Spare part set for a gearmotor series

A technology for structural components, gear motors, applied to components with teeth, electric components, belts/chains/gears, etc., to achieve the effect of reducing manufacturing tolerances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

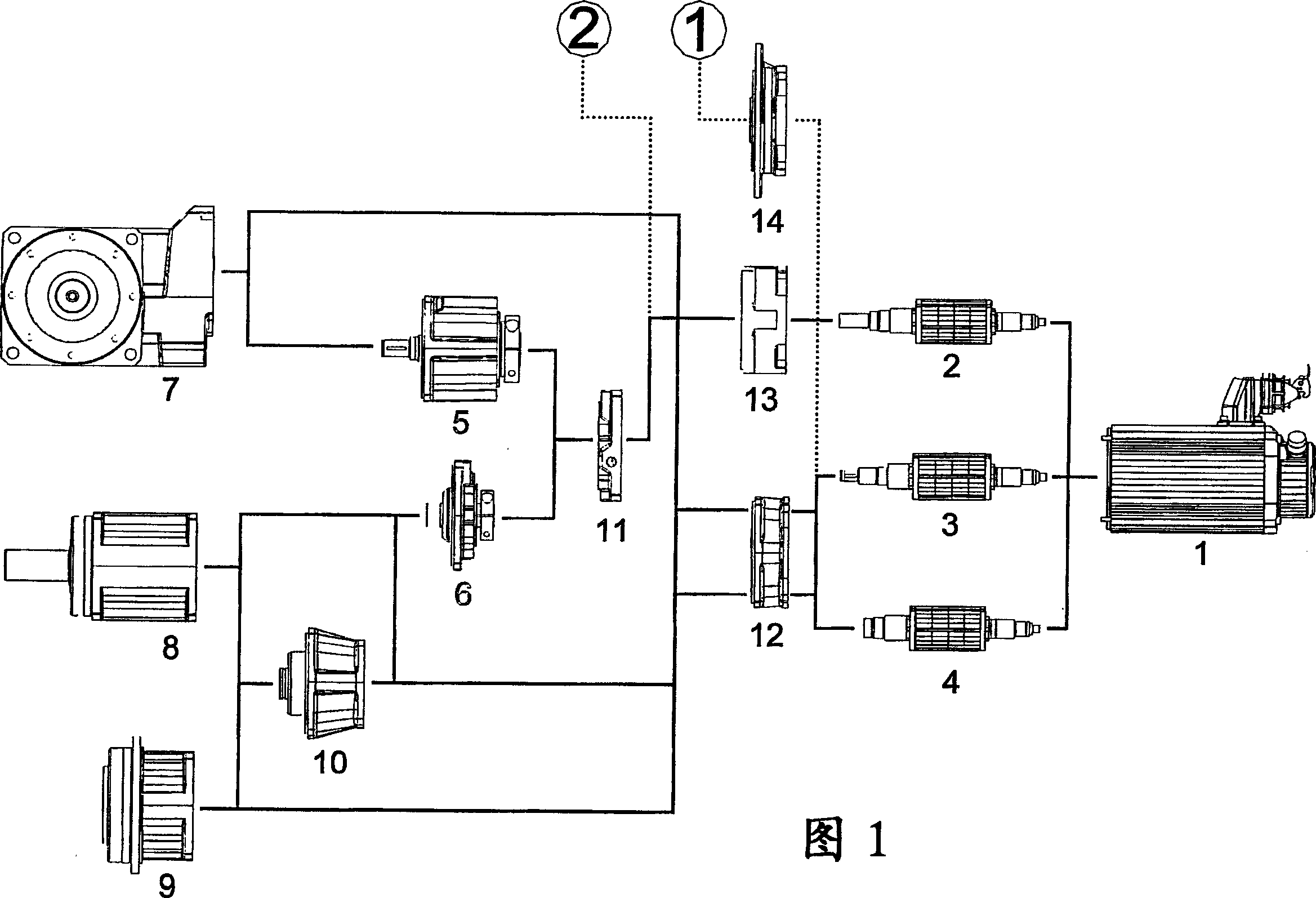

[0055] exist Figure 10 The combination possibilities of a design series of gear trains are shown in . In this case, the structural components of the series of geared motors are designed in such a way that different electric motors can be connected to different gears directly or by means of converters. exist Figure 10 The gear transmission shown in does not have to be designed as a servo gear transmission.

[0056]FIG. 1 shows the main part of the invention, which is adapted to the structural series of the gear motor, ie has a corresponding transition area. These essential parts according to the invention consist of servo gear motors which can be assembled in different combinations. The gear transmission shown here and which can be connected to the electric motor is a servo gear transmission.

[0057] The part shown in FIG. 1 will now be discussed first below.

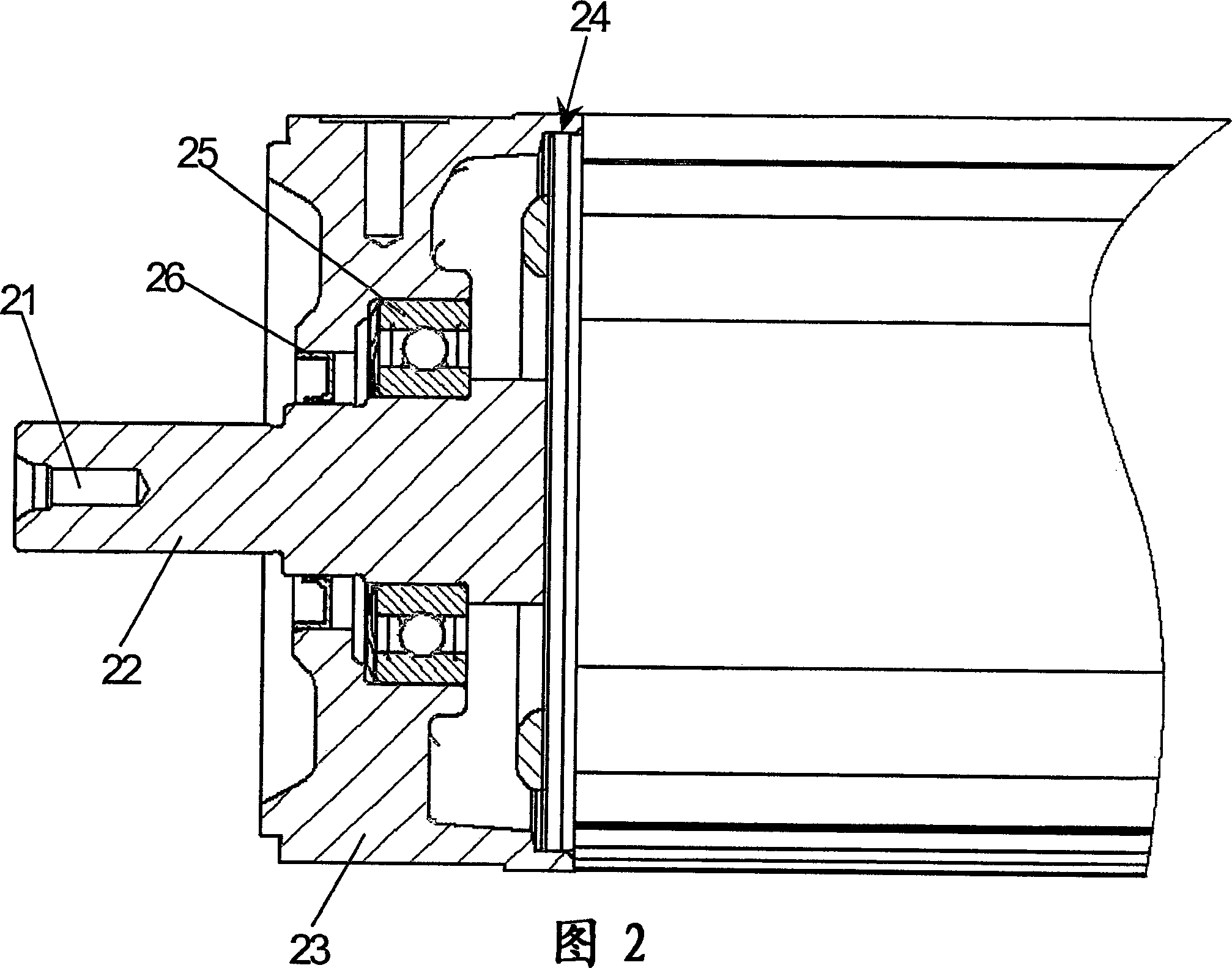

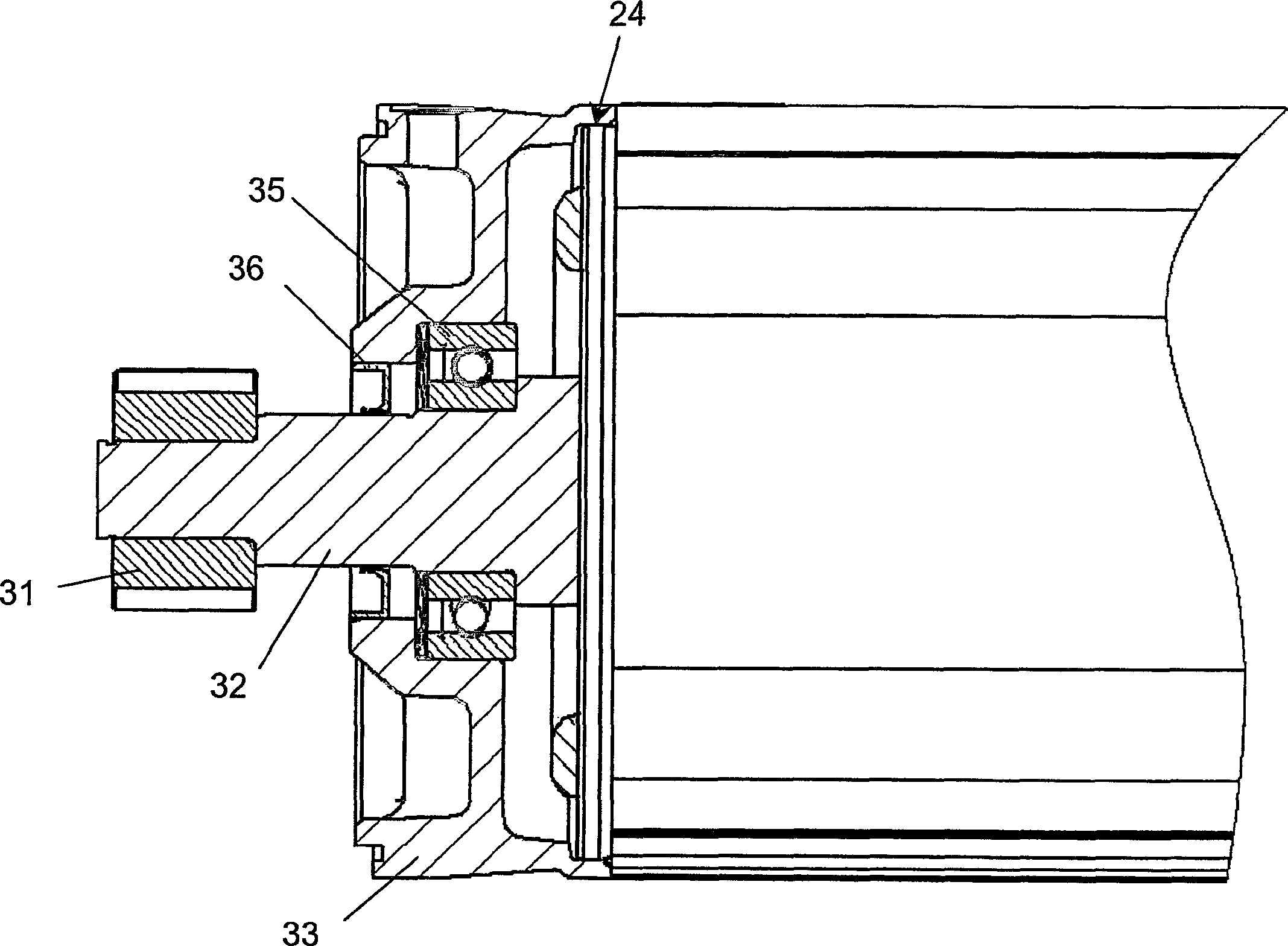

[0058] The motor includes a motor housing 1 with a stator. Sensors and / or brakes can be connected on the non-dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com