Body for a passenger car

A technology for passenger cars and car bodies, applied in the field of manufacturing passenger car bodies and equipment for manufacturing such passenger car bodies, can solve the problems of multiple single, high cost, expensive steps, etc., and achieve low industrialization cost and high integrity. Structure, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

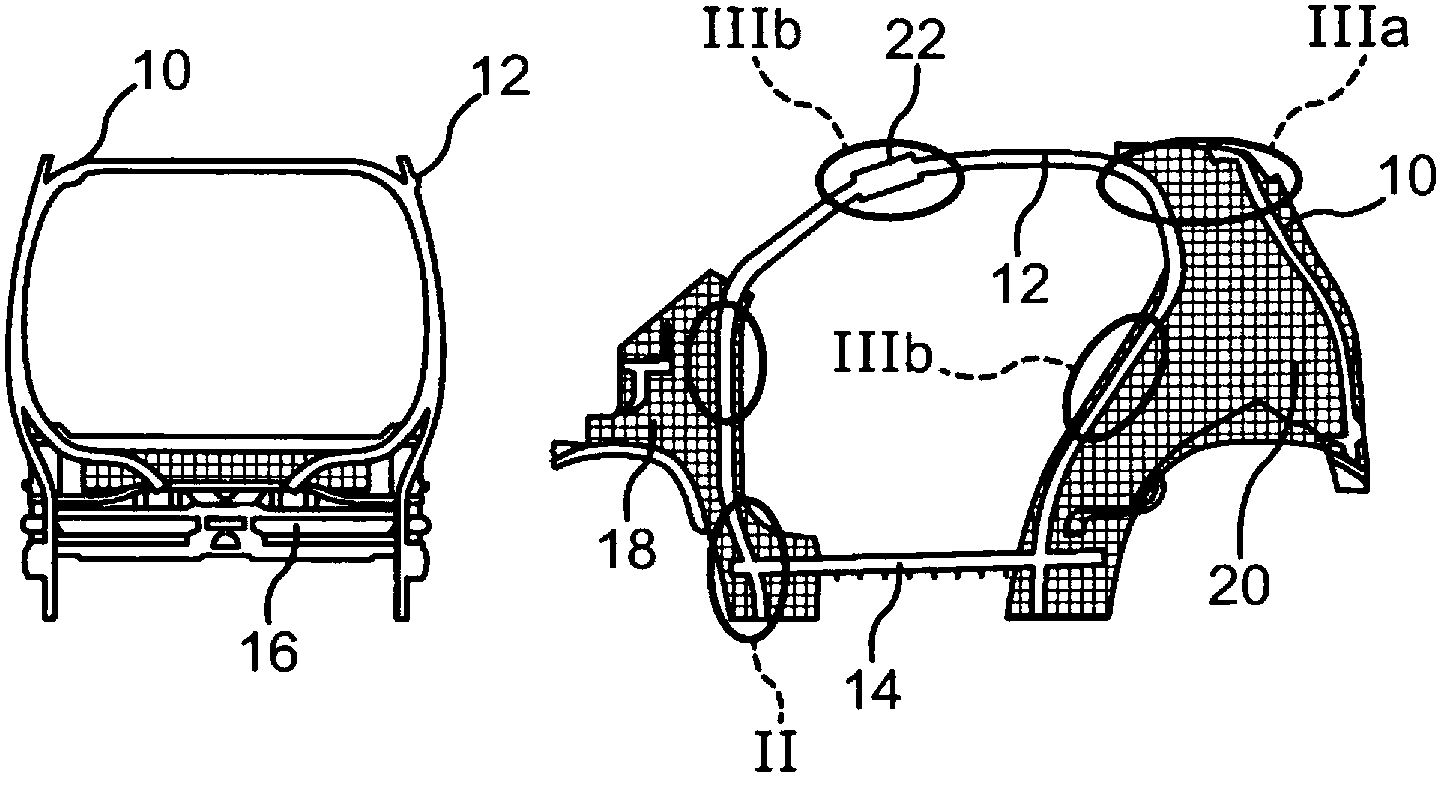

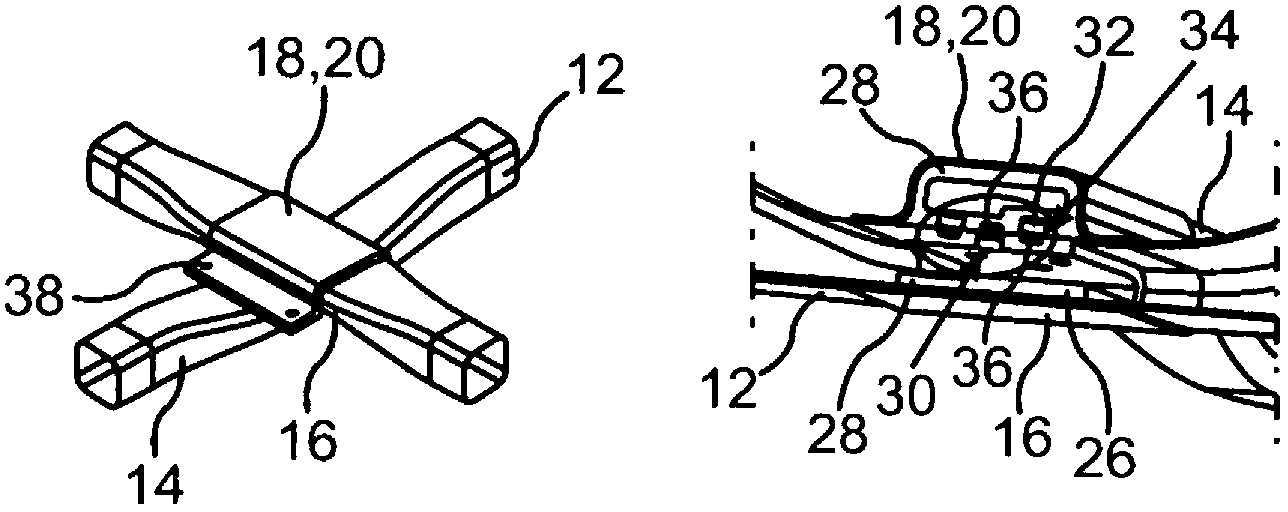

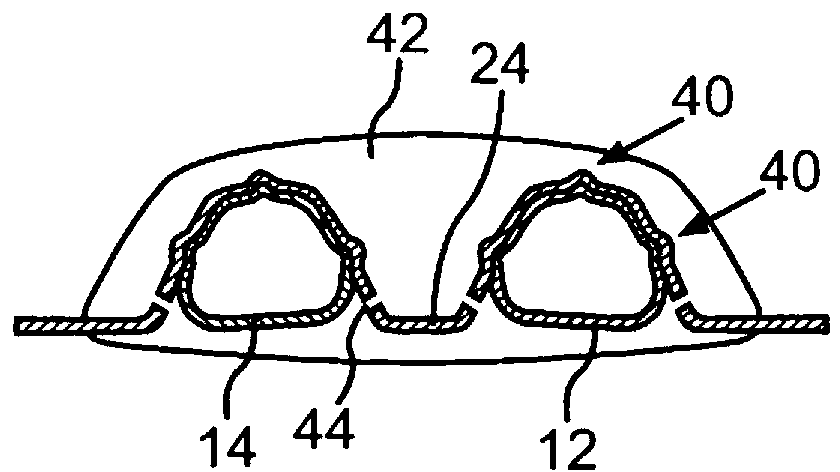

[0021] figure 1 The body of a passenger car is shown in schematic front and side views. What this case relates to is a kind of one-box type two-seater car, and wherein, the present invention described later can also be used on the car body of other structural types. In this regard, from figure 1 The following body components can be seen: a rear frame profile 10 , a corresponding side frame profile 12 and a corresponding side sill profile 14 . The body components 10 , 12 , 14 are each formed as internally hydroformed injection-molded components. Furthermore, a plastic-overmolded base plate 16 , a plastic-molded front structural panel 18 , a corresponding plastic-molded rear structural panel 20 and a gusset 22 formed as a roof frame receptacle can be seen. The body components 10 - 22 can thus primarily be tubes or hollow profiles or flat parts such as sheet metal. Body components 10 - 22 can consist of a metal base component that is overmolded with plastic, in particular fib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com