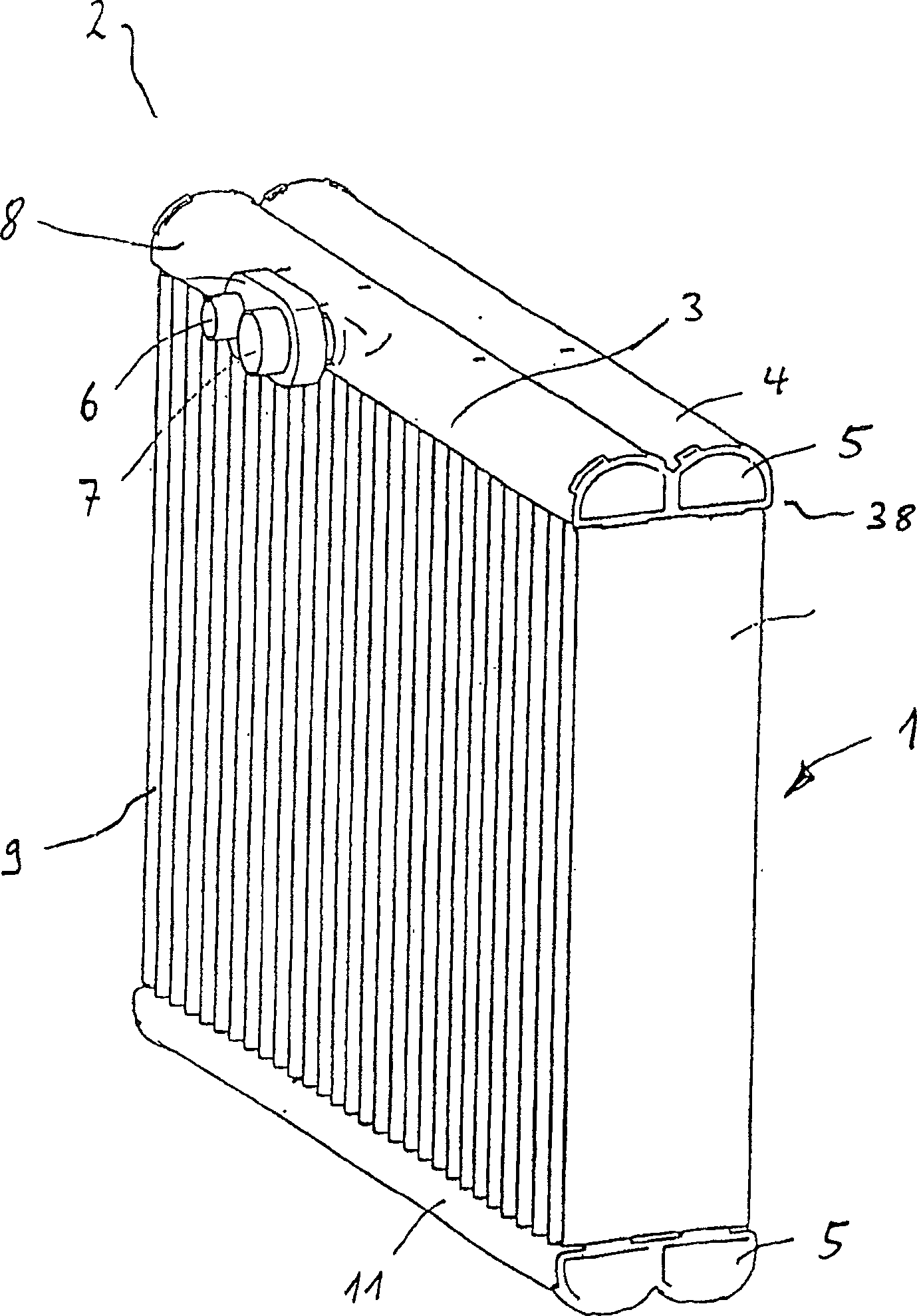

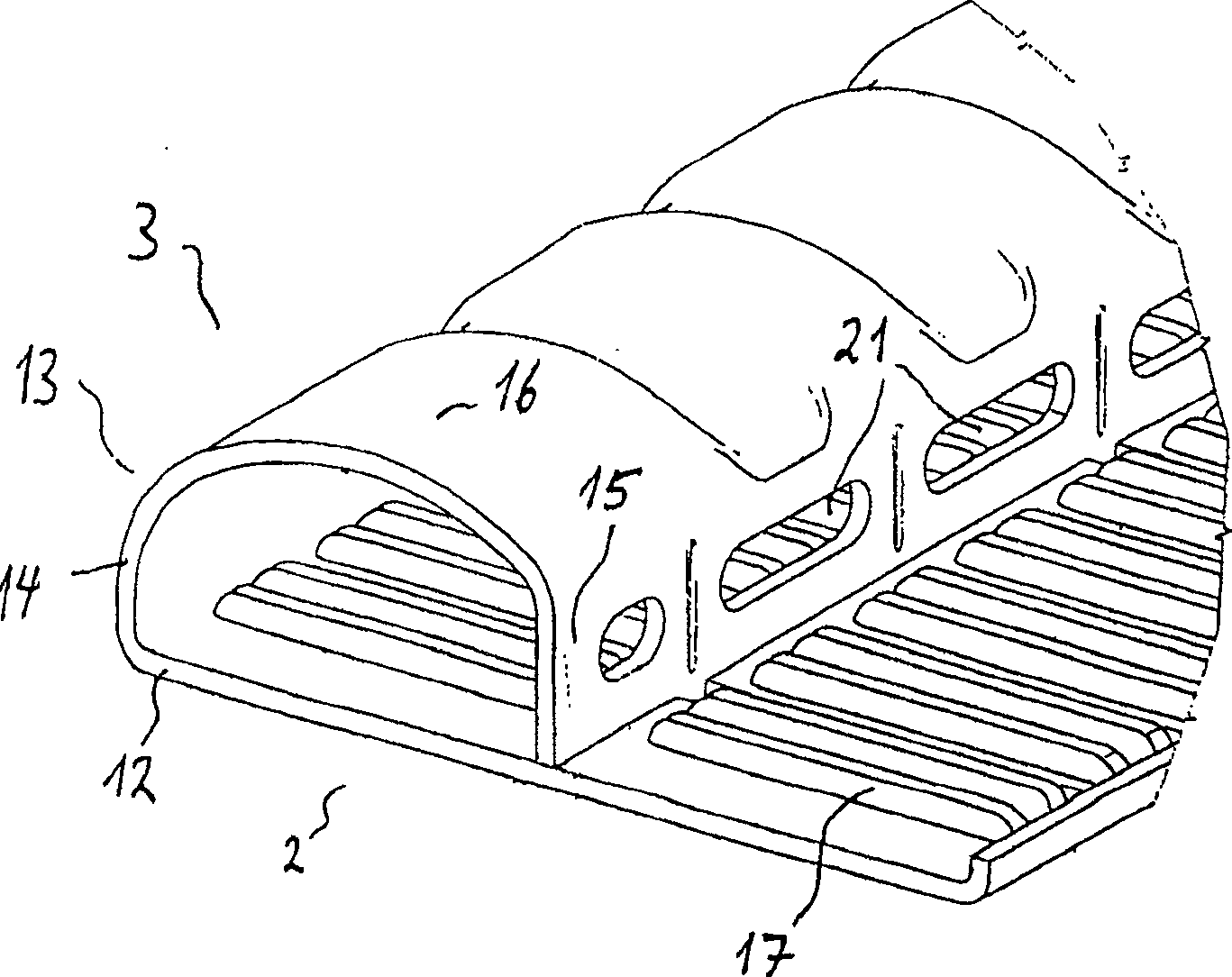

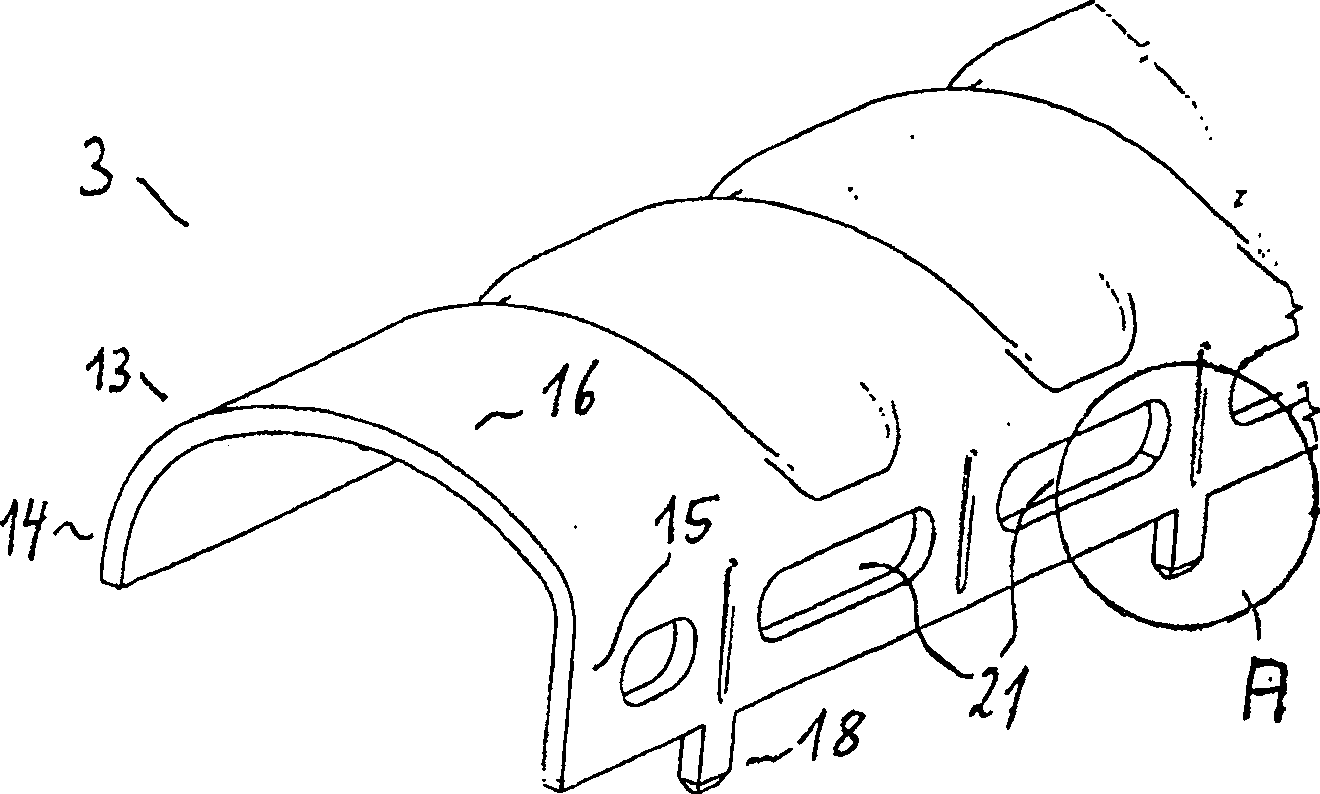

Heat exchanger in particular an evaporator for a vehicle air-conditioning unit

InactiveCN1666076AAppropriate gap widthReduce manufacturing costAir-treating devicesEvaporators/condensersEngineeringAir conditioning

A device is provided for heat transfer and in particular an evaporator for an air conditioning system of motor vehicles having at least one header tank including at least two header chambers which are substantially defined by a base device and a top device. The top device includes middle side walls which are arranged adjacent to one another at least over a portion. The distance between the two side walls increases with the height above the base device.

Owner:BEHR GMBH & CO KG

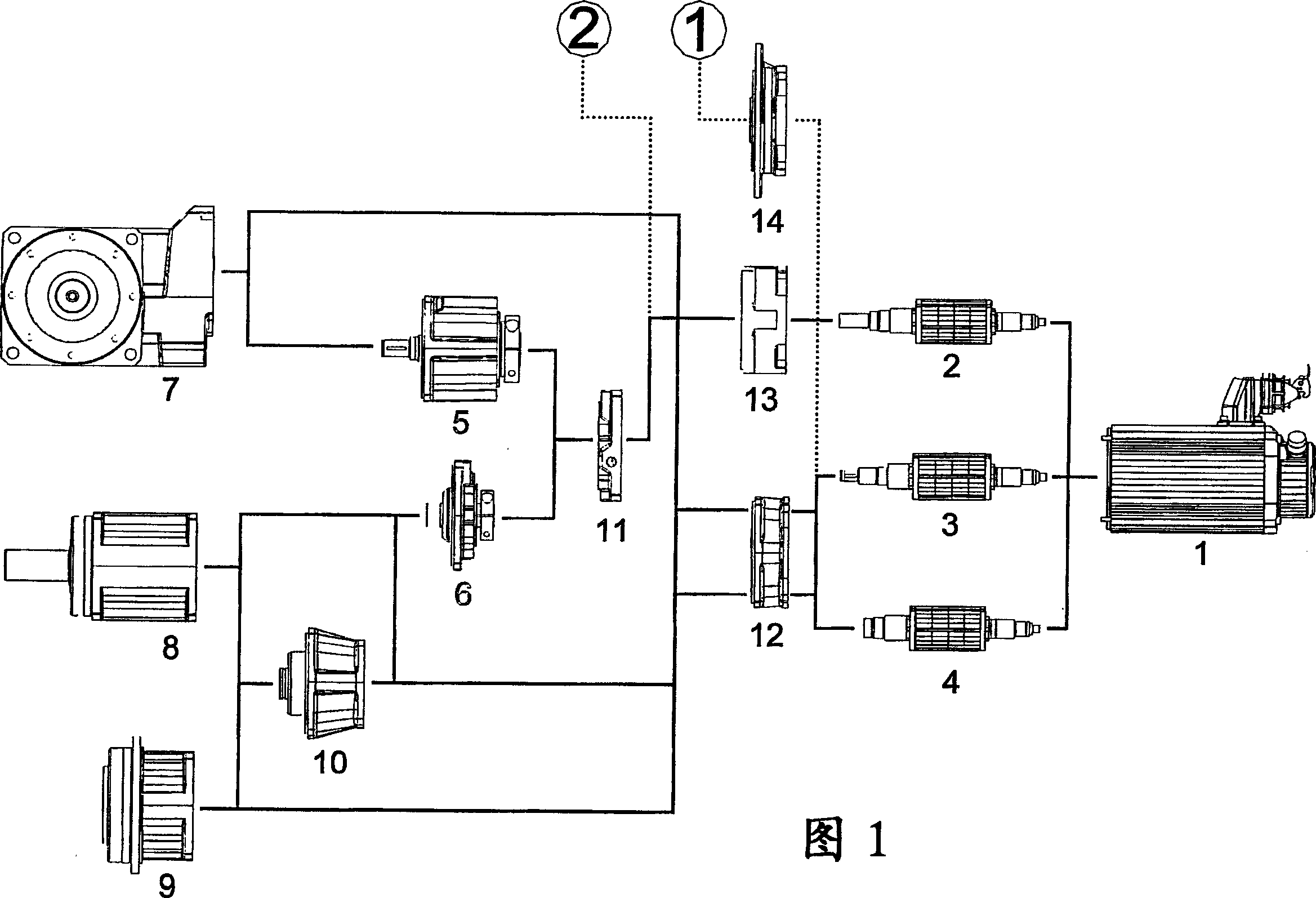

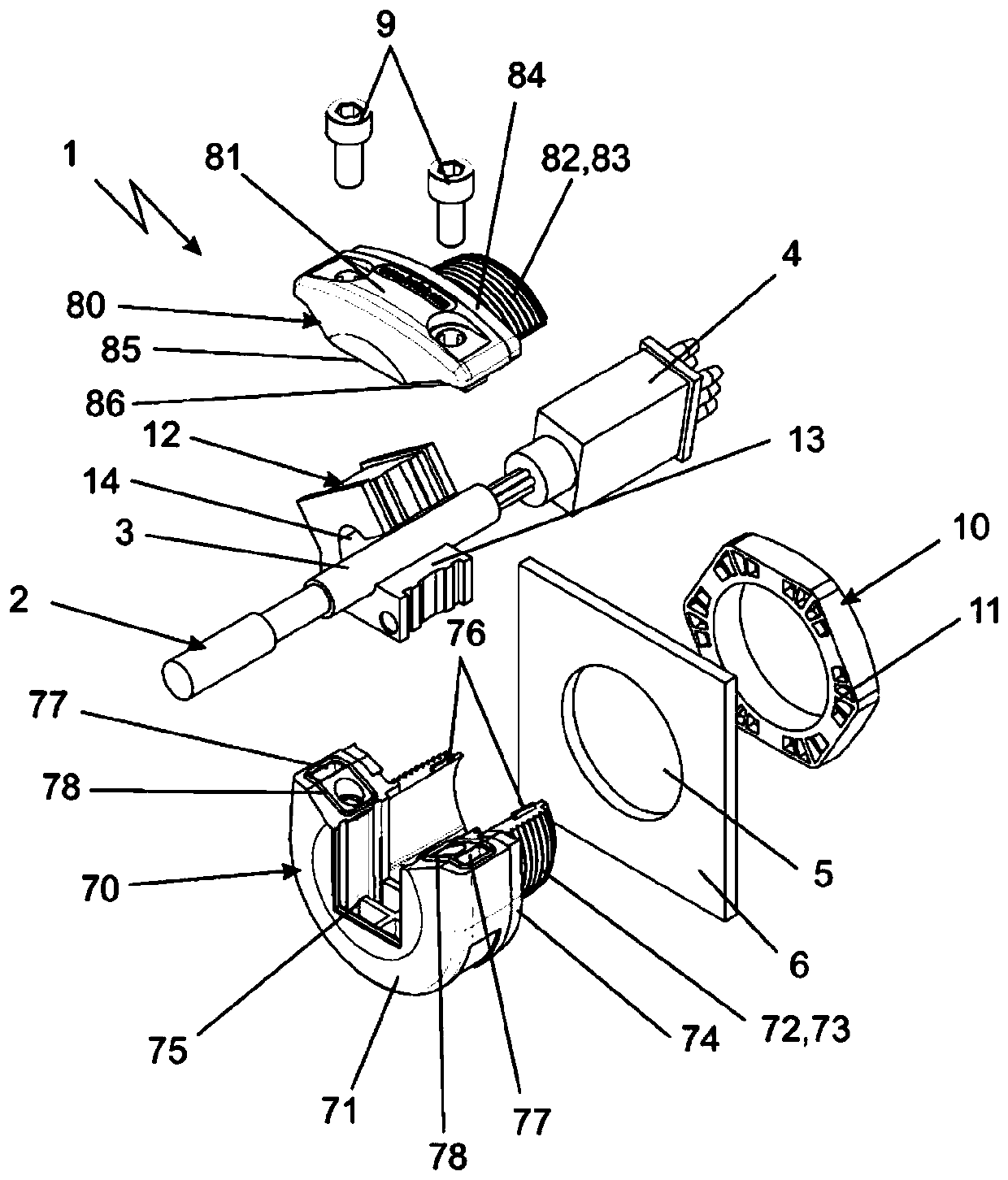

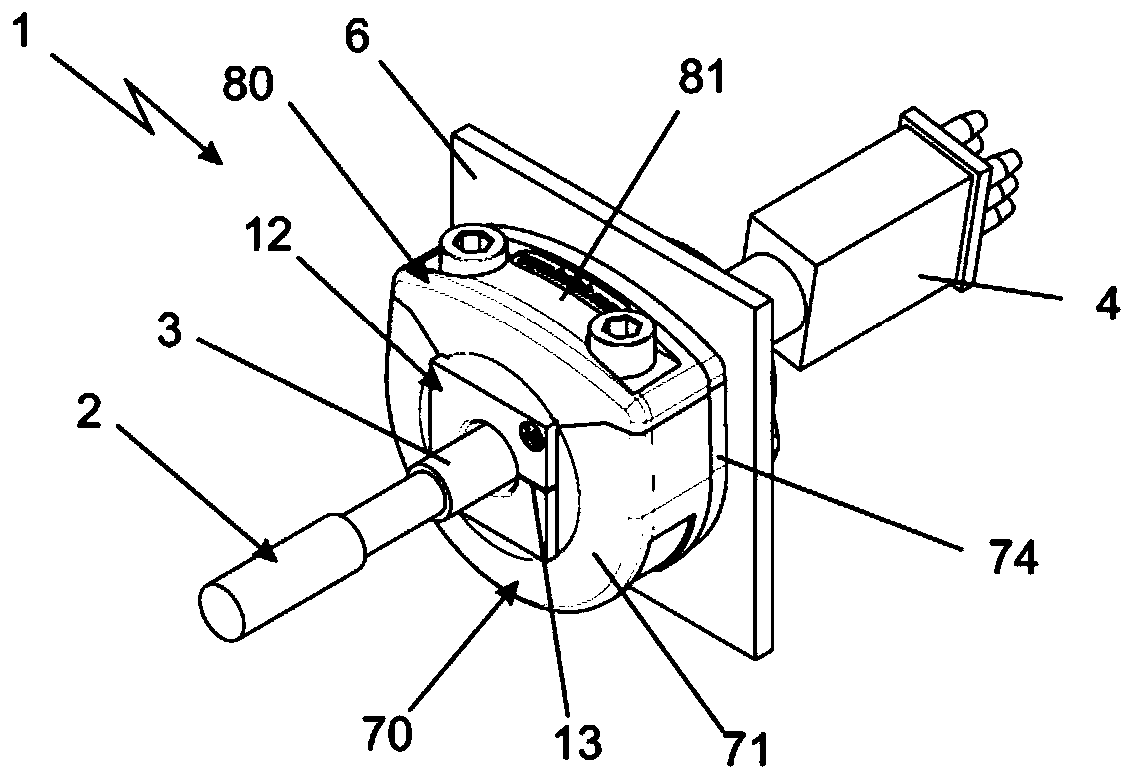

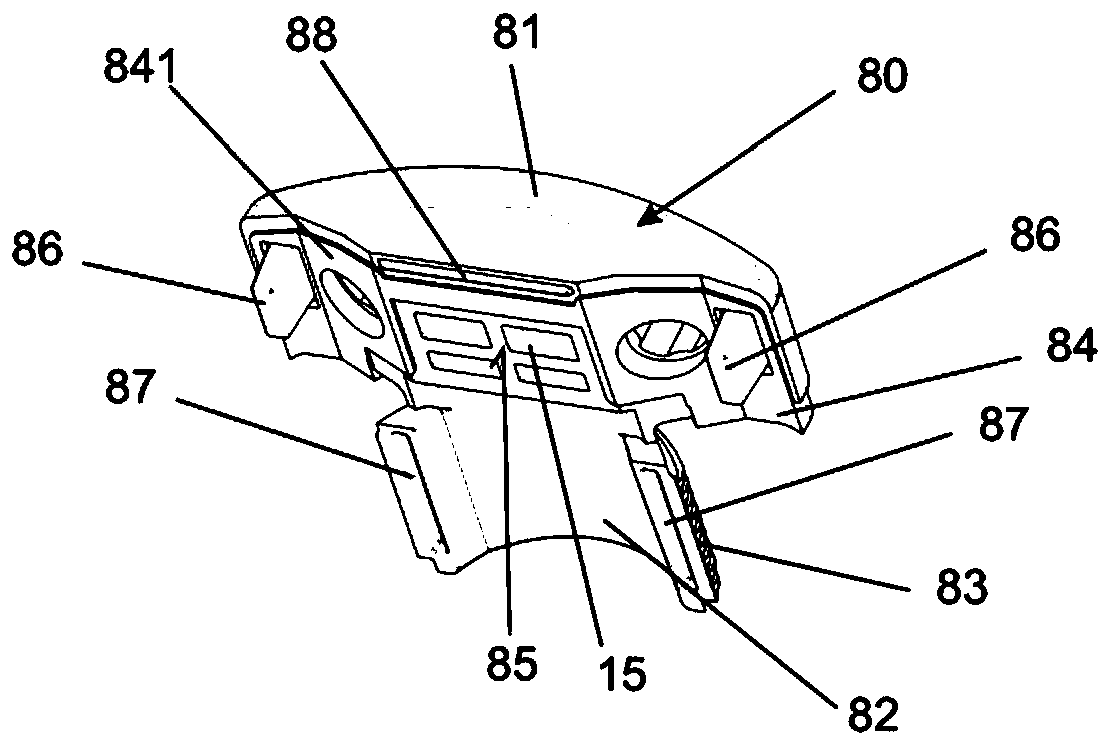

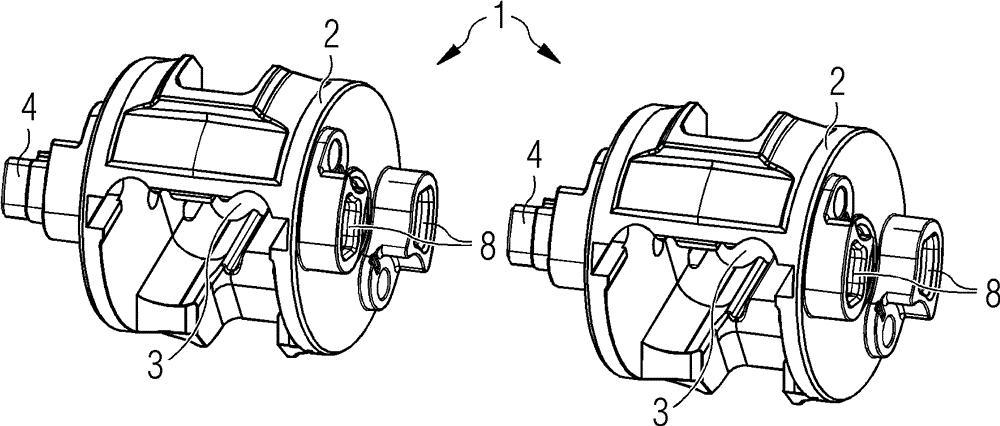

Spare part set for a gearmotor series

ActiveCN1754298ASmall manufacturing tolerancesLow costYielding couplingGearboxesGear transmissionGeometric quantity

The present invention relates to a structure constituent for a gearmotor series. The mentioned gearmotor includes gear transmission equipment drived by electromotor, this structural series includes at least structural quantity which characteristics can be described by at least one physical quantity, mechanical quantity and / or geometric quantity, especially the structural quantity is rating power, axis height or torque. The electromotor always includes at least a electromotor shell, a rotor containing rotor axis and a electromotor bearing cover on driving side, thus, the electromotor shell of the electromotor has a junction region with the electromotor bearing cover on the output side so as to have at least two various deformation of the output side electromotor bearing cover to connect with the electromotor shell.

Owner:SEW-EURODRIVE GMBH & CO KG

Braking system with safe torque take-up

InactiveCN1578100ANo need to oversizeSafe and reliable lockingAc motor stoppersBrake actuating mechanismsElectric machineBraking system

The present invention relates to a braking system for an electric motor, the braking system comprising: a chassis; and at least one brake supported by the chassis, the brake comprising: at least one brake disk connected via a fluted connection to a shaft driven by the motor; an armature that is movable in translation along an axis of rotation of the shaft; a plurality of armature-guiding spacers, at least one of the spacers being engaged at one end in a corresponding housing in the chassis, so as to enable the chassis to take up torque that is exerted on the brake during braking; a plurality of springs for urging the armature against the disk; and an electromagnet which, when powered, attracts the armature and moves it away from the disk against the action of the springs.

Owner:LEROY-SOMEMER ENGINE CO LTD

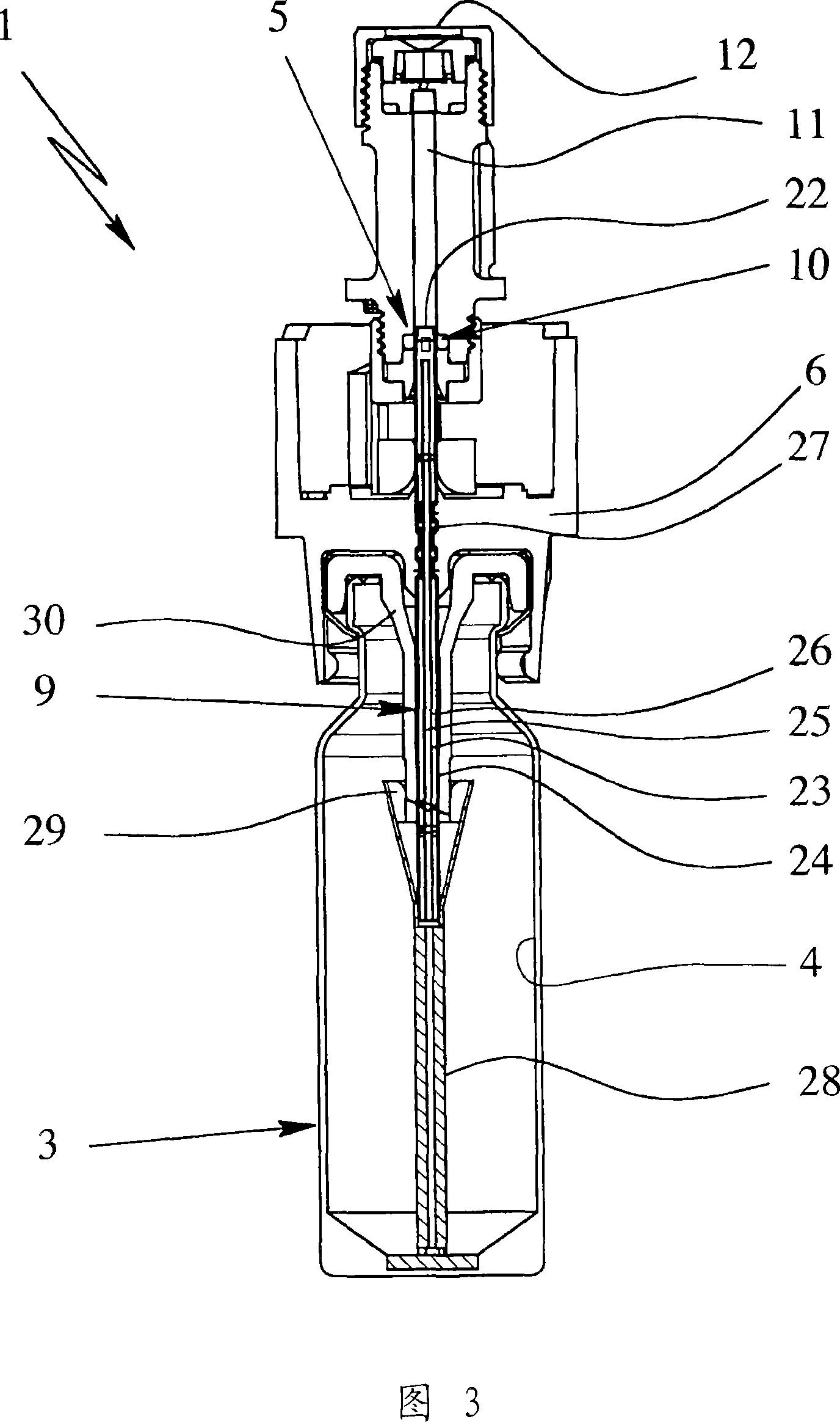

Atomizer

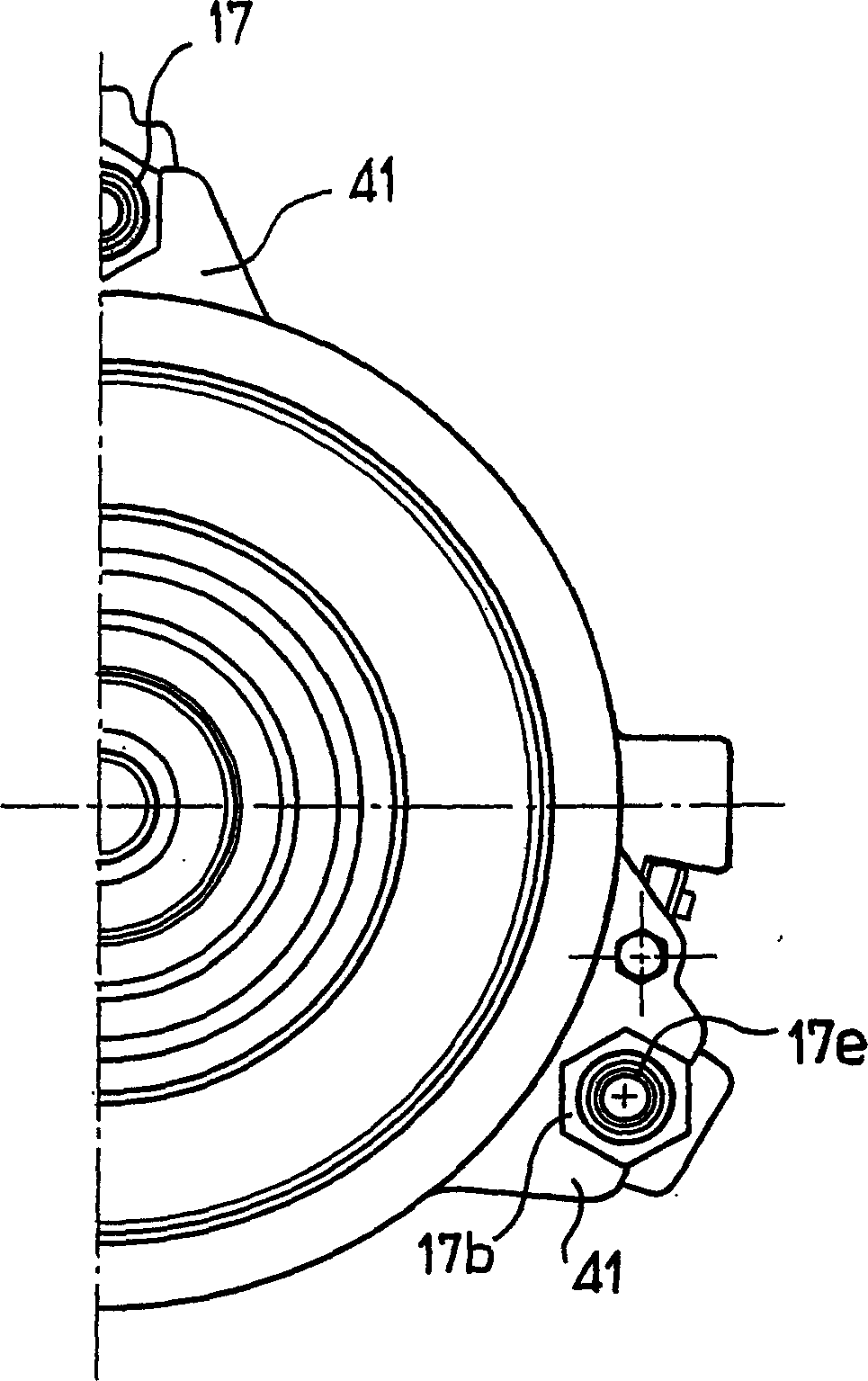

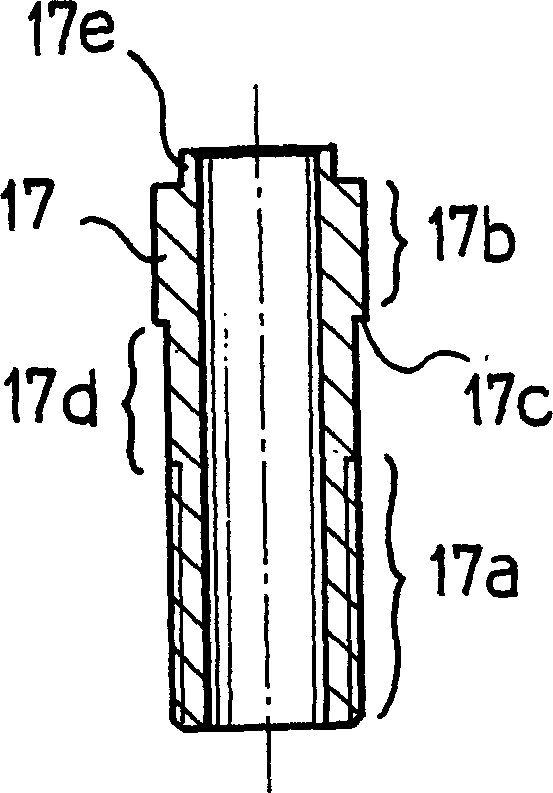

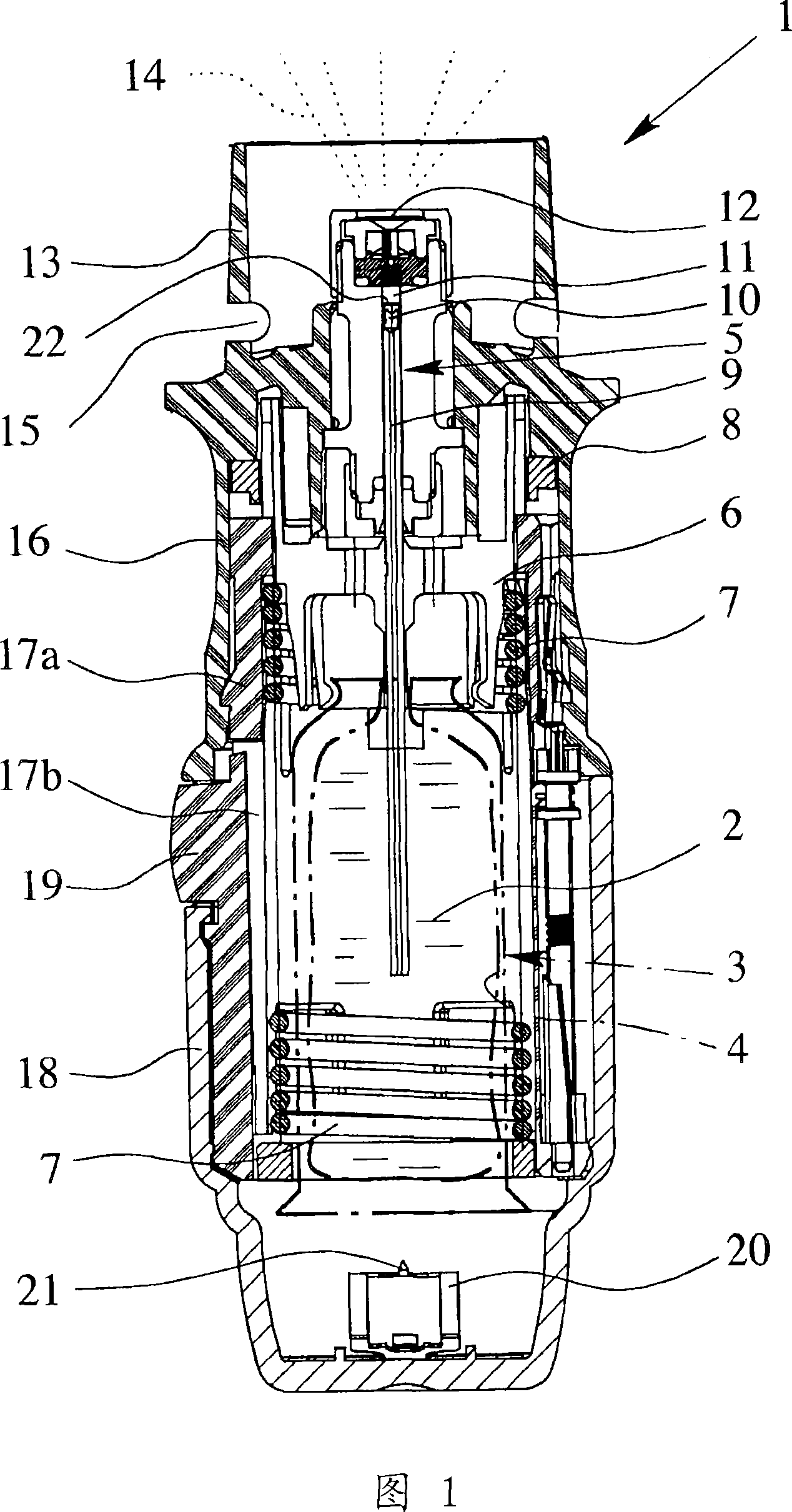

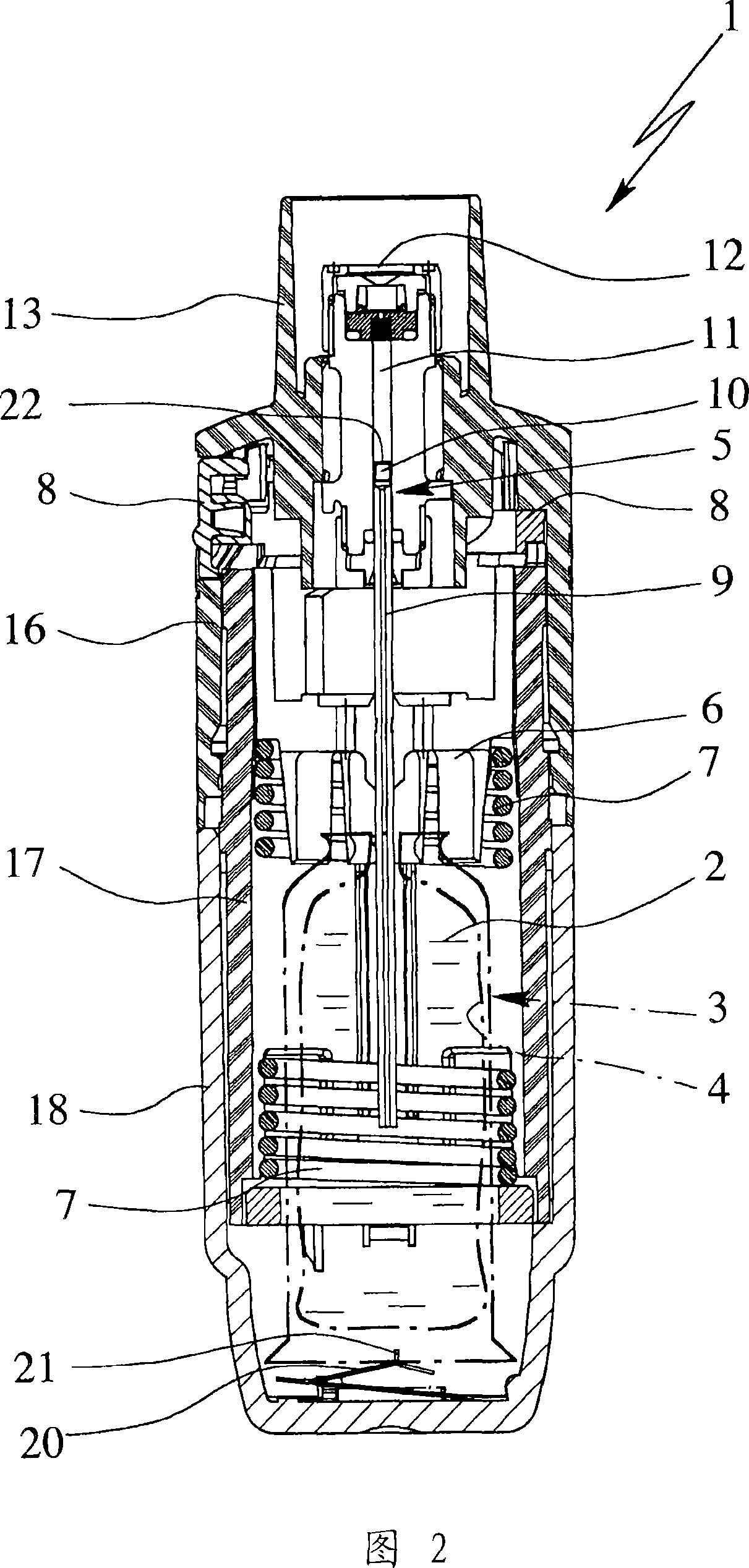

InactiveCN101189071AEasy to produceSmall manufacturing tolerancesSingle-unit apparatusLiquid spraying apparatusNebulizerThick wall

A nebuliser and a container in each case with an aeration device are proposed, the aeration device being designed for the direct aeration of a liquid space in the container. The container comprises a rigid, gas-tight outer case and a closure, which is opened by connecting or inserting a delivery element. A long storage life and long service life with low loss of fluid or solvent are thereby provided in the form of a simple and inexpensive construction.

Owner:BOEHRINGER INGELHEIM INT GMBH

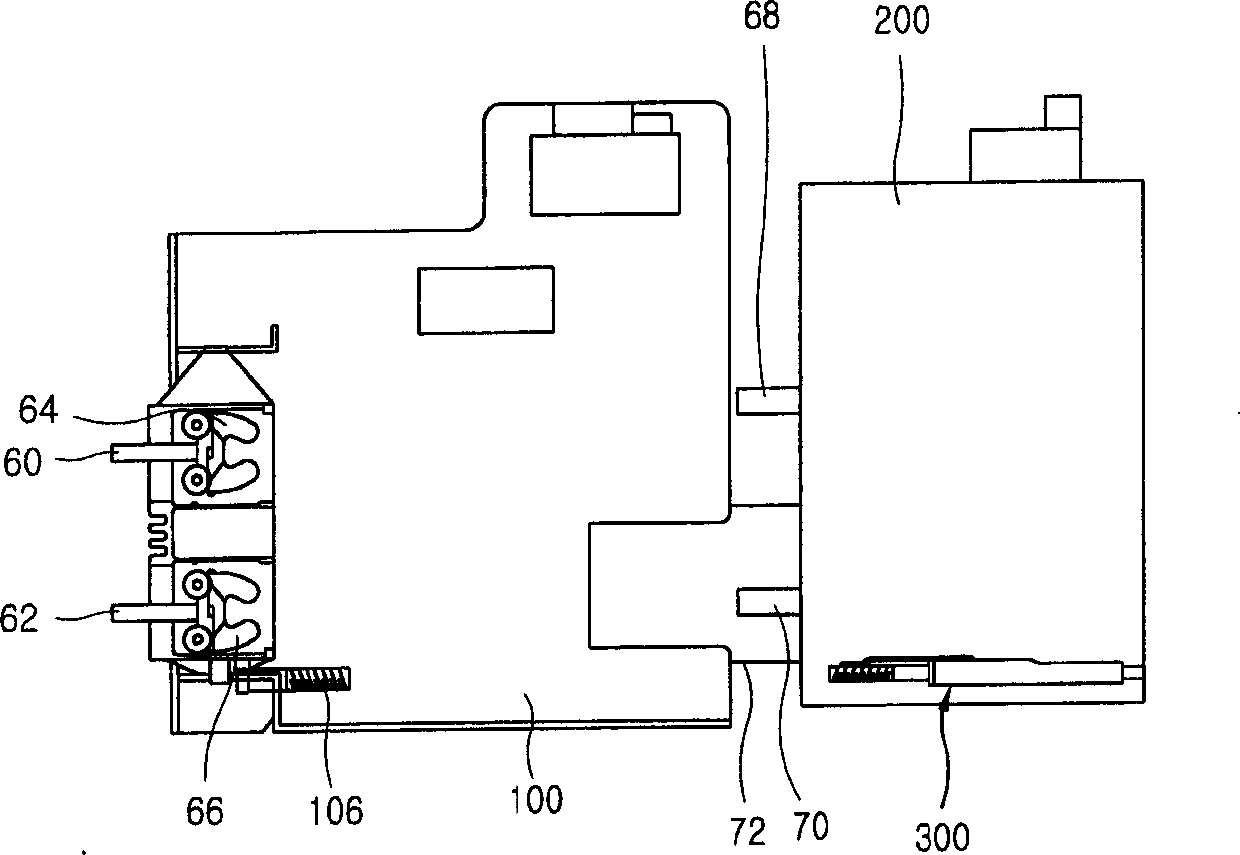

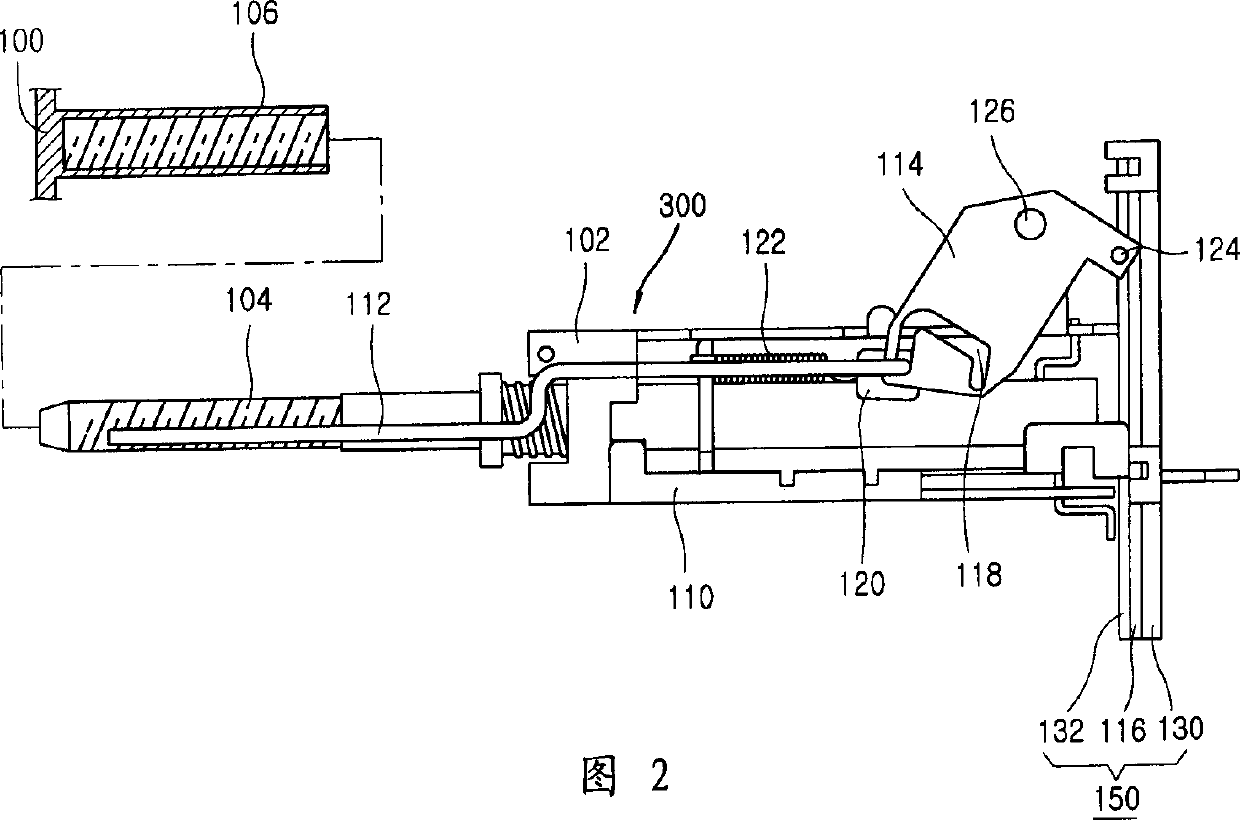

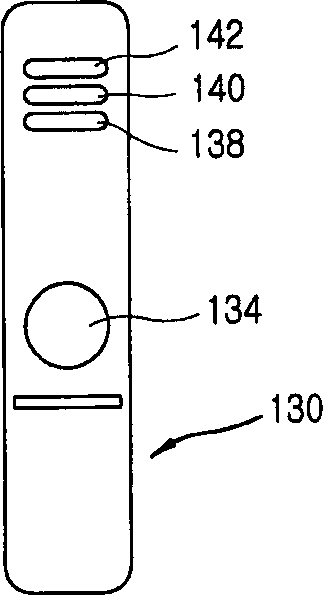

Air circuit breaker

InactiveCN1360325AAvoid deformationAvoid bendingSwitchgear detailsHigh-tension/heavy-dress switchesElectricityCircuit breaker

The present invention provides an air circuit breaker including an interlock apparatus. The air circuit breaker comprises a movable breaker body having a power source terminal and a load terminal and connecting or disconnecting a circuit between power source and a load, a cradle electrically and mechanically connected to or separated from the breaker body in accordance with movement of the breaker body and having a connector electrically and mechanically connected to the breaker body, a screw pipe guiding the connection to or separation from the breaker body and a power source terminal and a load terminal respectively connected to the power source and the load, a base frame fixed to the breaker body, a lead screw supported by the base frame so as to be rotatable and movable to a position for being inserted into the screw pipe and a position for being separated from the screw pipe, a interlock apparatus installed on the base frame and for indicating a position of the breaker body such as a disconnected position in which the breaker body is totally separated from the cradle, a testing position for testing the breaker body and a connected position in which the breaker body is connected to the cradle.

Owner:LG IND SYST CO LTD

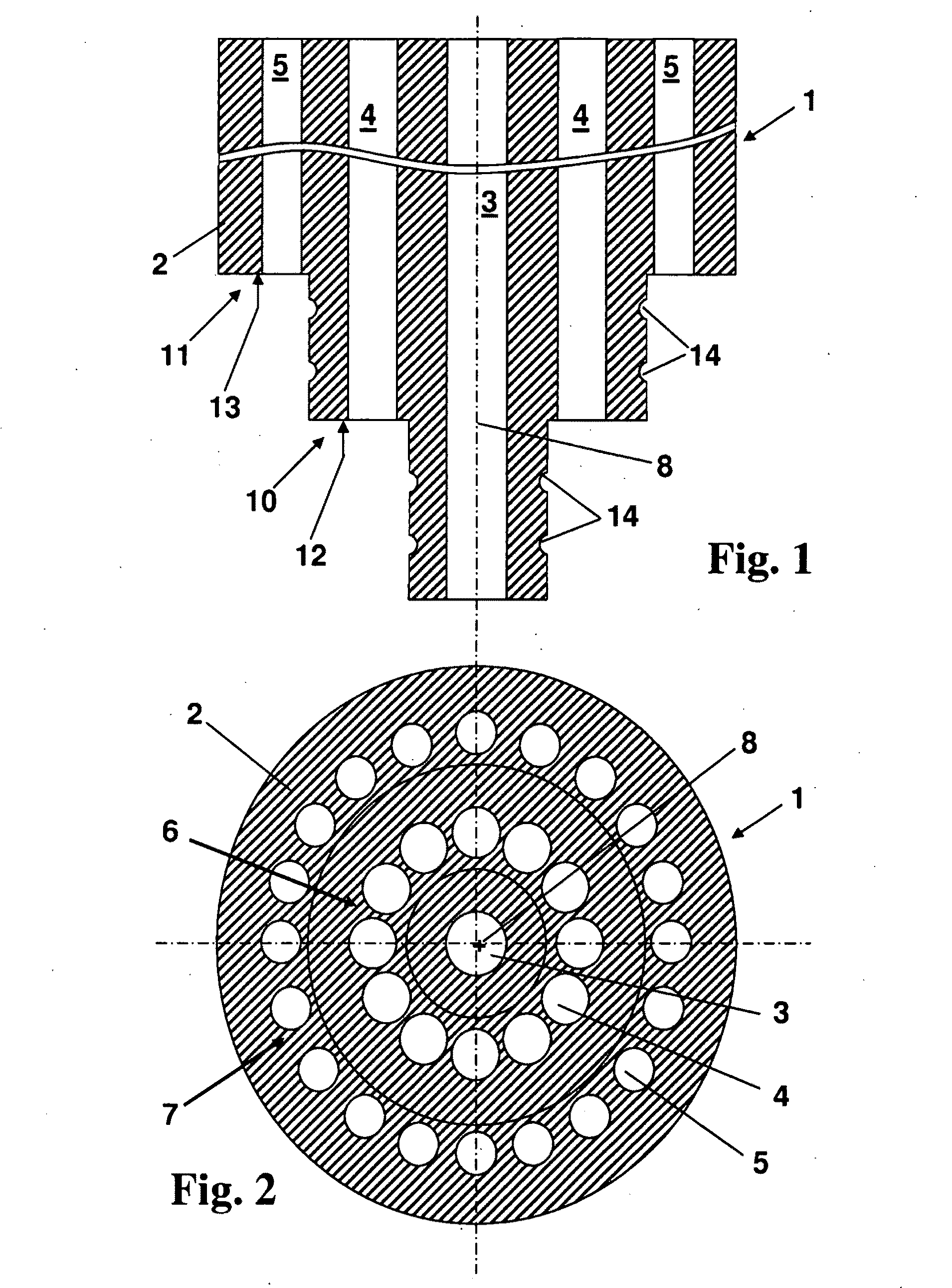

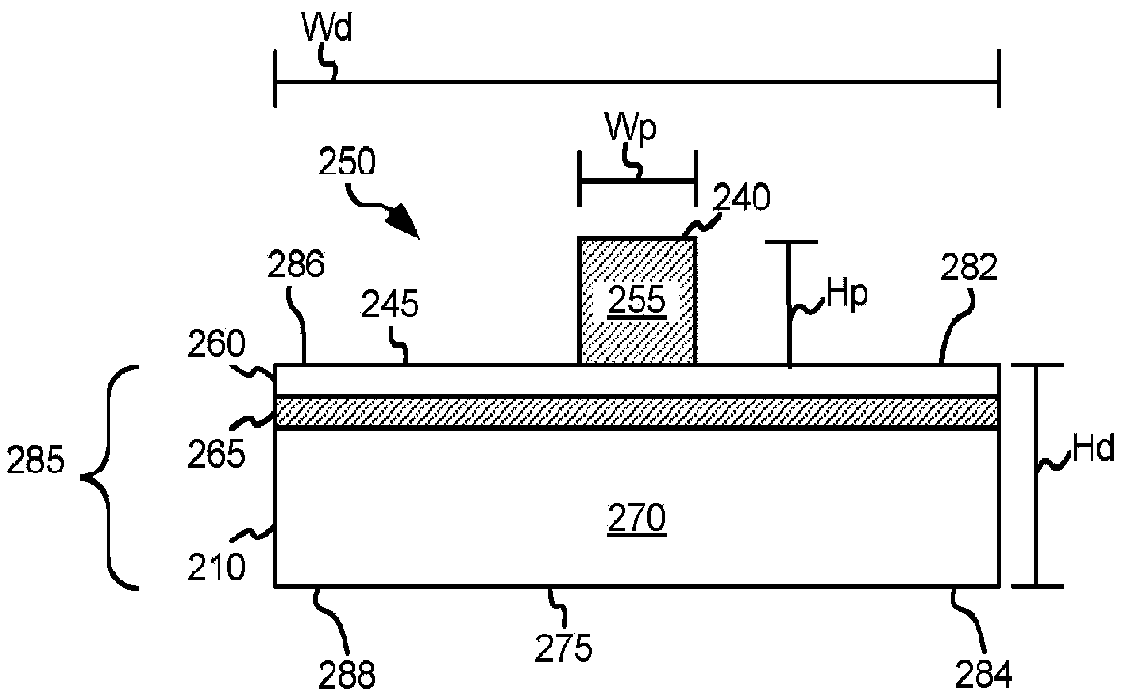

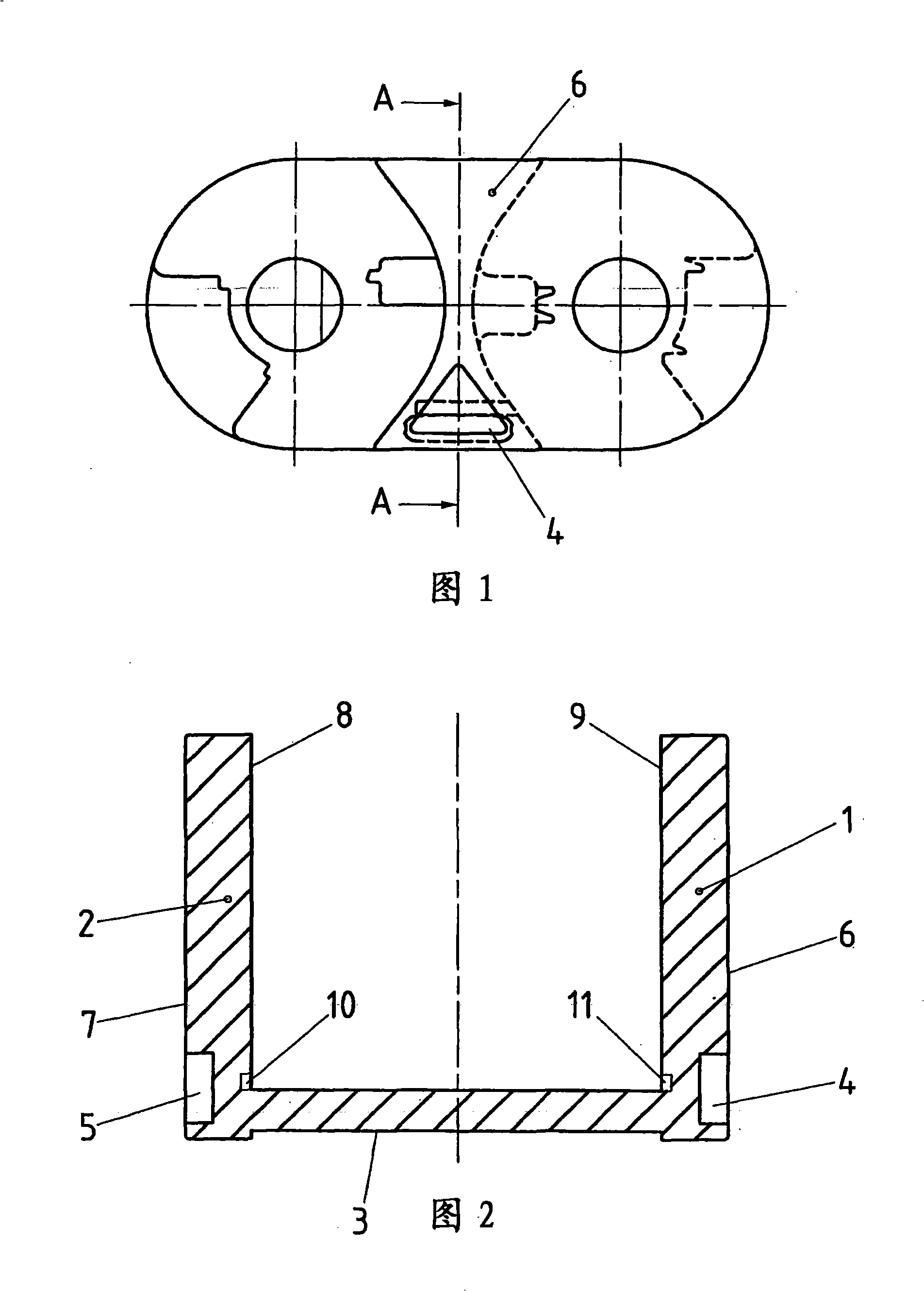

Chemical sensor and method for manufacturing such a chemical sensor

InactiveCN103969311AShort response timeAvoid damageSemiconductor/solid-state device manufacturingMaterial resistanceContact padOptoelectronics

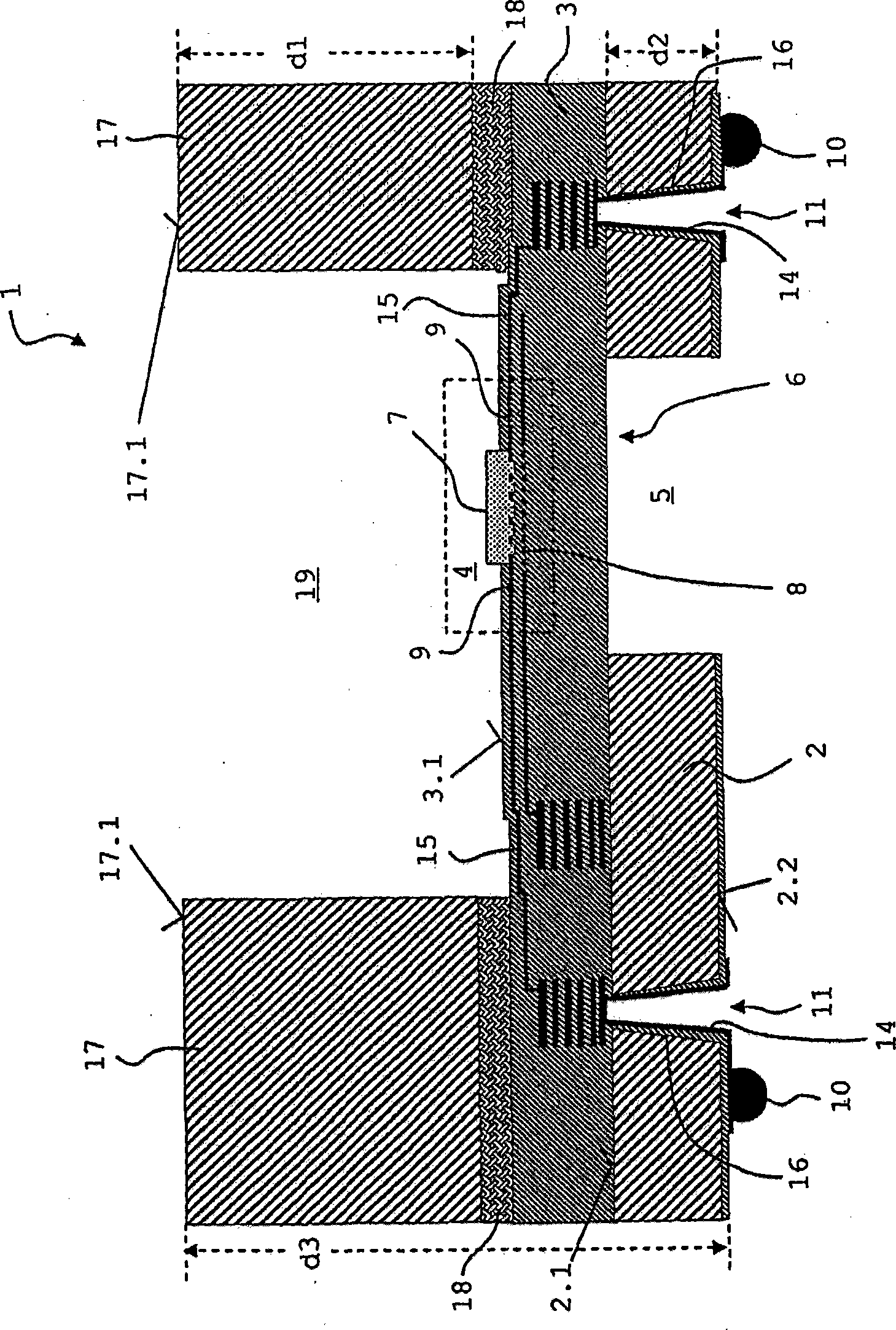

The invention relates to a chemical sensor and a method for manufacturing such a chemical sensor. The chemical sensor (1) comprises a substrate layer (2) having a front surface (2.1) and a back surface (2.2) and a sensing layer (3) arranged on the front surface (2.1) of the substrate layer (2), wherein the sensing layer (3) comprises a sensing element (4); the substrate layer (2) is provided with a well (5) in the back surface (2.2) to a form a membrane (6) that incorporates the sensing element (4); the substrate layer (2) is provided with contact pads (10) on the back surface (2.2) and with through holes (11) extending from the front surface (2.1) to the back surface (2.2) for electrically connecting the sensing element (4) with the contact pads (10); a handling layer (17) is provided on top of the sensing layer (3), the handling layer (17) surrounding the sensing element (4), and the thickness (d1) of the handling layer (17) is larger than the thickness (d2) of the substrate layer (2).

Owner:SENSIRION AG

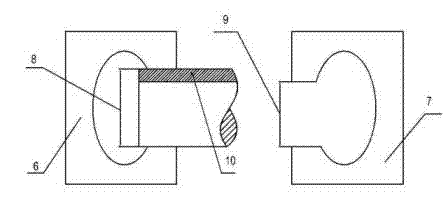

Valve and assembly method

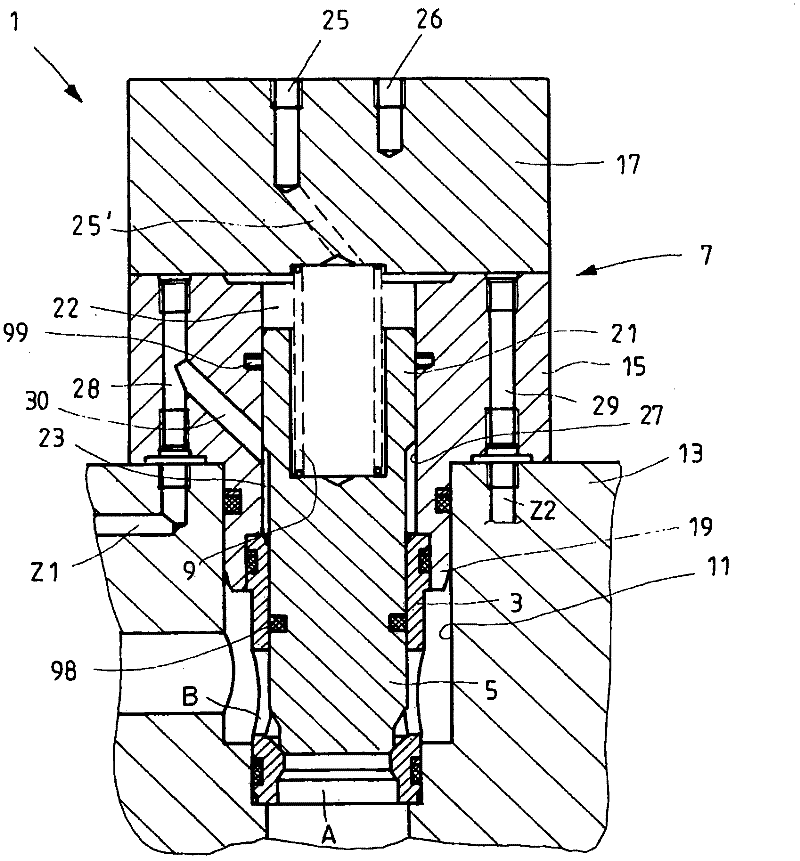

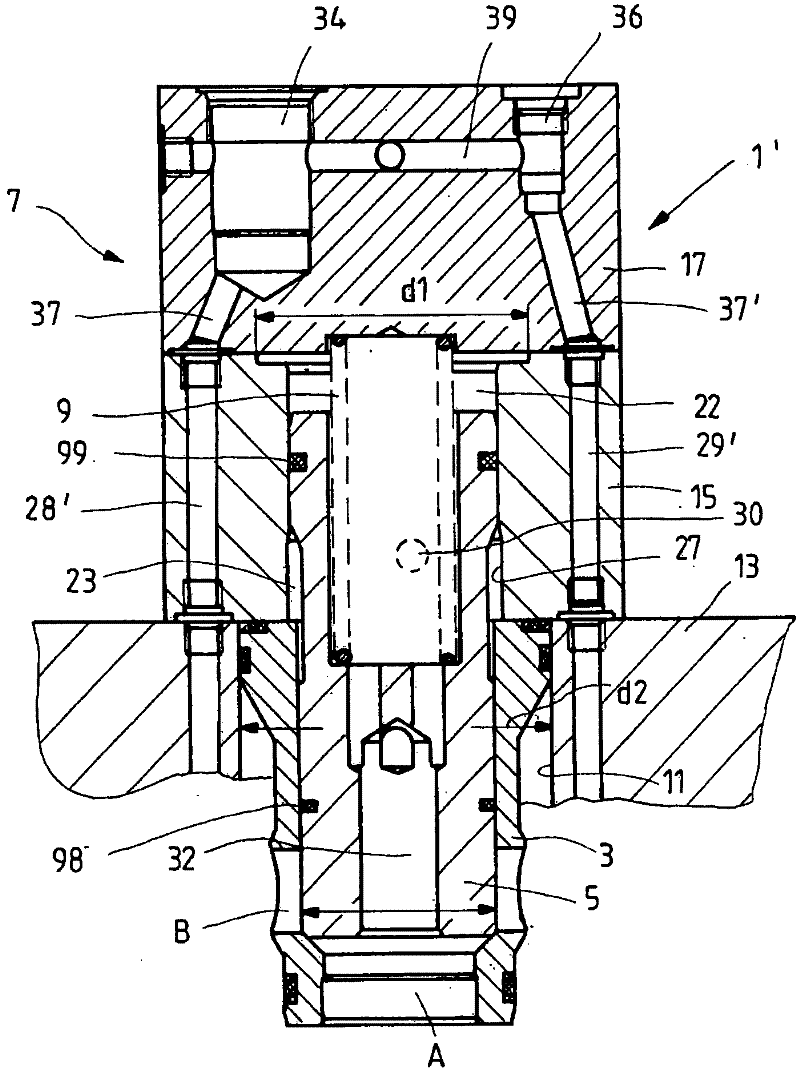

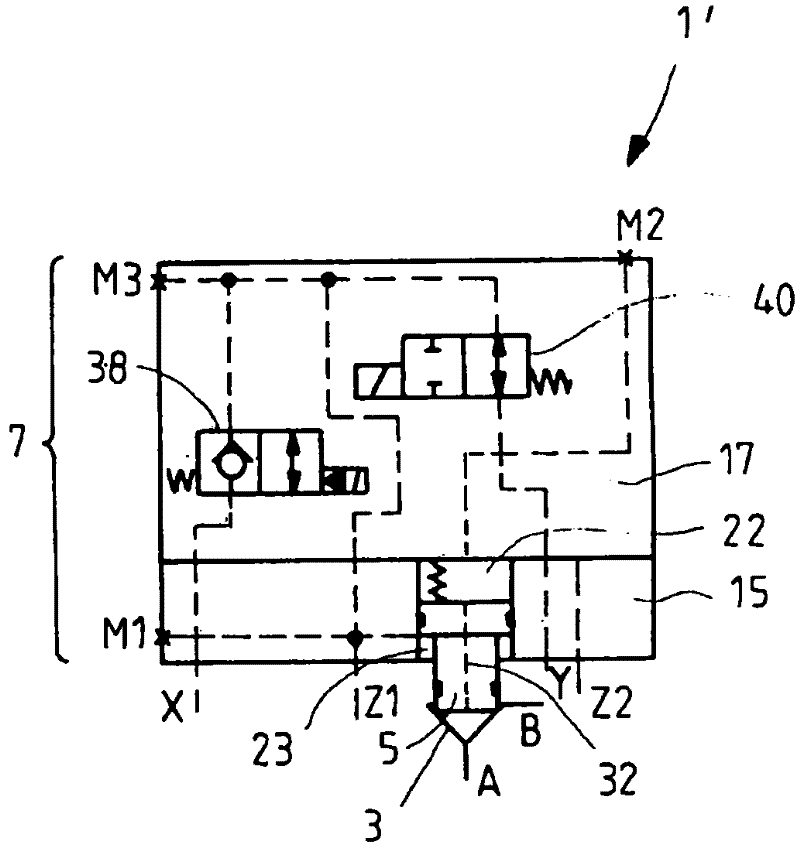

ActiveCN102216659ALow priceCheaply made cheaplyOperating means/releasing devices for valvesThin material handlingEngineeringControl channel

The invention relates to a valve for installation in a valve bore of a housing or valve block (13), comprising a valve bushing (3)- for insertion into the valve bore, a guided valve piston (5) that can be moved axially in the valve bushing, an activation section (21) of said piston projecting above the valve bushing axially, and a valve cover (7) that is intended to be arranged over the valve bore and that forms, together with the activation section of the valve piston, at least one activation pressure chamber (22, 23, 24). Because the valve cover is divided axially into two components - an intermediate cover (15) and a functional cover (17) with control channel - a high number of variants can be provided at little expense.

Owner:ROBERT BOSCH GMBH

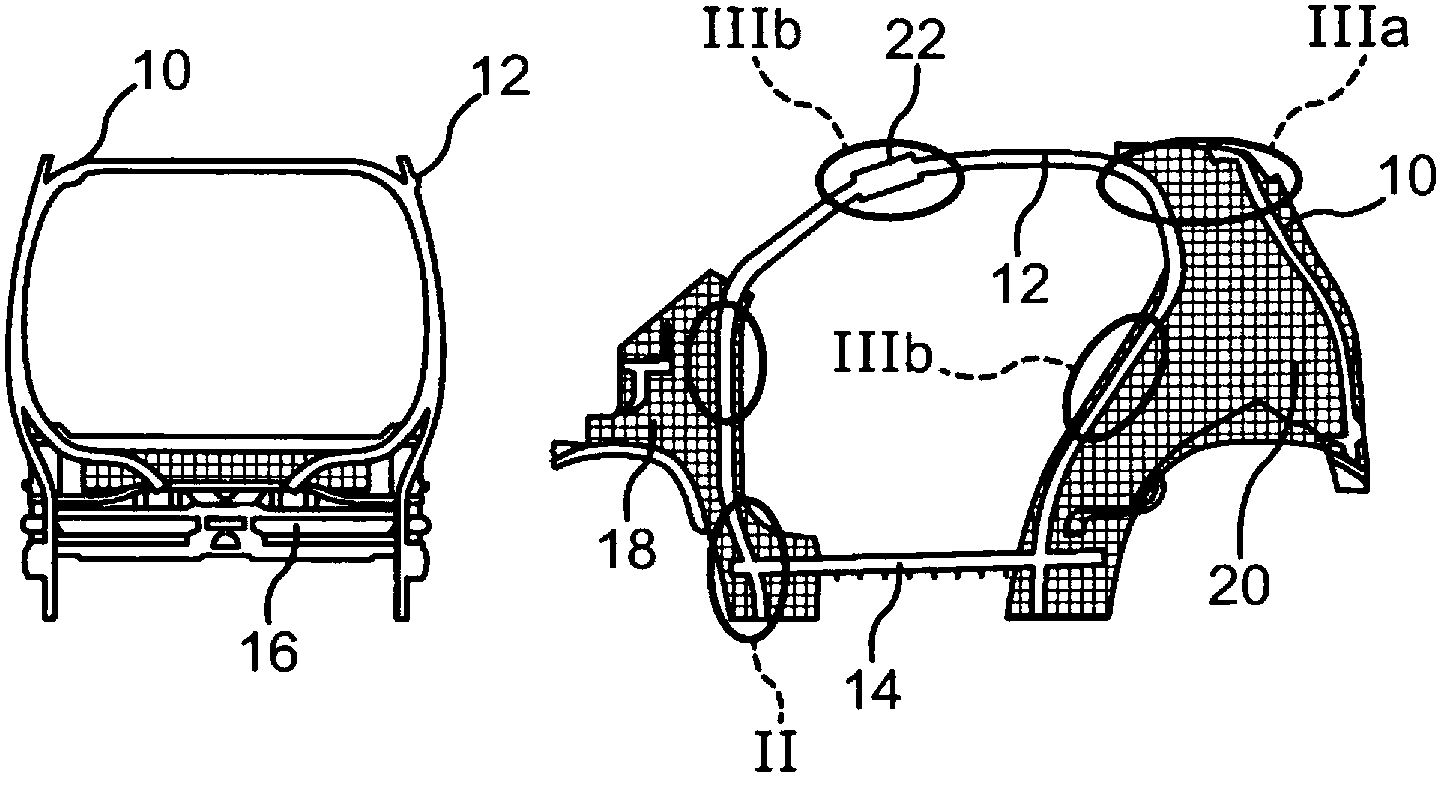

Body for a passenger car

ActiveCN102834238AReduce wall thicknessReduce weightBeltsDomestic articlesHigh pressureInjection molding process

The invention relates to a method for producing a body of a passenger car, in which a plurality of body components (10 to 20) are connected to each other, which are at least partially provided with a plastic (42). According to the invention, the body is produced in a combined internal high-pressure forming and injection molding process. The invention further relates to such a body and an installation for producing such a body.

Owner:MERCEDES BENZ GRP

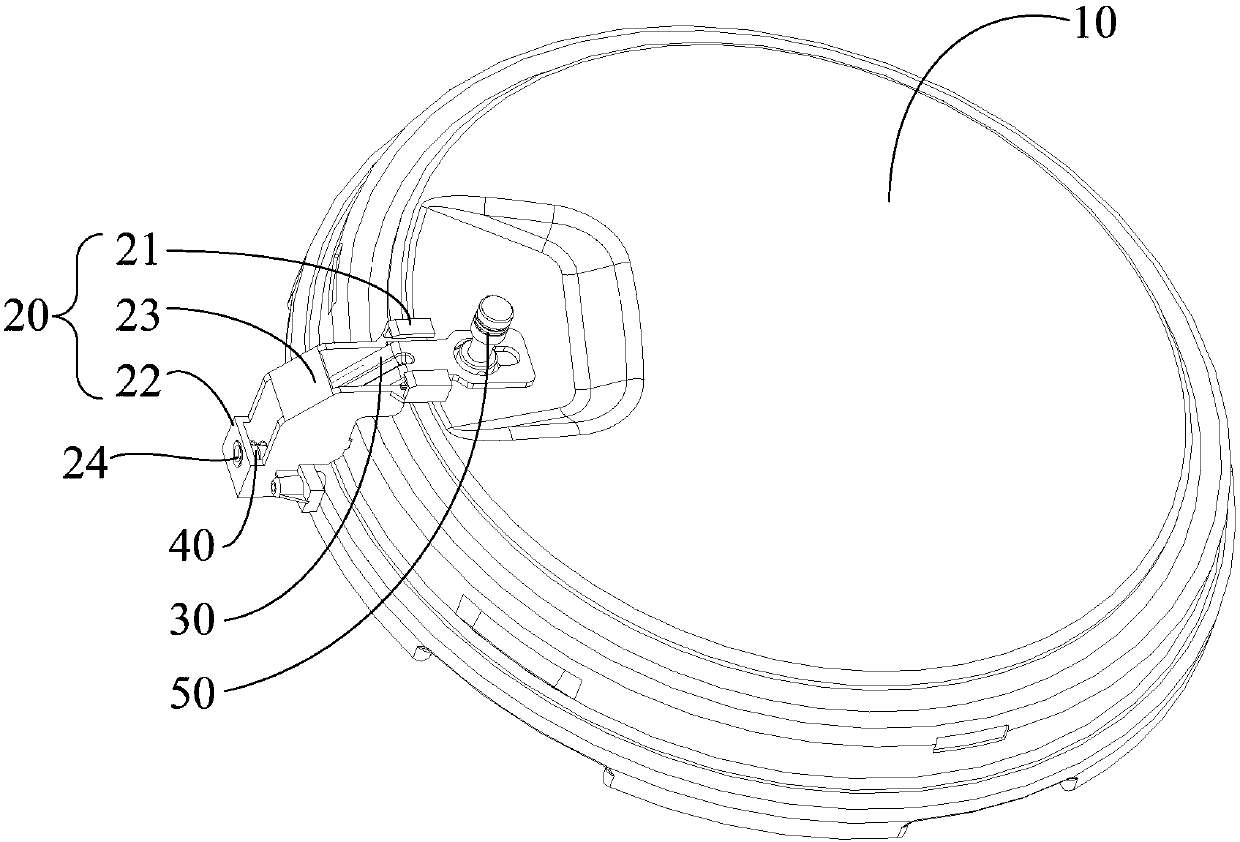

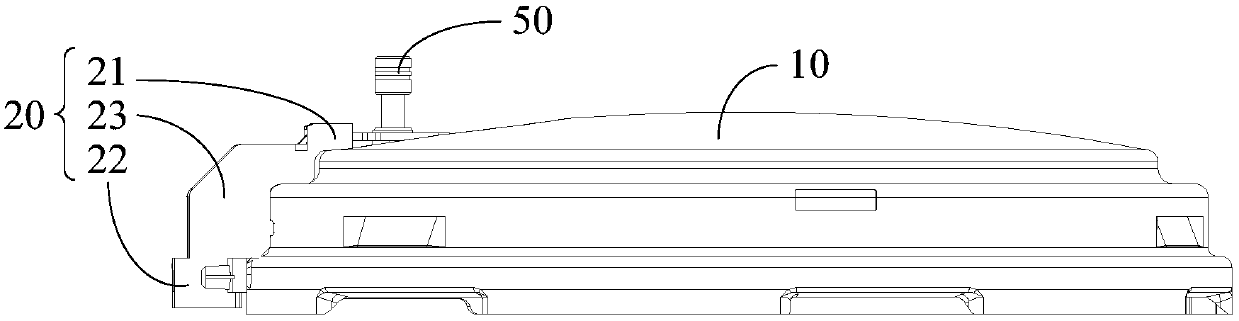

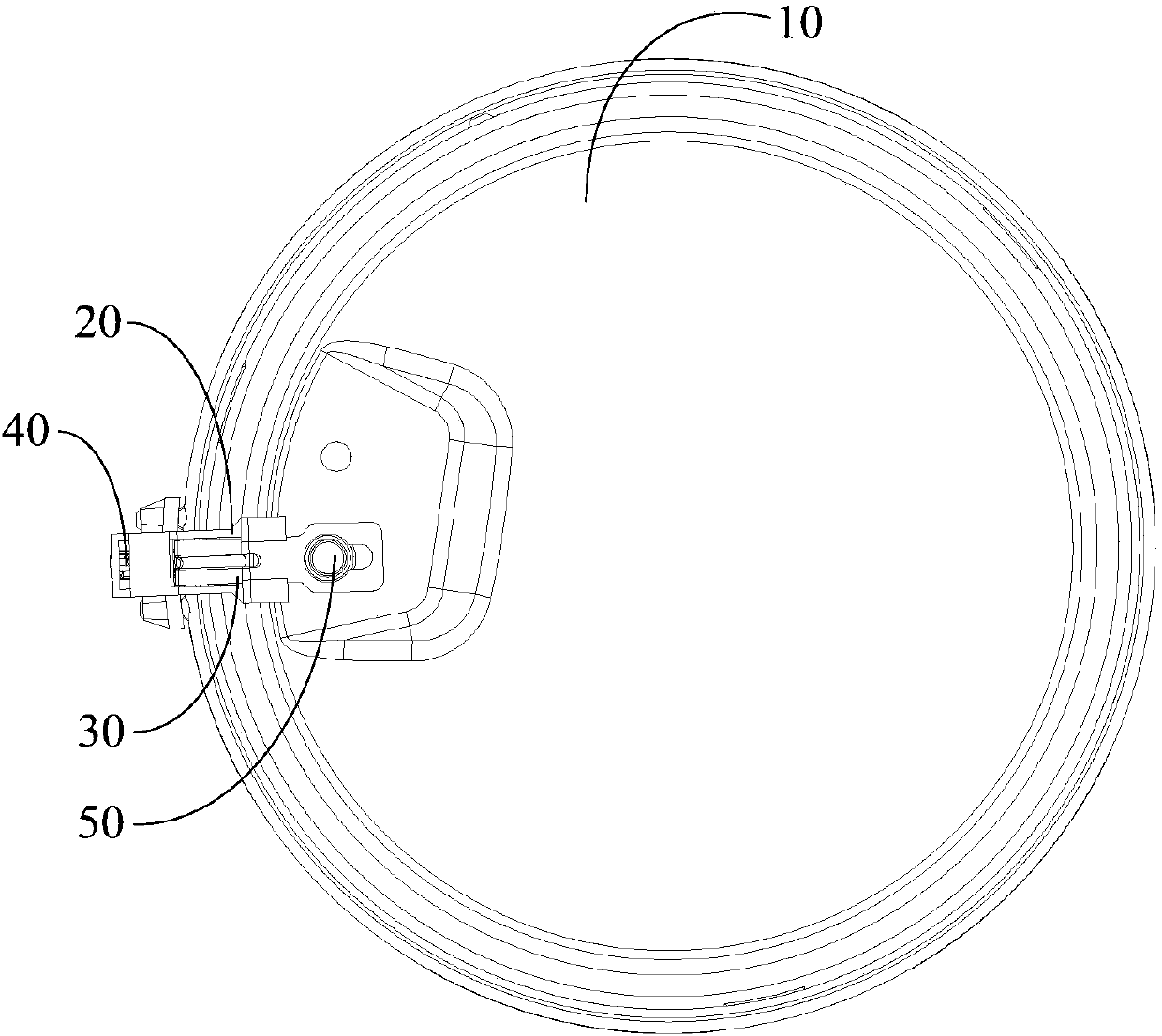

Pot cover assembly of pressure pot and pressure pot

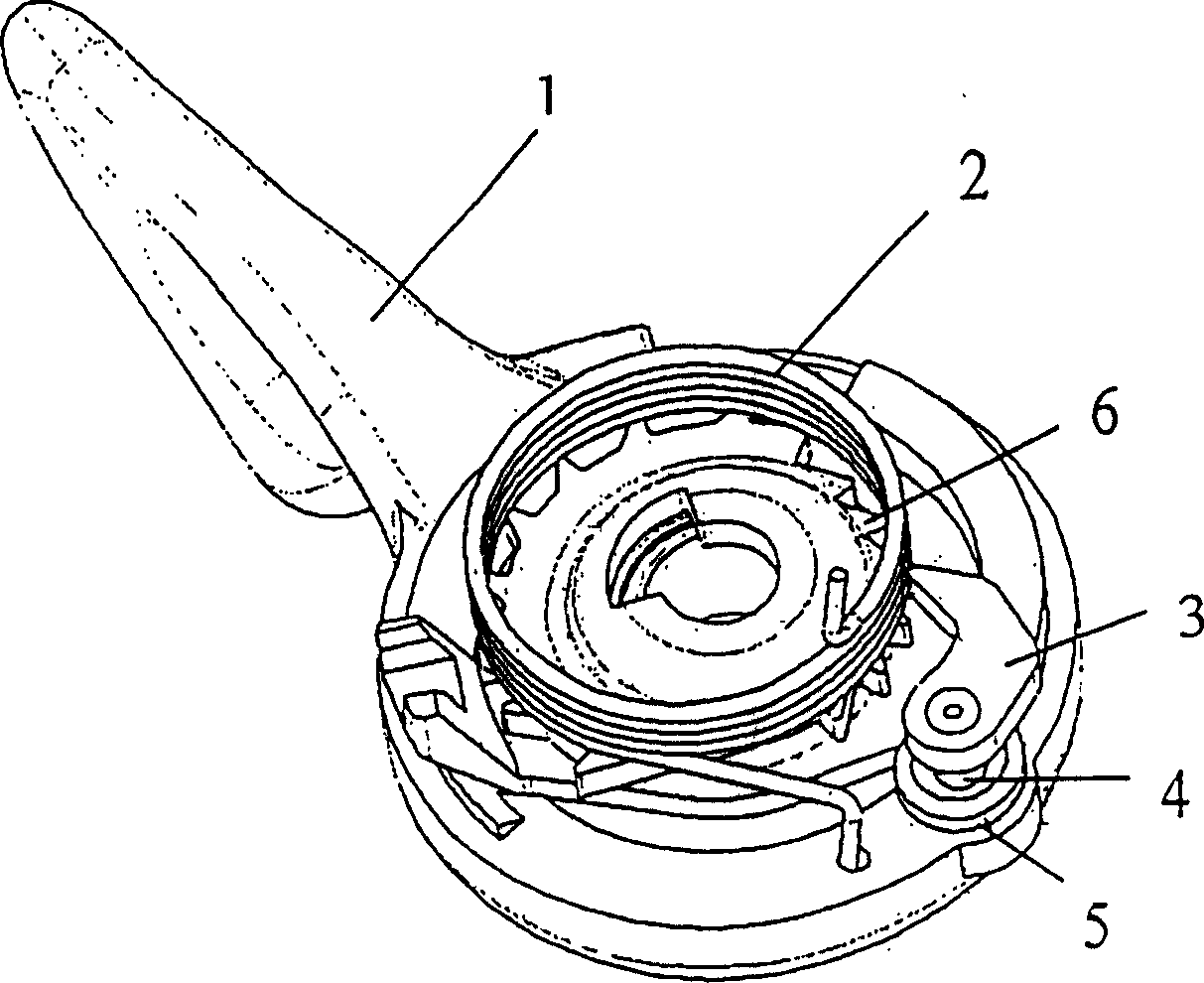

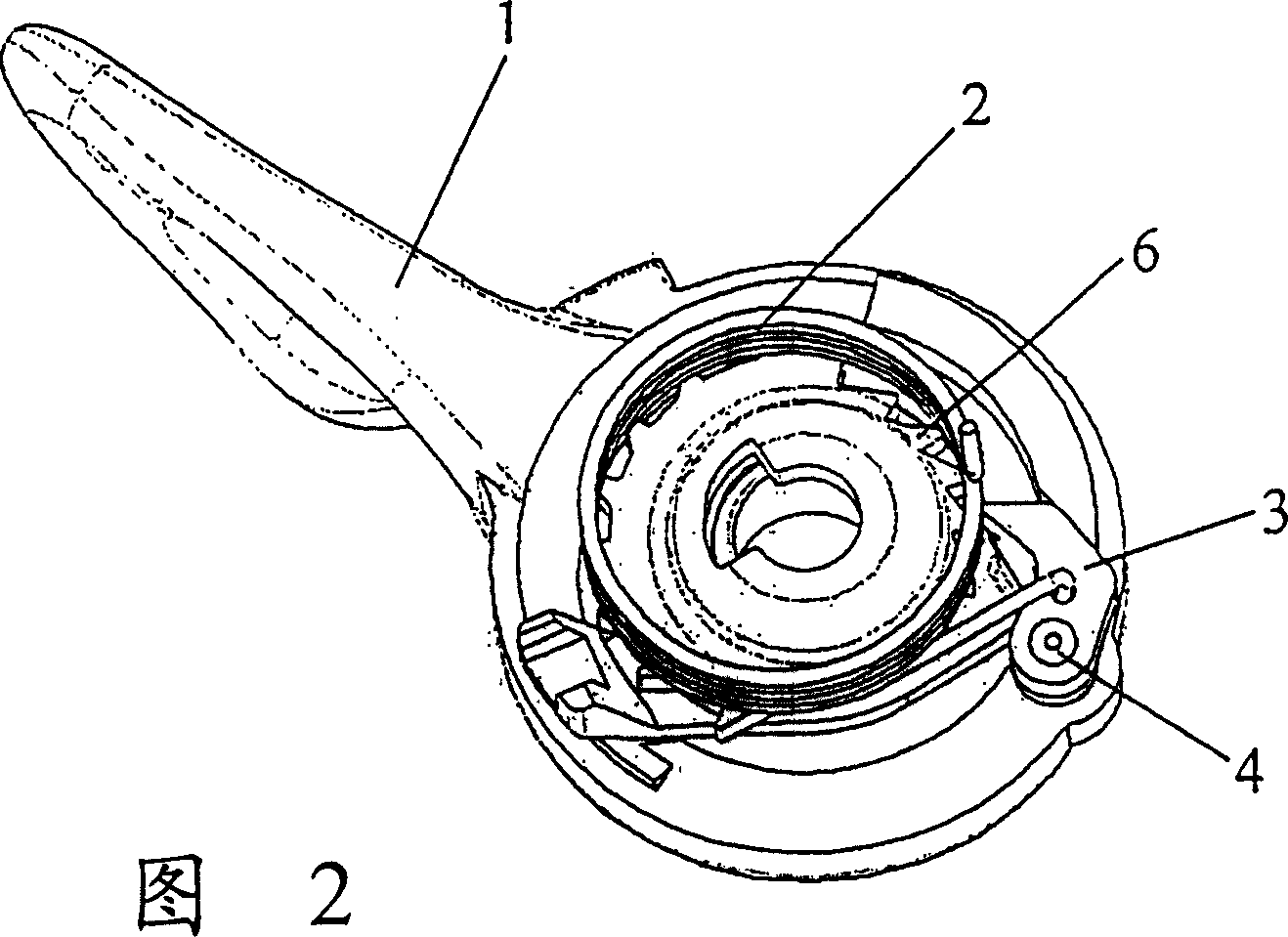

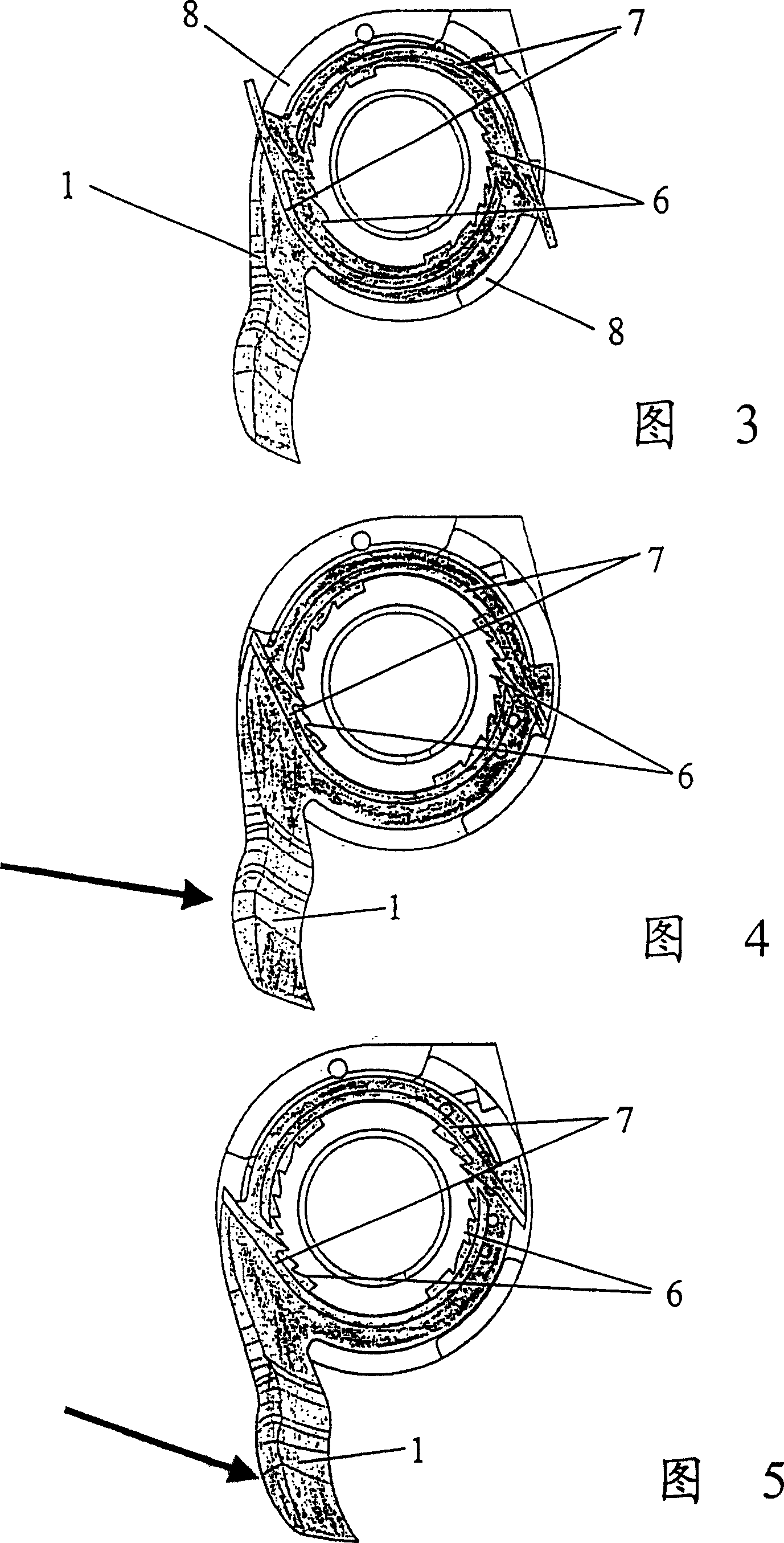

PendingCN107788828ASmall manufacturing tolerancesAvoid errorsPressure-cookersSelf lockingDegrees of freedom

The invention provides a pot cover assembly of a pressure pot and a pressure pot. The pot cover assembly includes: a pot cover, wherein a pot cover guide hole is formed in the pot cover; a guiding member arranged on the pot cover, wherein the guiding member includes a first guiding portion, a second guiding portion and a first connection portion connecting the first guiding portion and the secondguiding portion which are integrally formed and form a guiding chamber, and a guiding hole corresponding to the pot cover guide hole is formed in the second guiding portion; a sliding block arranged in the guiding chamber, wherein the guiding chamber is used for limiting the degree of freedom of vertical motion and horizontal swing of the sliding block; a self-locking pin arranged on the sliding block, wherein two ends of the self-locking pin pass through the pot cover guide hole and the guiding hole respectively; a floater, wherein a limiting portion is arranged on a part corresponding to thefloater, of the sliding block, and the limiting portion is configured to limit the degree of freedom of horizontal motion of the sliding block with the floater while the floater floats. The technicalscheme can effectively guide and limit motion of the sliding block in the guiding member, and can avoid the problem that when the floater floats, the sliding block can still slide under a small forceand the pot cover is opened.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD

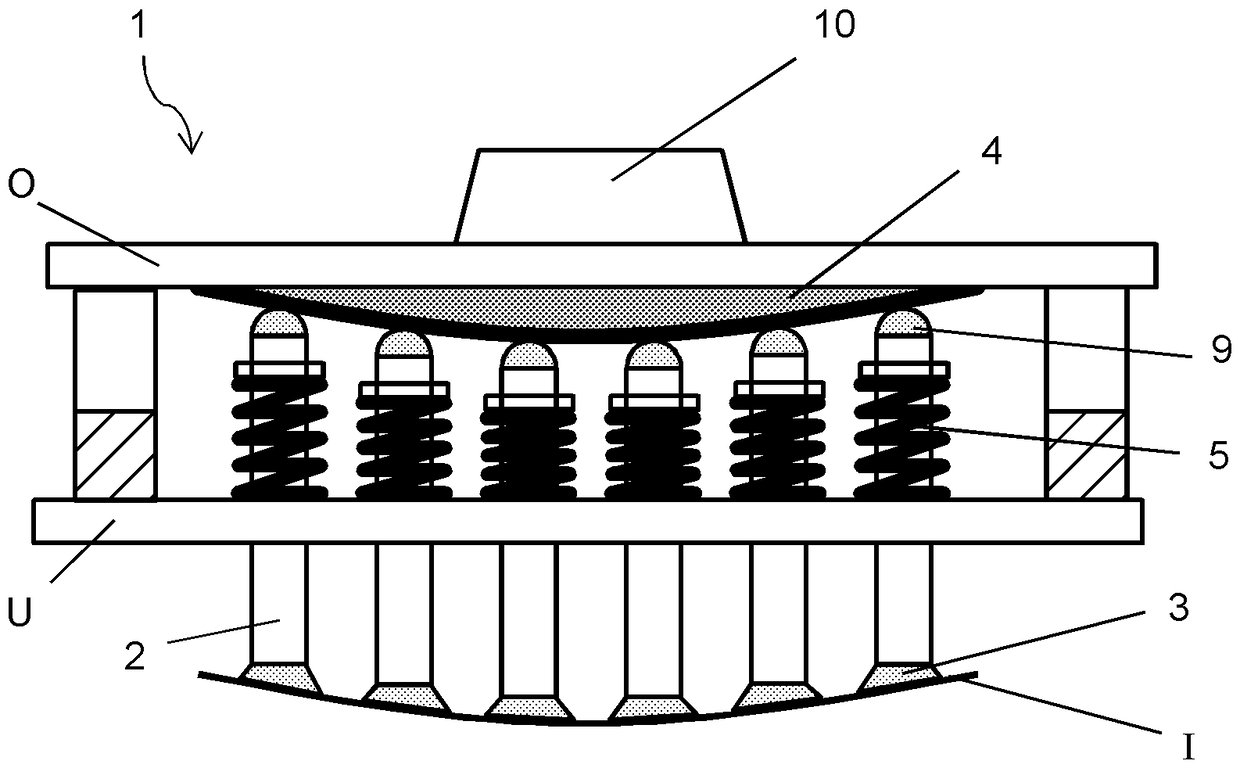

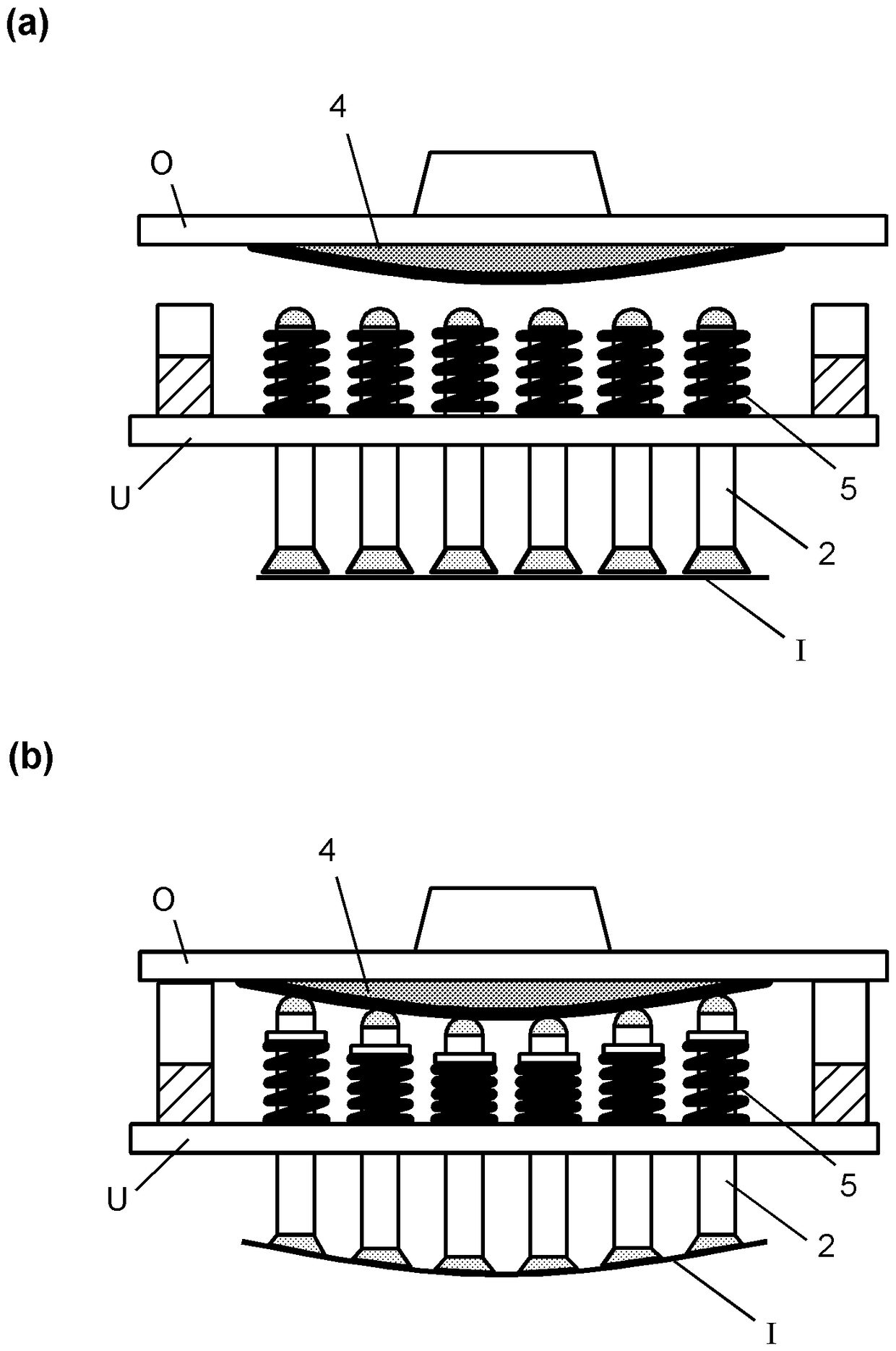

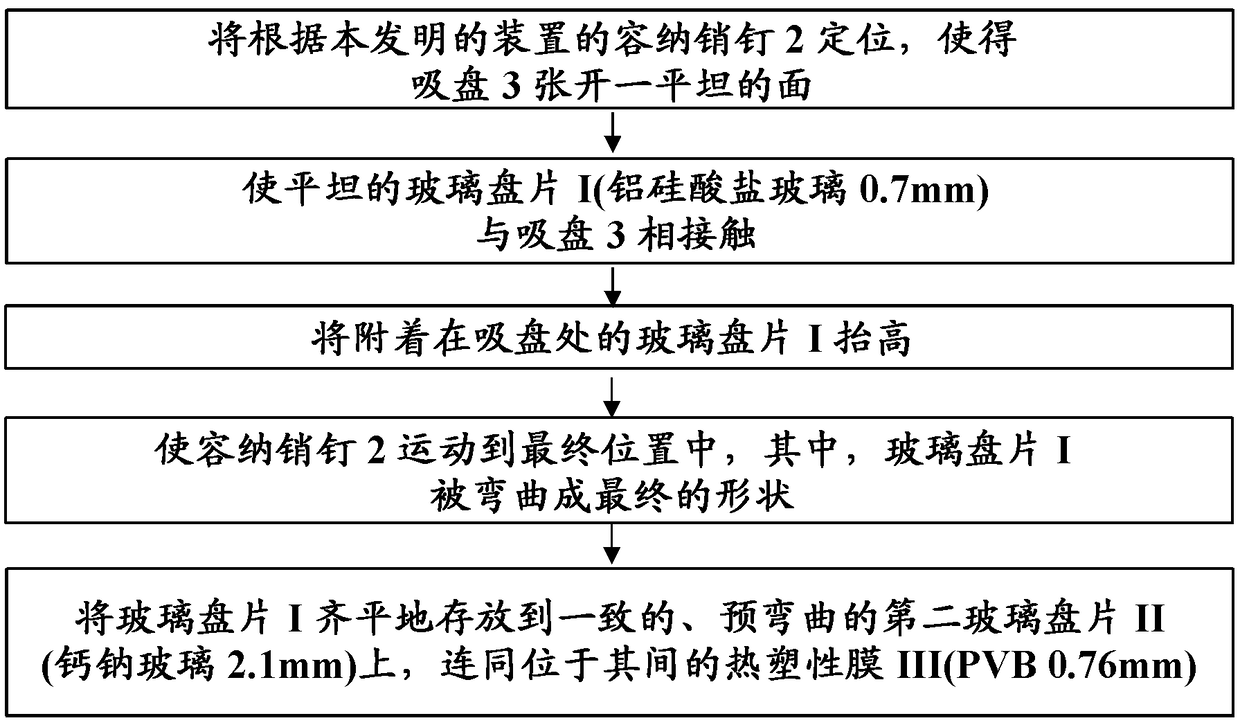

Device and method for picking up, deforming and depositing a thin glass pane

ActiveCN108934164AImproved edge flushnessSmall manufacturing tolerancesLamination ancillary operationsLayered product treatmentEngineeringStructural engineering

The present invention relates to a device for picking up, deforming and depositing a thin glass pane, comprising a frame (1) with an upper side (O) and a lower side (U), which is suitable to be directed onto a glass pane (I) having a thickness of less than 1 mm, and which is provided with a plurality of picking-up pins (2) which are arranged substantially parallel to one another and are provided with a suction cup (3) at the end directed onto the glass pane (I), wherein the picking-up pins (2) are movable independently of one another along the direction of their extent in order to adapt the arrangement of the suction cups (3) to an intended shape of the glass pane (I).

Owner:SAINT-GOBAIN GLASS FRANCE

Lantern-type gear unit

InactiveCN104633044AEasy to installReliable jointValve arrangementsToothed gearingsGear wheelEngineering

Owner:IWIS MOTORSYSTEME GMBH & CO KG

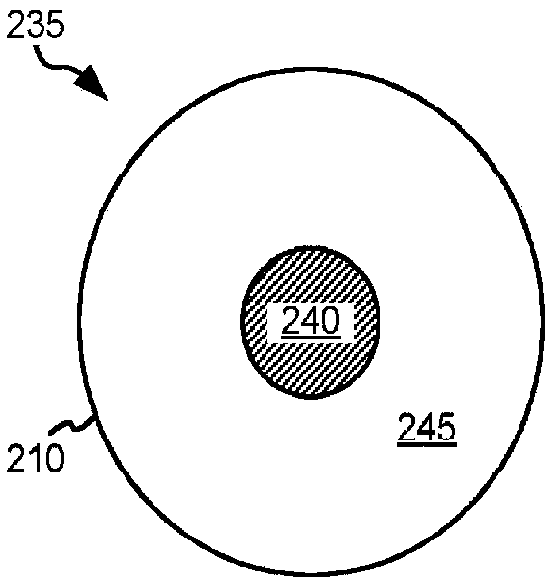

Diodes offering asymmetric stability during fluidic assembly

ActiveCN109643709AReduce the totalLower display costsSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringMechanical engineering

Embodiments are related to systems and methods for fluidic assembly, and more particularly to systems and methods for assuring deposition of elements in relation to a substrate.

Owner:ELUX INC

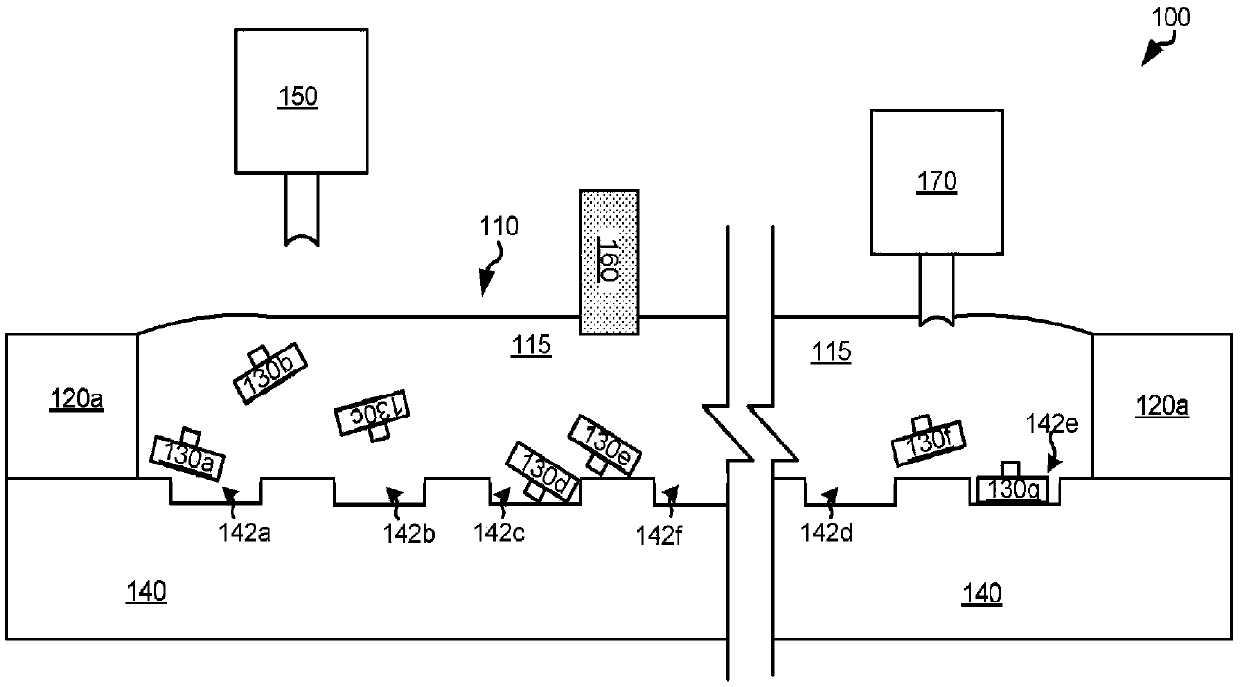

Device used for delivering quiding plane material

InactiveCN1533973AImprove machining accuracyTransmission impactArticle feedersArticle deliveryEngineeringMechanical engineering

This flat material guiding device 100 for guiding the flat material along a conveyance path inside a higher-level device for handling the flat material has at least one guide face on an upper side arranged on an upper side of the conveyance path, at least one guide face on a lower side arranged on a lower side of the conveyance path, and two side walls which are provided with at least one guide face on the lower side therebetween. Assembly rods 171, 172 are provided on both side walls, and the device 100 can be mounted in the higher-level device for handling the flat material by these assembly rods 171, 172.

Owner:HEIDELBERGER DRUCKMASCHINEN AG

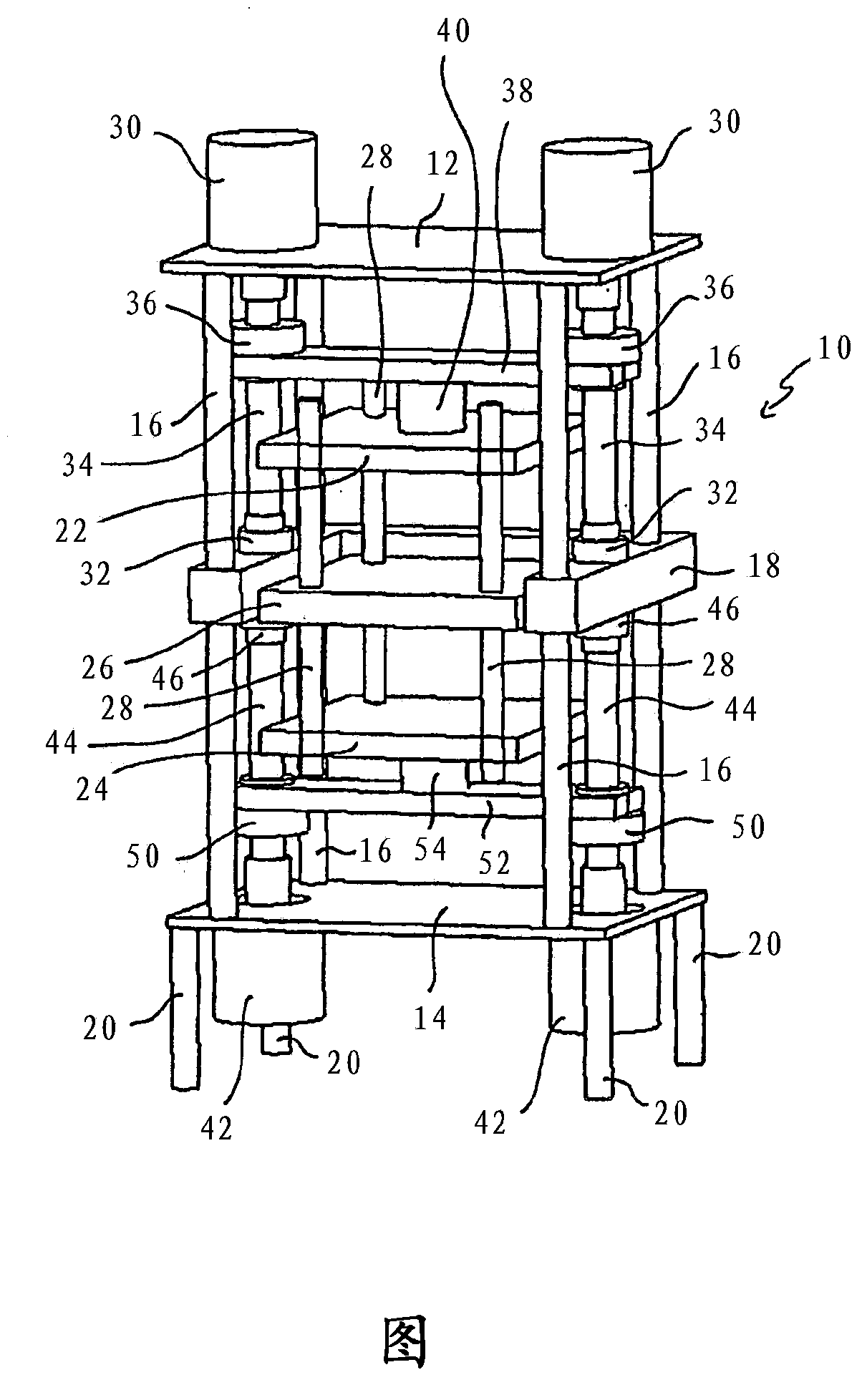

Press

A press for producing a pellet from powdered material, comprising a press frame with an upper and a lower retaining plate, which are connected to one another by several vertical spacers and with at least one supporting element, which is disposed between the upper and the lower retaining plate, a tool guiding unit with at least one upper punch unit with at least one upper press punch and / or at least one lower punch unit with at least one lower press punch and with a die assembly with at least one holder for powdered material, which is to be pressed by the upper and / or lower press punch, wherein the tool guiding unit is disposed at the supporting element, and at least one upper drive unit for moving the upper punch unit in the vertical direction and / or at least one lower drive unit for moving the lower punch unit and or the die assembly in the vertical direction, wherein, when the press is operating, the upper drive unit and / or the lower drive unit are supported at the supporting element in such a manner, that the reaction forces, which are produced during the pressing of the powdered material in the at least one holder, are generated as action forces, are passed into the supporting element.

Owner:MASCHFAB LAUFFER

Non-warping chain link

InactiveCN101405520AHigh angular accuracyConstant internal clear heightHauling chainsHoisting chainsSubject matterEngineering

Owner:椿本缆线牵引有限公司

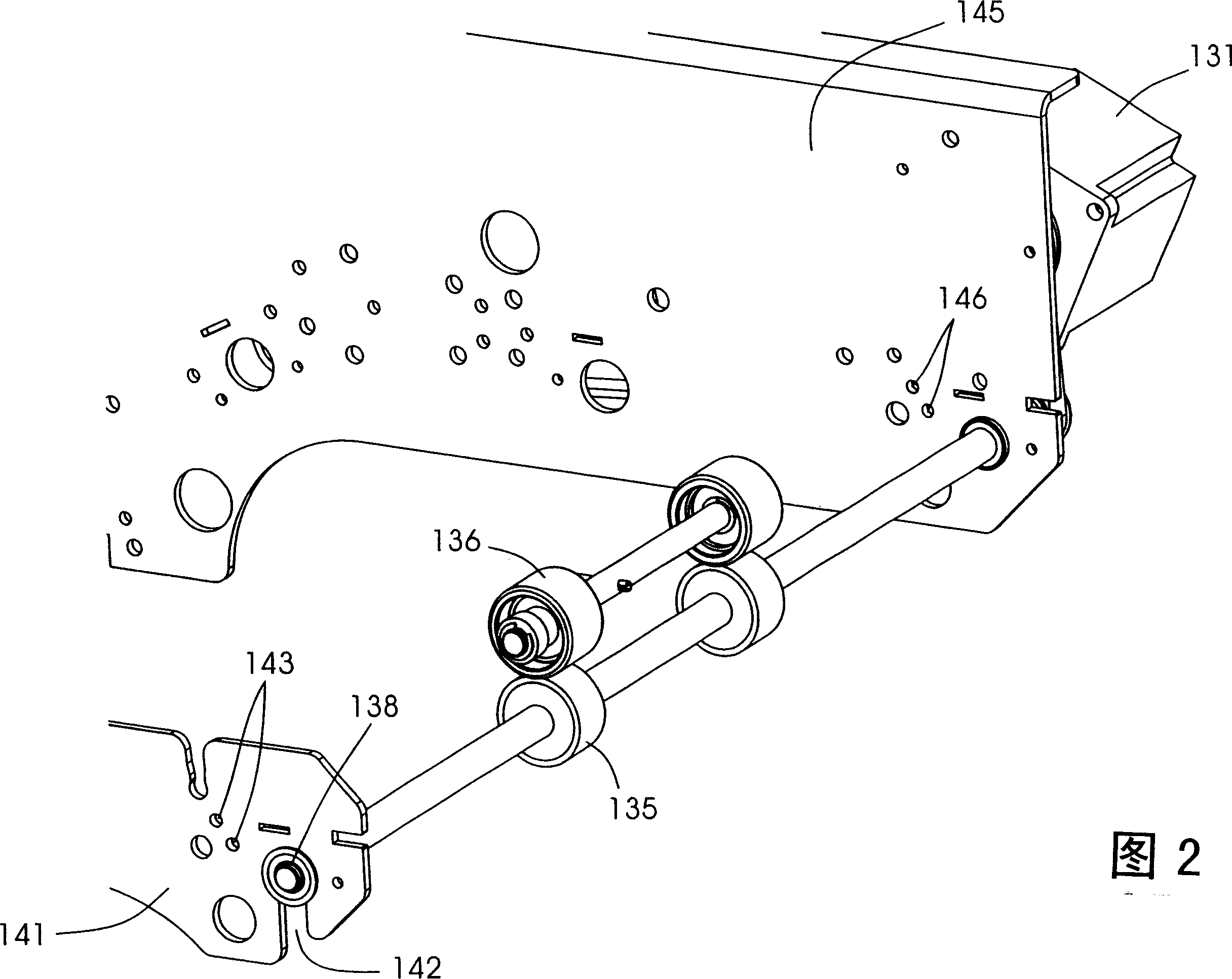

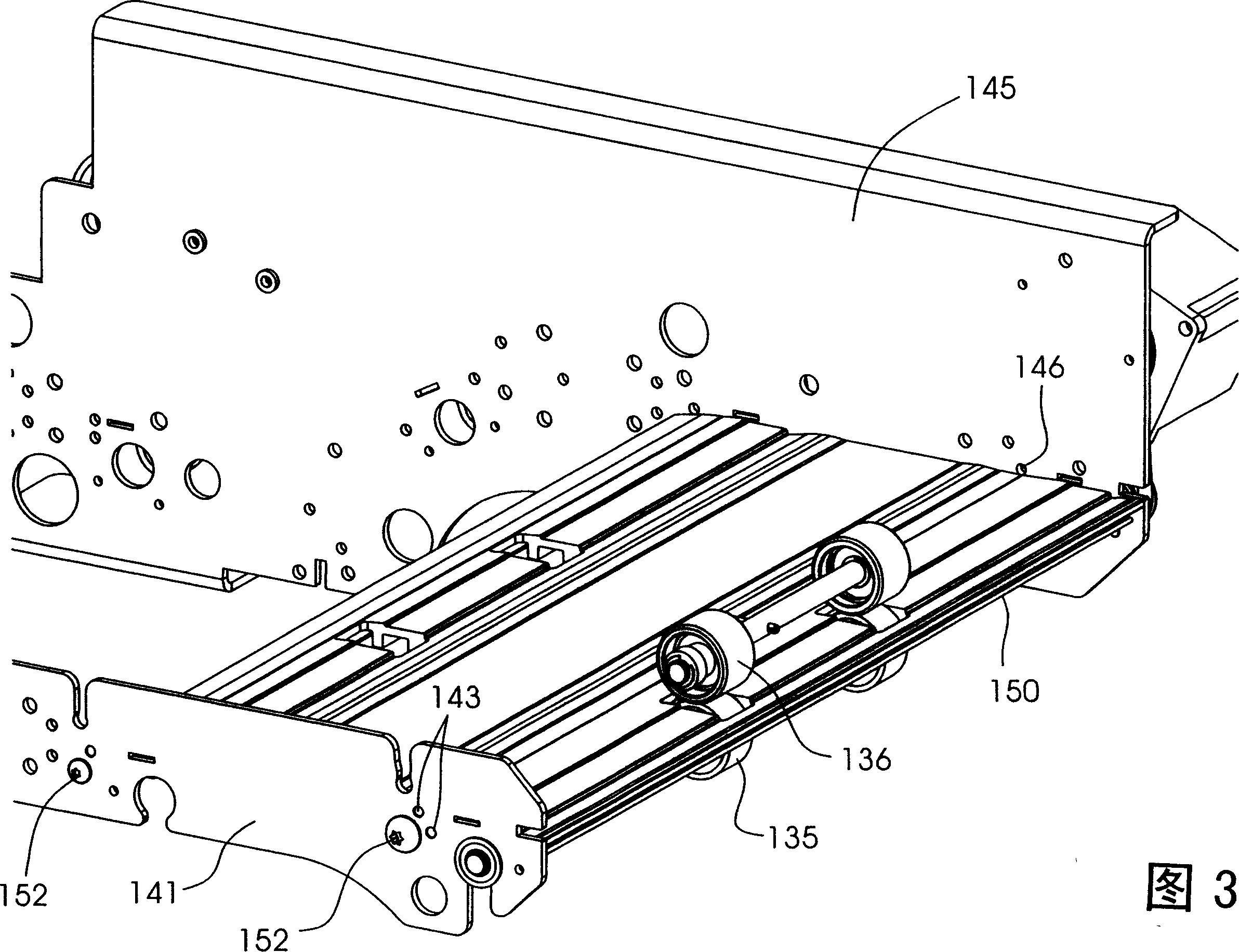

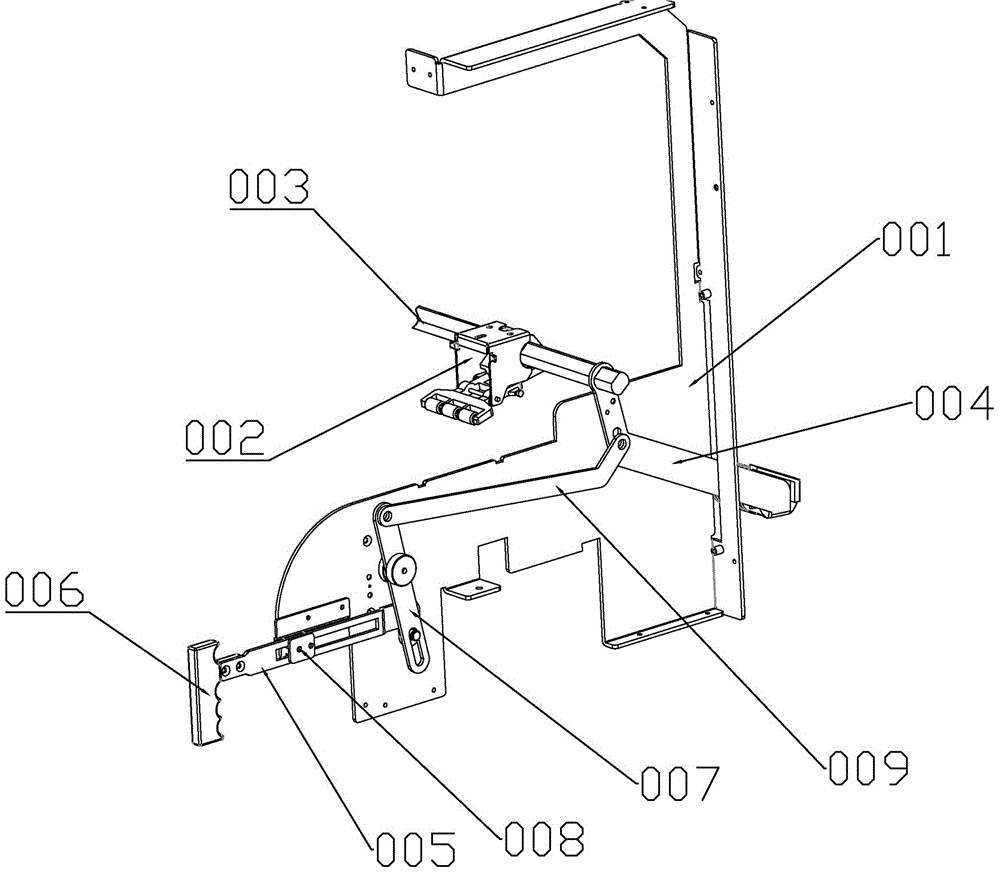

Horizontal type paper pressing operation mechanism of indoor printer

ActiveCN106739553AReduce distortionReduce eccentric torqueOther printing apparatusPush and pullPulp and paper industry

Owner:NEW CENTURY DIGITAL PRINT TECH

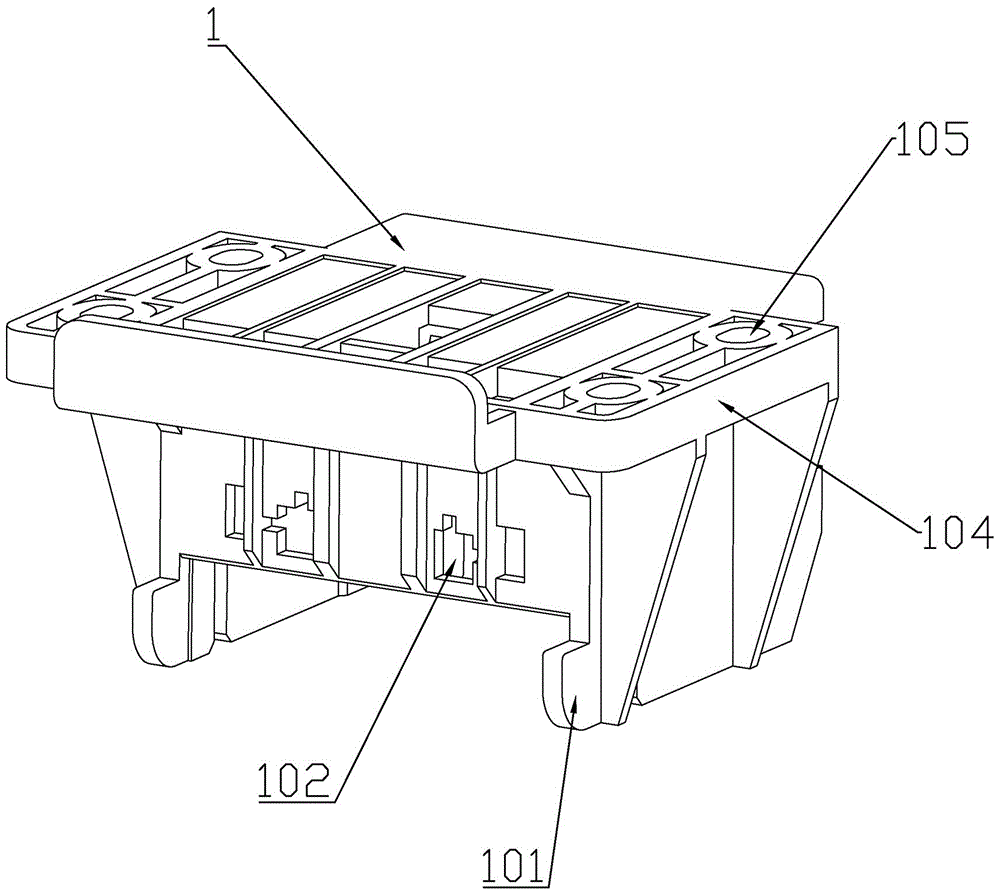

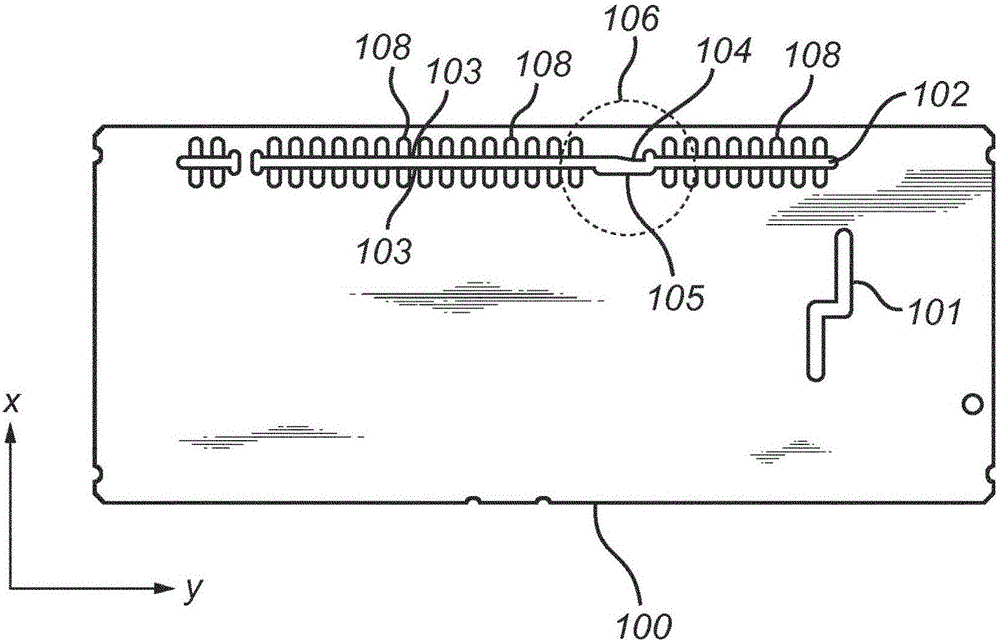

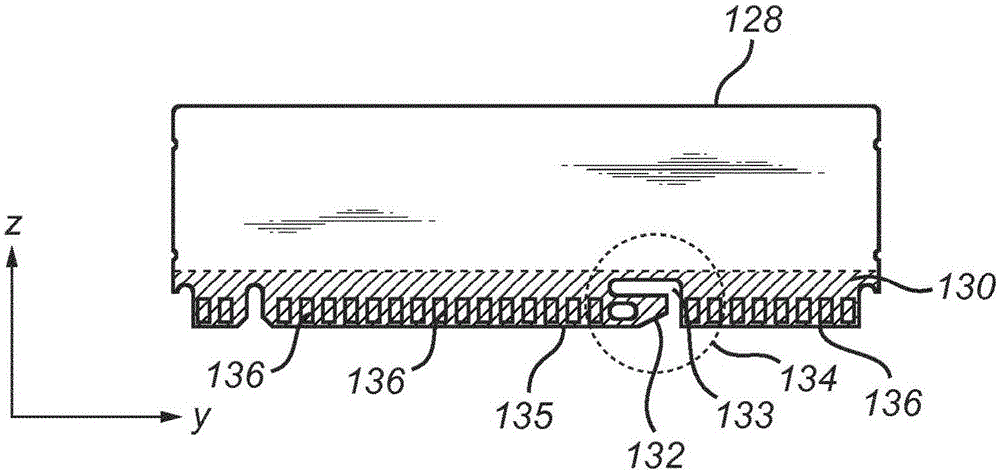

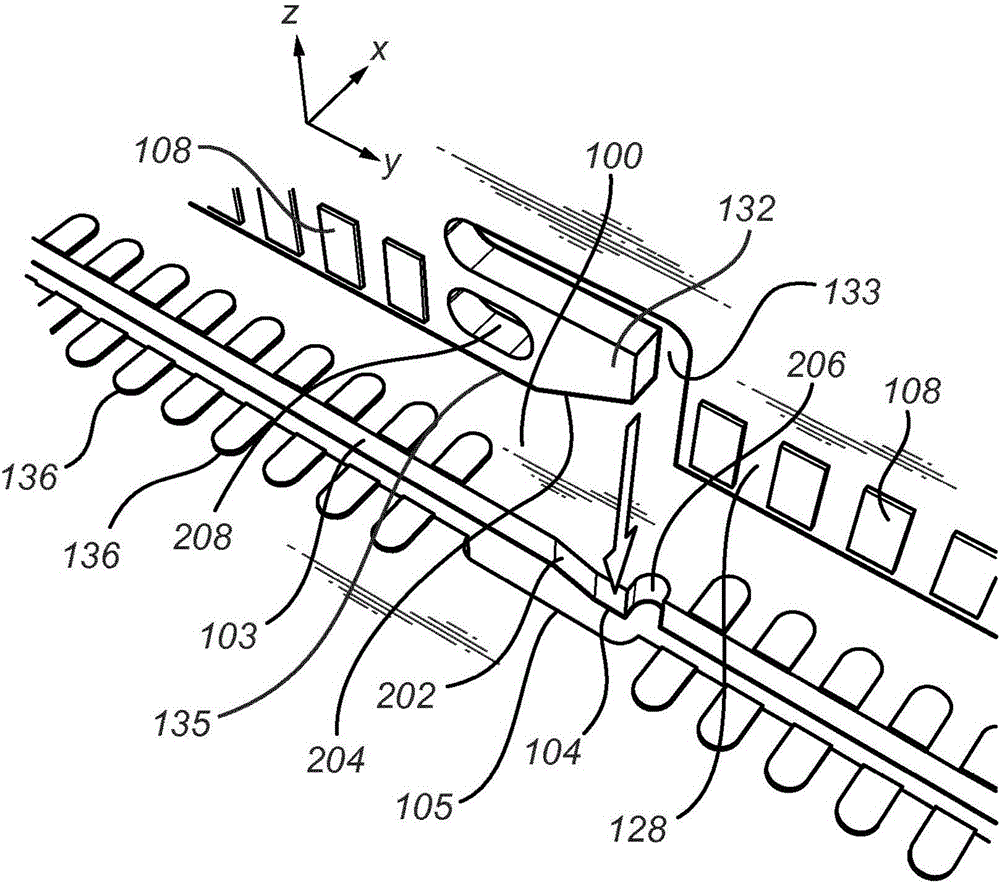

Printed circuit board arrangement and method for mounting a product to a main printed circuit board

ActiveCN106465542AReduce material requirementsDoes not interfere with the designPrinted circuit assemblingPrinted circuit aspectsPrinted circuit boardMechanical engineering

A printed circuit board arrangement and a method for mounting a product to a main printed circuit board (100) at a substantially perpendicular angle, the printed circuit board arrangement comprises a main printed circuit board (100) comprising an elongated slot (102), and a product (128) comprising a connector portion (130) configured to be inserted into the elongated slot (102). The connector portion (130) is such that the product (128) may be attached at a substantially perpendicular angle to the main printed circuit board (100). The elongated slot (102) comprises a protrusion (104), and the connector portion (130) comprises a spring portion (132) configured to engage with the protrusion (104) when the connector portion (130) is inserted into the elongated slot (102). This results in a force pressing the connector portion (130) of the product (128) to at least one side wall of the elongated slot (102).

Owner:SIGNIFY HLDG BV

Improved method for designing smooth limit gauge

InactiveCN102213577AObvious superiorityReduce percentageApertured gaugesImproved methodDesign methods

The invention discloses an improved method for designing a smooth limit gauge. The method is characterized by determining the manufacturing tolerance accuracy T of the gauge to be IT2-IT4; and reducing the percentage of a gauge tolerance zone relative to a workpiece tolerance zone, wherein the distance between the gauge go-end lower difference and the maximal physical dimension of a workpiece to be measured is expressed by a formula (Z+T / 2), and the value range of the (Z+T / 2) is from 0.0016 to 0.002.

Owner:CITIC DICASTAL

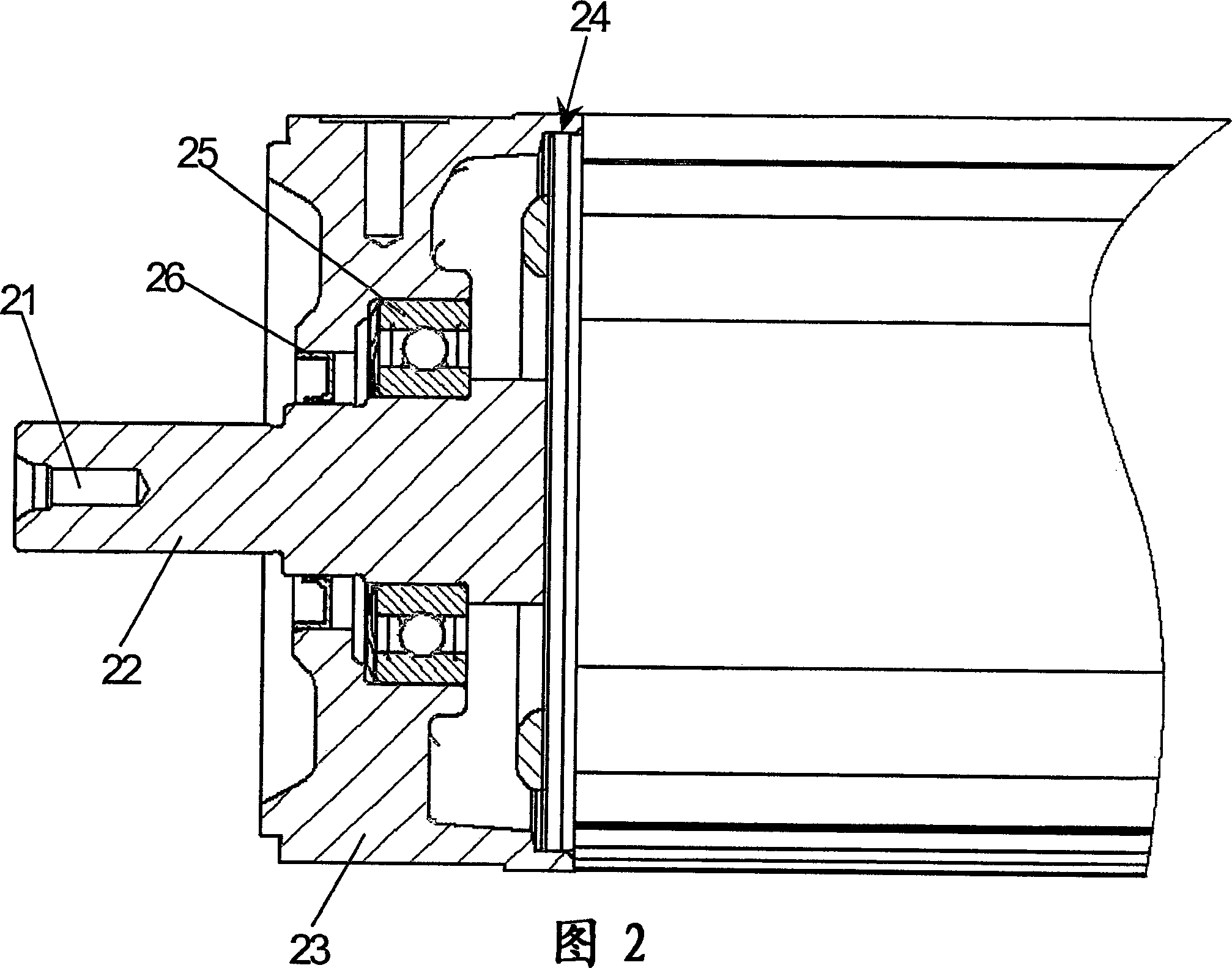

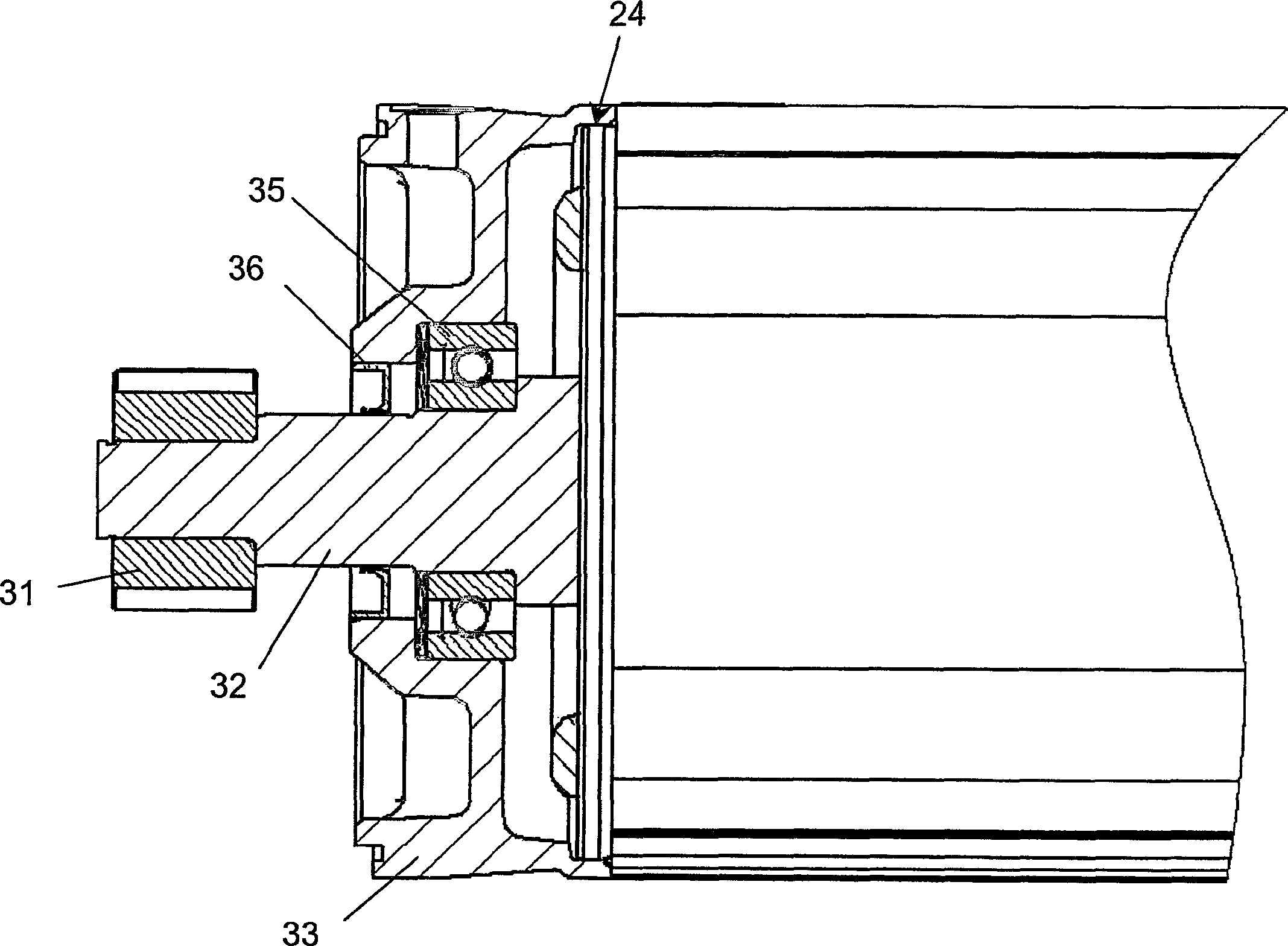

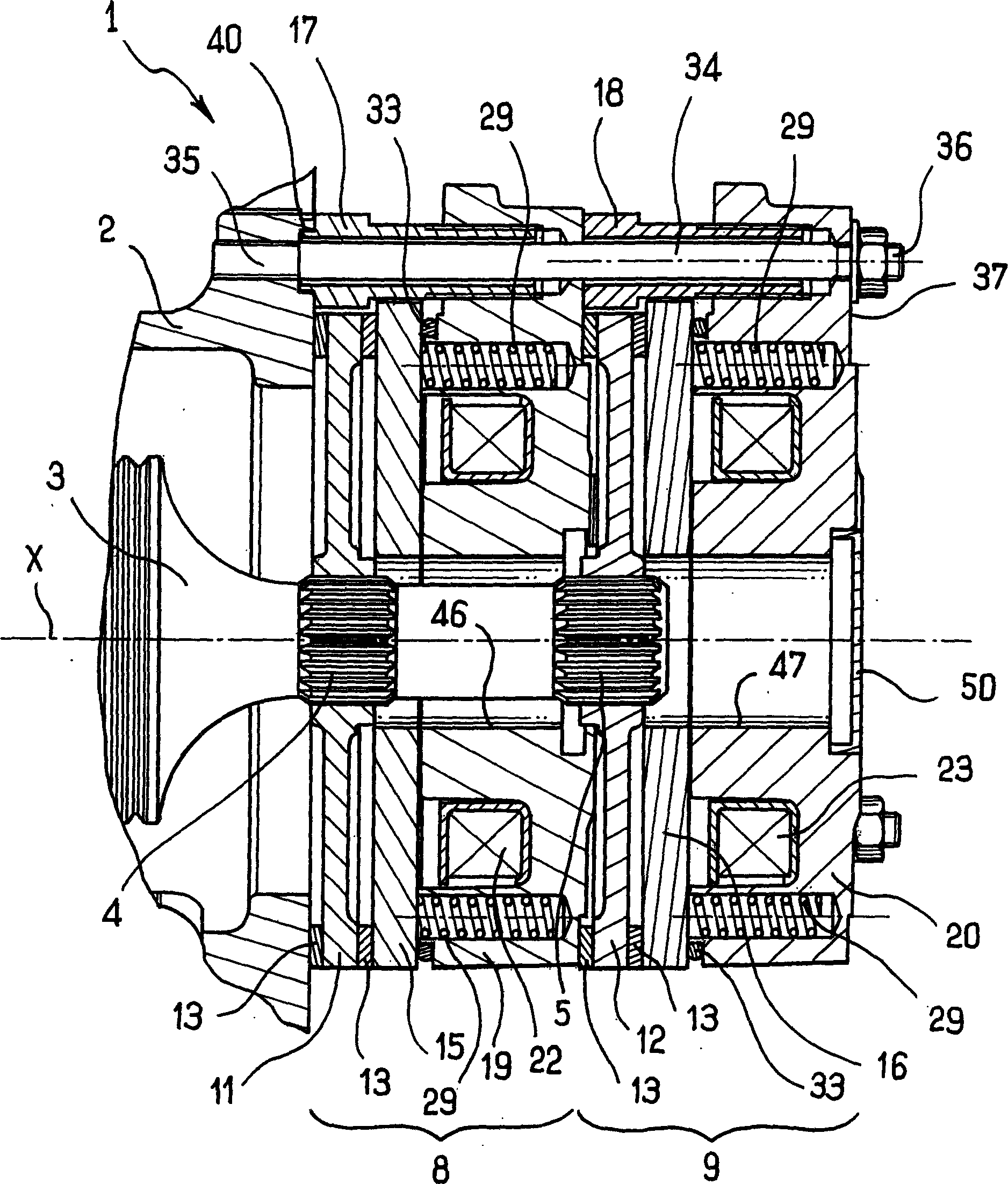

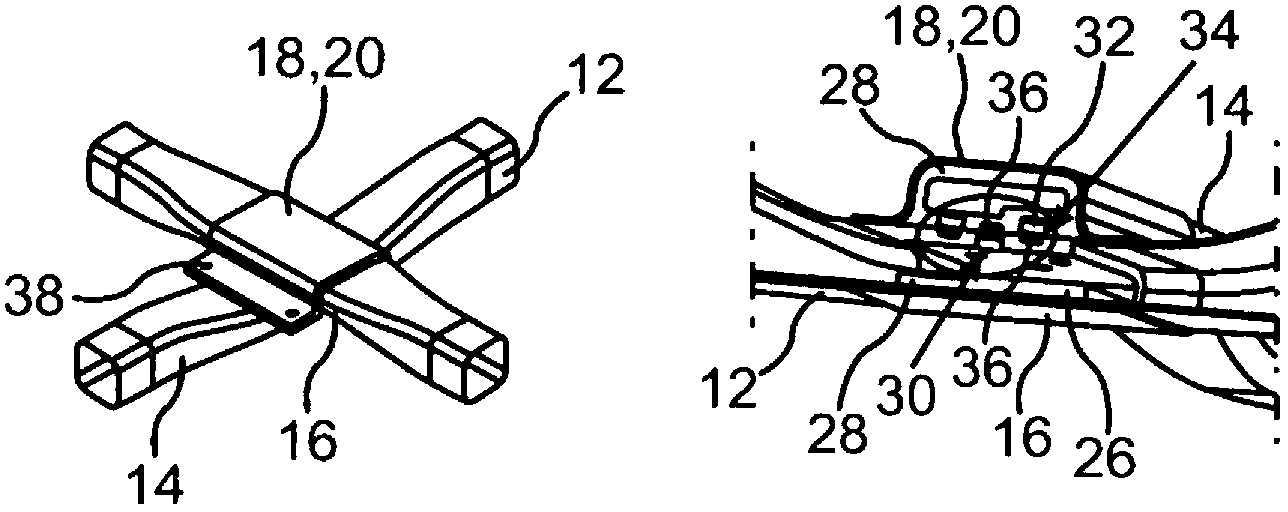

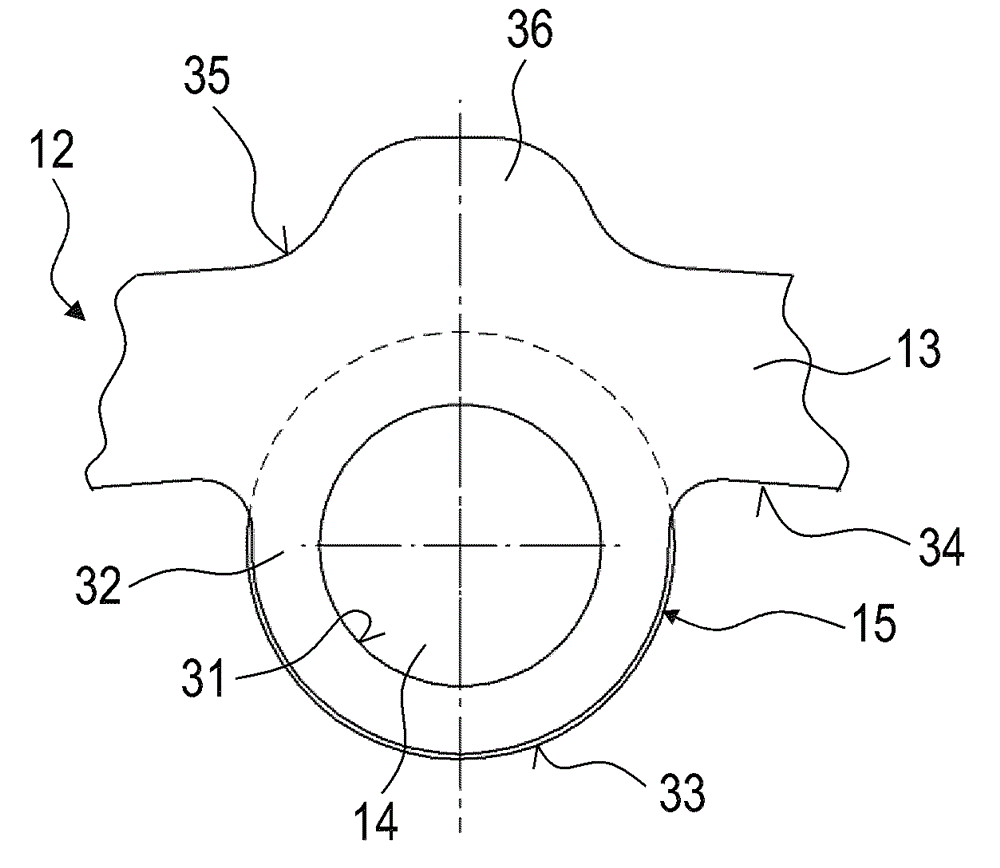

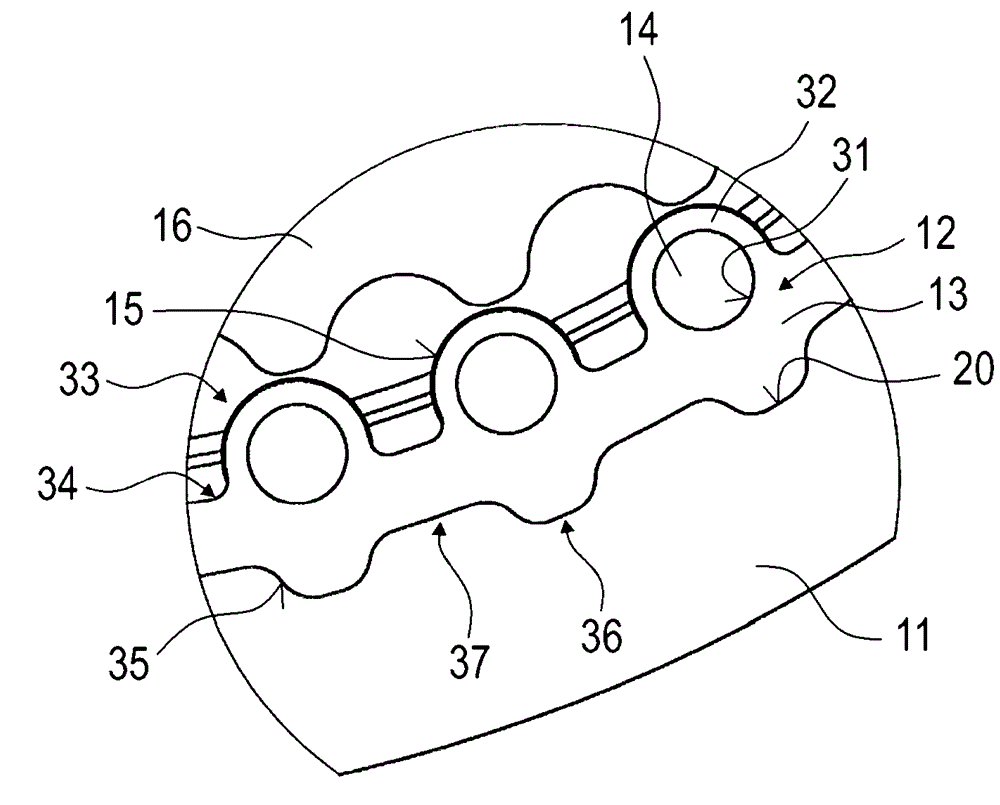

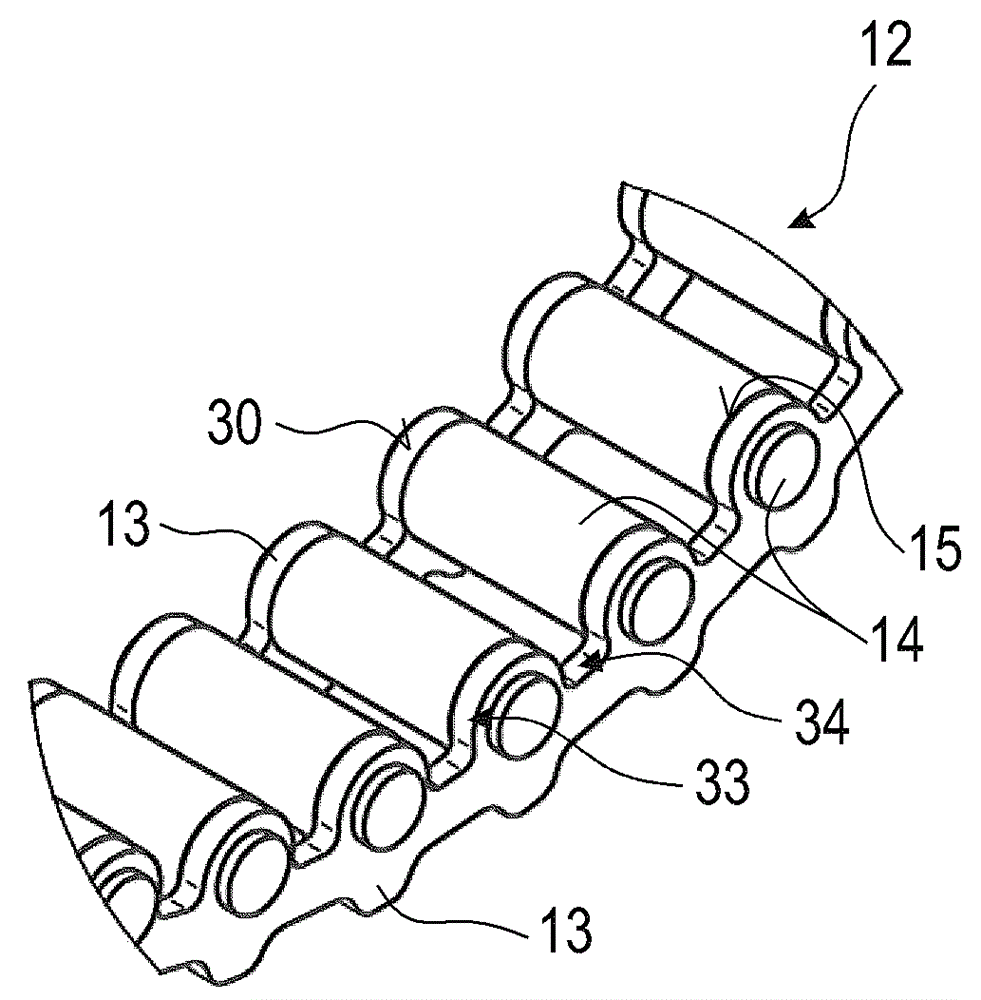

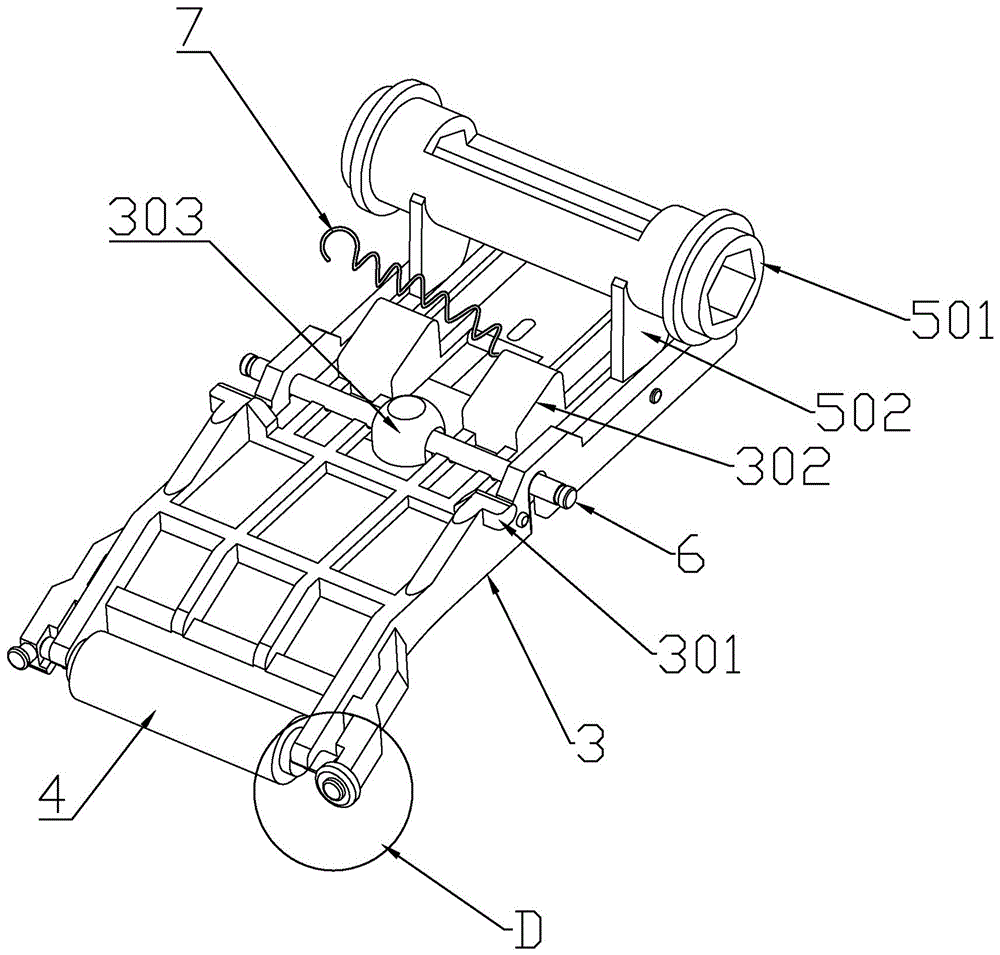

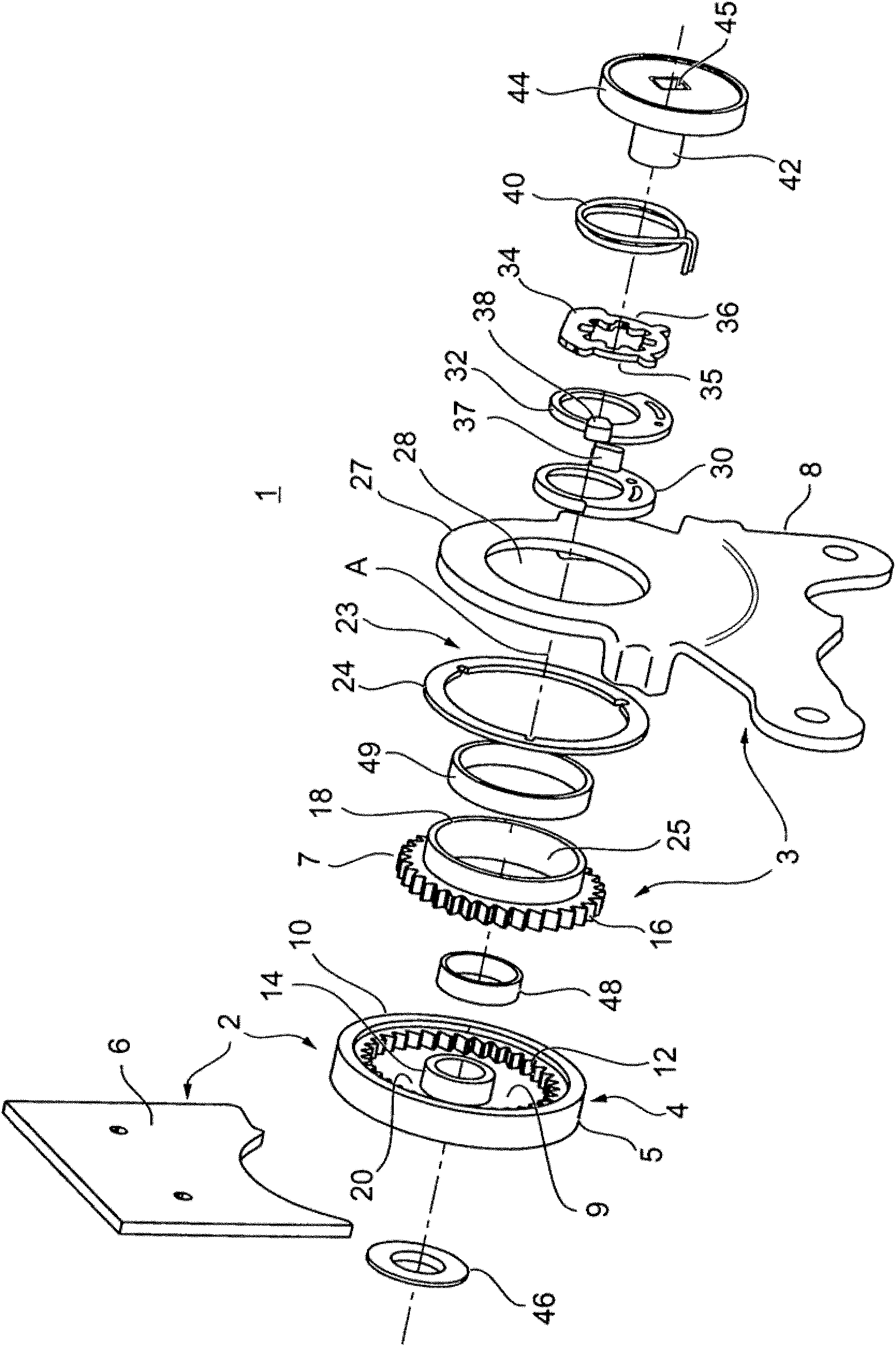

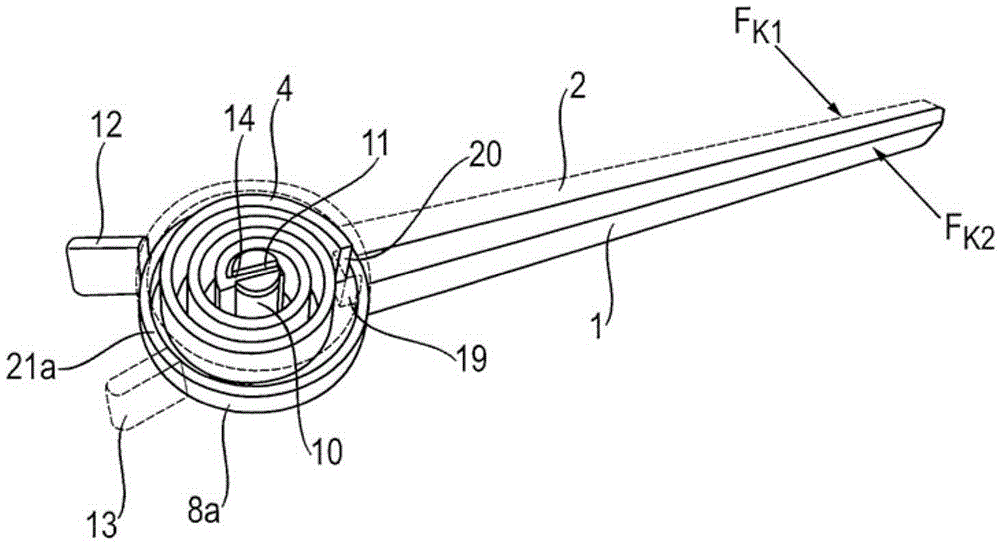

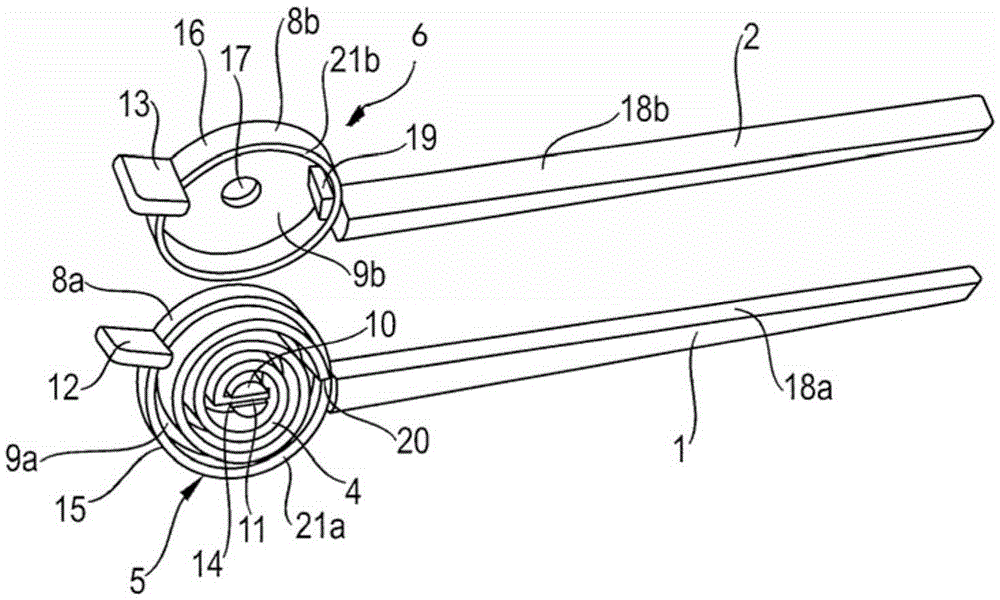

Method for producing an adjustment fitting

ActiveCN102056763AQuality improvementImprove operational reliabilityVehicle seatsMechanical apparatusRotational axisOperational safety

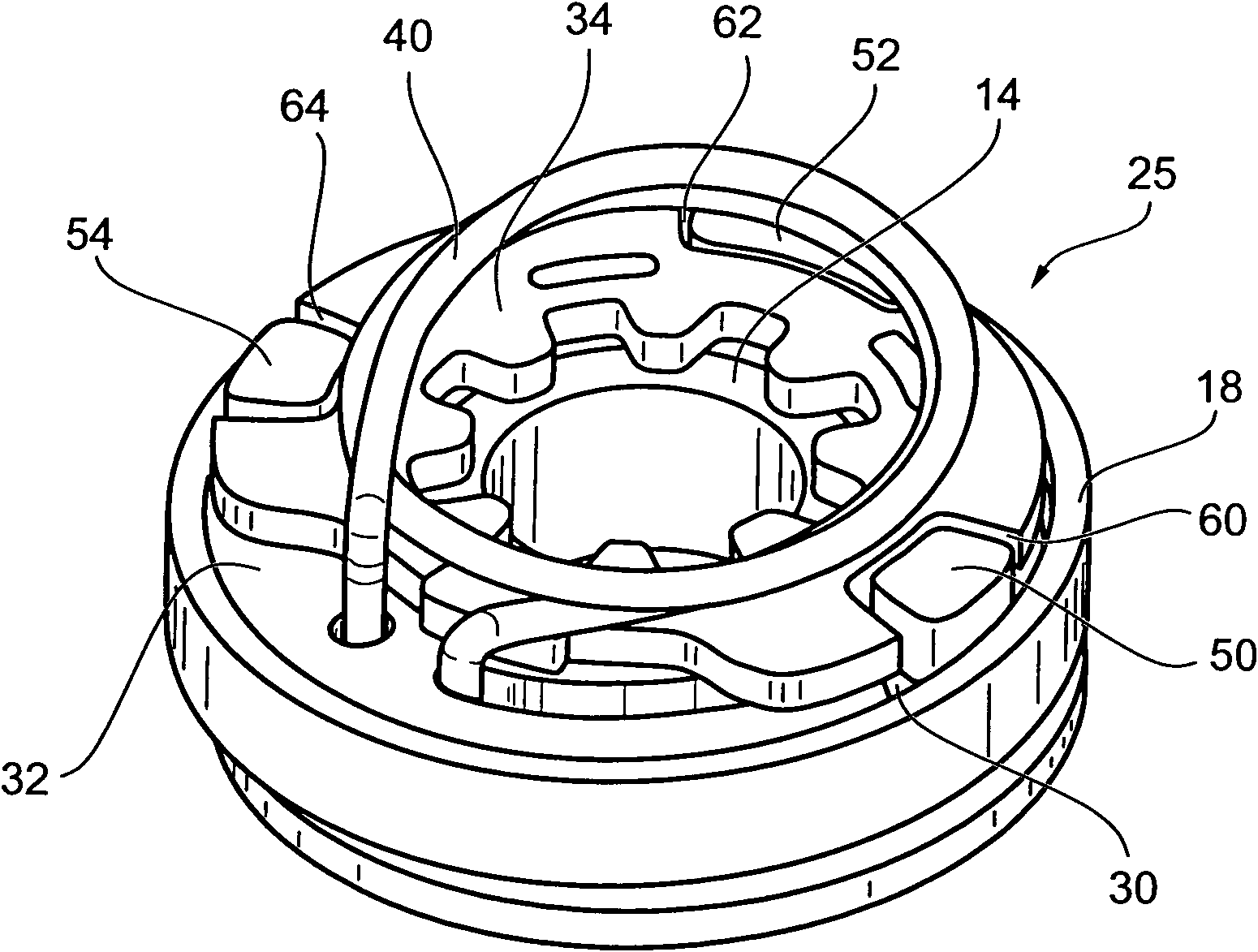

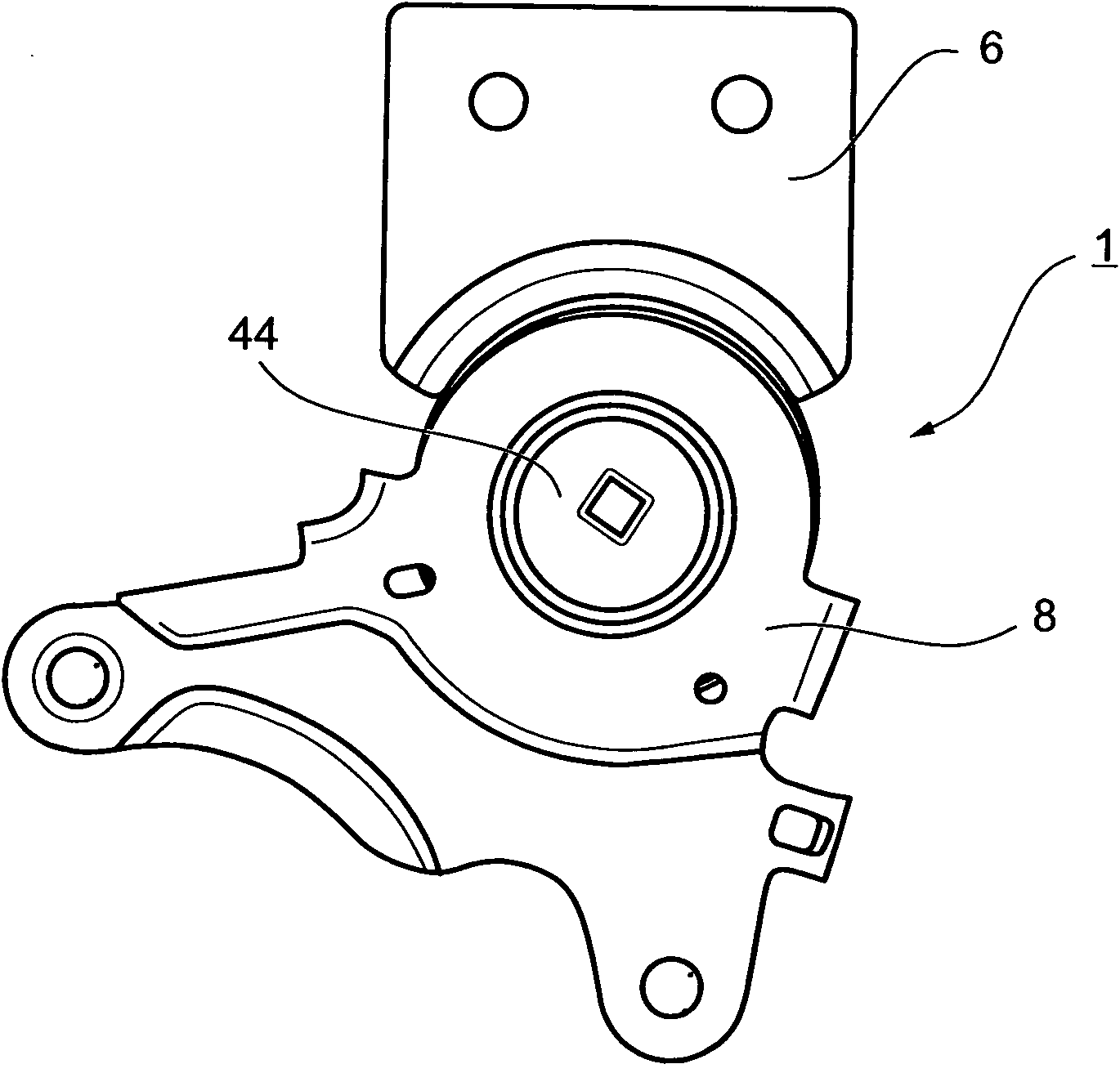

The invention relates to a method for producing an adjustment fitting (1), particularly for a vehicle seat, comprising an outer wheel (4) that can be associated with a first fitting part (2), said wheel having inner toothing (16), and comprising an inner wheel (7) that can be associated with a second fitting part (3), said wheel having outer toothing (16), wherein the inner wheel (7) having the outer toothing (16) is inserted into the outer wheel (4) having the inner toothing eccentrically to a rotational axis (A) in the manner of a wobble mechanism, wherein partial eccentric elements (30,32)are inserted rotatably with respect to each other in an eccentric receiving chamber (25) formed between the rotational axis (A) and the inner wheel (7) so as to produce variable eccentricity, whereinan transmission element (34) having an engagement means (60, 62, 64) for actuating the partial eccentric element (30,32) is inserted such that the engagement means (60, 62, 64) interacts with catch means (50, 52, 54) of the partial eccentric element (30, 32). In spite of the production tolerances of the components, overall higher quality and higher operational safety of the produced adjustment fitting are to be achieved. For this purpose, the geometry of the partial eccentric element (30, 32) is measured, and the geometry of the transmission element (34) is individually adapted according to the data of the measurement before inserting the transmission element (34).

Owner:BROSE FAHRZEUGTEILE GMBH & CO KG

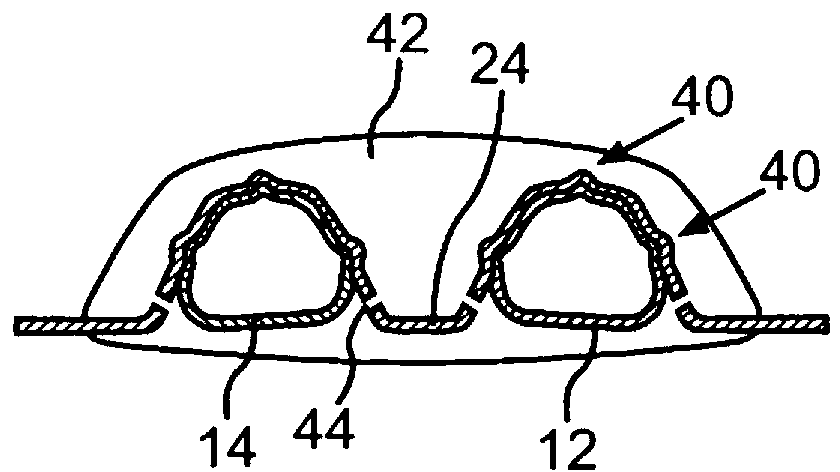

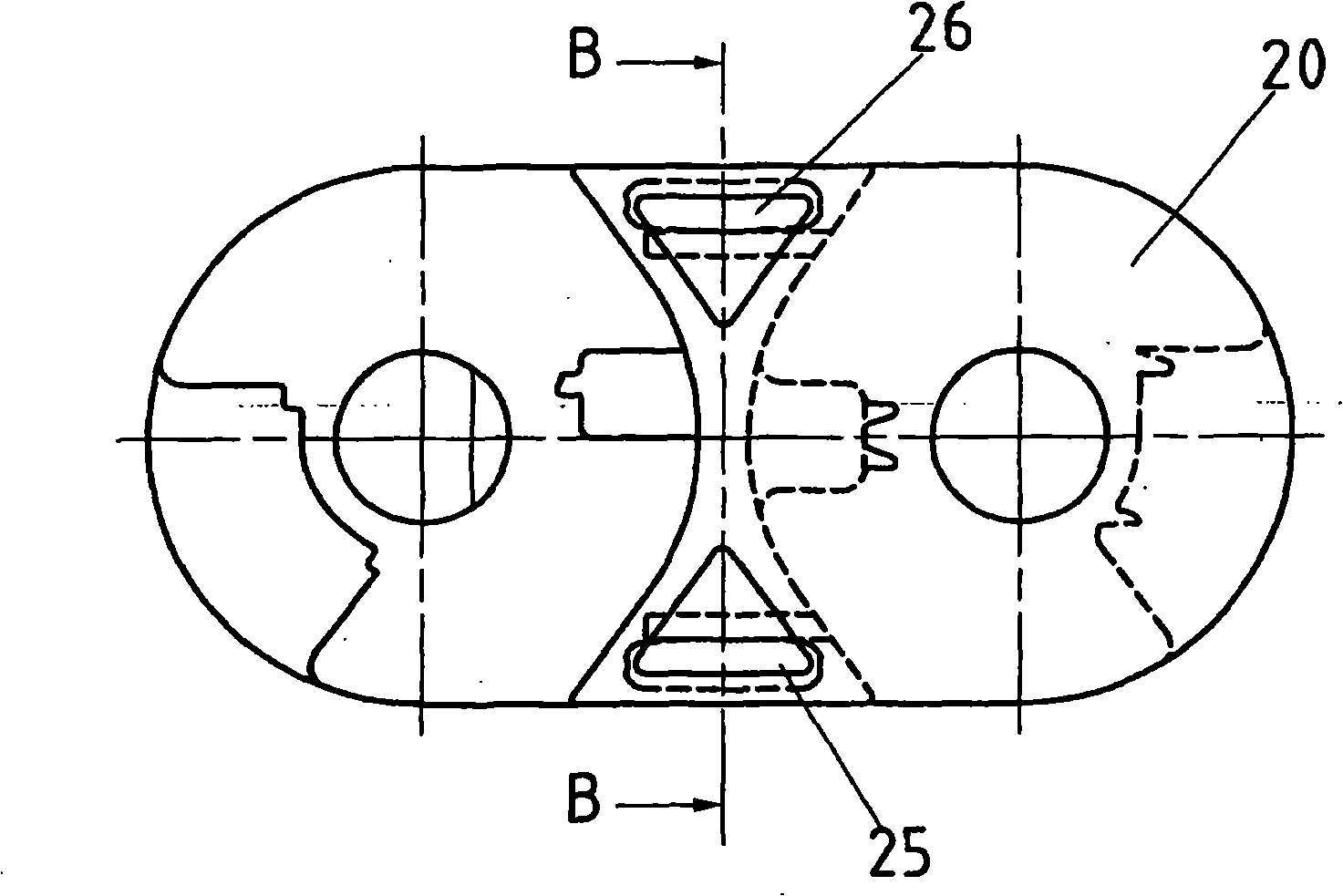

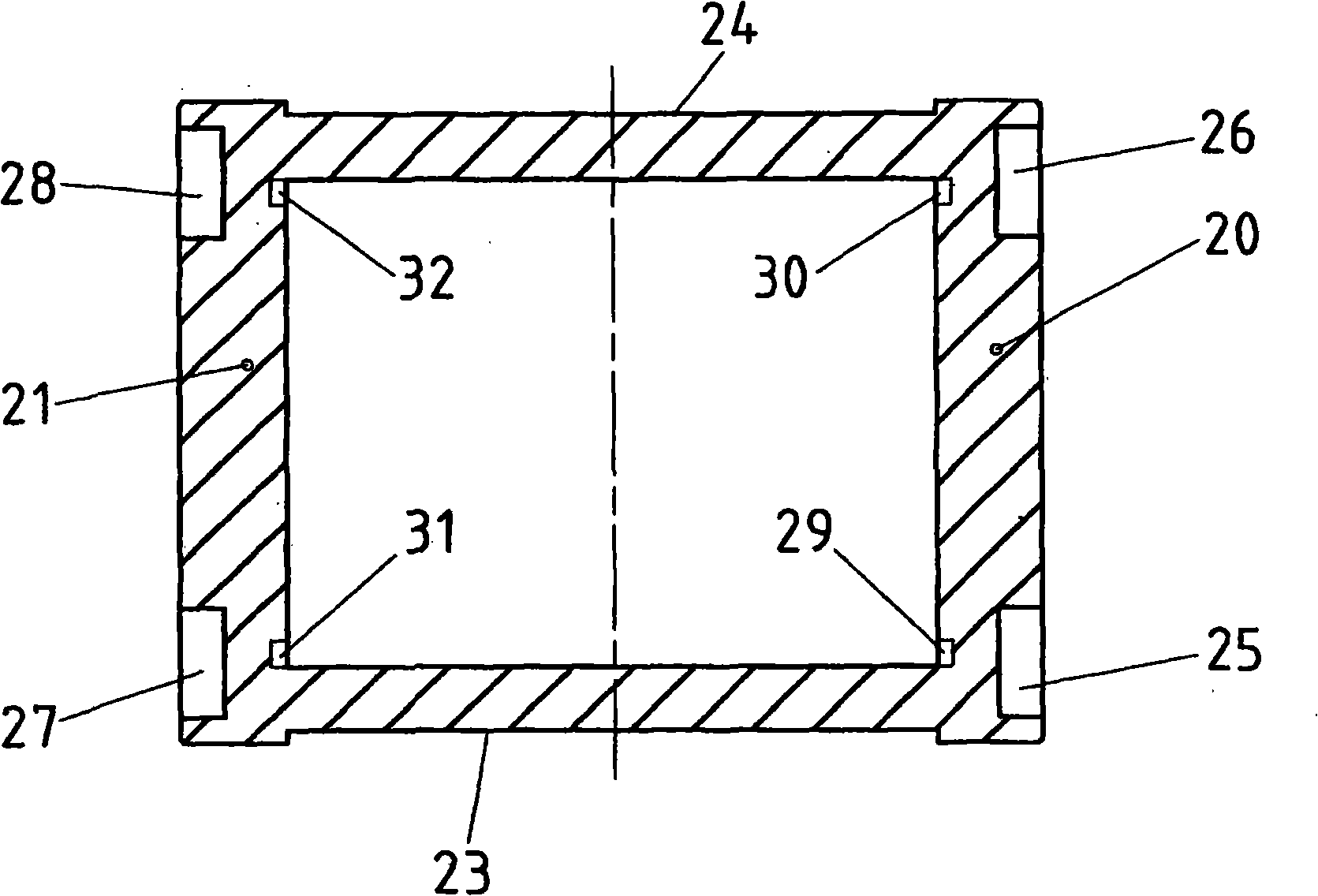

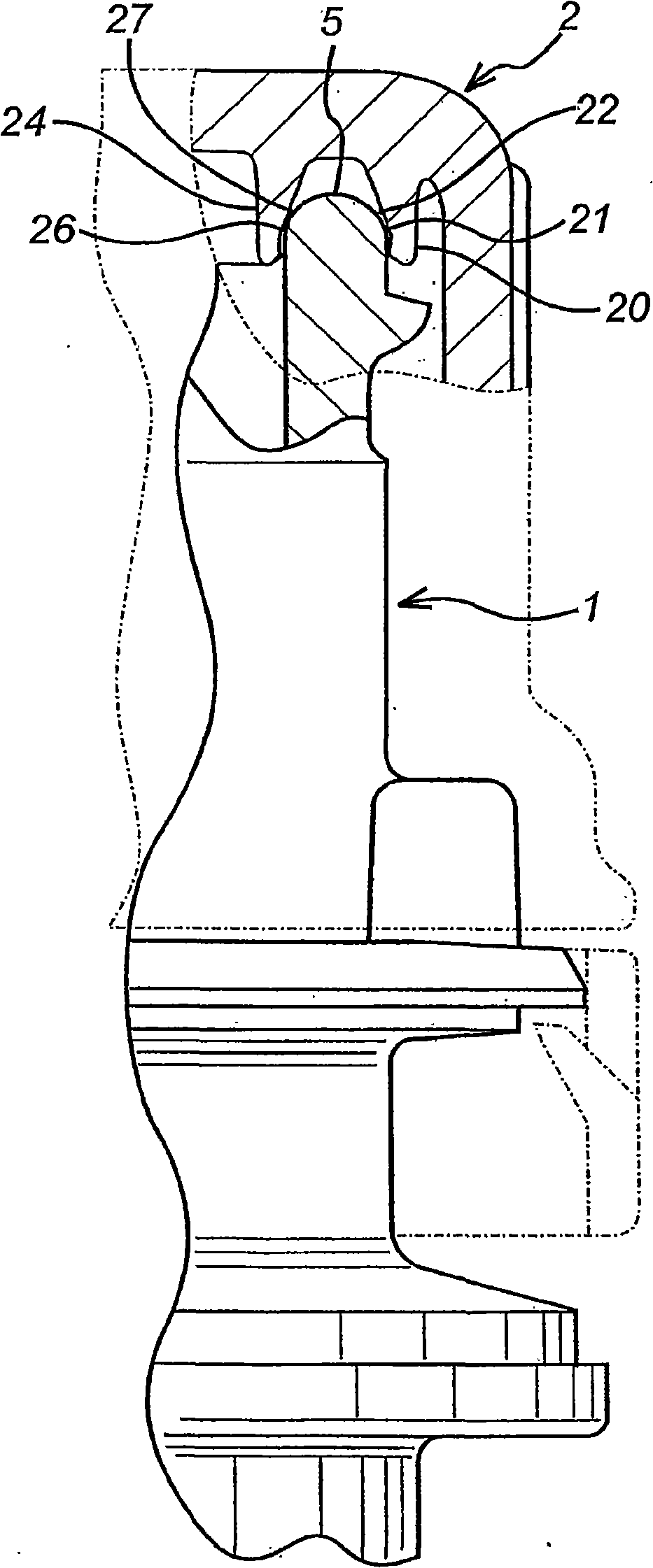

Jaw seals for container closure assemblies

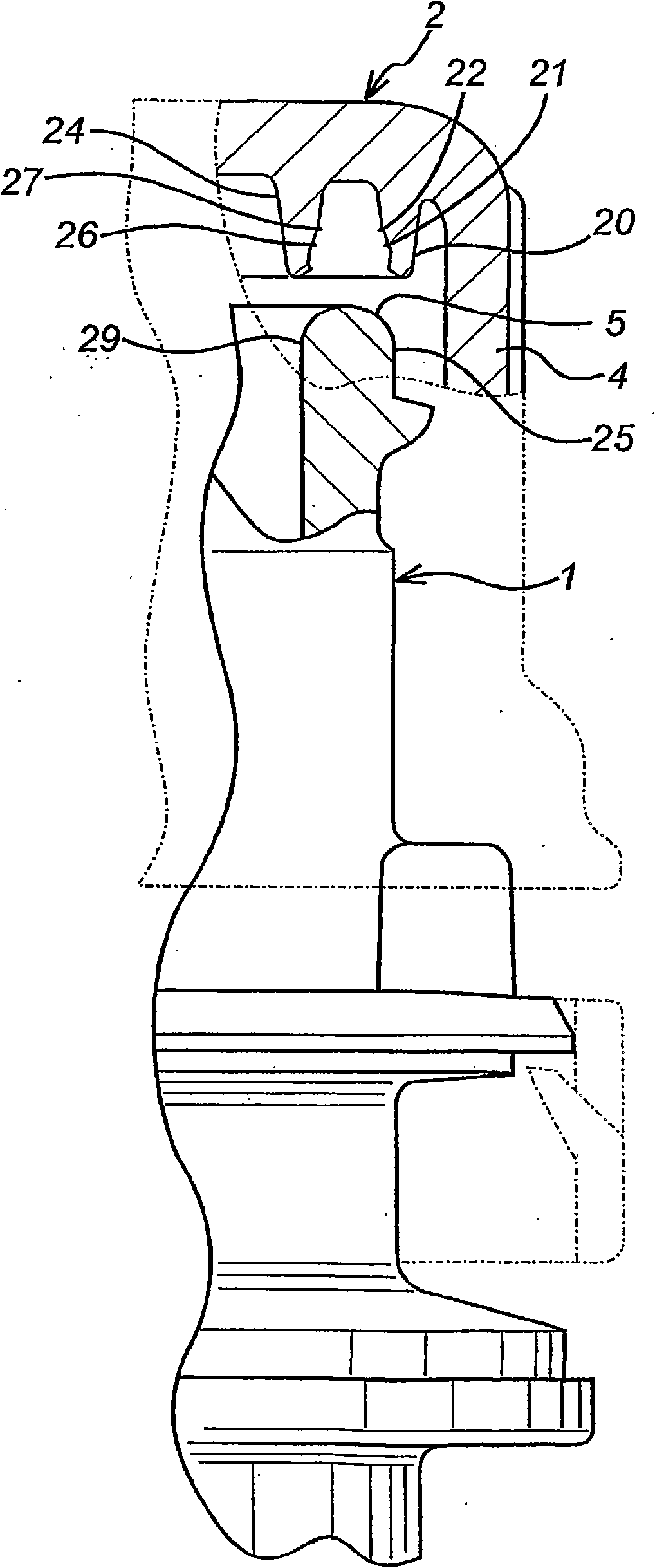

A container closure assembly comprising a threaded closure with a sealing plug (24) and a sealing skirt (20) pinching a container lip (5). The skirt and the plug comprise sealing ribs (21, 22, 26, 27) that engage the lip of the container. The ribs are located at substantially equal longitudinal distances from the base (3) of the closure.

Owner:BEESON & SONS

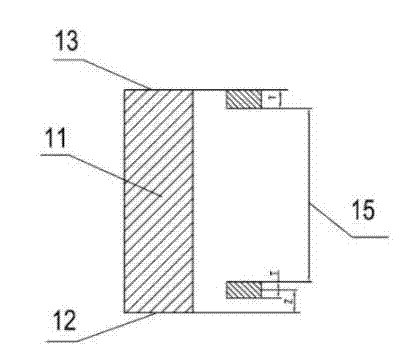

Cable bushing

ActiveCN110710073AImprove sealingOptimize layoutCable inlet sealing meansRotational axisScrew thread

The invention relates to a cable bushing to be screwed to a wall having an opening for at least one prefabricated cable, said cable bushing comprising: - two partial elements which are screwed to oneanother in the mounted state, a threaded portion to be guided through the opening, said threaded portion having a screw thread and being formed by the two partial elements, each forming a part of itsperiphery, a receiving portion which adjoins the threaded portion in the axial direction of a rotational axis of said threaded portion, and which has, at least in parts, a larger outer diameter than the threaded portion, and which has at least one receiving opening for receiving at least one strain relief ferrule. The cable bushing according to the invention is characterised in that the division between the two partial elements is designed eccentrically such that the periphery of the receiving opening, extending about the at least one strain relief ferrule, in one of the partial elements is larger than that in the other partial element.

Owner:ICOTEK PROJEKT

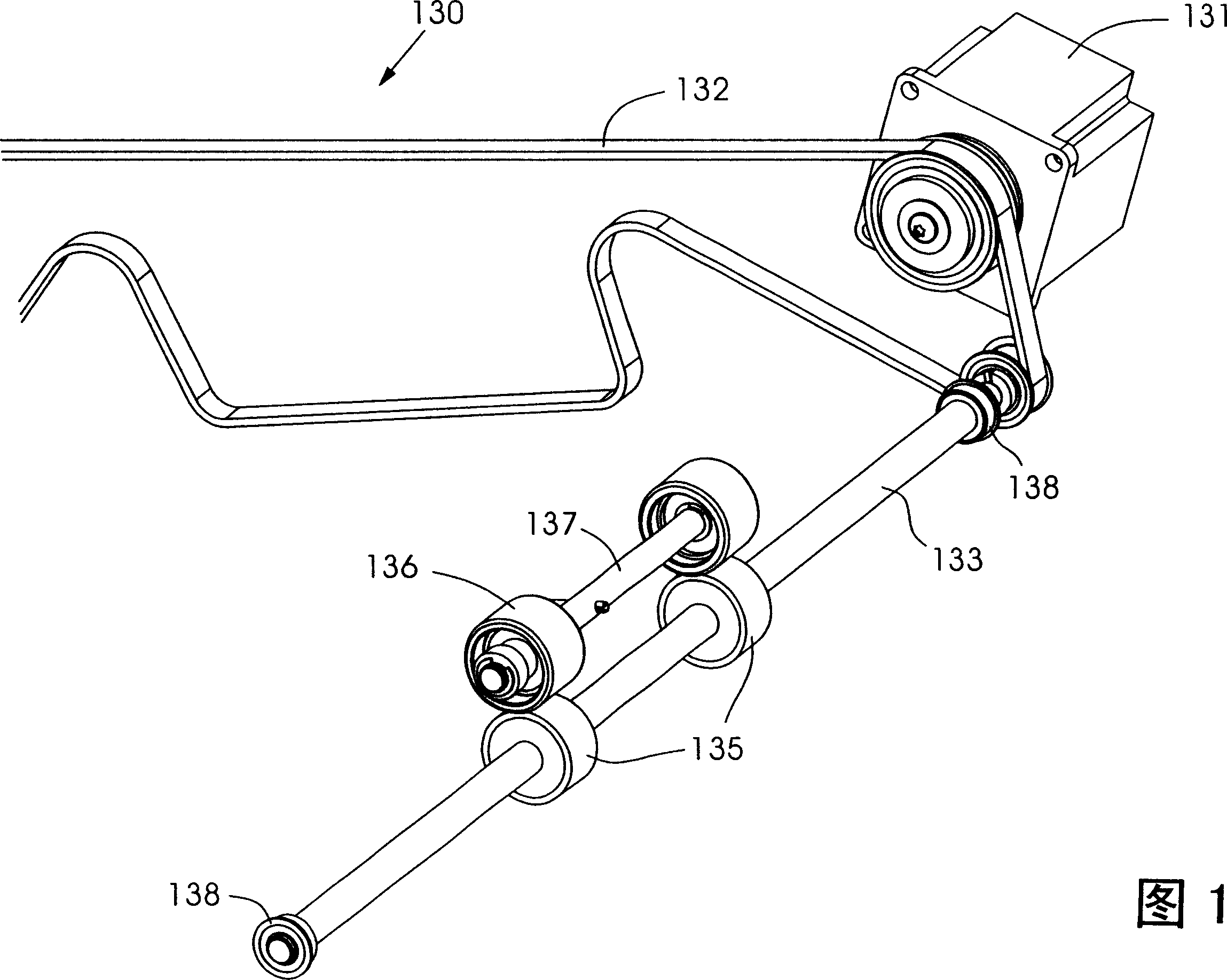

One-way force transmission system

InactiveCN1216765CReduce in quantityIncrease shift forceCycle control systemsCycle actuatorsPlastic materialsEngineering

The present invention relates to a one-way force transmission with restore-function for utilization in ratchet mechanism, e.g. in crank-switch, rotation-crank-switch, trigger-switch to operate the gear-shift of a bicycle, or in ratchet for tools, jacks and everywhere where a one-way transmission is asked with a restoring of the operation-element. The present invention reduces the number of the necessary switch-components by means of a multi-function without damaging the whole function. For example, the restore-spring for the operation-crank also takes over the tension of the one-way transmission element. The following switch-components are integrated together. The advantage of the present invention is that through skillful combination of many functions the number of the necessary components can be reduced and thus the cost, construction space and weight can also be saved. In addition, the elasticity and flexibility of the plastic material can be used for a spring purpose.

Owner:SRAM

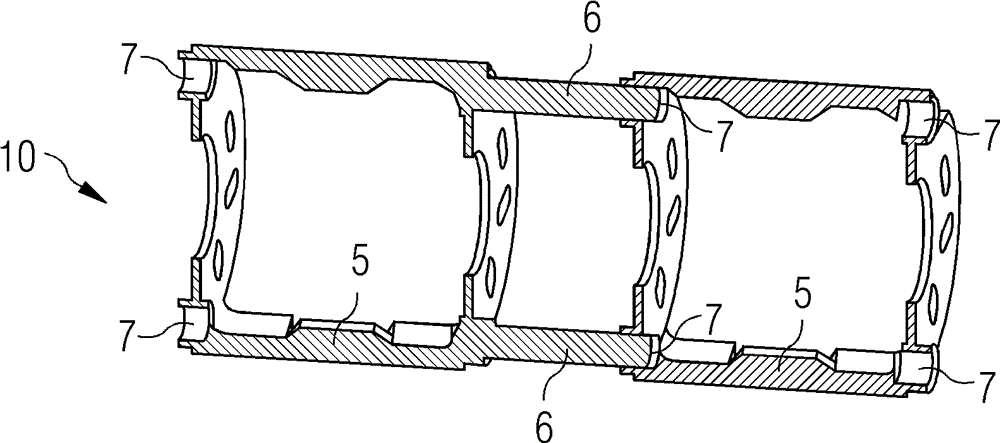

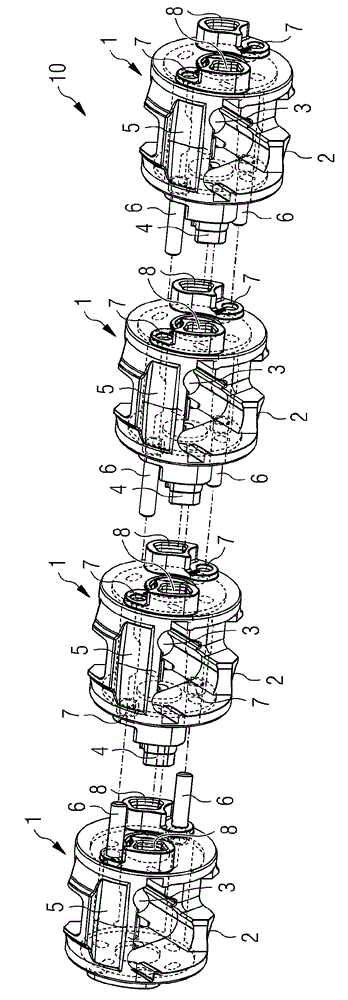

Rotor shaft module, rotor shaft, compact circuit breaker and method for producing rotor shaft module

InactiveCN104952639ASimplify the manufacturing processFirmly connectedProtective switch detailsEmergency actuatorsRotor (electric)Contact element

A rotor shaft module for a rotor shaft of a molded-case circuit breaker, includes a module body including an electrically insulating first material, the module body including a receptacle for a contact element of the molded-case circuit breaker. The rotor shaft module includes at least one coupling apparatus for connection to an opposing coupling apparatus of a further rotor shaft module. In addition, disclosed are a rotor shaft for a molded-case circuit breaker includes at least two coupled rotor shaft modules; a molded-case circuit breaker including a rotor shaft; and a method for producing a rotor shaft module for a rotor shaft of a molded-case circuit breaker.

Owner:SIEMENS AG

Surgical clip, in particular aneurysm clip

Owner:AESCULAP AG

Heat exchanger in particular for an evaporator of a vehicle air-conditioning unit

InactiveCN100510598CSmall manufacturing tolerancesAir-treating devicesEvaporators/condensersEngineeringAir conditioning

Owner:BEHR GMBH & CO KG

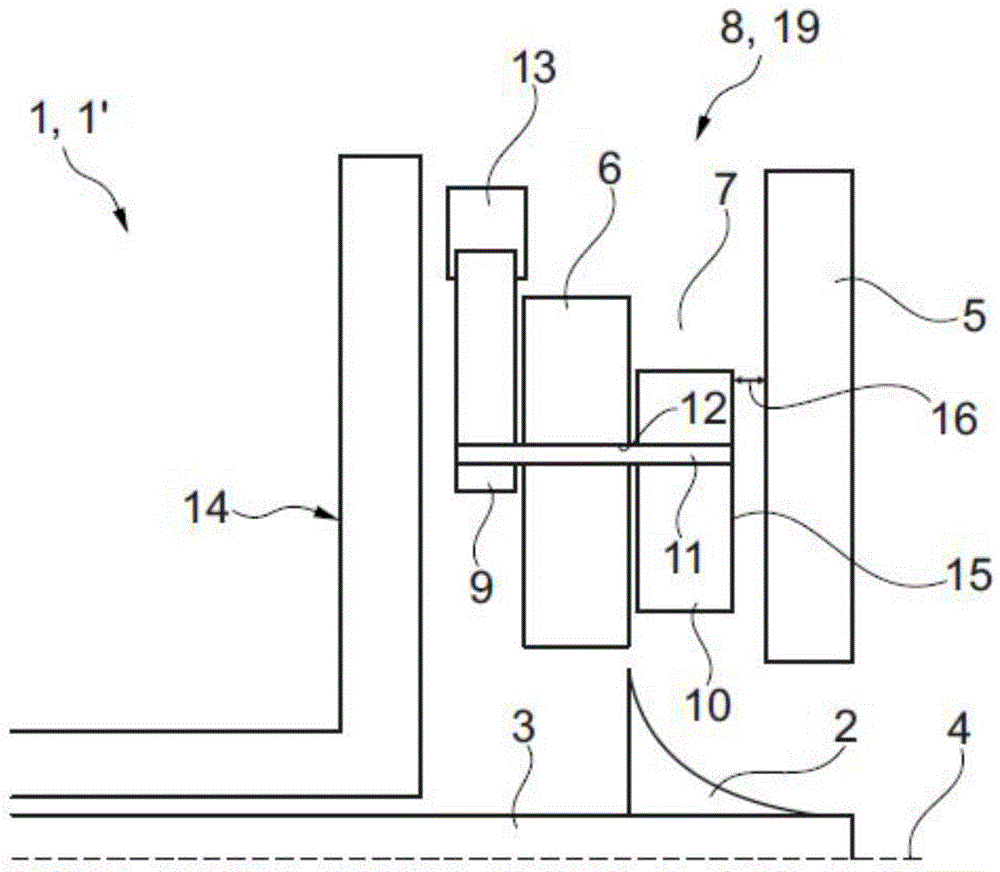

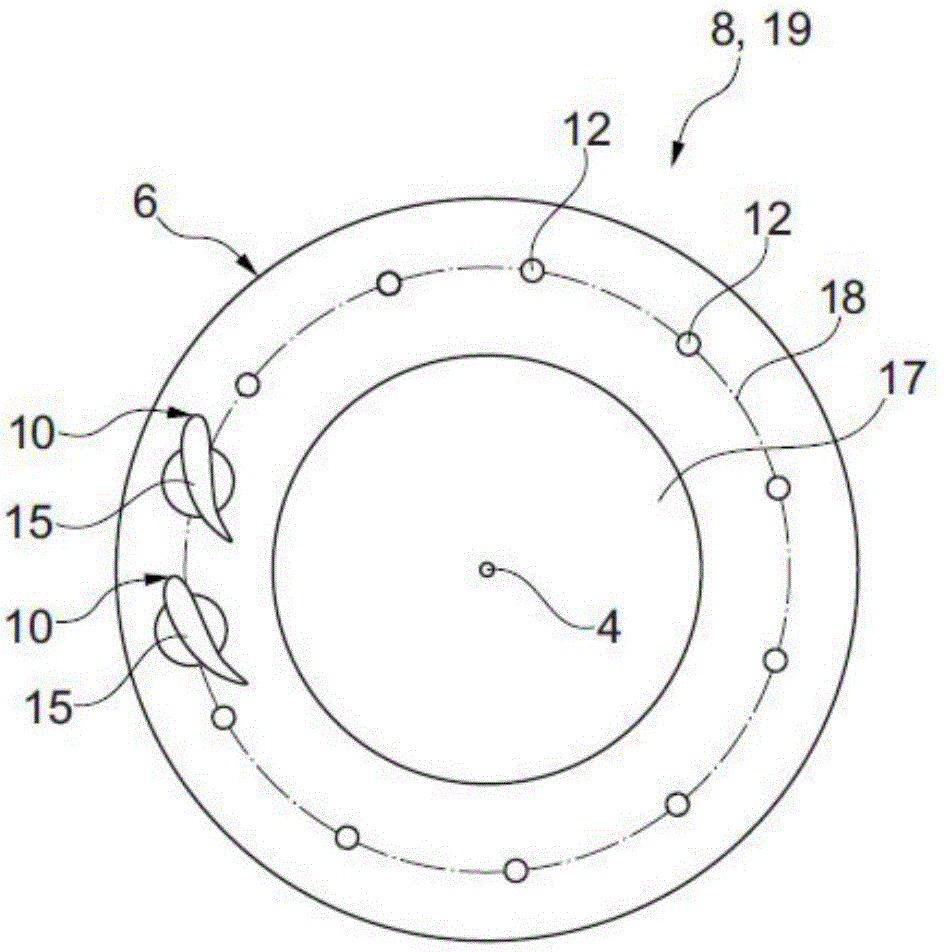

Method for producing a variable turbine geometry

ActiveCN105822362AMinimize Manufacturing TolerancesIncrease powerInternal combustion piston enginesStatorsTurbochargerEngineering

The invention relates to a method for producing a variable turbine geometry (8) of a charging device (1). The variable turbine geometry (8) has a plurality of guide blades (10) which are arranged on a blade mounting ring (6). Herein that at least two guide blades (10) are inserted into the blade mounting ring (6) is essential for the invention, and then in the mounting state, the at least two guide blades (10) are jointly processed on respective end side (15) facing away from the blade mounting ring (6) in order to produce a final shape of the end sides (15). Furthermore the invention relates to the variable turbine geometry (8), and a charging device (1) with the variable turbine geometry (8), and particularly to an exhaust gas turbocharger (1').

Owner:BOSCH MAHLE TURBO SYST GMBH & CO KG

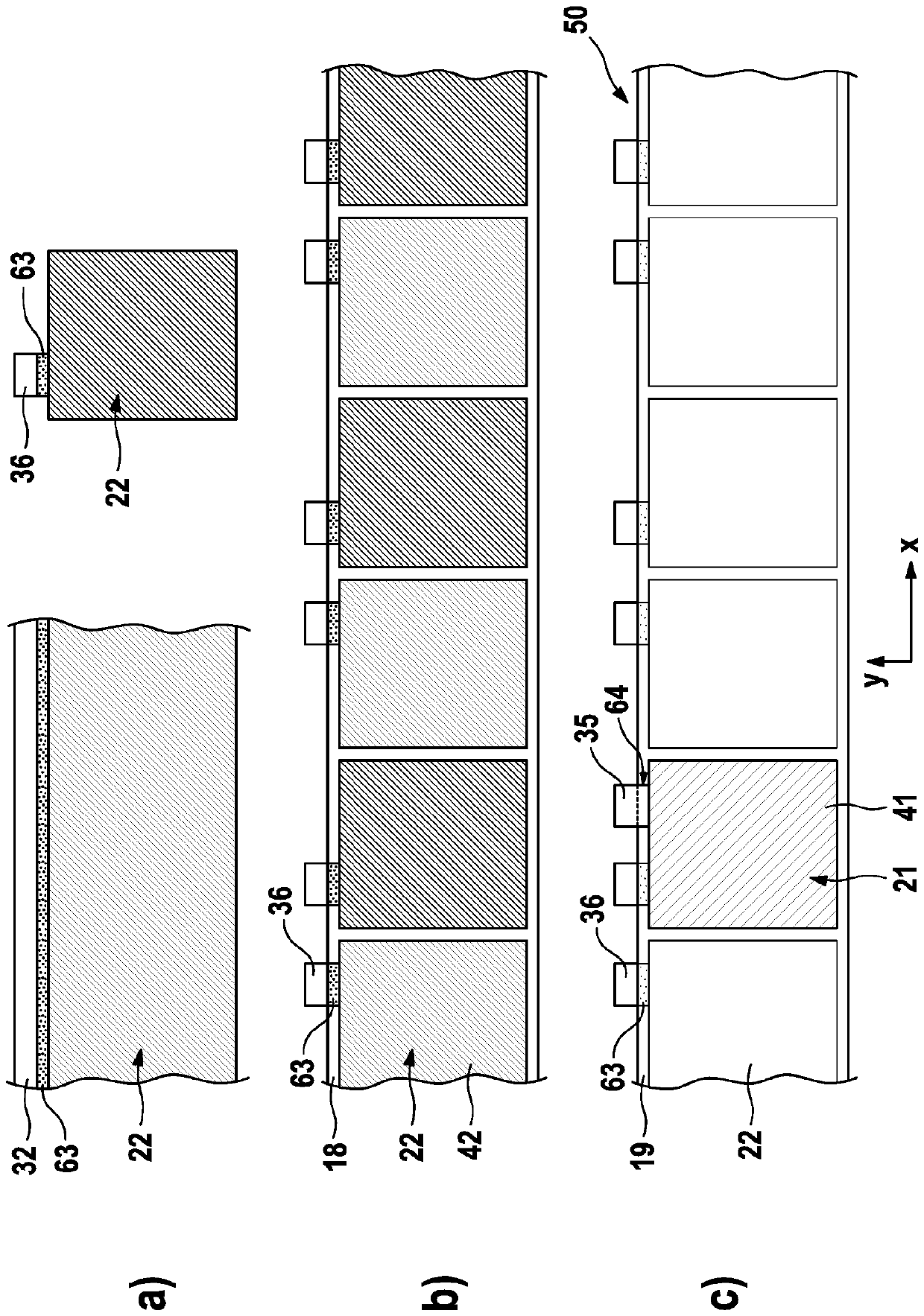

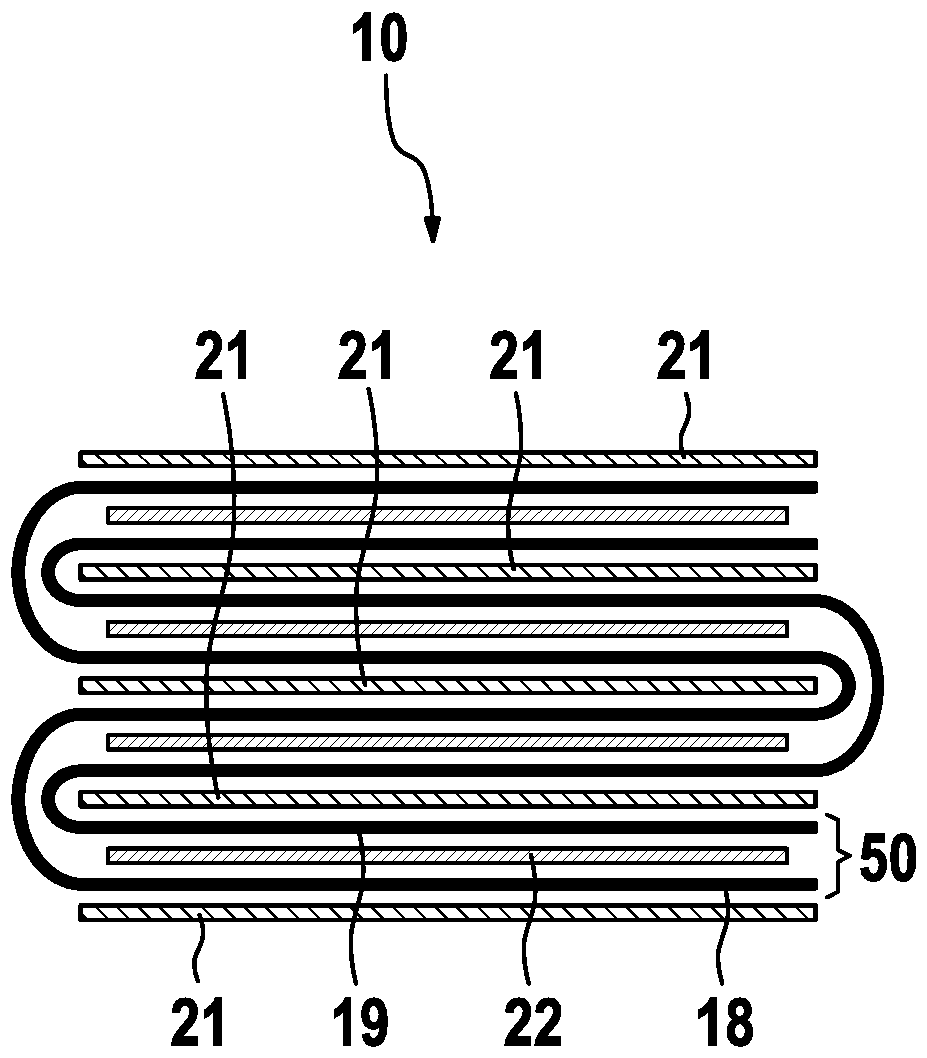

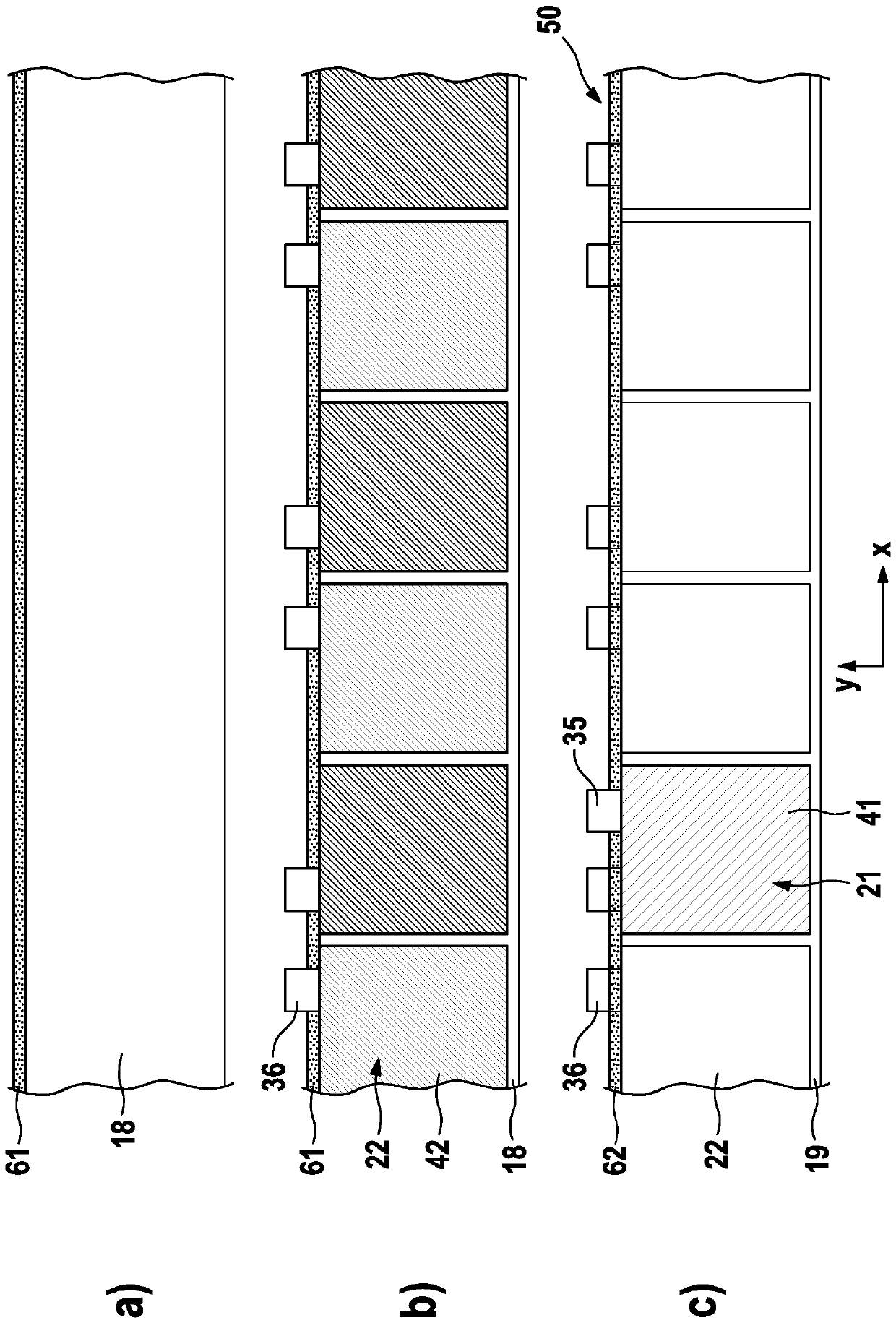

Method for producing an electrode unit for a battery cell and electrode unit

PendingCN109792072AProcessing speedSmall manufacturing tolerancesFinal product manufactureSecondary cells manufactureEngineeringComposite element

The invention relates to a method for producing an electrode unit for a battery cell. The method includes following steps: substance-to-substance bonding of contact lugs (35, 36) of a plurality of plate-shaped segments of a first electrode (21, 22) to a strip-shaped first separator layer (18); substance-to-substance bonding of a strip-shaped second separator layer (19) to the contact lugs (35, 36)of the segments of the first electrode (21, 22) or to the first separator layer (18) such that a strip-shaped composite element (50) is produced, wherein an active material (41, 42) of the segments of the first electrode (21, 22) is surrounded by the first separator layer (18) and by the second separator layer (19); and arrangement of a plurality of plate-shaped segments of a second electrode (21, 22) on the composite element (50). The invention further relates to an electrode unit for a battery cell, produced by the method according to the invention.

Owner:ROBERT BOSCH GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com