Press

一种压机、电动机的技术,应用在压力机、冲压机、材料成型的压力机等方向,能够解决可更换性没有给出说明等问题,达到避免变形、降低变形的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

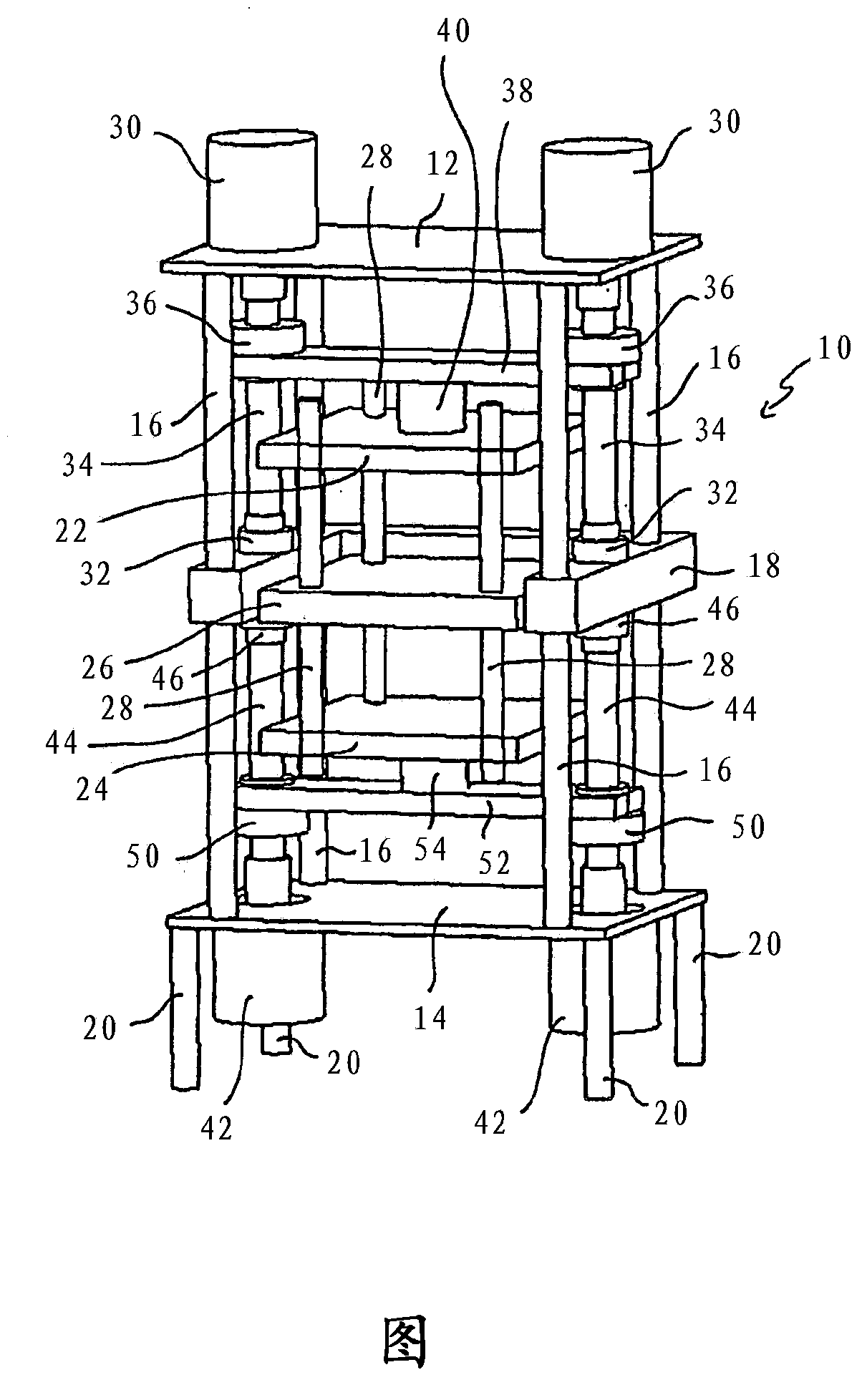

[0020] The press according to the invention has a press frame 10 with an upper holding plate 12 and a lower holding plate 14 . The upper holding plate 12 and the lower holding plate 14 are connected to each other and to a load bearing arranged approximately centrally between the upper holding plate 12 and the lower holding plate 14 via four vertically extending spacers 16 in the illustrated embodiment. 18 is connected. In the exemplary embodiment shown, the carrier part 18 is designed in one piece and has a U-shaped contour lying in a horizontal plane, ie, the plane of arrangement or extension. The lower holding plate 14 rests on the ground via four legs 20 . The press according to the invention also has a modular tool guide unit, which has an upper die unit, which can include an upper die plate 22 with a Shown upper die; Lower die unit, described lower die unit can comprise lower die plate 24, and described lower die plate has lower die not shown; And be arranged on upper d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com