Horizontal type paper pressing operation mechanism of indoor printer

A technology of operating mechanism and paper pressing mechanism, which is applied in the direction of printing and printing devices, can solve the problems of reduced operating accuracy, large amount of twisting and deformation of connecting rods, and large longitudinal eccentric torque, so as to improve operating accuracy, reduce deformation and Distortion, the effect of reducing eccentric torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

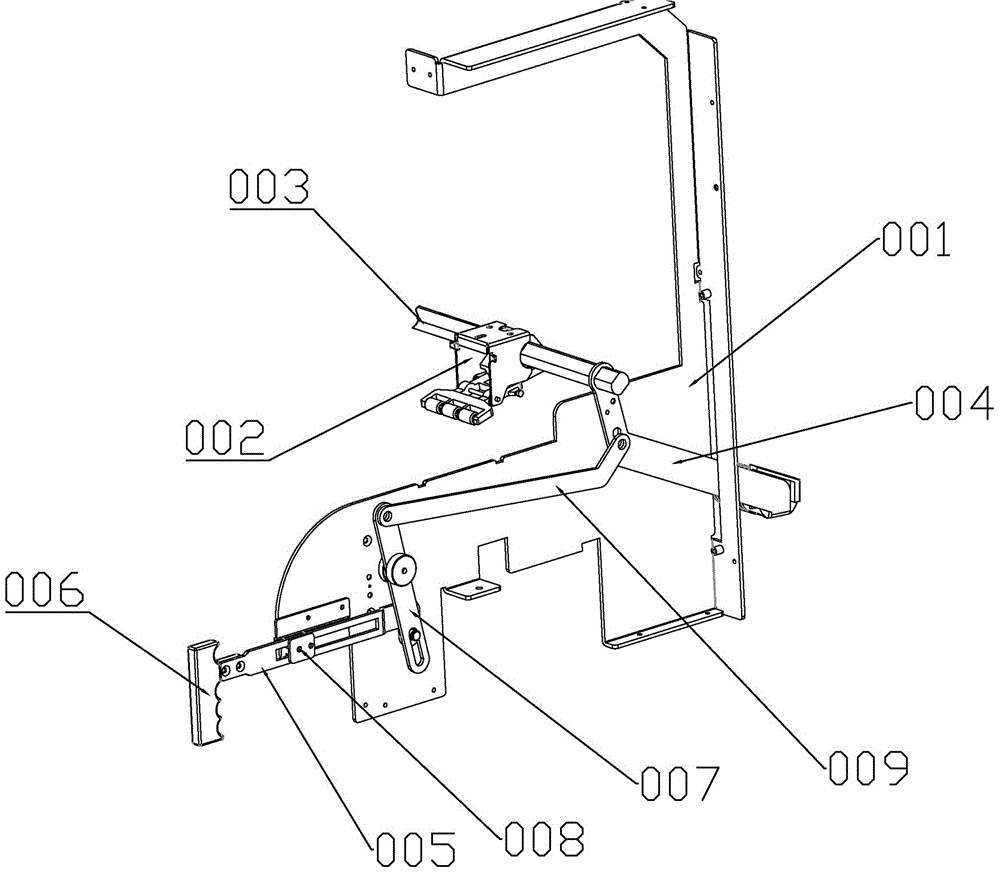

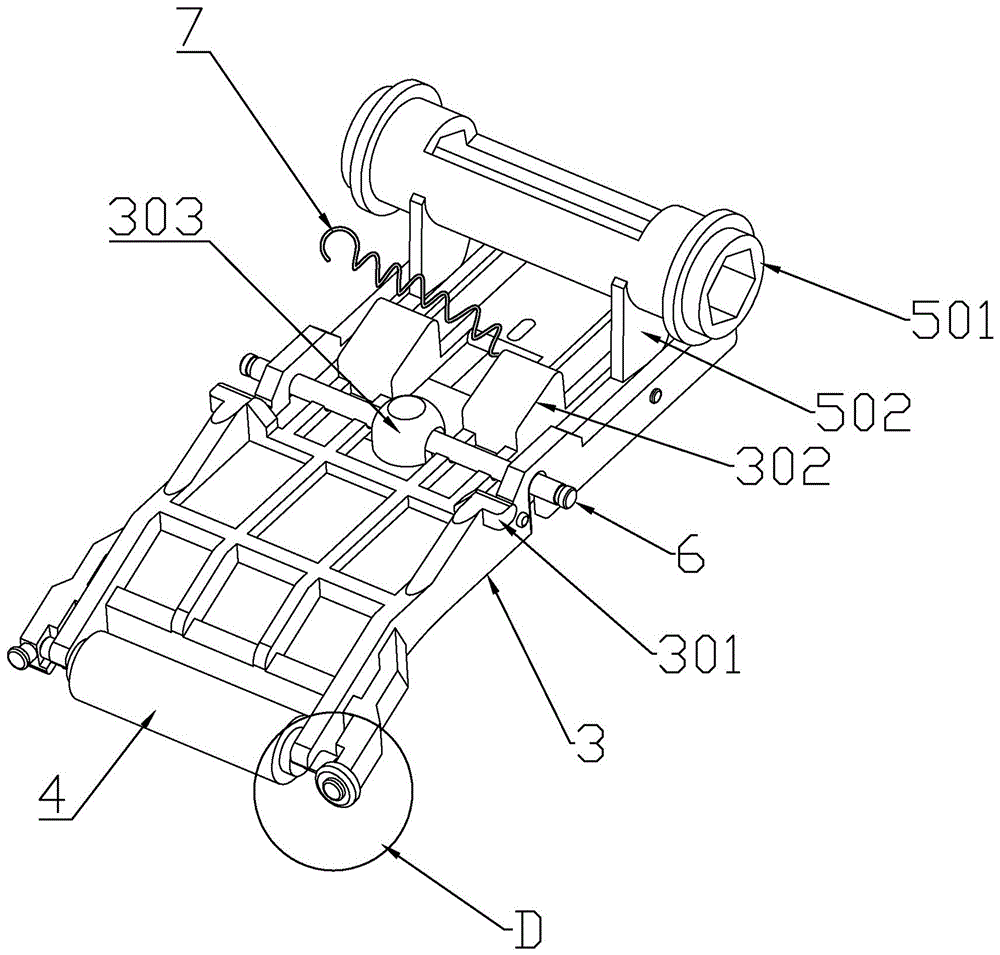

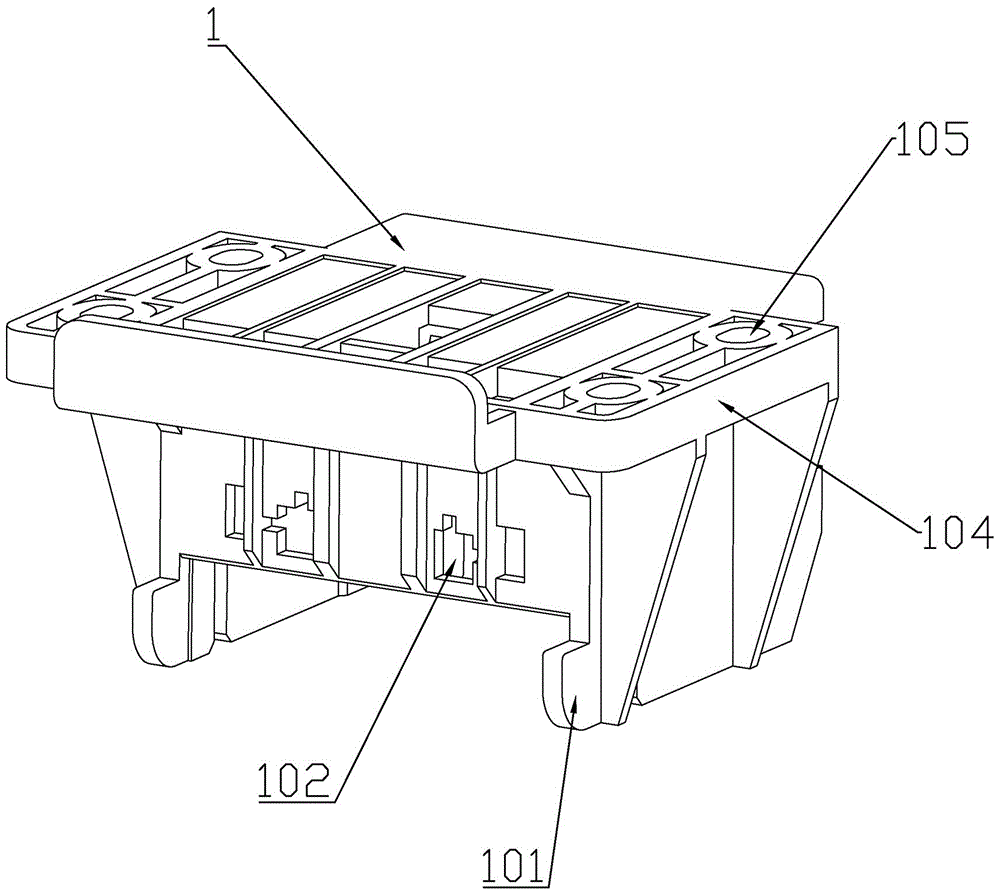

[0035] Embodiment 1 A horizontal platen operating mechanism of a photo machine, see Figure 1-2 : A horizontal paper press operating mechanism of a photo machine, including a frame, a connecting shaft, a connecting rod and a paper press mechanism, and a non-circular installation shaft is correspondingly assembled with a paper press mechanism and stretches out from the outside of the frame to connect to the first connecting rod. The second connecting rod is slidingly assembled on the side wall of the machine frame, and the second connecting rod is correspondingly hinged to the middle part of the first connecting rod through the third connecting rod and the fourth connecting rod; The second connecting rod is coupled to the end of the third connecting rod through the waist-shaped hole; the front end of the second connecting rod is correspondingly connected to the front operating handle, and the lower end of the first connecting rod is bent backward and extends to the rear of the f...

Embodiment 2

[0039] Embodiment 2 A horizontal platen operating mechanism of a photo machine, see Figure 1-17 : Including the frame, connecting shaft, connecting rod and paper pressing mechanism, the non-circular mounting shaft is correspondingly assembled with the paper pressing mechanism, extends out of the frame and connects to the first connecting rod, and the second connecting rod is slidably assembled on the side wall of the frame. The second connecting rod is hinged correspondingly to the middle part of the first connecting rod through the third connecting rod and the fourth connecting rod; the middle part of the third connecting rod is hinged to the side wall of the frame through a rotating pair, and the second connecting rod passes through the waist hole It is coupled to the end of the third link; the front end of the second link is correspondingly connected to the front operating handle, the lower end of the first link is bent backwards and extends to the rear of the frame, and it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com