Improved method for designing smooth limit gauge

A technology of limit gauge and design method, applied in measuring gauges, ring gauges, measuring devices, etc., can solve the problems of reducing the proportion of qualified products of workpieces and judging waste, and achieve the effect of increasing the proportion of qualified products and obvious advantages.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

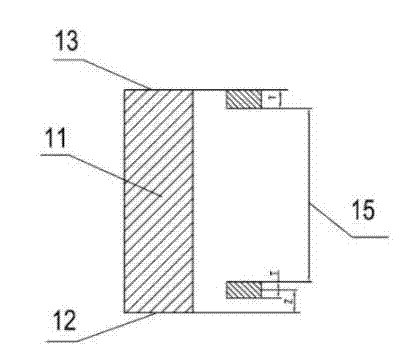

[0031] The technical solution of the present invention is: determine the manufacturing precision T of the gauge at IT2~IT4, reduce the percentage of the tolerance zone of the gauge relative to the tolerance zone of the workpiece, the position element Z determines the service life of the through end of the gauge, and the purpose is to pre-set Leave a wear limit. exist image 3 Among them, the ultimate meaning of the position element Z is to determine the distance between the drop of the gauge end and the maximum physical size of the workpiece to be measured, and the distance can be expressed by the formula Z+T / 2. The value range of Z+T / 2 is 0.0016~0.002.

[0032] Table 3 is a comparison between the design method of the prior art and the improved smooth limit through-gauge design method of the present invention when applied to different workpieces.

[0033] Table 3 List of calculation methods before and after the smooth limit gauge for holes.

[0034]

[0035] In Table 3, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com