Method for producing a variable turbine geometry

A turbine, variable technology, applied in the direction of stator, engine components, machine/engine, etc., can solve the problem that the gap cannot be optimally minimized, and achieve the effect of increasing power and accurate spacing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

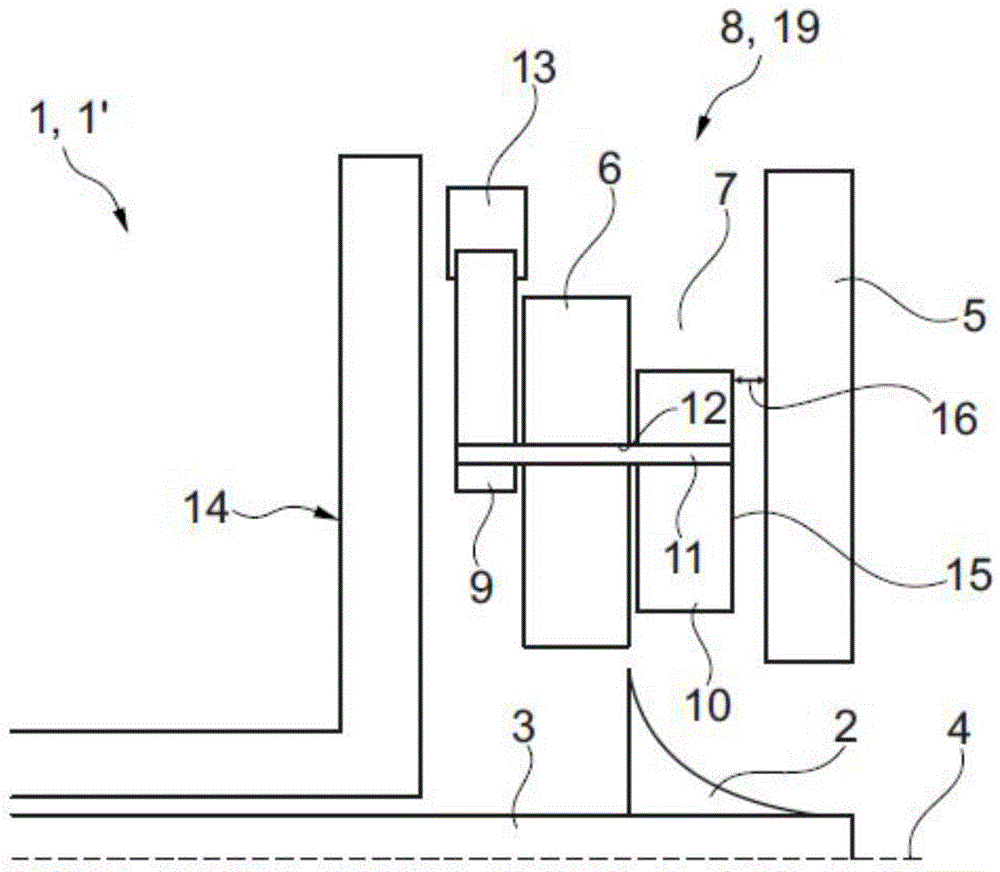

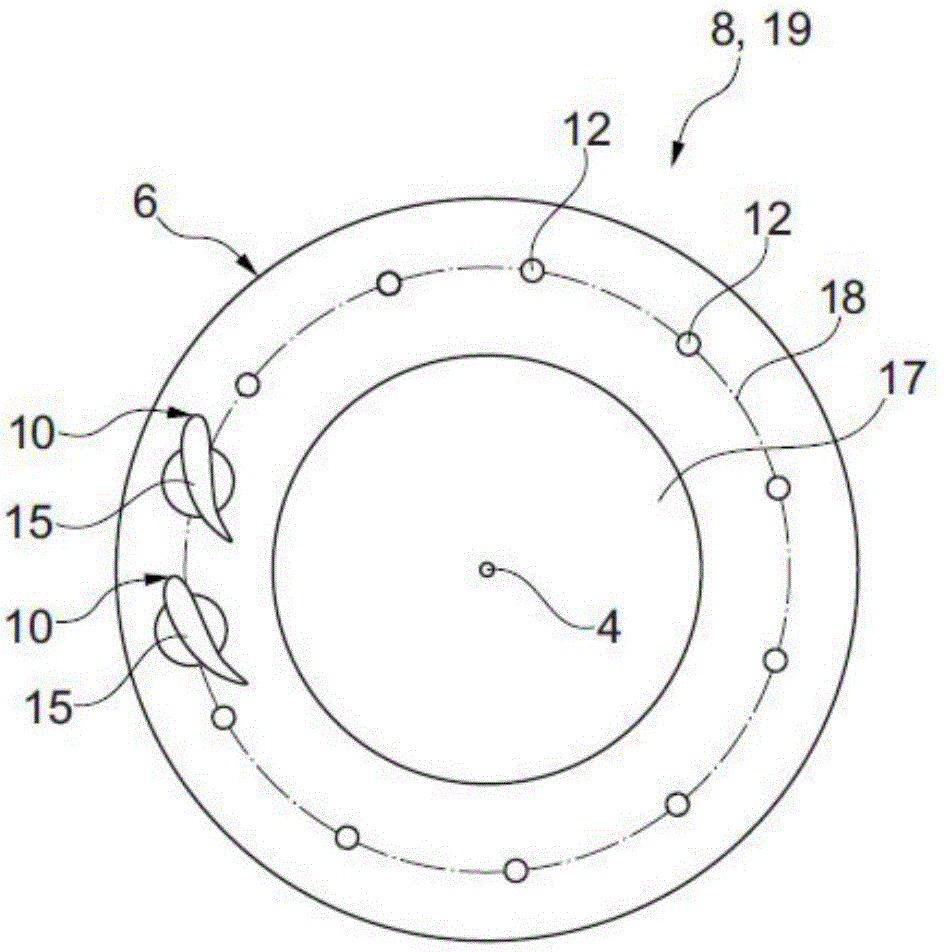

[0027] figure 1 A section through the charging device 1, in particular the exhaust gas turbocharger 1' is shown, wherein the charging device 1 is only partially visible. The charging device 1 has a turbine 2 connected to a shaft 3 for rotation therewith. The turbine 2 and the shaft 3 are rotatable about the axis of rotation 4 , wherein only the upper part of the charging device 1 is visible relative to the axis of rotation 4 . The rotation of the turbine 2 can be transmitted by means of a shaft 3 to a compressor wheel (not shown) of the charging device 1 . Here, the turbine 2 is driven by a fluid, in particular by exhaust gas generated from the internal combustion engine and flowing to the turbine 2 through a duct 7 formed between the cover disk 5 and the blade mounting ring 6 . The blade mounting ring 6 is part of a variable turbine geometry 8 which additionally has an adjusting ring 13 arranged on the side of the blade mounting ring 6 facing away from the duct 7 and at lea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com