Device used for delivering quiding plane material

A technology for plane and noodle feeding, which is applied in the field of devices for guiding and conveying plane materials, which can solve problems such as troublesome adjustments and adverse effects, and achieve the effect of easy operation and elimination of paper jams

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

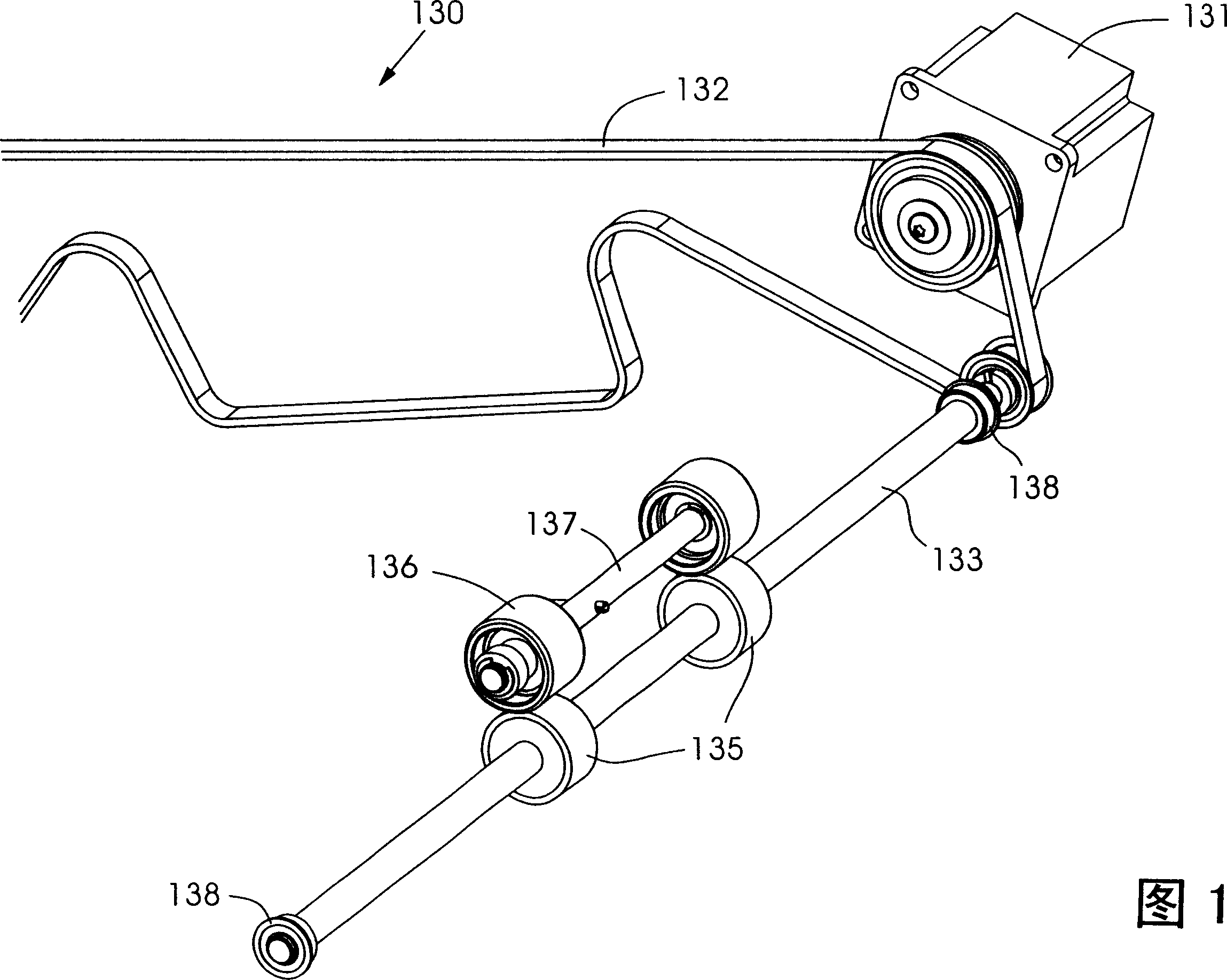

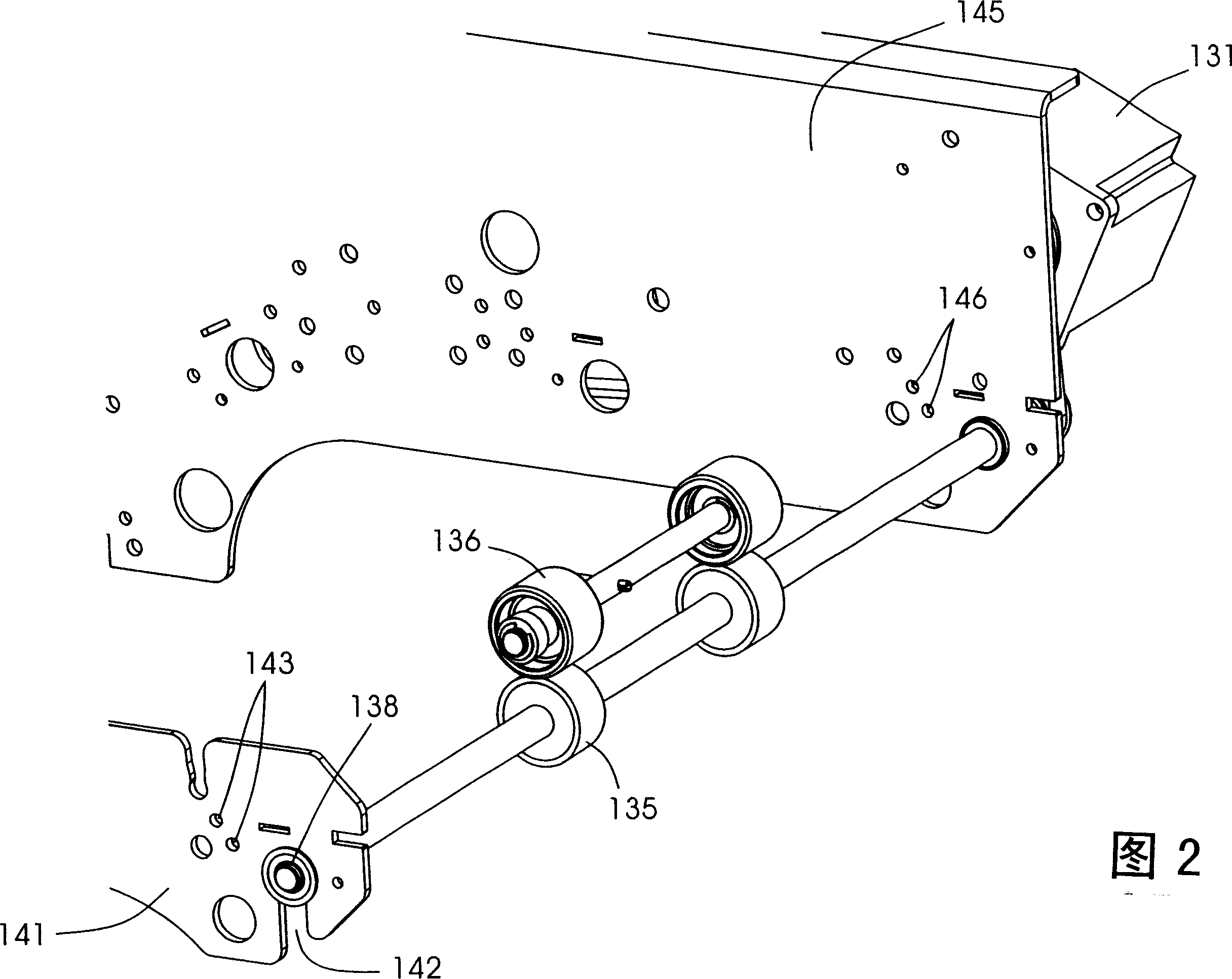

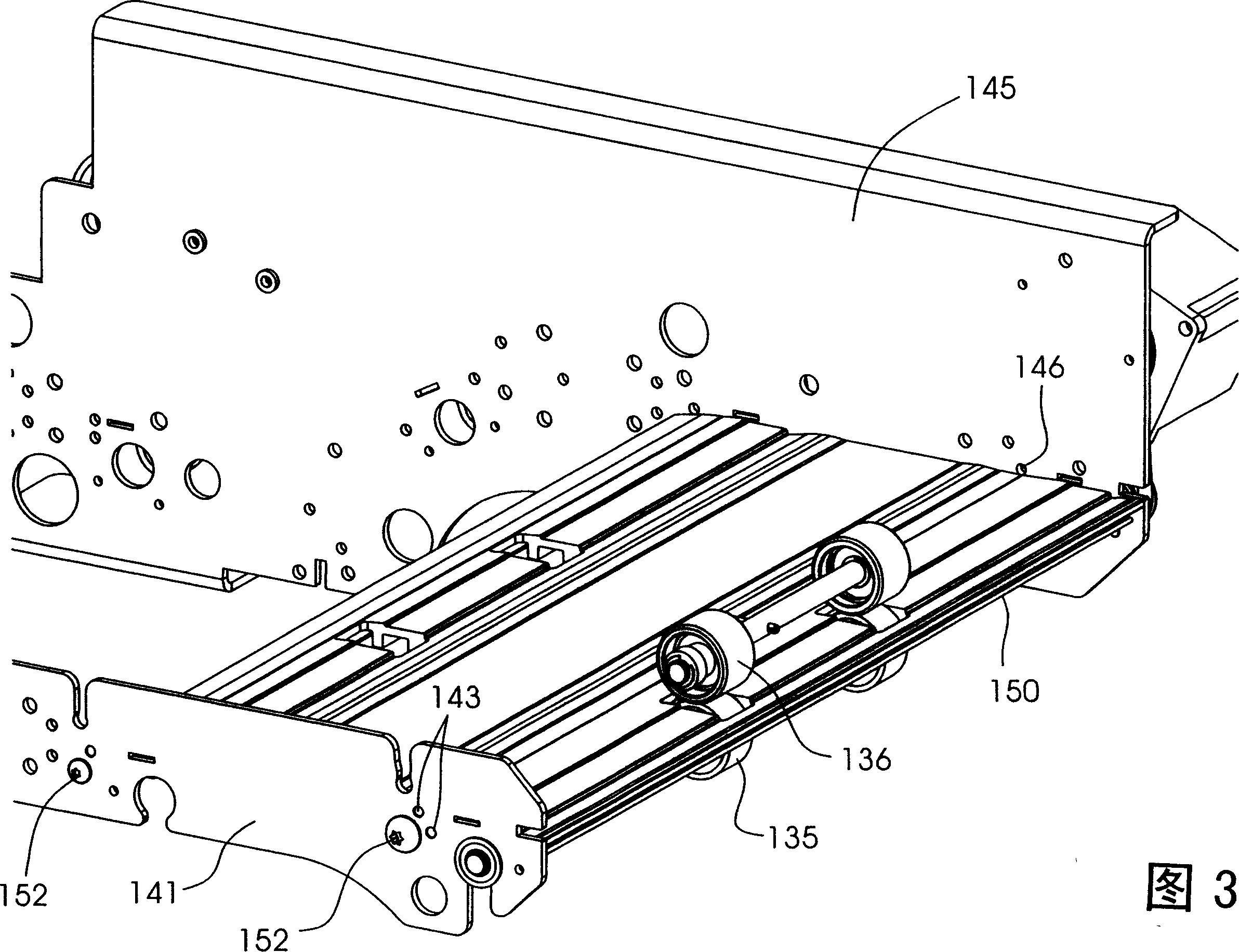

[0045] Figures 1 to 7 show in isometric views progressively increasing parts of the transmission path module 100 of the invention, Figure 8 shows different embodiments 100, 100', 100", 100'' of the transmission path module of the invention and Figures 9 and 10 Shown are progressively increasing parts of a higher-level device 200 for transferring flat materials, in particular sheet-like printing materials. Other drives, controls and / or guides and curves, which are generally known and which are necessary for the operation of the device The disc is only shown schematically or described in a general form.

[0046] First, the structure of the drive device 130 of the device 100 of the present invention is shown in FIG. 1 . Accordingly, the drive device 130 is guided by a drive motor 131 which acts via a tensioning belt 132 . The drive motor 131 is, for example, a stepper motor, which is fastened to the second side wall 145 , see FIG. 2 . The tension belt 132 drives a drive roller ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com