Chemical sensor and method for manufacturing such a chemical sensor

A chemical sensor and sensing layer technology, which is applied in semiconductor/solid-state device manufacturing, scientific instruments, and electrochemical variables of materials, etc., can solve problems such as limited space, and achieve the effect of reducing manufacturing tolerances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

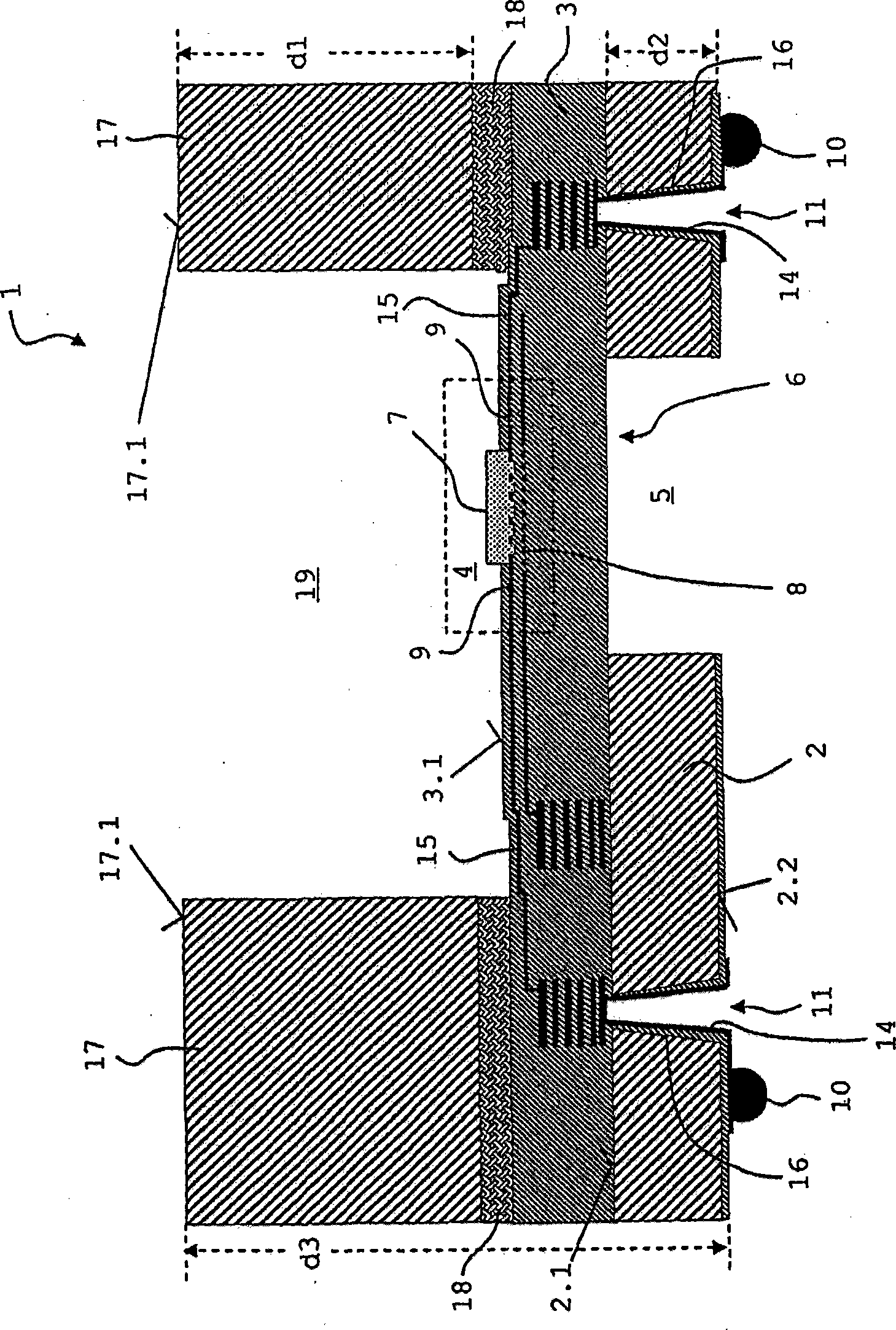

[0018] alone figure 1 A chemical sensor 1 according to the invention is described. The chemical sensor 1 comprises a substrate layer 2 having a front surface 2.1 and a rear surface 2.2. The substrate layer 2 preferably consists of silicon. On top of the substrate layer 2 is arranged a sensing layer 3 made of a dielectric material such as silicon oxide or silicon nitride. The sensing layer 3 includes sensing elements 4 . The substrate layer 2 has holes 5 at the rear surface 2 . 2 to form a membrane 6 containing the sensing element 4 .

[0019] The sensing element 4 preferably includes a fluid-sensitive, especially gas-sensitive thin film 7 and a heater 8 made of metal, which is used to heat the fluid-sensitive thin film 7 to promote the fluid to be measured and the fluid-sensitive thin film 7. chemical reaction. For this purpose, the fluid sensitive membrane 7 is formed on the front surface 3.1 of the sensing layer 3, while the heater 8 is located in the sensing layer 3 be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com