Lantern-type gear unit

A technology for gear units, lantern gears, applied to elements with teeth, gear drives, belts/chains/gears, etc., to reduce manufacturing tolerances and avoid unwanted axial movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

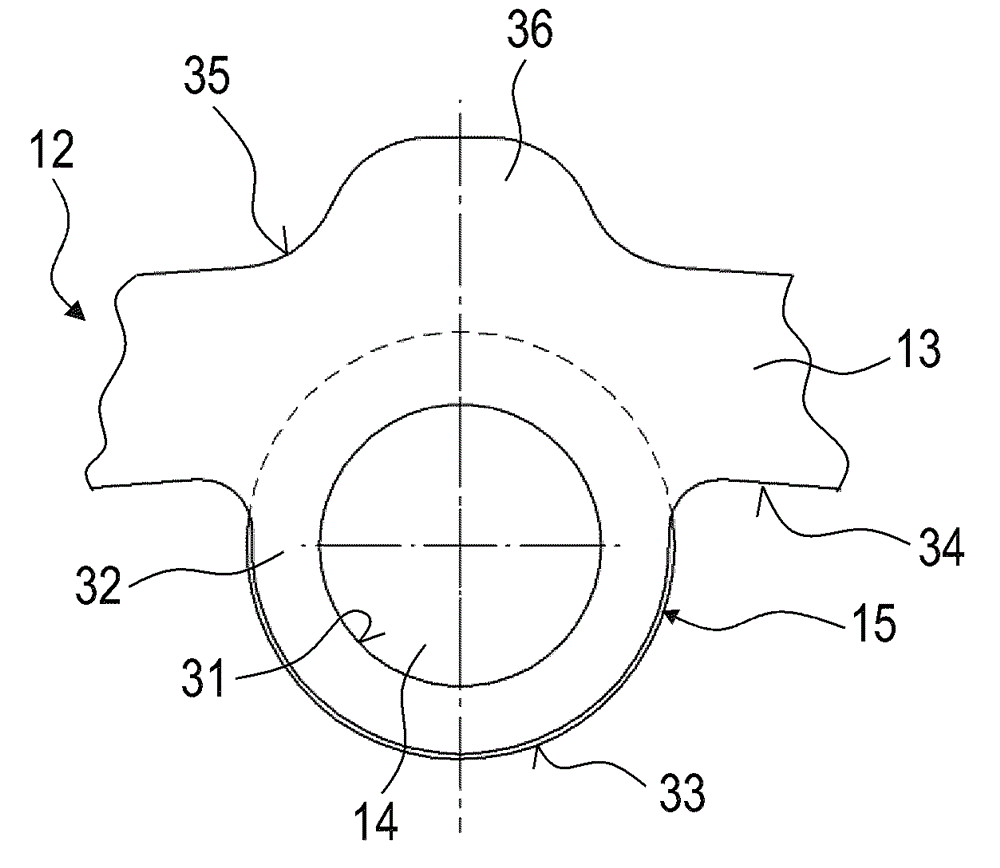

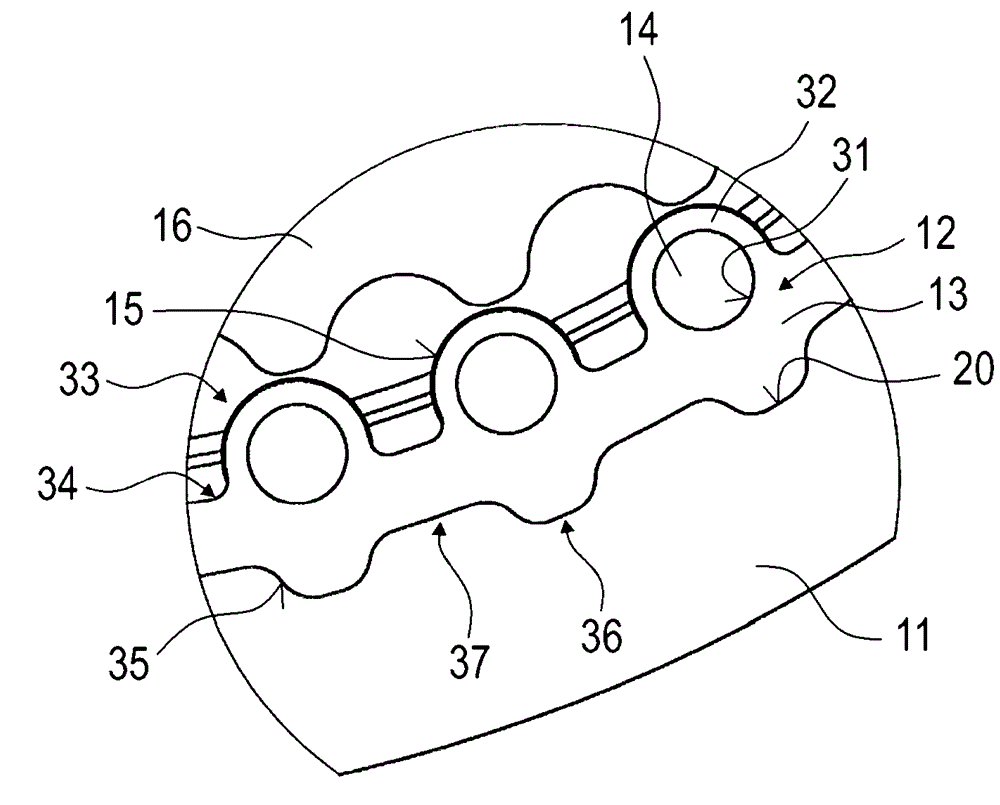

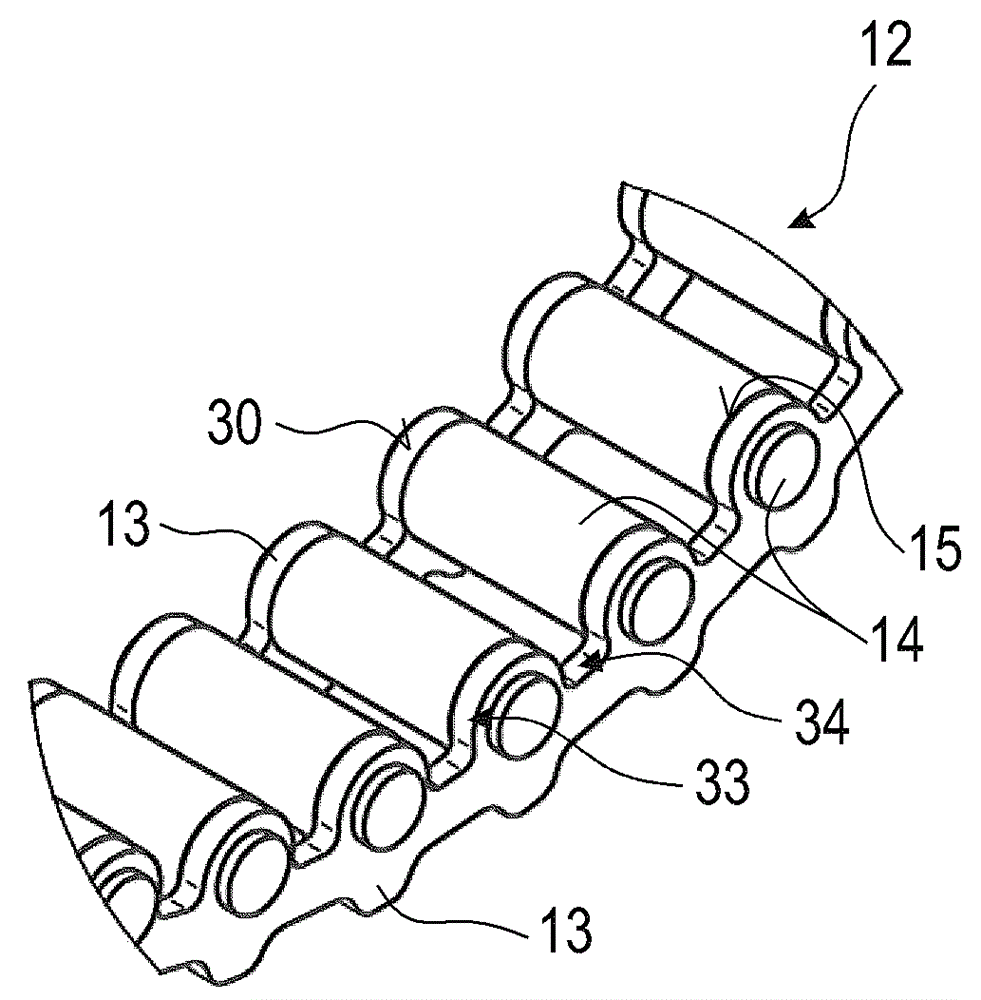

[0028] according to figure 1 The perspective partial exposure of FIG. 2 shows an embodiment of a lantern-type gear unit 1 according to the invention, in the embodiment shown here, the lantern-type gear unit 1 being used as a camshaft adjuster 2 of an internal combustion engine. For this purpose, a gear unit 1 is arranged on one end of the camshaft 3 and allows a rotational movement exerted via the gear unit 1 to be transmitted via the valve cam 4 to a control valve (not shown) of the internal combustion engine. It can be clearly seen from the exposed part of the gear unit 1 that the lantern-shaped gear unit 1 is configured as a two-stage gear unit, the first gear stage 5 is arranged on the side of the gear unit facing away from the camshaft 3, and the second gear stage 6 is arranged on the side facing away from the camshaft 3. Gear unit side of camshaft 3.

[0029] According to the configuration of this two-stage lantern-type gear unit 1 as an eccentric gear arrangement, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com