Non-warping chain link

A chain link and chain plate technology, which is applied in the field of energy guide chains, can solve the problems of internal net height reduction, chain plate angle offset, influence, etc., and achieve the effect of reducing manufacturing tolerance and high angular accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

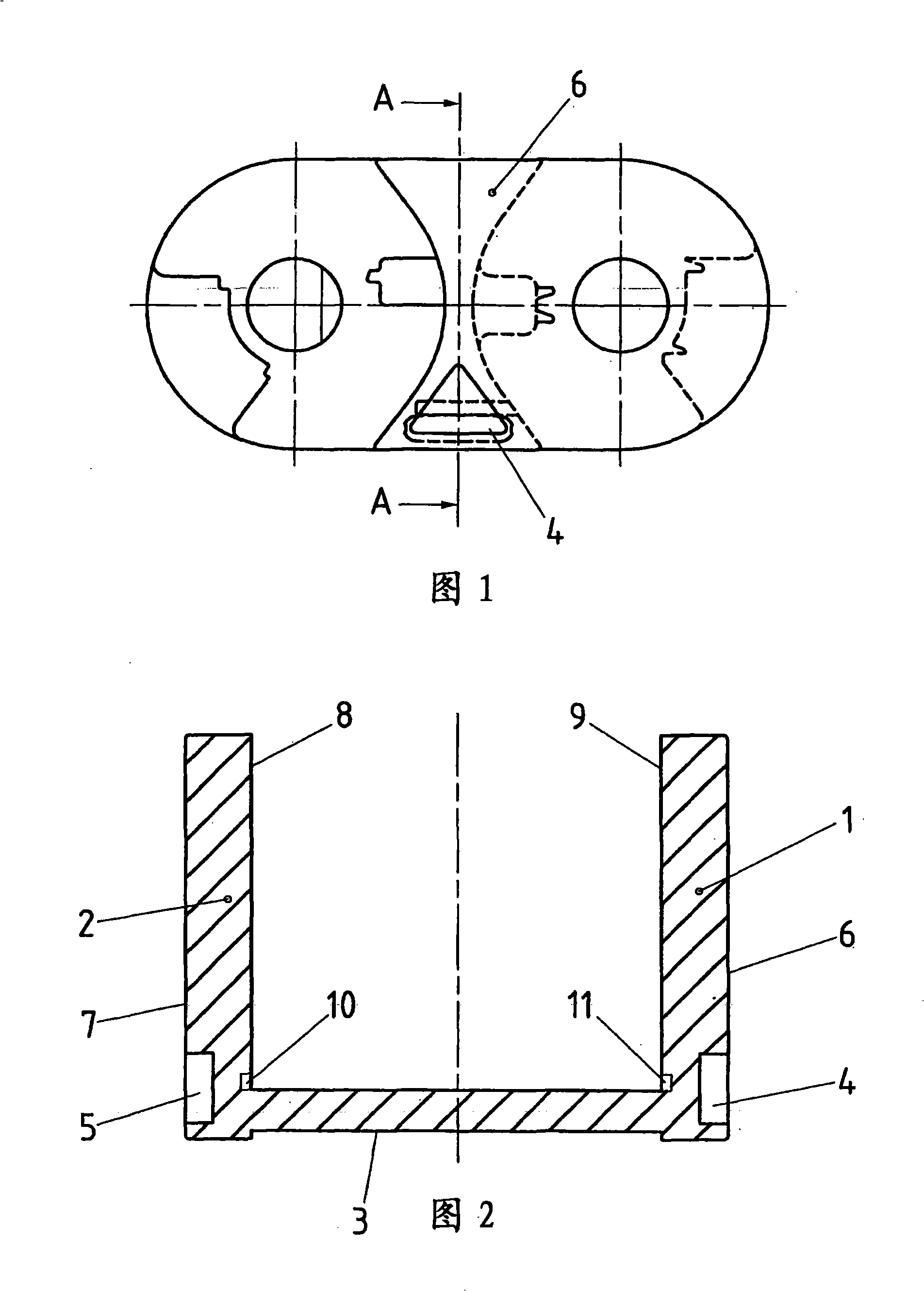

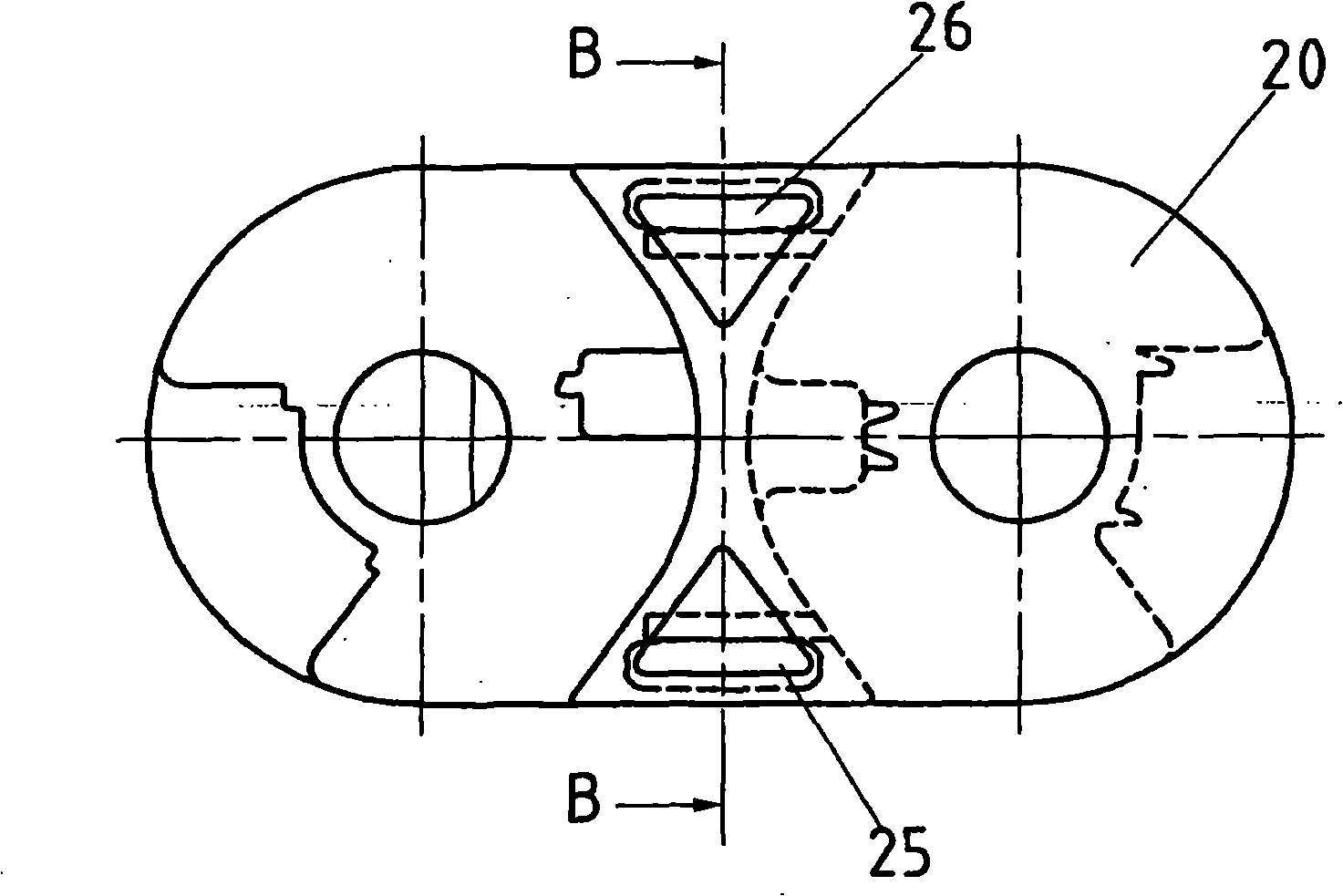

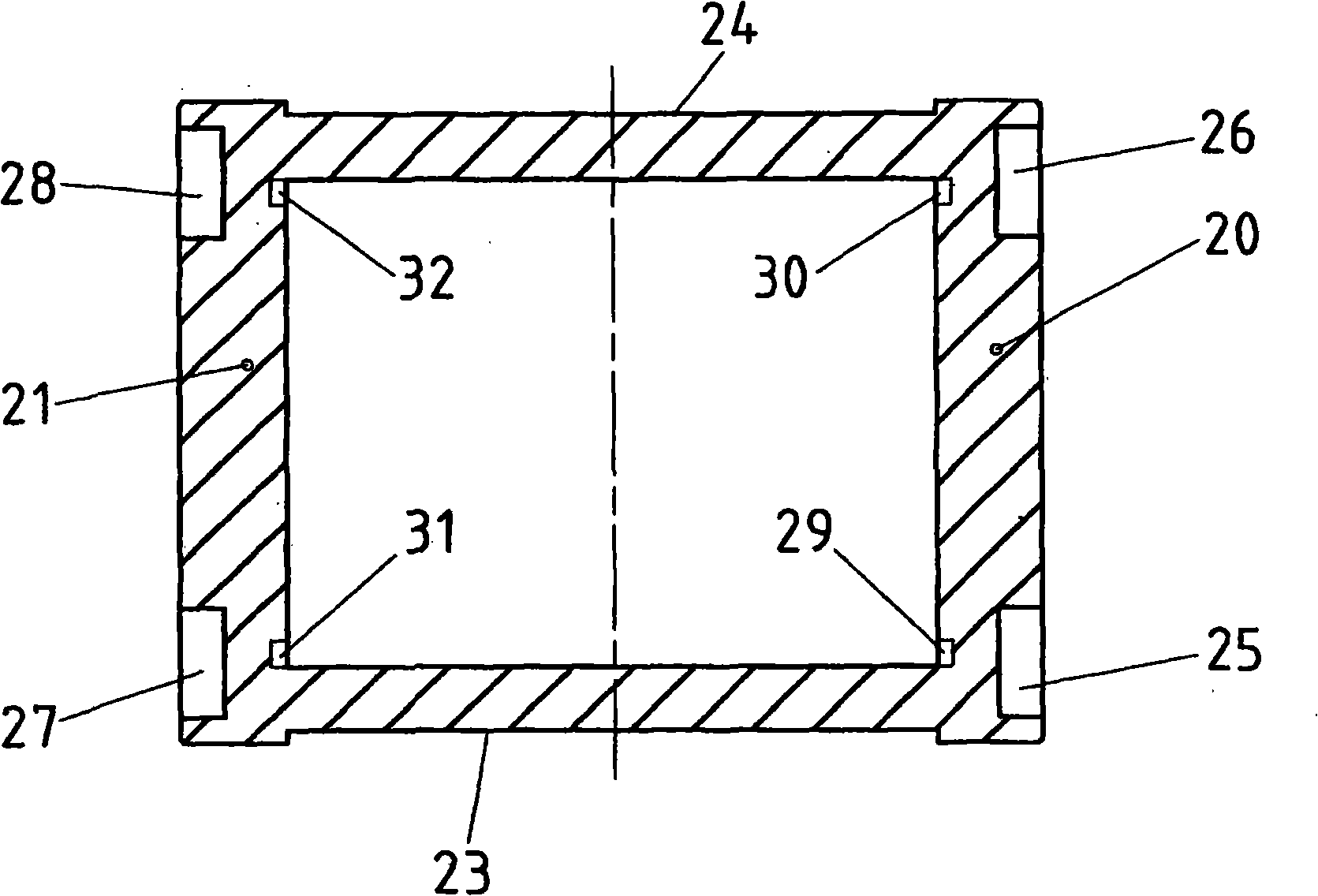

[0025] 1 and 2 show a first exemplary embodiment of a chain link of an energy guide chain for guiding cables, lines, pipes etc. between fixed and movable connection points. The chain link is formed by two chain plates 1 and 2 spaced apart from one another, which are connected to one another via transverse webs 3 . The link plates 1 , 2 and the transverse web 3 form a unit formed in one piece from plastic. It is not necessary to use the same plastic for the chain plates and cross members. It is also possible for the side links to be at least partially made of a first plastic, while the transverse webs are made of a second plastic.

[0026] To close the chain link, a transverse web (not shown) is provided, which is detachably connected to at least one side link plate.

[0027] Each link plate has a first region in which a hinge pin is formed. A hinge seat is provided in a second area opposite to the first area. The hinge seat and the hinge pin are designed so that the chain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com