Rotor shaft module, rotor shaft, compact circuit breaker and method for producing rotor shaft module

A technology of power switch and rotor shaft, which is applied to the parts of protection switch, electric switch, protection switch, etc. It can solve the problems of unreliable transmission, damage of coupling device, failure of compact power switch, etc., and achieve the effect of reliable circuit breaker

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

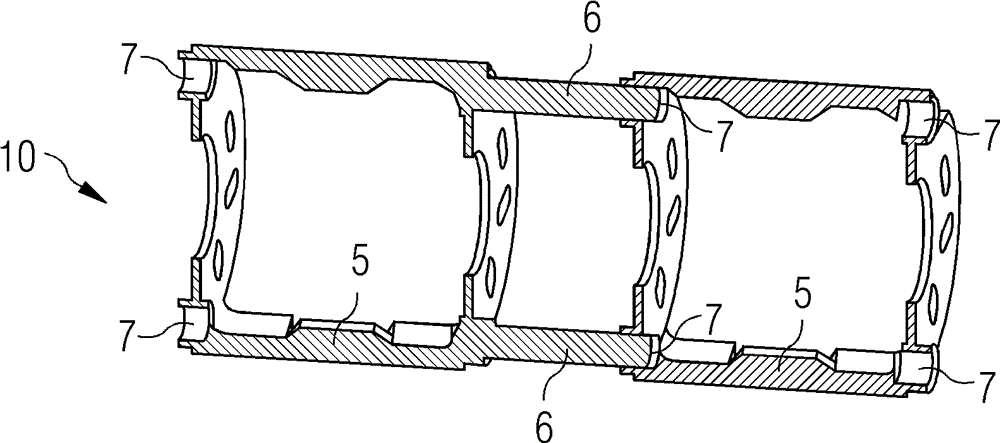

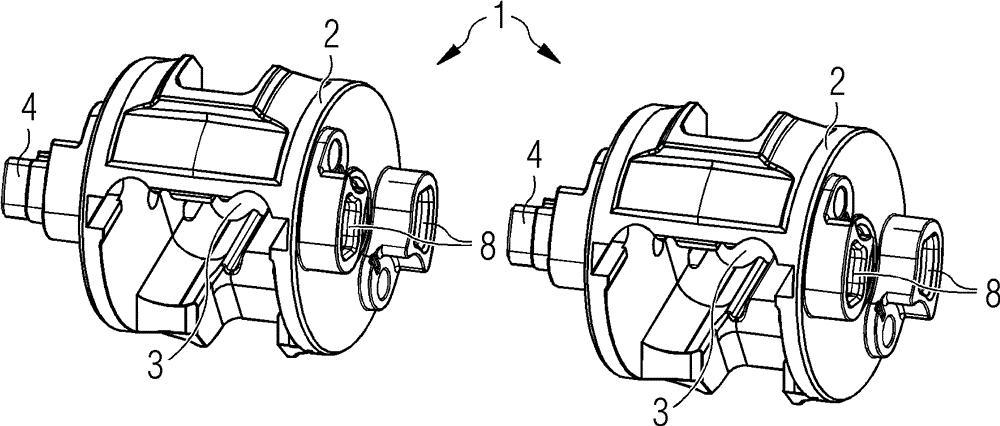

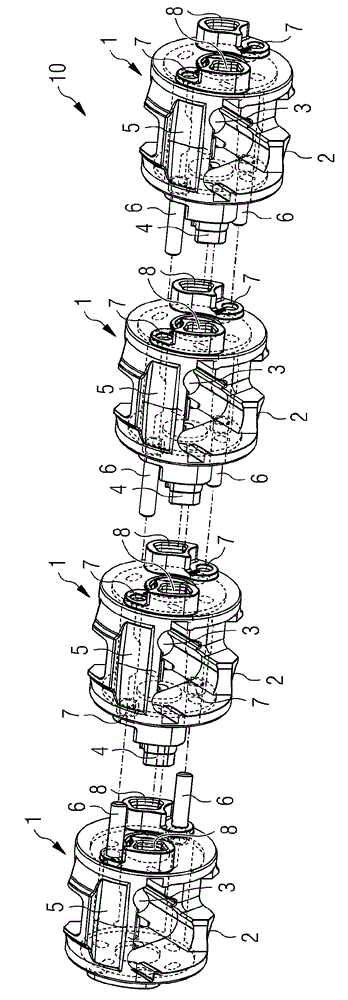

[0046] figure 1 A compact power switch 20 according to the invention is shown. The compact power switch 20 here has a locking mechanism 22 which is designed in particular for actuating a contact system 24 . The contact system 24 here comprises a fixed contact 23 and a contact element 21 for each individual phase which can be switched by the compact power switch 20 , wherein figure 1 One of these contact systems 24 can be seen in . The contact element 21 is arranged here in the rotor shaft module 1 of the rotor shaft 10 of the compact power switch 20 . By rotating the rotor shaft 10 , the contact elements 21 and the fixed contacts 23 can be brought into contact, whereby the contact system 24 is closed and current can flow. In this case, the compact power switch 20 is designed to switch a plurality of phases, which can be seen by a plurality of first connections 25 and second connections 26 . By actuating the locking mechanism 22 , all contact systems 24 of the individual ph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com